High-entropy ferrite porous ceramic material as well as preparation method and application thereof

A porous ceramic and ferrite technology, applied in the field of high-entropy ferrite porous ceramic materials and its preparation, can solve the problems of weak synergistic catalytic effect of multi-components, no self-supporting ability, low recovery rate, etc., and achieve pore Controllable structure and chemical components, easy operation and production, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

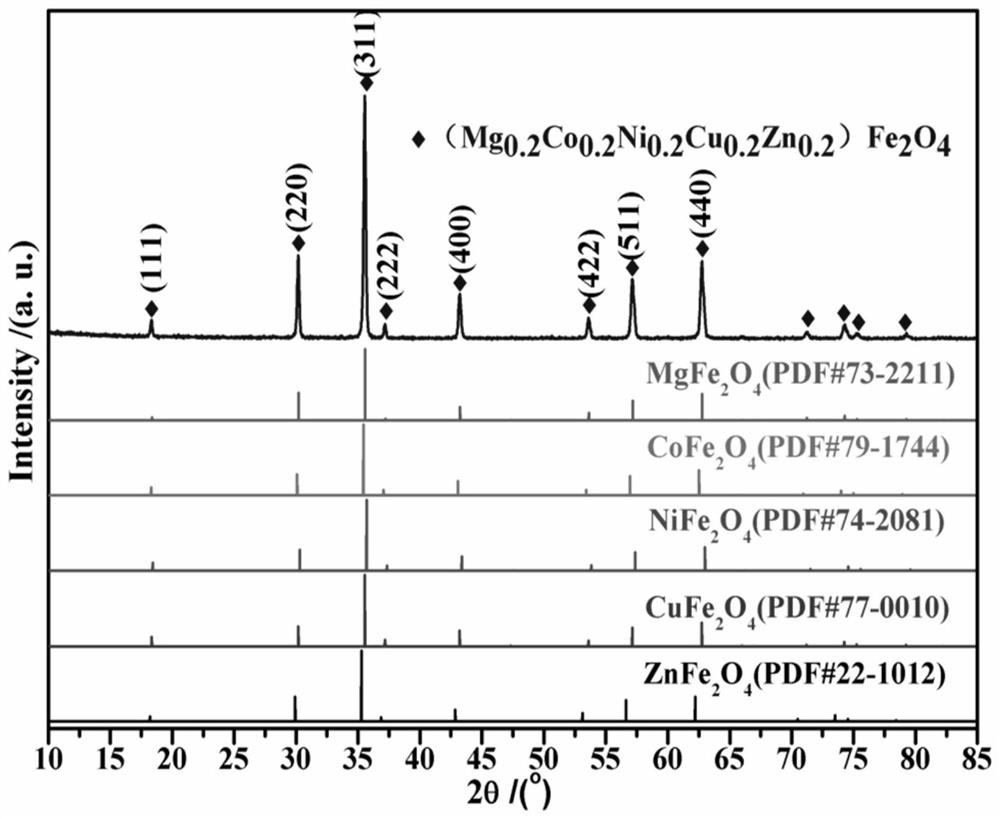

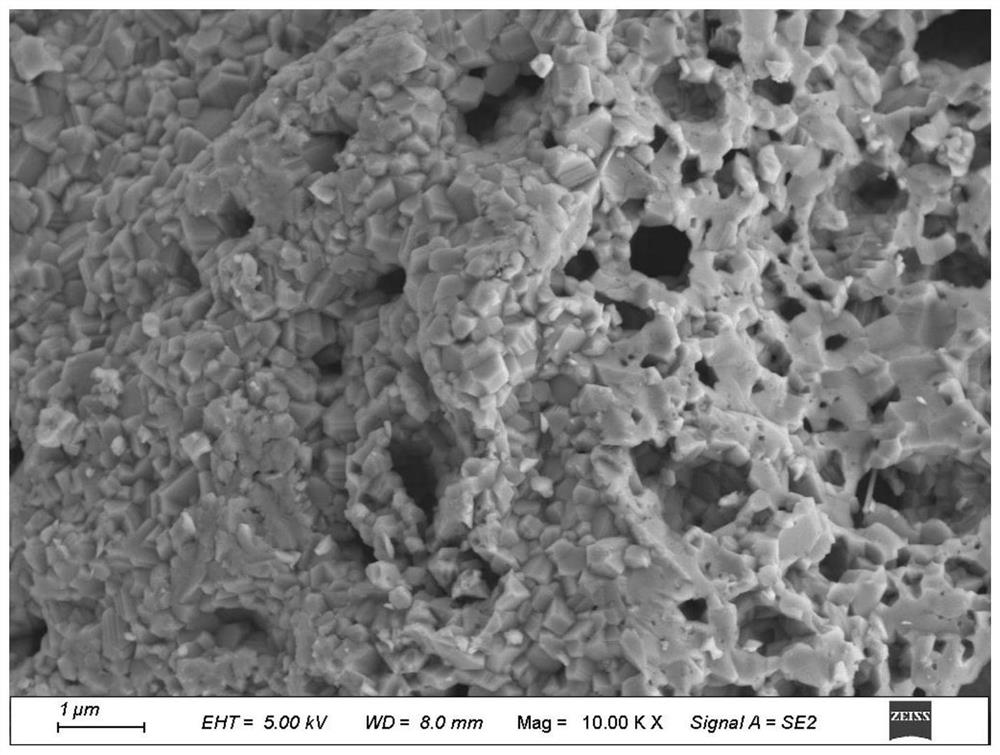

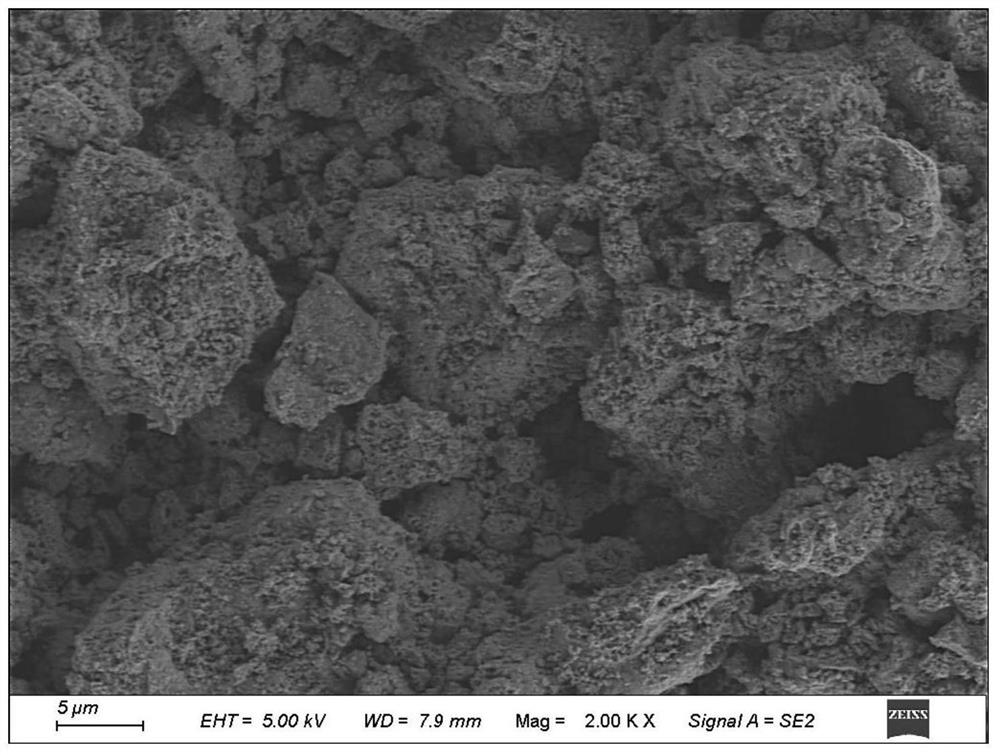

[0061] Embodiment 1 high entropy (Mg 0.2 co 0.2 Ni 0.2 Zn 0.2 Cu 0.2 )Fe 2 o 4 Preparation of Porous Ceramic Materials

[0062] According to (Mg 0.2 co 0.2 Ni 0.2 Zn 0.2 Cu 0.2 )Fe 2 o 4 The stoichiometric ratio is carried out batching, (that is (0.4-x): x: 0.2: 0.2: 0.2: 2, x=0.2) takes by weighing magnesium nitrate, cobalt nitrate, nickel nitrate, zinc nitrate, copper nitrate and ferric nitrate, will The obtained mixture is mixed with distilled water; in addition, fuel glycine is added according to the chemical equation of complete combustion reaction, and the molar ratio of nitrate ion to glycine is 2:1, and stirred to completely dissolve to obtain a mixed solution.

