Patents

Literature

56 results about "Isobutylaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for the oxidation of a mixed aldehyde feedstock to methacrylic acid and methods for making and using same

InactiveUS20070021296A1Improve distributionOrganic compound preparationHeterogenous catalyst chemical elementsIndiumCerium

A heteropolyacid catalyst for oxidation of isobutyraldehyde, methacrolein or mixtures or combinations thereof to methacrylic acid is disclosed where the heteropolyacid catalyst includes at least molybdenum (Mo), phosphorus (P), vanadium (V), and a first component including bismuth (Bi) and / or boron (B). The heteropolyacid catalyst can also optionally include a second component including potassium (K), rubidium (Rb), cesium (Cs), and / or thallium (Tl) and optionally a third component including antimony (Sb), cerium (Ce), niobium (Nb), indium (In), iron (Fe), chromium (Cr), cobalt (Co), nickel (Ni), manganese (Mn), arsenic (As), silver (Ag), zinc (Zn), germanium (Ge), gallium (Ga), zirconium (Zr), magnesium (Mg), barium (Ba), lead (Pb), tin (Sn), titanium (Ti), aluminum (Al), silicon (Si), tantalum (Ta), tungsten (W), and / or lanthanum (La). The heteropolyacid catalyst can also include an ammonium-containing compound designed to increase a value of medium pores in the final heteropolyacid catalyst. A method for oxidizing isobutanal to methacrylic acid using the heteropolyacid catalyst is also disclosed.

Owner:SAUDI BASIC IND CORP SA

Method for producing epoxy cyclohexane

The epoxy cyclohexane producing process includes using cyclohexene as main material, molecular oxygen as oxygen source, n-valeraldehyde or isovaleraldehyde or isobutylaldehyde as intermediate; adopting re-compounded catalyst including at least one oxide of Mn, Fe, Co and Ni, at least one oxide of Mo and W, and at least one oxo acid of N, P and As; and reaction at 30-80 deg.c for 2-12 hr. The re-compounded catalyst can oxidize aldehyde into per-acid in high selectivity and catalyze the reaction between per-acid with cyclohexene in high selectivity to obtain epoxy cyclohexane as the destination product in the same reactor, with the single-path cyclohexene converting rate reaching 23 % and selectivity reaching 98 %. The reaction process uses no solvent and the metal oxide in the re-compounded catalyst may be reused.

