Preparation method and application of porous Pd-PdO nanorod

A technology of nanorods and potassium chloropalladate, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problem that it is difficult to effectively control the ratio of Pd and O in Pd-PdO nanorods, and achieve enhanced methanol oxidation reaction activity, The preparation method is simple and green, and the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pour 2mL of 0.05mol / L ethanol solution of 1,10-phenanthroline into 1mL of 0.05mol / L K 2 PdCl 4 Mix the aqueous solution evenly, and let the resulting mixture stand for 1 to 2 minutes to make K 2 PdCl 4 Fully complexed with 1,10-phenanthroline to form a 1,10-phenanthroline-palladium complex, ultrasonicated for 10 minutes to make the size uniform; then centrifuged and washed with a 1:1 hydrated ethanol mixture for 3 Then pour it into a magnetic boat and dry it in a 60°C oven; finally put the magnetic boat into a tube furnace, calcinate at 260°C under air conditions for 2 hours, centrifuge, wash, and vacuum dry to obtain the product.

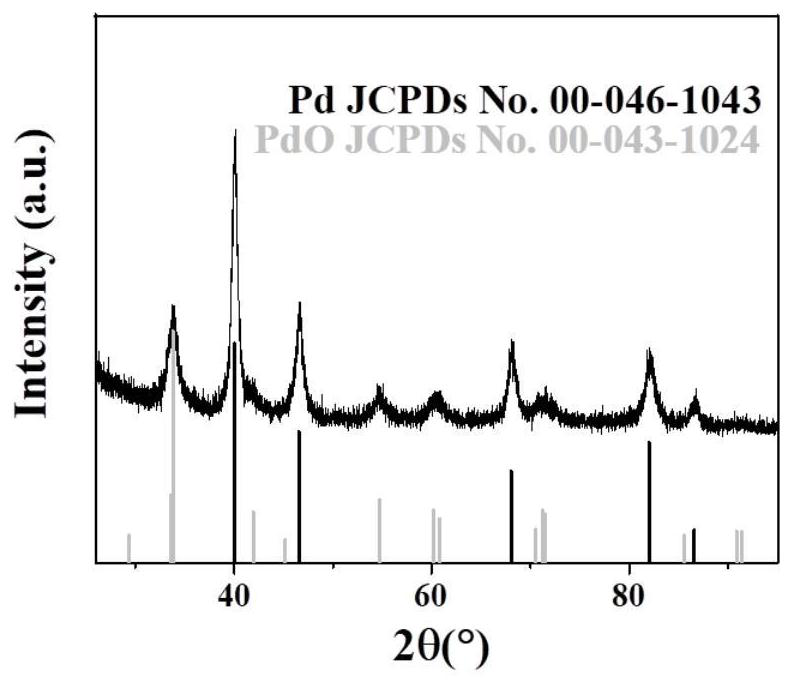

[0027] Depend on figure 1 It can be seen that the obtained product is a mixture of Pd and PdO.

