Preparation and application of Silicalite-1 and silicon oxide coated ZSM-5 catalyst

A ZSM-5 and catalyst technology, which is applied in the preparation and application of catalysts, can solve problems such as multiple side reactions and acid site dispersion, and achieve the effect of increasing yield and facilitating diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

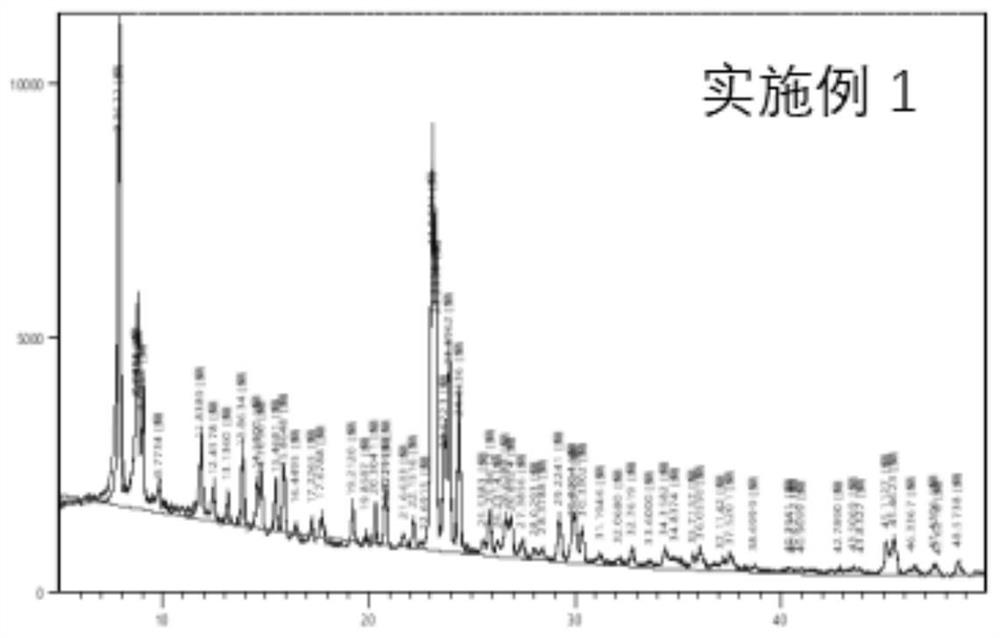

Embodiment 1

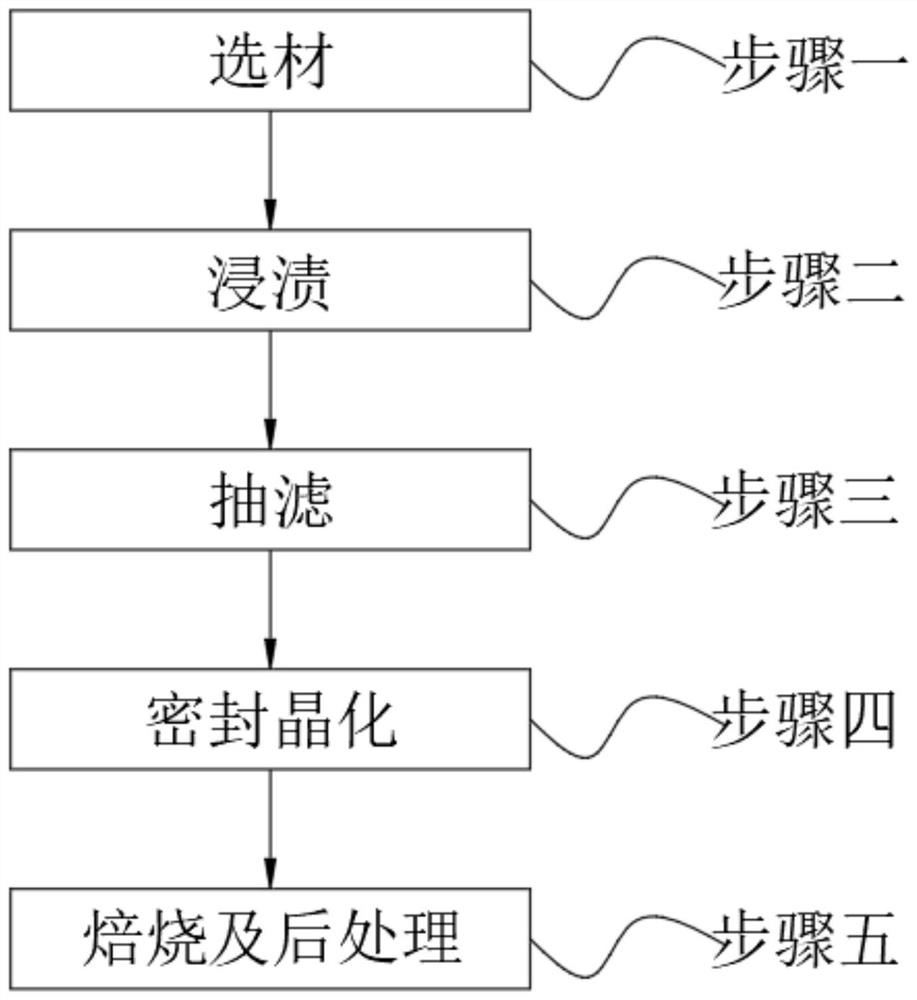

[0025] The preparation of Silicalite-1 and silicon oxide-coated ZSM-5 catalysts includes step 1, material selection; step 2, impregnation; step 3, suction filtration; step 4, sealed crystallization; step 5, roasting and post-treatment;

[0026] In the above-mentioned step 1, respectively select ZSM-5 molecular sieves weighed at 140°C, SB powder weighed at 140°C, and safflower powder at a mass ratio of 100:25:3, fully kneaded with 10wt% nitric acid solution and extruded The strips are formed, and the strips are dried in an oven at 120°C overnight, and then baked in a muffle furnace. The roasting procedure is to heat up to 300°C for 3 hours at room temperature and maintain for 1 hour; then heat up to 550°C for 3 hours and maintain for 5 hours. Cool down to below 200°C and take out;

[0027] Wherein in the above step 2, the forming agent is placed in the mixed solution of TEOS and n-pentane, the mass ratio of TEOS and n-pentane is 3:7, and it is left standing at room temperature ...

Embodiment 2

[0032] The preparation of Silicalite-1 and silicon oxide-coated ZSM-5 catalysts includes step 1, material selection; step 2, impregnation; step 3, suction filtration; step 4, sealed crystallization; step 5, roasting and post-treatment;