Owner:BALING PETRO CHEM CO LTD SINOPEC

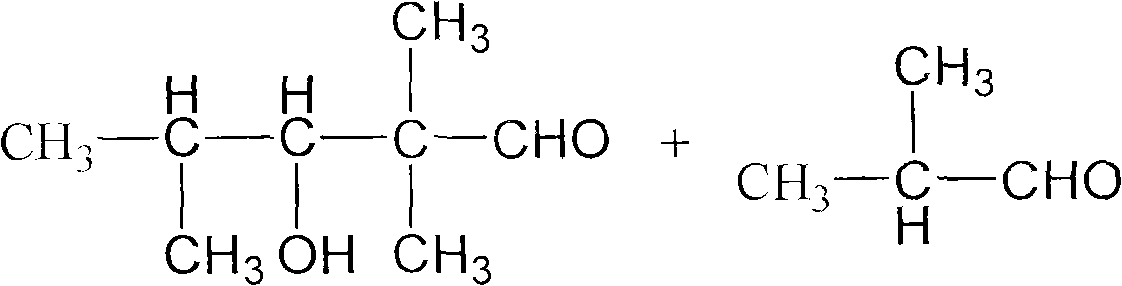

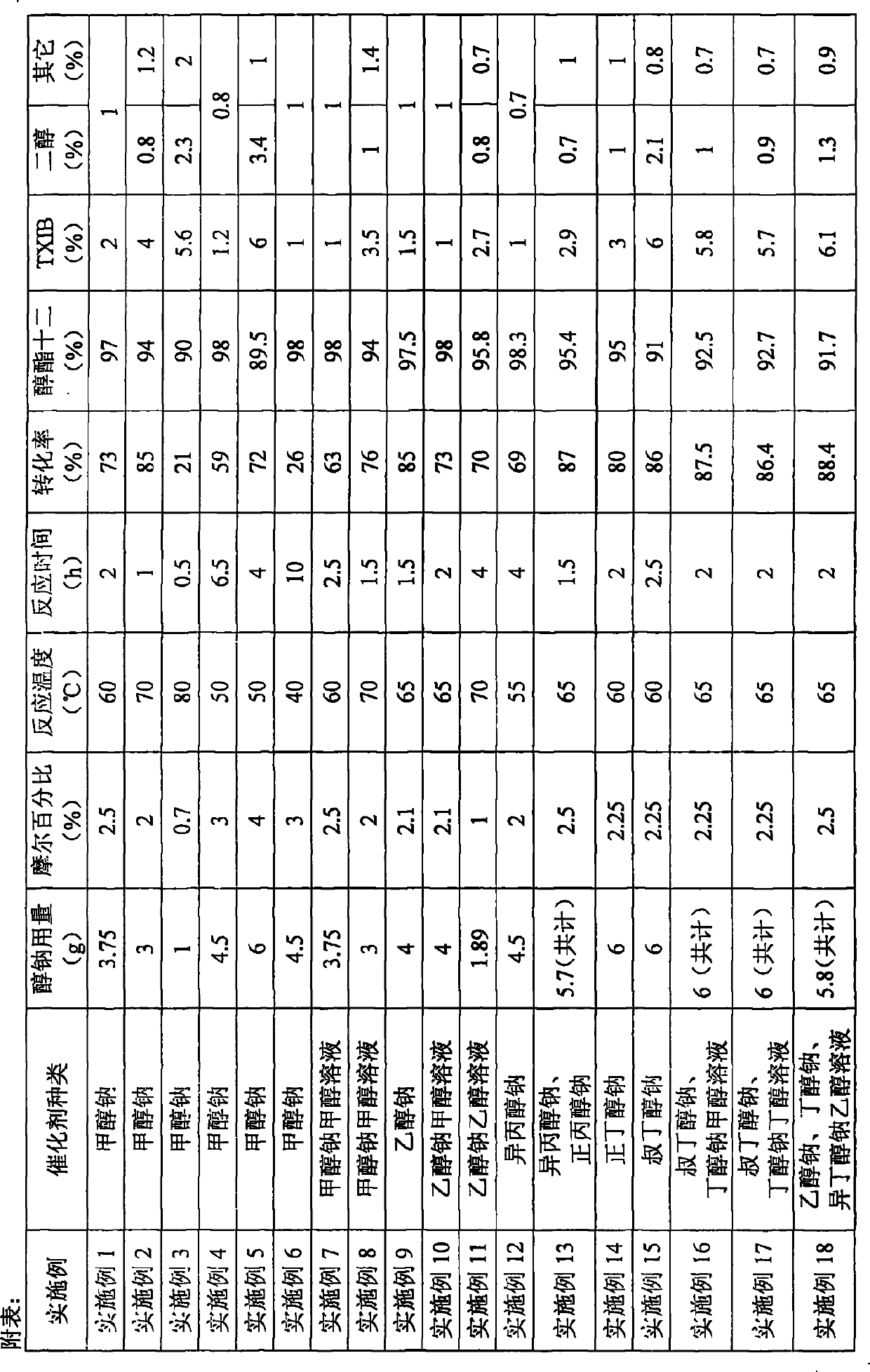

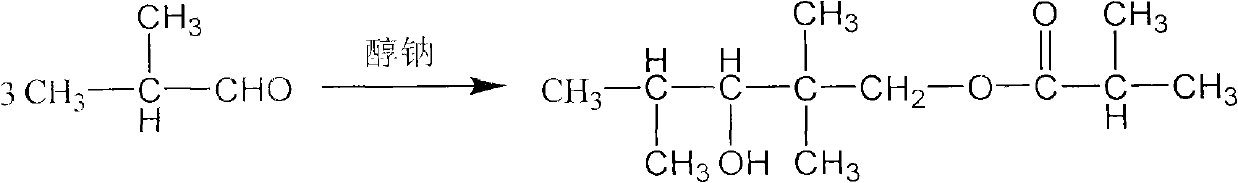

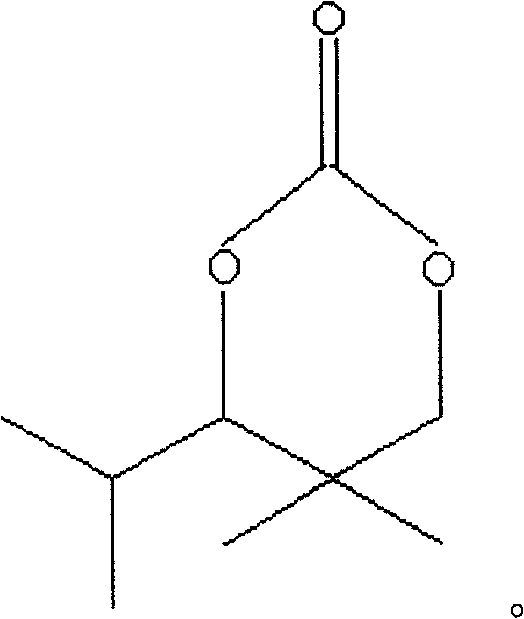

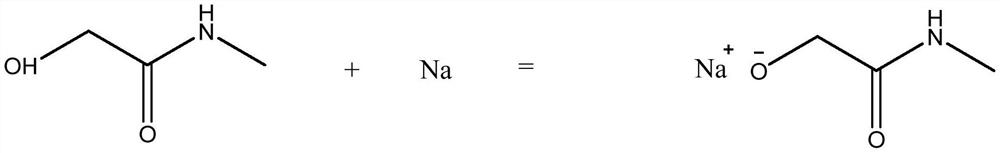

Method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate

ActiveCN101948386AAvoid process problemsAvoid energy consumptionPreparation by aldehyde oxidation-reductionAlcoholOrganic synthesis

The invention discloses a method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, which relates to the technical field of organic synthesis. In the invention, isobutylaldehyde is used as a raw material, aldol condensation and Cannizzaro reactions are completed by a one-step reaction process in the presence of a catalyst, and the process adopts sodium alcoholate as the catalyst; and the isobutylaldehyde is used to form alcohol ester-12 in the presence of the sodium alcoholate catalyst, so the complex and high-energy consumption drawbacks of a two-step reaction process using an inorganic alkali as a catalyst are overcome, the drawbacks of toxic catalyst and high quality requirement on the isobutylaldehyde raw material of a one-step reaction process using Ba(OH)2 as a catalyst are overcome, and simple process, high single-pass yield, small catalyst dosage, low energy consumption, safety and environmental protection are realized.

