Preparation method of photo anode material of battery prepared through photocatalytic decomposition of water into hydrogen

A technology of photolysis of water to produce hydrogen and photoanode, applied in the direction of electrodes, nanotechnology for materials and surface science, electrode shape/type, etc., can solve the problems of limited photoelectric conversion efficiency, limited surface area, low photocatalytic activity, etc. , to achieve the effects of good diffusion, good size uniformity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

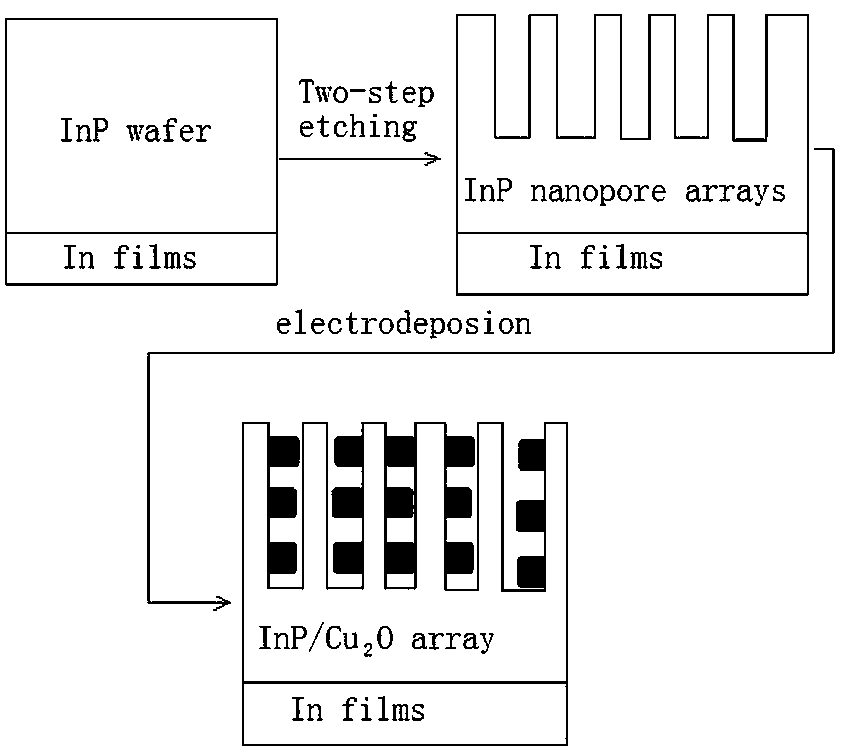

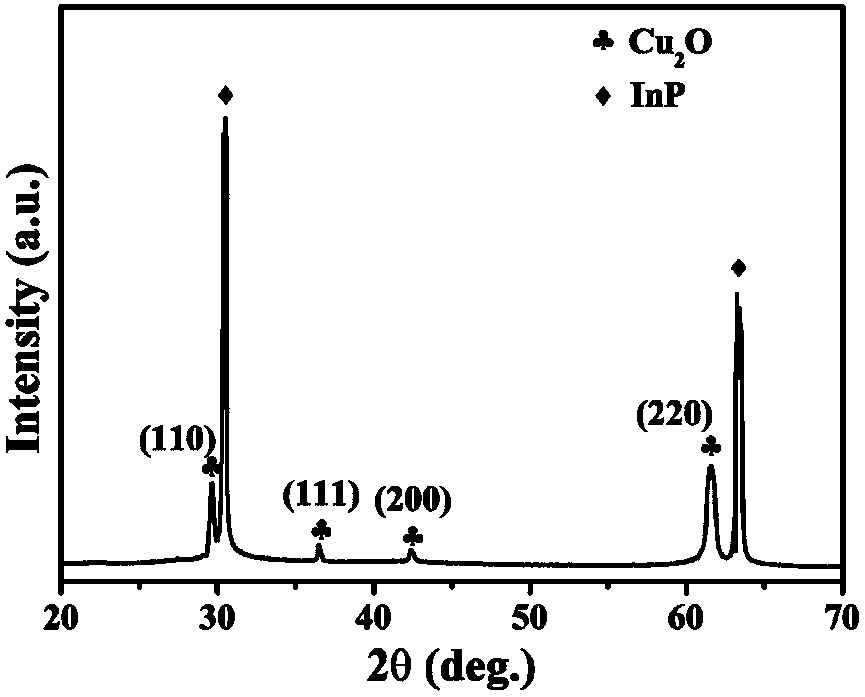

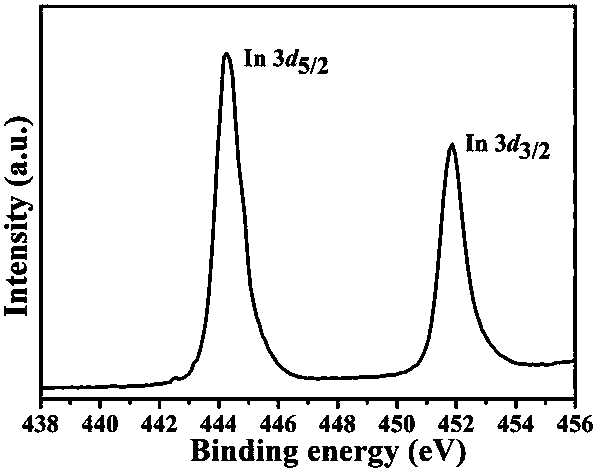

[0036] A method for preparing photoanode materials for photolysis of water to produce hydrogen cells, firstly using InP wafer as substrate, copper source and carboxylic acid as Cu 2 The precursor solution of O was prepared by electrochemical anodic etching and wet etching to prepare one-dimensional InP nanopore arrays, and then using the one-dimensional InP nanopore arrays as a template, the Cu 2 O nanoparticles loaded in InP nanopore arrays to construct InP / Cu 2 O nano-heterojunction array composite structure.

[0037] Such as figure 1 Shown, InP / Cu 2 The fabrication of O nanoheterojunction arrays can be divided into two steps, first, an ordered InP nanohole array is prepared by a two-step etching method, and then the InP / Cu 2 O nanoheterojunction arrays.

Embodiment 2

[0039] A method for preparing a photoanode material for photolysis of water to produce hydrogen, the steps are as follows:

