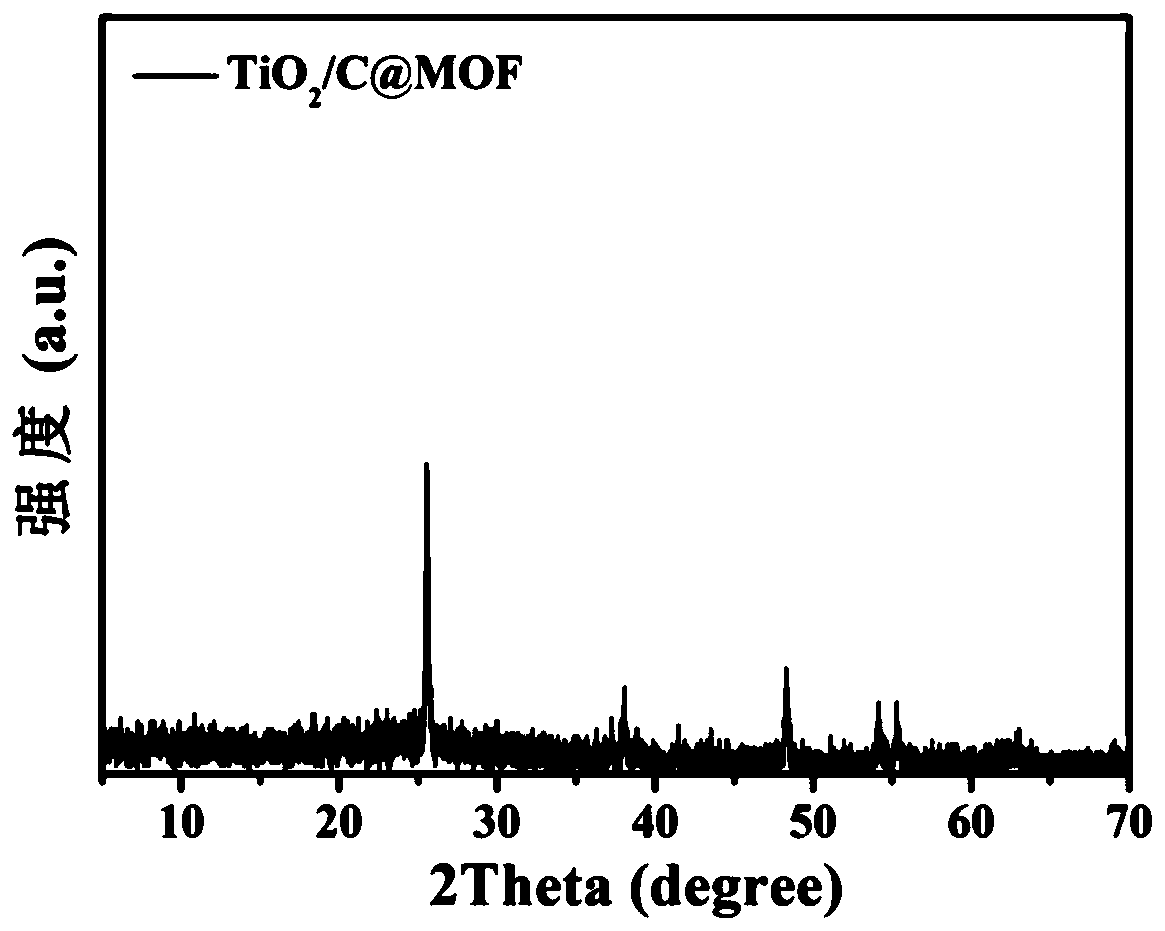

Preparation method and application of multi-stage structure TiO2/C@MOF nanofiber membrane photo-catalytic material

A technology of photocatalytic materials and nanofiber membranes, applied in the field of preparation and application of composite photocatalytic materials, to achieve the effects of improved utilization, excellent photocatalytic activity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