Owner:YIXING HENGXING FINE CHEM

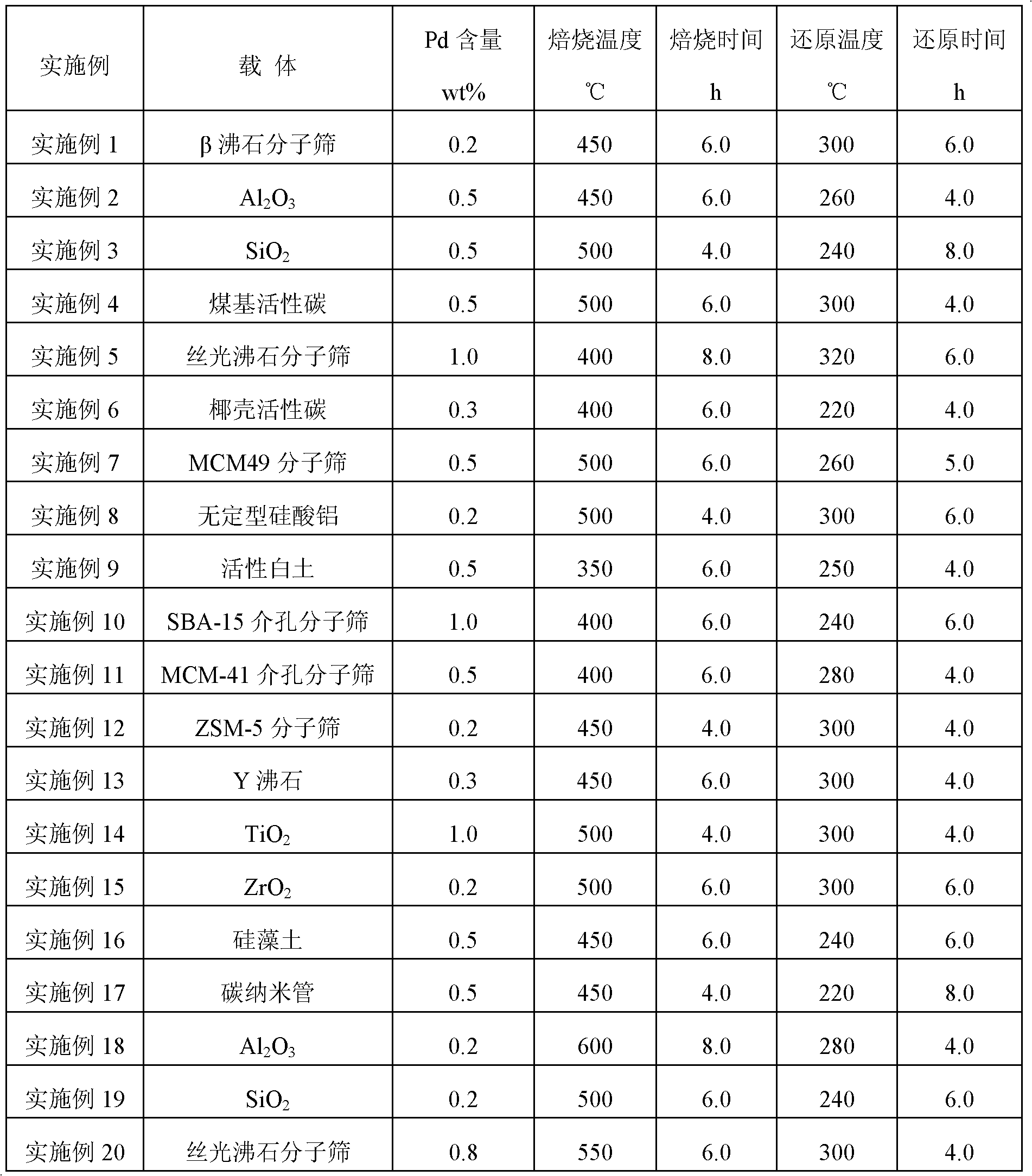

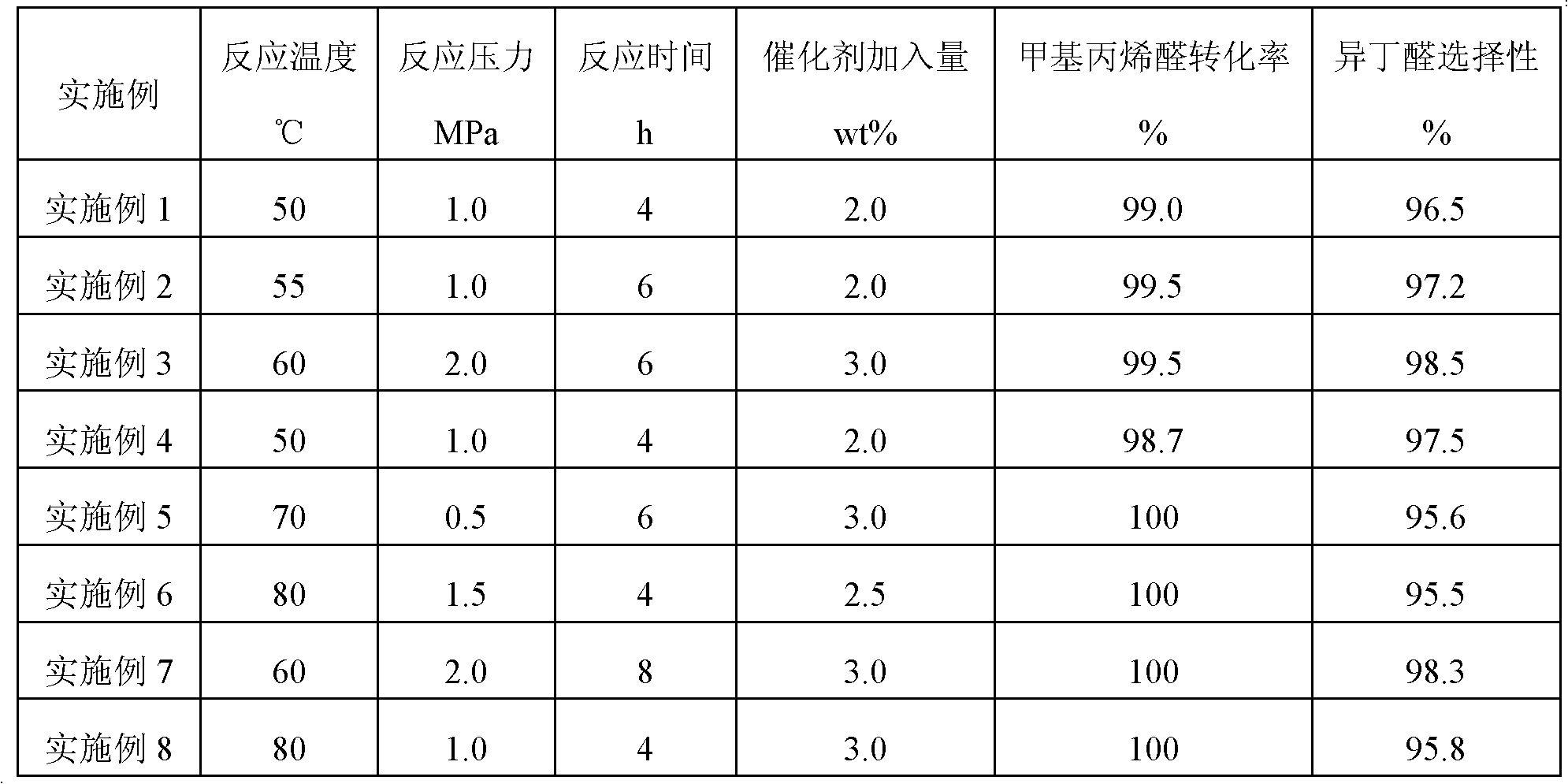