[0040] (1) Cut the n-InP wafer into samples of the same size, then put the cut InP samples into acetone and absolute ethanol for more than 5 minutes and ultrasonically clean them to remove the oil on the surface of the InP samples, and then clean them with deionized water Rinse the InP sample three times, then dry it for later use;

[0041] (2) Sputter an indium film on the back of the InP sample in step 1 by DC magnetron sputtering, then put the InP sample into a fully dried quartz boat, place it in a chemical vapor deposition furnace with a controllable heating rate, and N 2In the atmosphere environment, the temperature is raised at a rate of 2-5°C / min and maintained at 350°C for 1 minute to form a good ohmic contact between the InP and the indium film, and then use high-purity conductive silver paste to cover the back of the InP sample Connect with ...

Embodiment 3

[0053] A method for preparing a photoanode material for photolysis of water to produce hydrogen, the steps are as follows:

[0054] (1) Cut the n-InP wafer into samples of the same size, then put the cut InP samples into acetone and absolute ethanol for more than 5 minutes and ultrasonically clean them to remove the oil on the surface of the InP samples, and then clean them with deionized water Rinse the InP sample three times, then dry it for later use;

[0055] (2) Sputter an indium film on the back of the InP sample in step 1 by DC magnetron sputtering, then put the InP sample into a fully dried quartz boat, place it in a chemical vapor deposition furnace with a controllable heating rate, and N 2 In the atmosphere environment, the temperature is raised at a rate of 2-5° C. / min and maintained at 350° C. for 1 minute, so as to form a good ohmic contact between the InP and the indium film. Then use high-purity conductive silver paste to connect the back of the InP sample wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com