[0033] Wherein in the above-mentioned step one, select the forming agent prepared in the same batch as that of Example 1;

[0034] Wherein in the above step 2, the forming agent is placed in the water glass solution, the water glass modulus is 3.0, and the solid content is 30.2%, and it is allowed to stand at room temperature for 6 hours;

[0035] Wherein in the above-mentioned step 3, the impregnated catalyst in the step 2 is taken out, then placed in the suction filtration funnel, and suction filtered for 2 hours, and the excess components on the catalyst are extracted;

[0036] In the above step 4, take 20g of the above-mentioned forming agent and place it in the upper layer of the hydrothermal kettle, take 5g of water and 8g of n-butylamin...

Embodiment 3

[0039] The preparation of Silicalite-1 and silicon oxide-coated ZSM-5 catalysts includes step 1, material selection; step 2, impregnation; step 3, suction filtration; step 4, sealed crystallization; step 5, roasting and post-treatment;

[0040] Wherein in the above-mentioned step one, select the forming agent prepared in the same batch as that of Example 1;

[0041] Wherein in the above step 2, the forming agent is placed in a mixed solution of TEOS, 30wt% TPAOH, ethanol, and water, the ratio of which is 10:2:15:15; stand at room temperature for 6 hours;

[0042] Wherein in the above-mentioned step 3, the impregnated catalyst in the step 2 is taken out, then placed in the suction filtration funnel, and suction filtered for 2 hours, and the excess components on the catalyst are extracted;

[0043] Among them, in the above step 4, take 20g of the above-mentioned forming agent and place it in the upper layer of the hydrothermal kettle, and take 8g of water and place it in the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com