Catalyst for producing propylene by catalytic pyrolysis and preparation method thereof

A catalytic cracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, bulk chemical production, etc., can solve the problems of less research on the optimization and utilization of olefins, achieve improved yield and selectivity, simple process flow, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

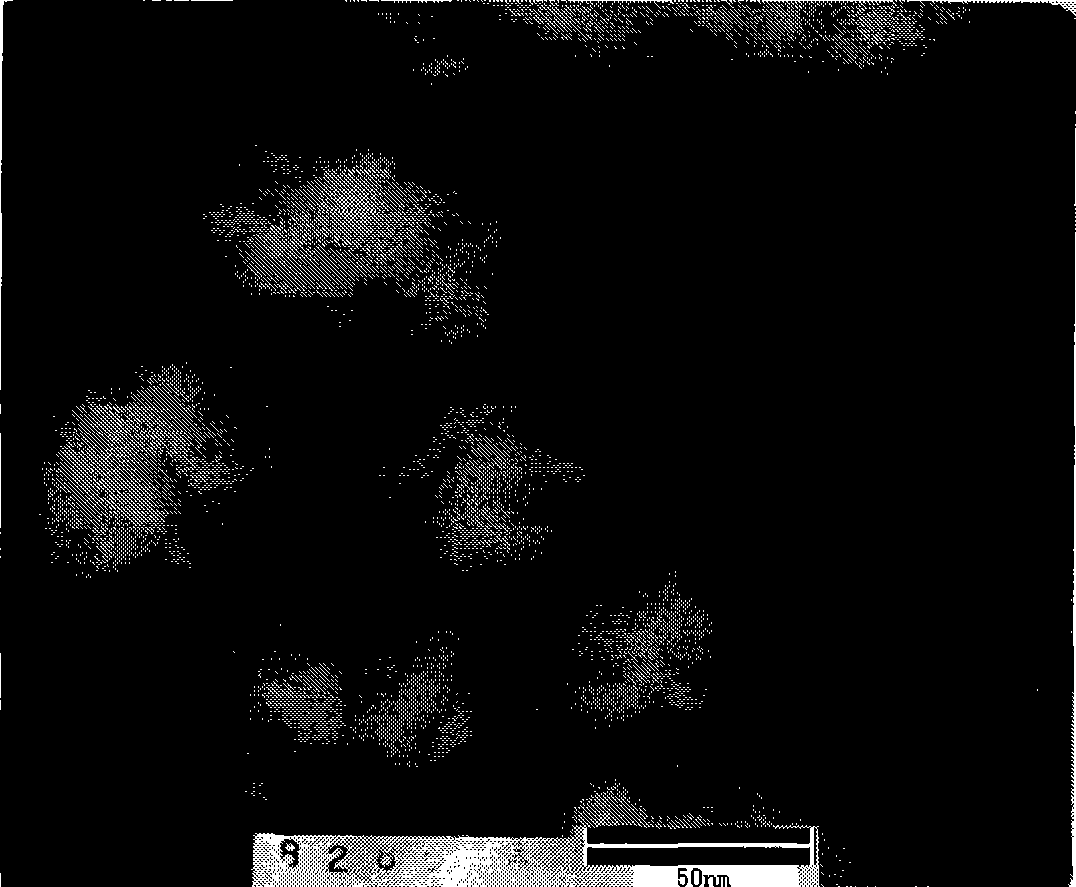

[0026] The preparation method of olefin catalytic cracking to produce propylene catalyst provided by the invention, the step of this method comprises:

[0027] 1) Roast the molecular sieve raw powder with a grain size of 10-100nm at 400-700°C to remove the template agent, exchange it in a solution containing ammonium ions for 1-4 times, each time for 2-4 hours, and the exchange temperature is 50 ~120°C, the concentration of ammonium ions in the solution is 0.5~2mol / L, after the exchange is completed, dry and then roast to obtain hydrogen molecular sieves;

[0028] 2) impregnating the hydrogen-type molecular sieve in a solution containing phosphorus and / or group IB metal ions, then drying and calcining at 400-700°C for 2-6 hours to obtain a modified molecular sieve;

[0029] 3) Mix the modified molecular sieve with heat-resistant inorganic oxide or its precursor and water evenly, shape it into the desired shape, dry it, and bake it at 400-800°C for 2-8 hours, preferably at 500-...

Embodiment 1

[0051] 1) The ZSM-23 molecular sieve raw powder with a particle size of 10-100nm was roasted at 550°C to remove the template agent, and then mixed with 1mol / L NH 4 NO 3 The solution was ion-exchanged twice at 100° C. for 4 hours each time, dried after the exchange, and calcined at 550° C. for 4 hours to obtain hydrogen-type molecular sieves.

[0052] 2) Put the hydrogen type ZSM-23 molecular sieve in a certain concentration of (NH) 2 HPO 4 Immersed in the solution, then dried, and roasted at 500° C. for 3 hours to obtain a P-modified molecular sieve; so that the content of P is 2.0% by weight based on the total weight of the molecular sieve;

[0053] 3) Mix the phosphorus-modified molecular sieve obtained in step 2, silica sol and appropriate amount of water according to the weight ratio of molecular sieve dry basis: silica sol=25:75, grind it evenly, extrude it, and obtain catalyst A1 after drying and roasting .

Embodiment 2

[0055] 1) The ZSM-5 molecular sieve raw powder with a particle size of 10-100nm was roasted at 600°C to remove the template agent, and then mixed with 1mol / L NH 4 NO 3 The solution was ion-exchanged twice at 100° C. for 4 hours each time, dried after the exchange, and calcined at 600° C. for 4 hours to obtain hydrogen-type molecular sieves.

[0056] 2) The hydrogen ZSM-5 molecular sieve was mixed with a certain concentration of AgNO 3 Immersed in the solution, then dried, and roasted at 550° C. for 2 hours to obtain an Ag-modified molecular sieve; so that the content of Ag is 2.2% by weight based on the total weight of the molecular sieve;

[0057] 3) Silver modified molecular sieve, pseudo-boehmite and an appropriate amount of water obtained in step 2 are mixed in a weight ratio of molecular sieve on a dry basis: pseudo-boehmite=40:60, and after being uniformly ground, it is extruded into strips, dried, Catalyst A2 was obtained after calcination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com