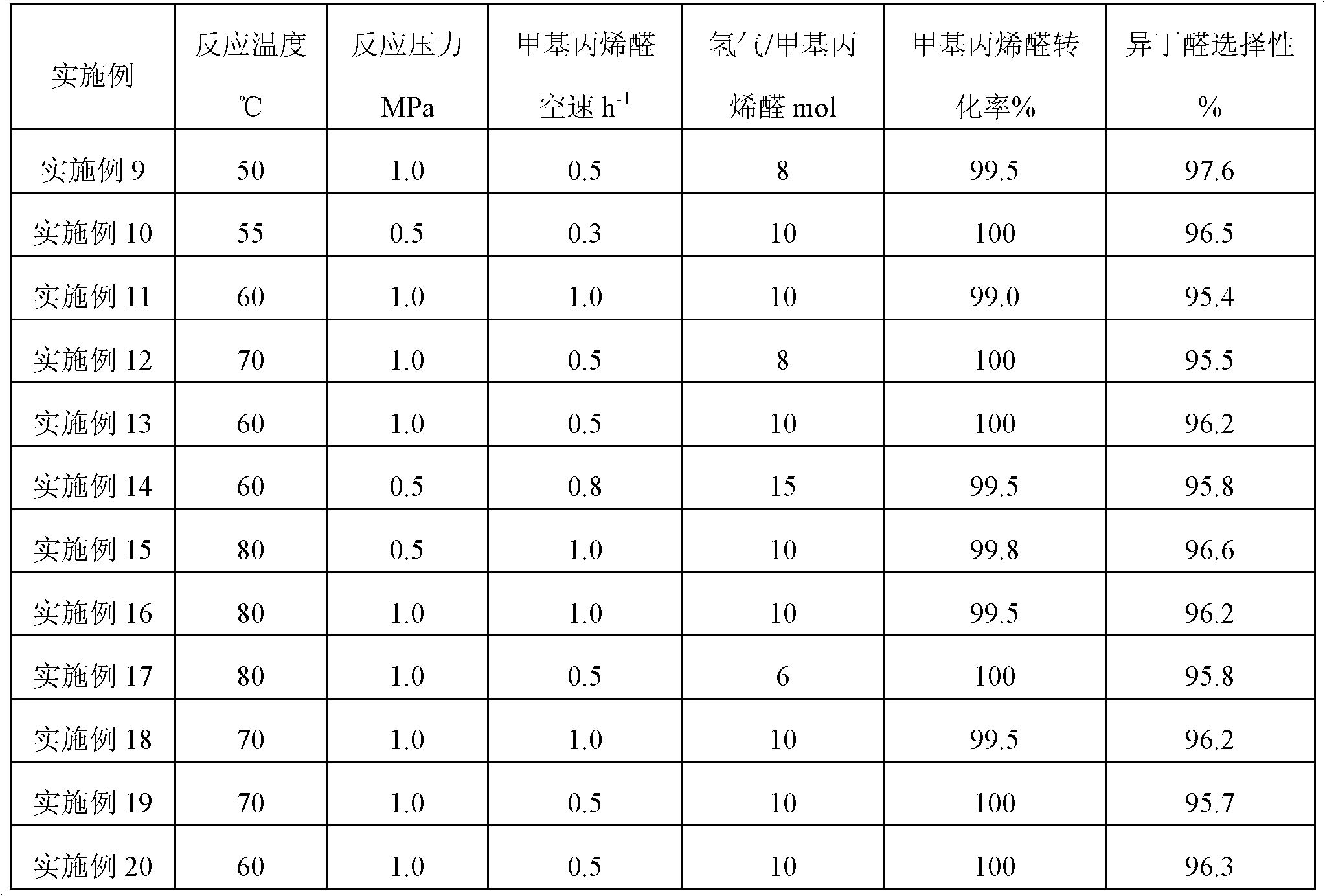

Method for preparing isobutylaldehyde by performing selective hydrogenation on methylacrolein