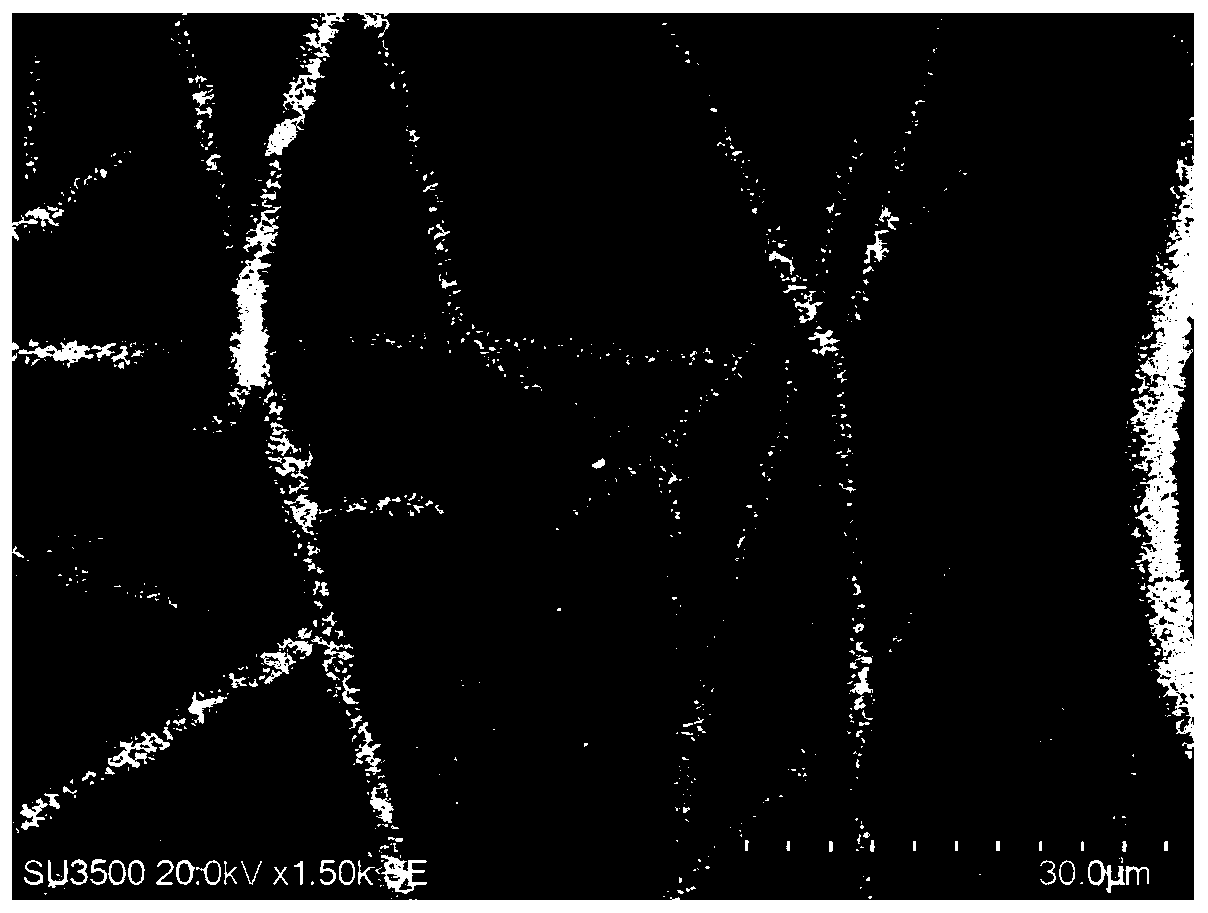

[0022] Step 1: Dissolve 3 mL of tetrabutyl titanate and 2 g of PAN in 20 mL of N,N-dimethylformamide, transfer to a syringe with a stainless steel needle, and spin in an electrospinning device with tin foil as a collector Electrospinning was carried out at a solution flow rate of 0.5 mL / h. The resulting film was removed from tinfoil on glass and dried under vacuum at room temperature

[0023] The second step: at 5°C min -1 The heating rate is raised to 380 ° C for 1 hour to obtain TiO 2 / C fiber membrane.

[0024] Step 3: Weigh 4mL (0.02mol / L) of zinc nitrate and 4ml (0.16mol / L) of 2-methylimidazole solution and dissolve them in water. After sonicating and obtaining a homogeneous solution, 0.02 g of TiO 2 / C fiber membrane, keep the temperature at 40°C for 5 hours. Remove, wash, dry.

