Titanium dioxide catalyst with high strength and large specific surface area for sulfur recovery and preparation method thereof

A technology for the recovery of titanium dioxide and sulfur, which is used in physical/chemical process catalysts, chemical instruments and methods, and sulfur preparation/purification. It can solve the problems of low crushing strength and small specific surface area, and achieve high crushing strength. The effect of large surface area and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

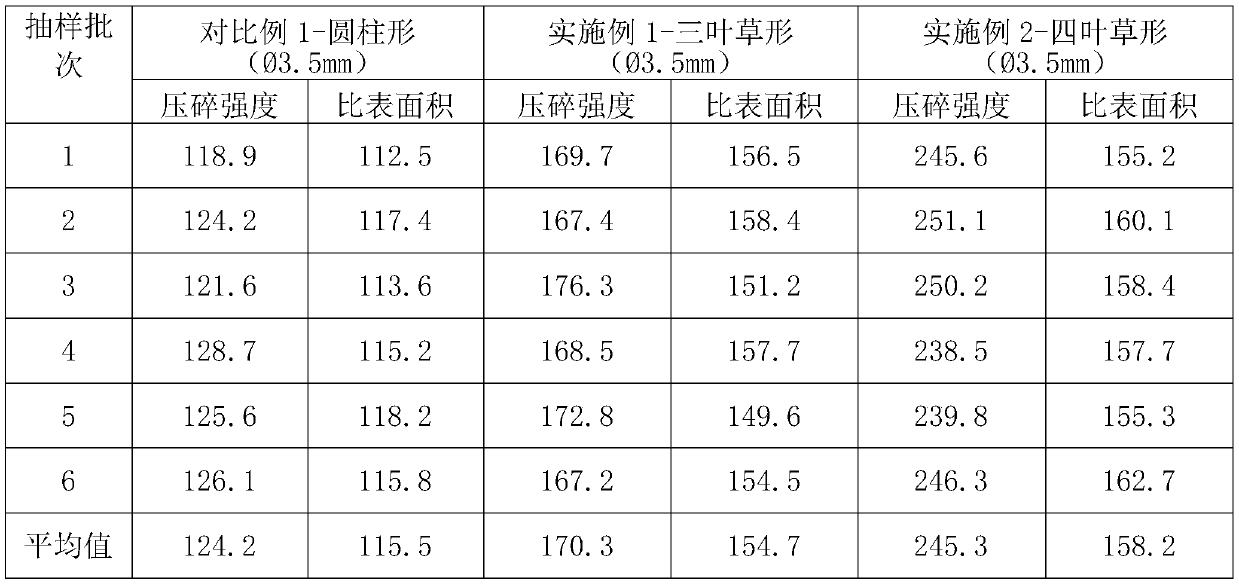

Embodiment 1

[0034] Raw material: wet metatitanic acid (dry TiO 2 Content ≥90wt%, water content 4 2- content <2wt%), alumina dry rubber powder and sesame powder as raw materials.

[0035] Preparation:

[0036] Mix the raw material wet metatitanic acid with alumina dry rubber powder and sesame powder in proportion, and roll for 20 minutes. Add a certain amount of water, organic acid and nitric acid to the rolled material, and continue rolling for 30 Minutes, moisturizing and aging for 20 minutes;

[0037] The material obtained by moisturizing and aging is added to the automatic pressing and extruding machine, and the clover template is selected for extruding. The extrudate is dried in a drying box to remove water. The temperature of the drying box is 100℃, the drying time is 2 hours, and then it passes through the muffle furnace. Calcination, the calcination temperature is 400 ℃, the calcination time is 4 hours to obtain the clover-shaped titanium dioxide catalyst, TiO 2 Content ≥85wt%, Al 2 O 3 ...

Embodiment 2

[0039] Raw material: wet metatitanic acid (dry TiO 2 Content ≥90wt%, water content 4 2- content <2wt%), alumina dry rubber powder and sesame powder as raw materials.

[0040] Preparation:

[0041] Mix the raw material wet metatitanic acid with alumina dry rubber powder and sesame powder in proportion, and roll for 20 minutes. Add a certain amount of water, organic acid and nitric acid to the rolled material, and continue rolling for 30 Minutes, moisturizing and aging for 20 minutes;

[0042] The material obtained by moisturizing and aging is added to the automatic pressing and extruding machine, and the four-leaf clover template is selected for extruding. The extrudate is dried in a drying box to remove moisture. The temperature of the drying box is 100℃, and the drying time is 2 hours. The calcination temperature is 400℃ and the calcination time is 4 hours to obtain the four-leaf clover-shaped titanium dioxide catalyst, TiO 2 Content ≥85wt%, Al 2 O 3 The content is ≥10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com