Metal-doped hierarchical porous biochar with three-dimensional frame structure and preparation method of metal-doped hierarchical porous biochar

A technology of metal doping and hierarchical porosity, which is applied in the preparation/purification of carbon, structural parts, non-metallic elements, etc., can solve the problems of lack of macropores and ultra-large pores, and the inability to fully utilize the electrochemical performance of sulfur materials to achieve enhanced Effects of conductivity, improvement of electrochemical performance, and improvement of rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

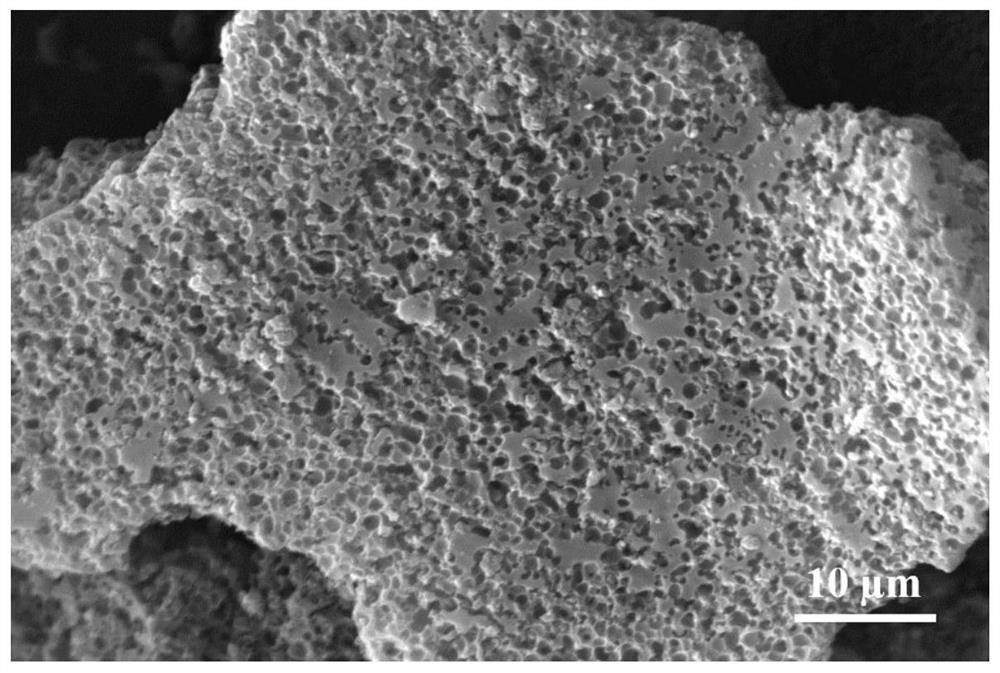

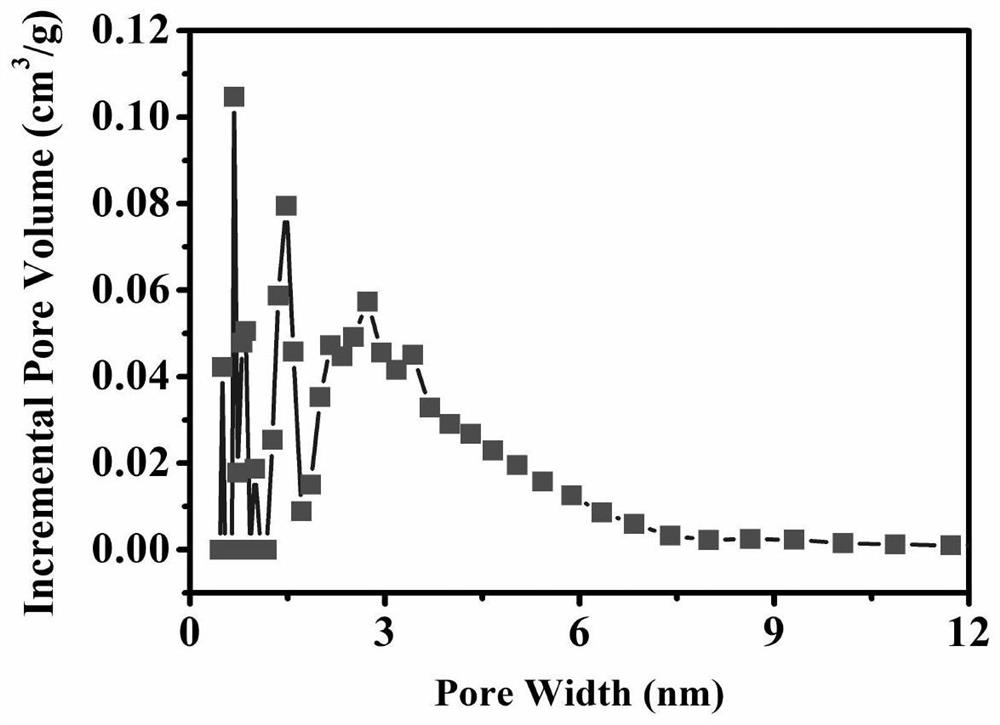

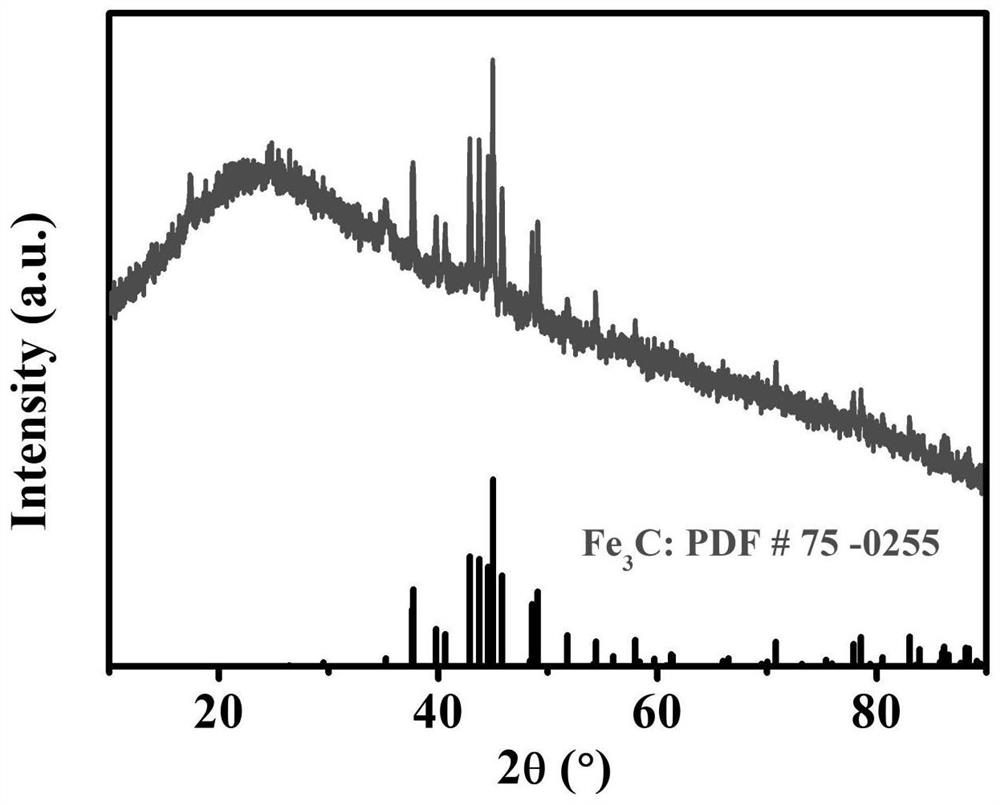

[0033] (1) Tremella is used as a raw material, soaked, drained, dried, crushed into fine powder with a crusher, and freeze-dried tremella powder is obtained. Then add 1g white fungus powder, 0.2g potassium hydroxide and 0.2g FeCl 3 (5:1:1), mixed in 60mL deionized water, stirred and ultrasonicated until uniform and viscous mixture was obtained;

[0034](2) Use a high-shear emulsifier to shear and emulsify the viscous mixture in (1), with a rotation speed of 8000r / min and an emulsification time of 10 minutes. Then place the emulsified mixture in a freeze dryer and freeze it at minus 60°C for 4 hours, then seal the drying chamber and vacuumize it so that the pressure in the chamber is 1 Pa, dry it for 48 hours, and dry it thoroughly;

[0035] (3) Put the dry powder in (2) into a porcelain boat, and perform high-temperature carbonization in a tube furnace. The specific process steps of heat treatment are: heating up to 100°C at a heating rate of 5°C / min and holding for 1 hour, ...

Embodiment 2