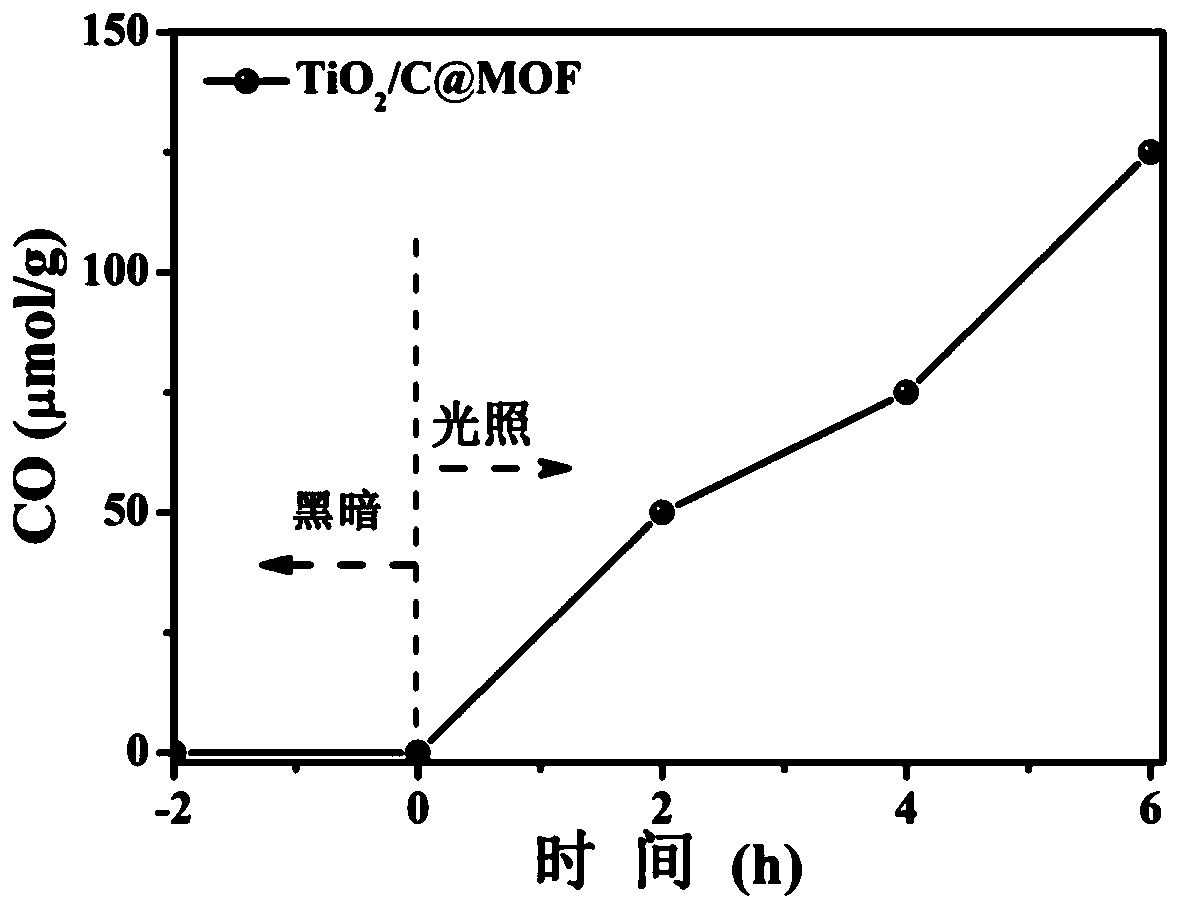

[0025] Step 4: Weigh 20 mg of the catalyst and a small amount of water, use a 300W xenon lamp as the light source for the photocatalysis experiment, and use carbon dioxide as the reaction ...

Embodiment 2

[0027] Step 1: Dissolve 2 mL of tetrabutyl titanate and 1 g of PAN in 20 mL of N,N-dimethylformamide, transfer to a syringe with a stainless steel needle, and spin in an electrospinning device with tin foil as a collector Electrospinning was carried out at a solution flow rate of 0.7 mL / h. The resulting film was removed from tinfoil on glass and dried under vacuum at room temperature

[0028] The second step: at 10°C min -1 The heating rate is raised to 800 ° C for 2 hours to obtain TiO 2 / C fiber membrane.

[0029] Step 3: Weigh 3mL (0.05mmol / L) zinc nitrate and 3ml (0.3mmol / L) 2-methylimidazole solution and dissolve in water. After sonicating and obtaining a homogeneous solution, 0.03 g of TiO 2 / C fiber membrane, kept at 25°C for 6 hours. Remove, wash, dry.

[0030] Step 4: Weigh 10 mg of the catalyst and a small amount of water, use a 150W xenon lamp as the light source for the photocatalysis experiment, and use carbon dioxide as the reaction atmosphere. First, equil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com