InactiveCN102351667AHigh activityMild reaction conditionsOrganic compound preparationCarbonyl compound preparationCarbon nanotubeAluminum silicate

The invention discloses a method for preparing isobutylaldehyde by performing selective hydrogenation on methylacrolein. In the method, isobutylaldehyde is prepared by performing selective hydrogenation on methylacrolein under the catalytic action of a loaded Pd catalyst, wherein the content of Pd in the catalyst is 0.1-5 percent by weight; and a catalyst carrier is selected from one or more of a molecular sieve, a metal oxide, mesoporous silica, amorphous aluminum silicate, active carbon or a carbon nanotube. The method has a mild reaction condition, high catalyst activity and high selectivity, the conversion rate of the methylacrolein is more than or equal to 99 percent, the isobutylaldehyde selectivity is more than or equal to 95.4 percent, and the catalyst has continuously stable performance after over 1,000 hours of continuous reaction. The method is an effective measure for preparing the isobutylaldehyde by performing selective hydrogenation on the methylacrolein which is prepared by oxidizing isobutene or tertiary butanol serving as a C4 raw material with the air.

Owner:SHANGHAI HUAYI GRP CO

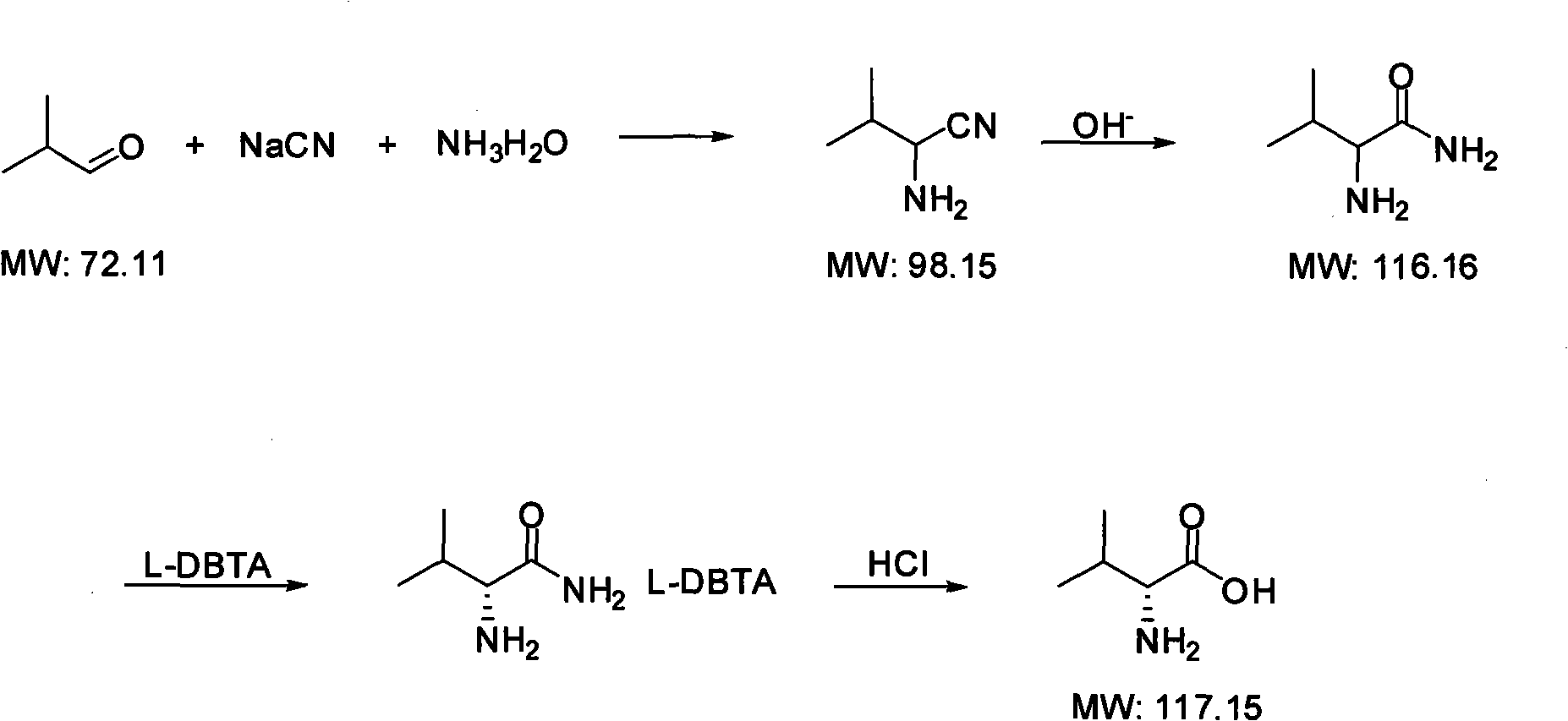

Method for synthesizing D-valine

ActiveCN102070473AReduce dosageReduce pollutionOrganic compound preparationAmino-carboxyl compound preparationKetoneSolvent

The invention discloses a method for synthesizing D-valine, which comprises the following steps of: cyaniding isobutylaldehyde serving as an initiative raw material to prepare 2-amino-3-methyl-butanenitrile; performing catalytic hydrolysis by adopting inorganic base and a ketone catalyst to obtain mix spin freebase(+ / -)-2-amino-3-methylbutyrylamide; resolving by using a resolving agent of dibenzoyl-L-tartaric acid (L-DBTA) in a mixed solvent of acetone and water to obtain D-2-amino-3-methylbutyrylamideL-DBTA salt solid with optical activity; and acidifying and separating the resolving agent, and performing reflux hydrolysis and refining to obtain D-2-amino-3-methyl-butanoic acid, namely D-valine. The method has the advantages that: raw materials are low in cost and easily obtained, the method is easy and convenient to operate, the cost is low, the environmental pollution is light, and the method is suitable for industrial production.