[0039] (1) Sweet potatoes are used as raw materials, soaked, drained, dried, and crushed into fine powder with a crusher to obtain freeze-dried sweet potato powder. Add 1g of sweet potato powder, 0.2g of potassium hydroxide and 0.2g of FeCl 3 (5:1:1), mixed in 60mL deionized water, stirred and ultrasonicated until uniform and viscous mixture was obtained;

[0040] (2) Use a high-shear emulsifier to shear and emulsify the viscous mixture in (1), with a rotation speed of 8000r / min and an emulsification time of 10 minutes. Then place the emulsified mixture in a freeze dryer and freeze it at minus 60°C for 4 hours, then seal the drying chamber and vacuumize it so that the pressure in the chamber is 1 Pa, dry it for 48 hours, and dry it thoroughly;

[0041] (3) Put the dry powder in (2) into a porcelain boat, and perform high-temperature carbonization in a tube furnace. The specific process steps of heat treatment are: heating up to 100°C at a heating rate of 5°C / min and holding ...

Embodiment 3

[0045] (1) Tremella is used as a raw material, soaked, drained, dried, crushed into fine powder with a crusher, and freeze-dried tremella powder is obtained. Then add 1g white fungus powder, 0.2g potassium hydroxide and 0.2g CoCl 2 ·6H 2 O (5:1:1), mixed in 60mL deionized water, stirred and ultrasonicated until uniform and viscous mixture was obtained;

[0046] (2) Use a high-shear emulsifier to shear and emulsify the viscous mixture in (1), with a rotation speed of 8000r / min and an emulsification time of 10 minutes. Then place the emulsified mixture in a freeze dryer and freeze it at minus 60°C for 4 hours, then seal the drying chamber and vacuumize it so that the pressure in the chamber is 1 Pa, dry it for 48 hours, and dry it thoroughly;

[0047] (3) Put the dry powder in (2) into a porcelain boat, and perform high-temperature carbonization in a tube furnace. The specific process steps of heat treatment are: heating up to 100°C at a heating rate of 5°C / min and holding fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com