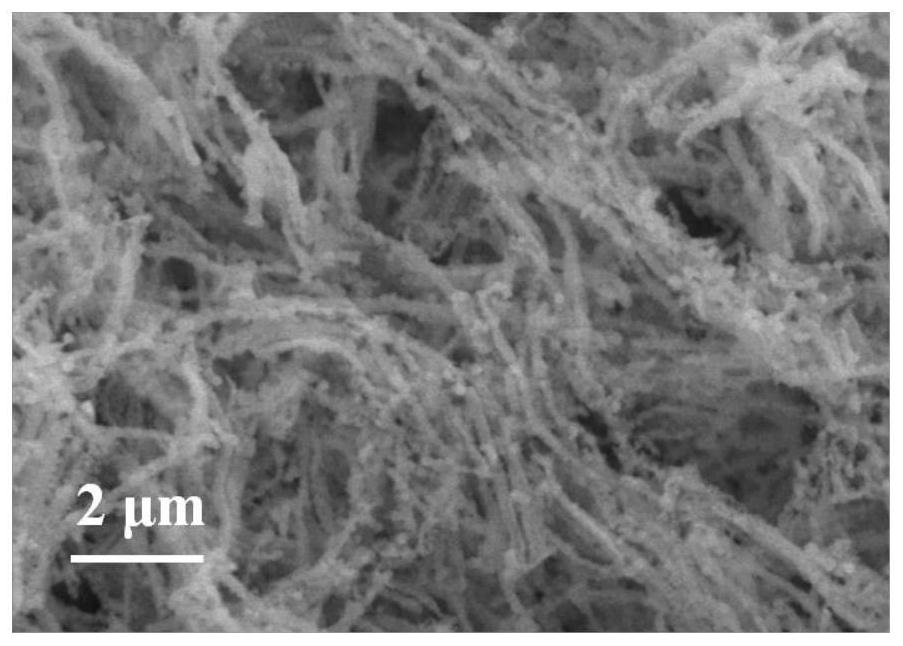

[0028] Depend on figure 2 It can be seen that the obtained product is a one-dimensional rod-like structure.

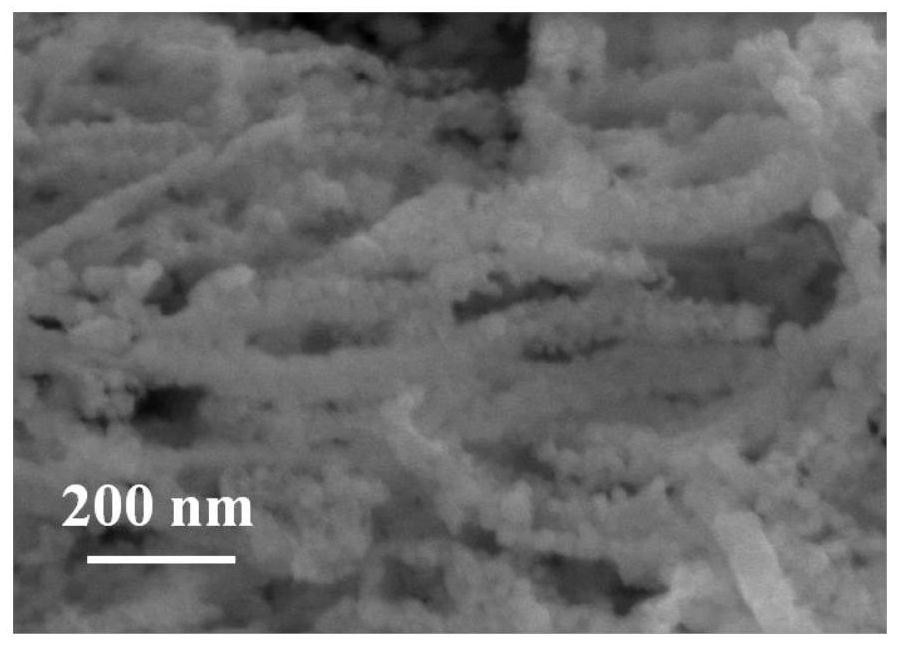

[0029] pass image 3 After observation, it can be seen that the surface of Pd-PdO nanorods is rough and has many holes.

[0030...

Embodiment 2

[0034] Pour 6mL 0.05mol / L 1,10-phenanthroline ethanol solution into 3mL 0.05mol / L K 2 PdCl 4 Mix the aqueous solution evenly, and let the resulting mixture stand for 1 to 2 minutes to make K 2 PdCl 4 Fully complexed with 1,10-phenanthroline to form a 1,10-phenanthroline-palladium complex, ultrasonicated for 10 minutes to make the size uniform; then centrifuged and washed with a 1:1 hydrated ethanol mixture for 3 Then pour it into a magnetic boat and dry it in an oven at 60°C; finally put the magnetic boat into a tube furnace, calcinate at 260°C under air conditions for 2 hours, centrifuge, wash, and dry in vacuum to obtain porous Pd-PdO nanorods. See Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com