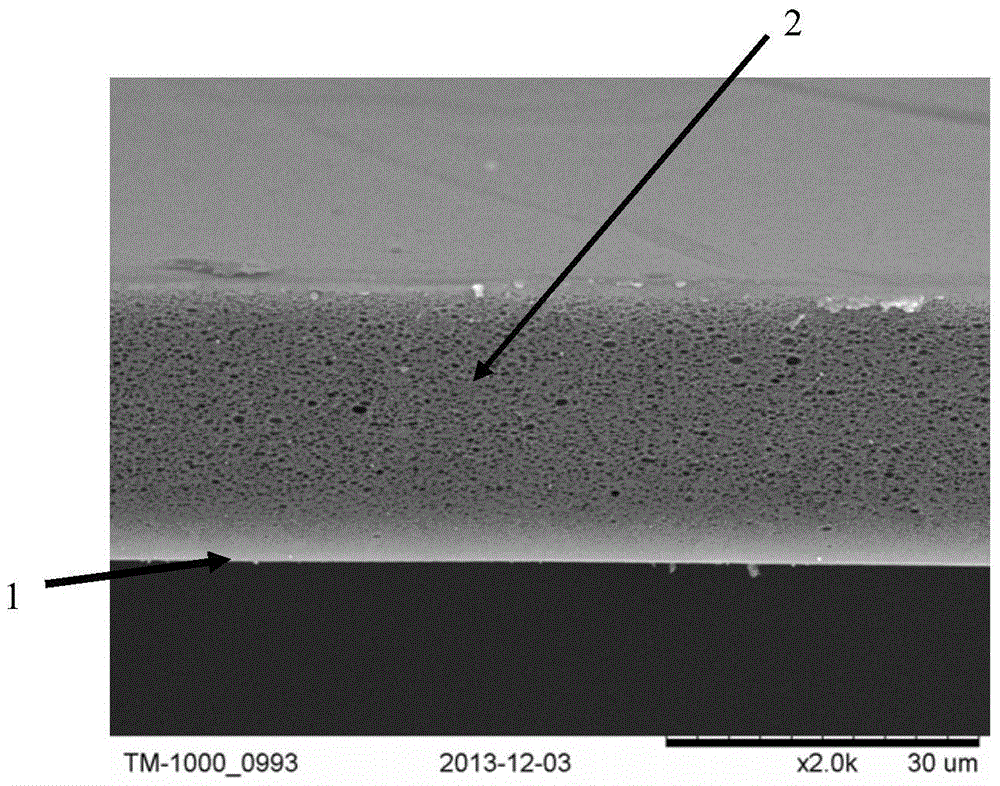

A kind of cellulose acetate forward osmosis membrane material and preparation method thereof

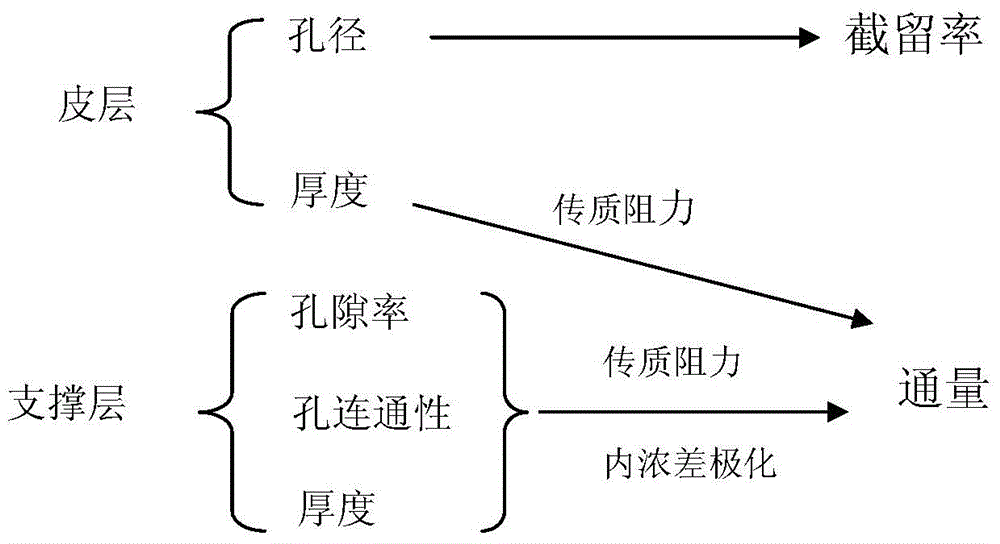

A technology of cellulose acetate and cellulose triacetate, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low retention rate, easy peeling off of the cortex, uneven bonding of the interfacial polymerized cortex, etc. Achieve high rejection rate, good hydrophilicity and good connectivity of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of cellulose acetate forward osmosis membrane material in the present embodiment is as follows:

[0055] 1) Preparation of casting solution: Add 19g of a mixture of cellulose triacetate and cellulose diacetate with a mass ratio of 2:1 into 45g of N-methylpyrrolidone, 30g of methyl acetate and 6g of acetone at a temperature of 40°C Stir and dissolve to form a uniform casting solution;

[0056] 2) Degassing the casting solution: the degassing temperature is 25°C;

[0057] 3) Scrape the film with a film scraping machine: apply the defoamed casting solution in step 2) on a dry and clean glass plate, scrape the film with a film scraping machine to form a nascent eco-film, and place the nascent eco-film on The temperature is 25°C and the relative humidity is 65% in the air for 3 seconds;

[0058] 4) Gel bath treatment: Put the nascent membrane formed in step 3) into the gel bath to separate and solidify to form a membrane material; wherein, the medium...

Embodiment 2

[0065] The preparation method of cellulose acetate forward osmosis membrane material in the present embodiment is as follows:

[0066] 1) Preparation of casting solution: add 19g of cellulose triacetate to 45g of N-methylpyrrolidone, 30g of methyl acetate and 6g of acetone, stir and dissolve at a temperature of 25°C to form a uniform casting solution;

[0067] 2) Degassing the casting solution: the degassing temperature is 25°C;

[0068] 3) Scrape the film with a film scraping machine: apply the defoamed casting solution in step 2) on a dry and clean glass plate, scrape the film with a film scraping machine to form a nascent eco-film, and place the nascent eco-film on Volatilize for 3 seconds in air with a temperature of 25°C and a relative humidity of 59%;

[0069] 4) Gel bath treatment: Put the nascent membrane formed in step 3) into a gel bath to separate and solidify to form a membrane material; wherein, the medium of the gel bath is selected from water; the temperature o...

Embodiment 3

[0075] The preparation method of cellulose acetate forward osmosis membrane material in the present embodiment is as follows:

[0076] 1) Preparation of casting solution: Add 17g of cellulose triacetate to 50g of N-methylpyrrolidone, 23g of tetrahydrofuran and 10g of acetone, stir and dissolve at a temperature of 30°C to form a uniform casting solution;

[0077] 2) Degassing the casting solution: the degassing temperature is 30°C;

[0078] 3) Scrape the film with a film scraping machine: apply the defoamed casting solution in step 2) on a dry and clean glass plate, scrape the film with a film scraping machine to form a nascent eco-film, and place the nascent eco-film on Volatilize for 5 seconds in air at a temperature of 25°C and a relative humidity of 57%;

[0079] 4) Gel bath treatment: Put the nascent membrane formed in step 3) into the gel bath to separate and solidify to form a membrane material; wherein, the medium of the gel bath is selected from water; the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com