Owner:ABA CHEM SHANGHAI

Catalyst for producing methacrylic acid and preparation method thereof

InactiveUS7825061B2Organic compound preparationHeterogenous catalyst chemical elementsGas phaseActive component

The object of the present invention is to provide a catalyst for producing methacrylic acid in high yield and highly selectively by subjecting methacrolein, isobutylaldehyde or isobutyric acid to gas phase catalytic oxidation, and the preparation method thereof. The catalyst contains Mo, V, P, Cu, Cs and NH4 as the essential, active components, and the feature is to use for preparing the catalyst a cesium weak acid salt or cesium hydroxide as the Cs raw material and ammonium acetate as the NH4 raw material. A coated catalyst of the present invention is obtainable by supporting the active component on an inert carrier of alumina or the like.

Owner:NIPPON KAYAKU CO LTD

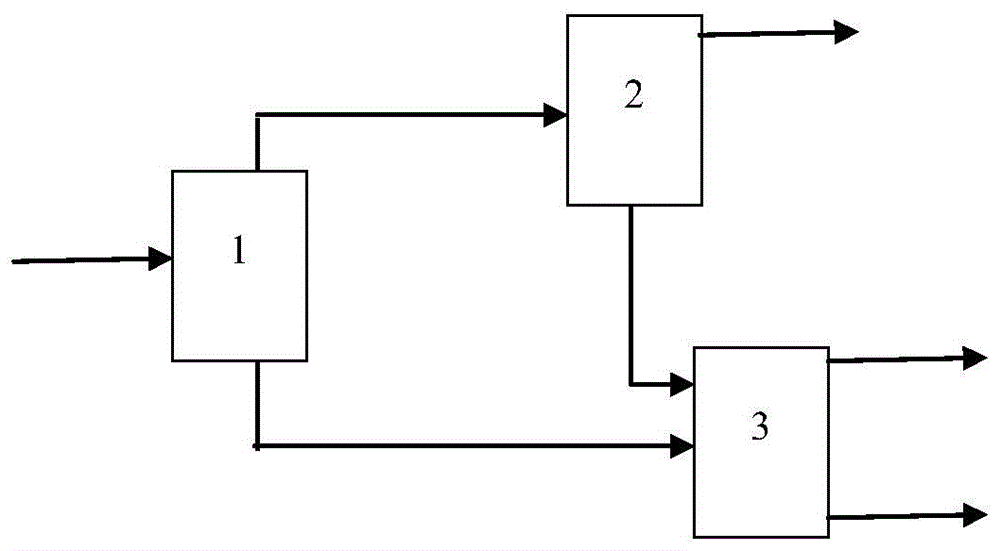

Separation and purification system and method of n-butyraldehyde and isobutylaldehyde

InactiveCN104788302AHigh priceImprove competitive advantageDistillation separationCarbonyl compound separation/purificationProcess engineeringOctanol

The invention relates to a separation and purification system of n-butyraldehyde and isobutylaldehyde. The separation and purification system comprises a butyraldehyde isomer tower, a first rectifying tower and a second rectifying tower, wherein the tower top discharging end of the butyraldehyde isomer tower is communicated with the middle part of the first rectifying tower, and the tower kettle discharging end of the butyraldehyde isomer tower is communicated with the middle part of the second rectifying tower; the tower kettle discharging end of the first rectifying tower is communicated with the butyraldehyde isomer tower. Mixed gas containing n-butyraldehyde and isobutylaldehyde isomer enters the butyraldehyde isomer tower to be separated, and isobutylaldehyde is discharged from the tower top of the butyraldehyde isomer tower and enters the first rectifying tower for further separation and purification; the n-butyraldehyde is discharged from the tower bottom of the butyraldehyde isomer tower and enters the second rectifying tower for further separation and purification. The first rectifying tower is used for separating and recovering the high-purity isobutylaldehyde, mixed butylaldehyde separated from the tower bottom of the first rectifying tower can be returned to an original butyraldehyde isomer tower and can also directly enter a hydrogenation system of a butyl octanol device, the produced n-butyraldehyde and the produced isobutylaldehyde are used as products for sales, and the flexibility is higher.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

