Method for preparing fixed carrier compound membrane for CO2 separation by utilizing interfacial polymerization

A technology of interfacial polymerization and immobilized carrier, applied in separation methods, semi-permeable membrane separation, dispersion particle separation, etc., to achieve low cost, easy operation, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

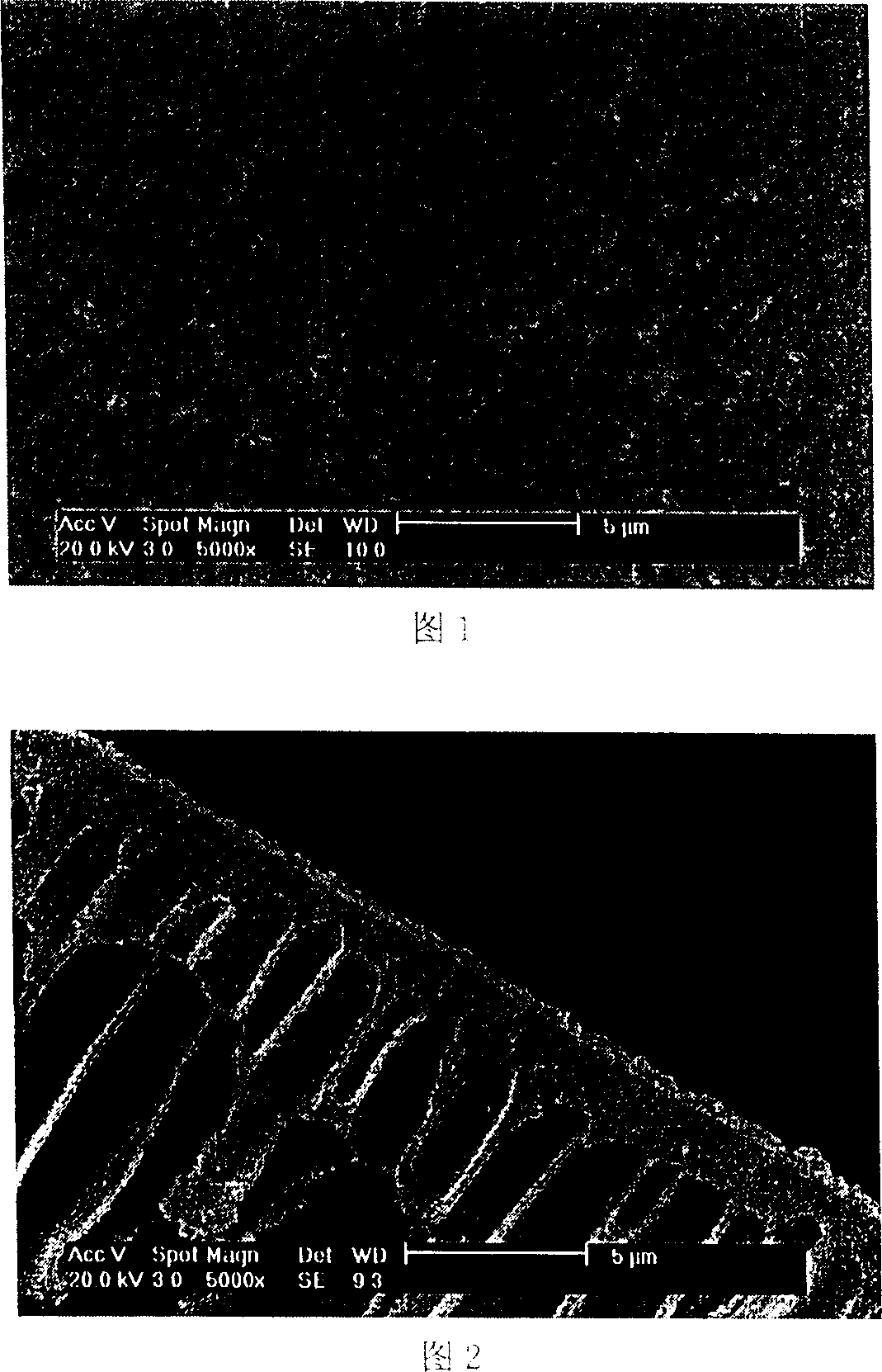

Image

Examples

example 1

[0019] The polyethersulfone ultrafiltration membrane is treated with surfactant sodium dodecylsulfonate dilute aqueous solution (mass concentration 0.5%); Get electrodeionized water 1400ml, triethylenetetramine 45ml, be made into a mass concentration of 2.8% Aqueous solution, in addition, add 7.283g of anhydrous sodium carbonate to the aqueous solution; take 1300ml of n-hexane and 12.466g of trimesoyl chloride to prepare a n-hexane solution with a mass concentration of 1.4%. First, immerse the treated polyethersulfone ultrafiltration membrane in the aqueous solution for 10 minutes at room temperature (25° C.), take it out, immerse it in n-hexane solution, take out the interfacial polymerization time for 3 minutes, take it out, wash the composite membrane with electrodeionized water, and then The composite film is heat-treated at 70° C. for 3 minutes, and finally dried at room temperature. With mixed gas 90vol% CO 2 / 10vol%CH 4 Composite membranes were tested. When the feed ...

example 2

[0021] The polysulfone ultrafiltration membrane is treated with surfactant sodium dodecylsulfonate dilute aqueous solution (0.5% in mass concentration); 1000ml of electrodeionized water and 87ml of diethylenetriamine are taken to form an 8% aqueous solution with a mass concentration , in addition, add 9.266g of anhydrous sodium carbonate to the aqueous solution; take 1000ml of n-hexane, 19.678g of trimesoyl chloride, and 20.022g of isophthaloyl chloride, the mass ratio of the two is about 50:50, and the mass concentration is 6%. n-hexane solution. First, immerse the treated polysulfone ultrafiltration membrane in the aqueous solution at room temperature (20°C) for 20 minutes, take it out, immerse it in n-hexane solution, take out the interfacial polymerization time for 5 minutes, take it out, wash the composite membrane with electrodeionized water, and then wash it at a temperature of 15 Dry naturally at room temperature. With mixed gas 90vol% CO 2 / 10vol%CH 4 Composite mem...

example 3

[0023] The polysulfone ultrafiltration membrane is processed with tensio-active agent sodium dodecylsulfonate dilute aqueous solution (0.5wt%); Get electrodeionized water 1000ml, tetraethylenepentamine 130ml, be made into the aqueous solution that mass concentration is 12%, In addition, 5.421 g of anhydrous sodium carbonate was added to the aqueous solution; 1000 ml of n-hexane and 26.452 g of trimesoyl chloride were taken to prepare a n-hexane solution with a mass concentration of 4%. At room temperature (25°C), immerse the treated polysulfone ultrafiltration membrane in the aqueous solution for 5 minutes, take it out, immerse it in n-hexane solution, and take out the interfacial polymerization time for 2 minutes, take it out, wash the composite membrane with electrodeionized water, and then put it at 45°C The composite film was heat-treated for 15 minutes, and finally dried at room temperature. With mixed gas 90vol% CO 2 / 10vol%CH 4 Composite membranes were tested. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com