Composite metal oxide catalyst for one-step preparation of isobutyl isobutyrate from isobutyraldehyde, and preparation method of composite metal oxide catalyst

A technology of isobutyl isobutyrate and composite metal, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, aldehyde redox preparation, catalyst activation/preparation, etc. Replaced by hydroxyl groups, deactivated and other problems, to achieve the effect of improving stability and service life, good surface distribution, and high loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

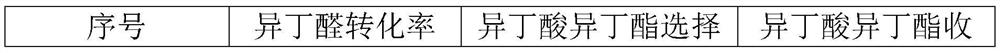

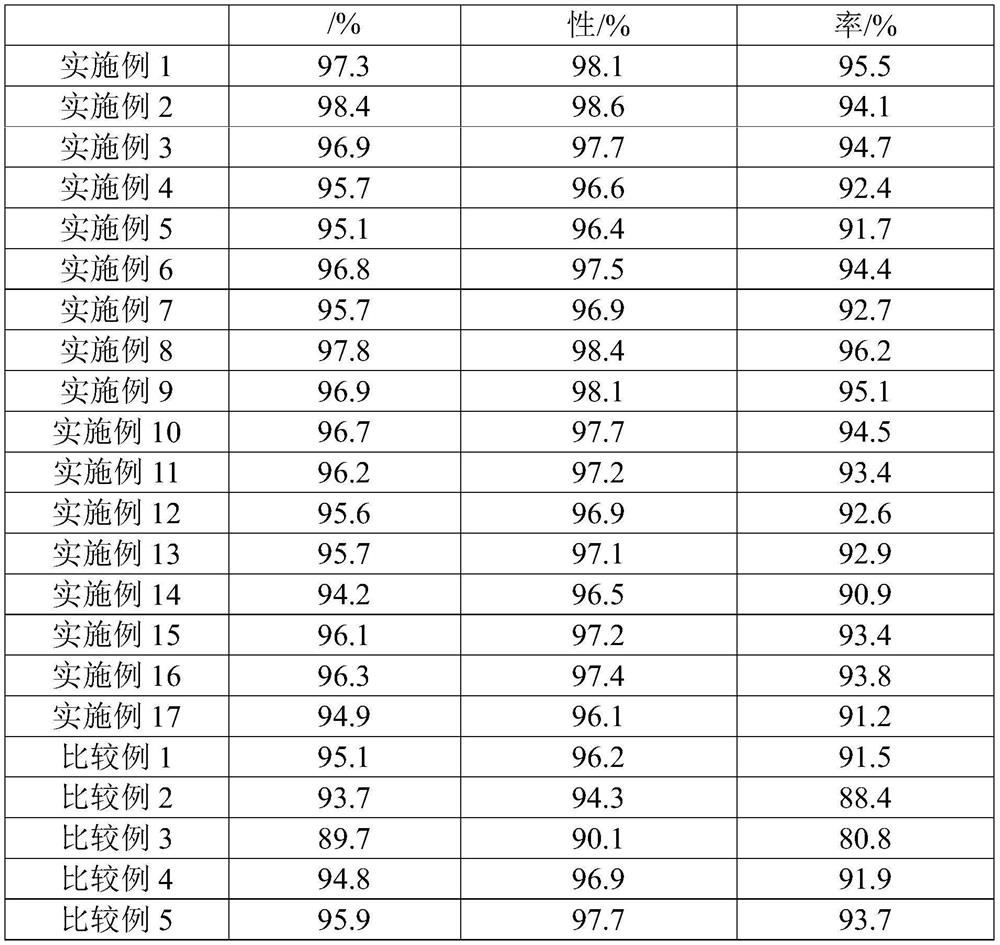

Examples

Embodiment 1

[0021] (1) Preparation of carrier

[0022] Weigh 9.0 g of copper nitrate and 3.0 g of cerium nitrate, and dissolve them in 120 ml of water after mixing uniformly to prepare a metal salt mixed solution. Dry 3.6g of carbon black at 150°C for 24 hours, then fully impregnate the carbon black with ethanol, use it after the ethanol evaporates, and perform surface active treatment on the carbon black to enhance its adsorption capacity. Then the pretreated carbon black was dispersed in an alkali solution with a concentration of 0.1 mol / L TPAOH, and the prepared metal salt mixed solution was added dropwise thereto, and stirred at room temperature for 5 hours. Then add 1.2 g of F127, and add 2 mol / L ammonium hydroxide solution dropwise thereinto with stirring until the pH is 10. Then put it in an autoclave, and crystallize in a microwave system at 180°C for 6 hours. Then the product was filtered, washed several times with distilled deionized water, and dried in an oven at 80° C. for 2...

Embodiment 2

[0030] In step (3), 0.3g aluminum isobutoxide is changed into 0.6g aluminum isobutoxide, and other operations are with embodiment 1.

Embodiment 3

[0032] In step (3), 0.3g aluminum isobutoxide is changed into 0.9g aluminum isobutoxide, and other operations are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com