[0063] Adjust the pH of the mixed solution to 4.1 with ammonia water to obtain a precursor solution, transfer the precursor solution to a quartz crucible, heat on an electric furnace to evaporate the water and finally undergo a combustion reaction to obtain a precursor powder.

[0064] The obtain...

Embodiment 2

[0069] Embodiment 2 high entropy (Mg 0.3 co 0.1 Ni 0.2 Zn 0.2 Cu 0.2 )Fe 2 o 4 Preparation of Porous Ceramic Materials

[0070] According to (Mg 0.3 co 0.1 Ni 0.2 Zn 0.2 Cu 0.2 )Fe 2 o 4 The stoichiometric ratio is carried out batching, (that is (0.4-x): x: 0.2: 0.2: 0.2: 2, x=0.1) takes by weighing magnesium nitrate, cobalt nitrate, nickel nitrate, zinc nitrate, copper nitrate and ferric nitrate, will The obtained mixture is mixed with distilled water; in addition, fuel glycine is added according to the chemical equation of complete combustion reaction, and the molar ratio of nitrate ion to glycine is 3:1, and it is stirred to completely dissolve to obtain a mixed solution.

[0071]Adjust the pH of the mixed solution to 5.2 with ammonia water to obtain a precursor solution, transfer the precursor solution to a quartz crucible, heat on an electric furnace to evaporate the water and finally undergo a combustion reaction to obtain a precursor powder.

[0072] The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com