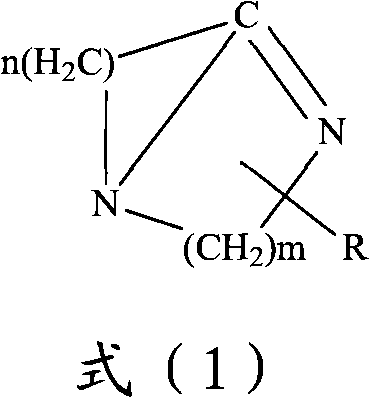

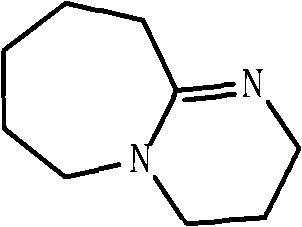

Method for preparing 2,2-dimethyl-3-hydroxy propanal

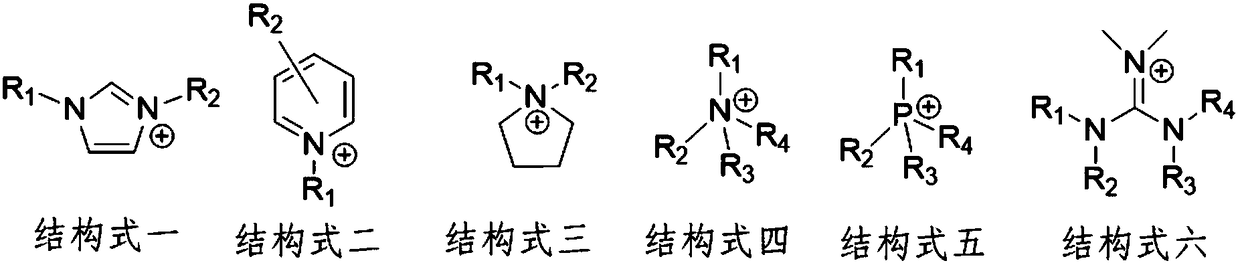

ActiveCN102153456AReduce dosageEasy to recycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCondensation reactionIsobutylaldehyde

The invention provides a method for preparing 2,2-dimethyl-e-hydroxy propanal. The method is characterized by comprising the following step of: catalyzing a condensation reaction between isobutylaldehyde and formaldehyde by taking a compound having a structure shown in the specifications as a catalyst to obtain 2,2-dimethyl-e-hydroxy propanal, wherein n is equal to 2-11, m is equal to 2-6, and R is H or alky of C1-C8. In the preparation method, the consumption of the catalyst is small, and the catalyst is easy to recycle. Moreover, the reaction condition is mild, and the post treatment is simple. The transformation rate of the isobutyl aldehyde is over 99 percent, and the selectivity of hydroxyl pivalaldehyde is over 98 percent.

Owner:WANHUA CHEM GRP CO LTD

Flavoring agent and method for preparing same

InactiveCN101624389AIncrease aromaIncrease the fragranceOrganic chemistryEssential-oils/perfumesMethyl carbonateToothpaste

Owner:HUBEI CHINA TOBACCO IND

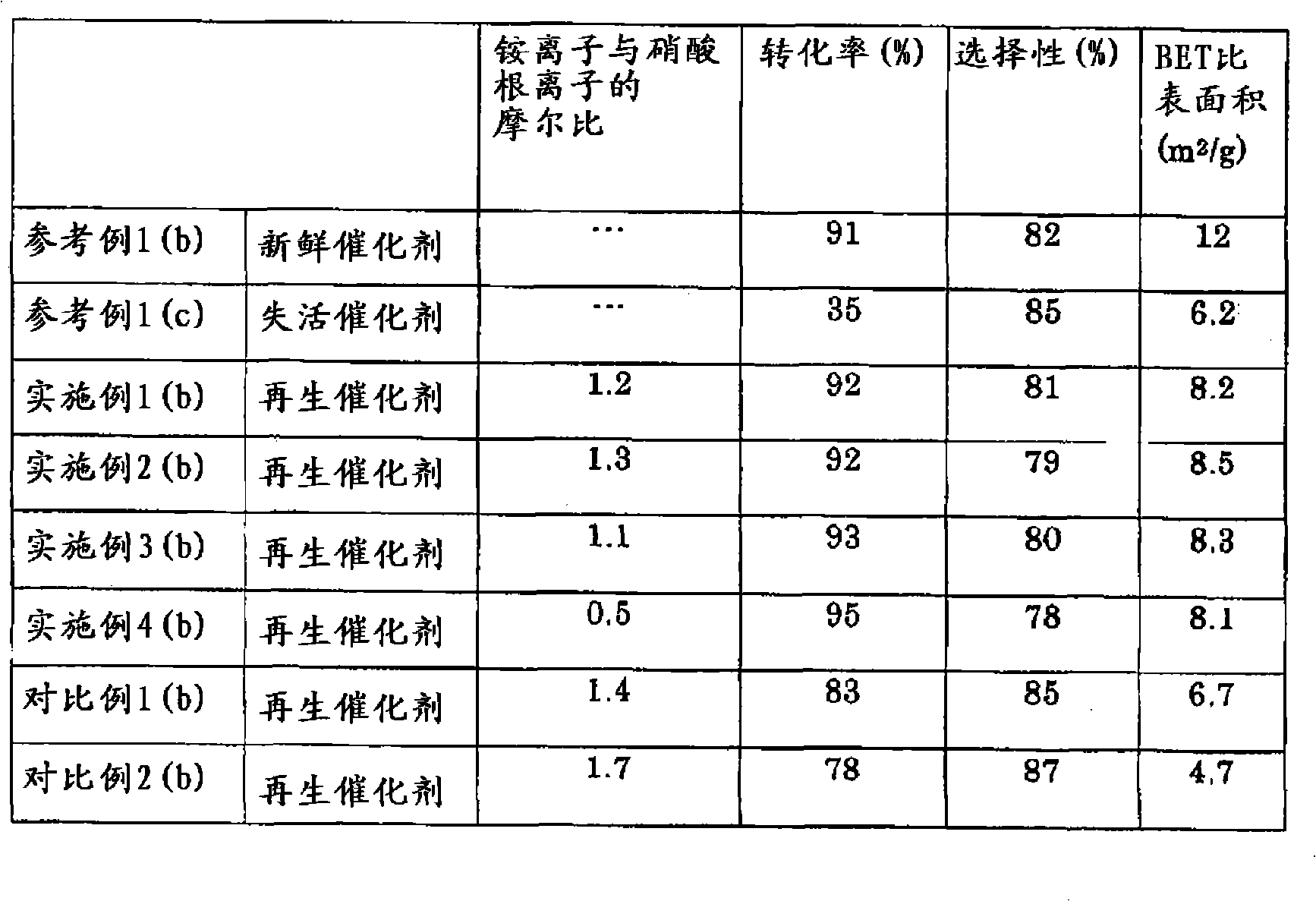

Method for regenerating catalyst for the production of methacrylic acid and process for preparing methacrylic acid

InactiveUS20090259070A1Speed up the conversion processGood choiceOrganic compound preparationOther chemical processesGas phaseCatalytic oxidation

A catalyst for the production of methacrylic acid comprising a heteropolyacid compound containing phosphorus and molybdenum is regenerated by a method comprising the steps of heat-treating a mixture containing a deactivated catalyst, water, a nitrate ion and an ammonium ion having a molar ratio to the nitrate ion of 1.3 or less at a temperature of at least 100° C., drying the mixture to obtain a dried catalyst, and calcining the dried catalyst. The regenerated catalyst has substantially the same catalytic activity as a fresh catalyst in a gas phase catalytic oxidation reaction of methacrolein, isobutylaldehyde, isobutane or isobutyric acid to prepare methacrylic acid.

Owner:SUMITOMO CHEM CO LTD

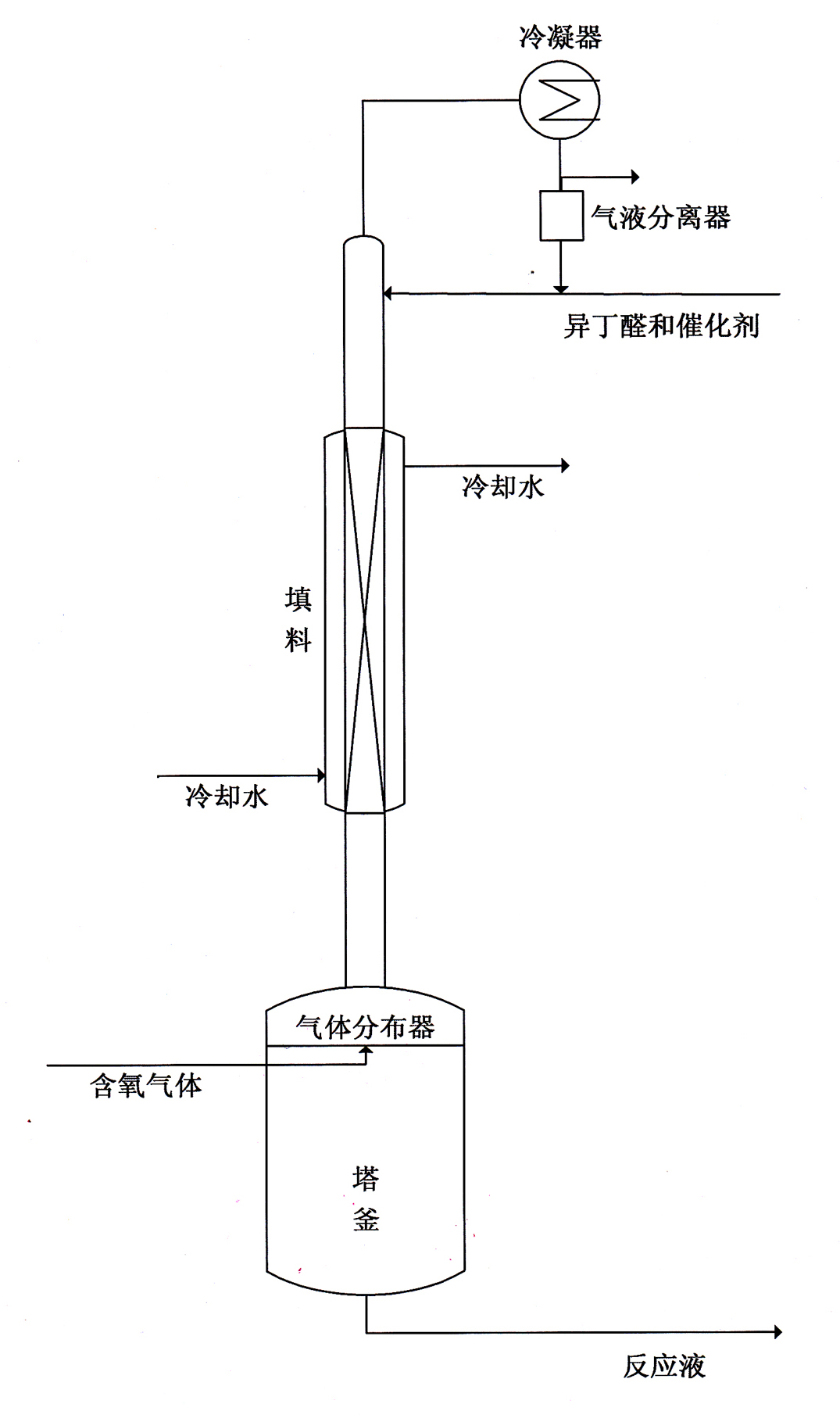

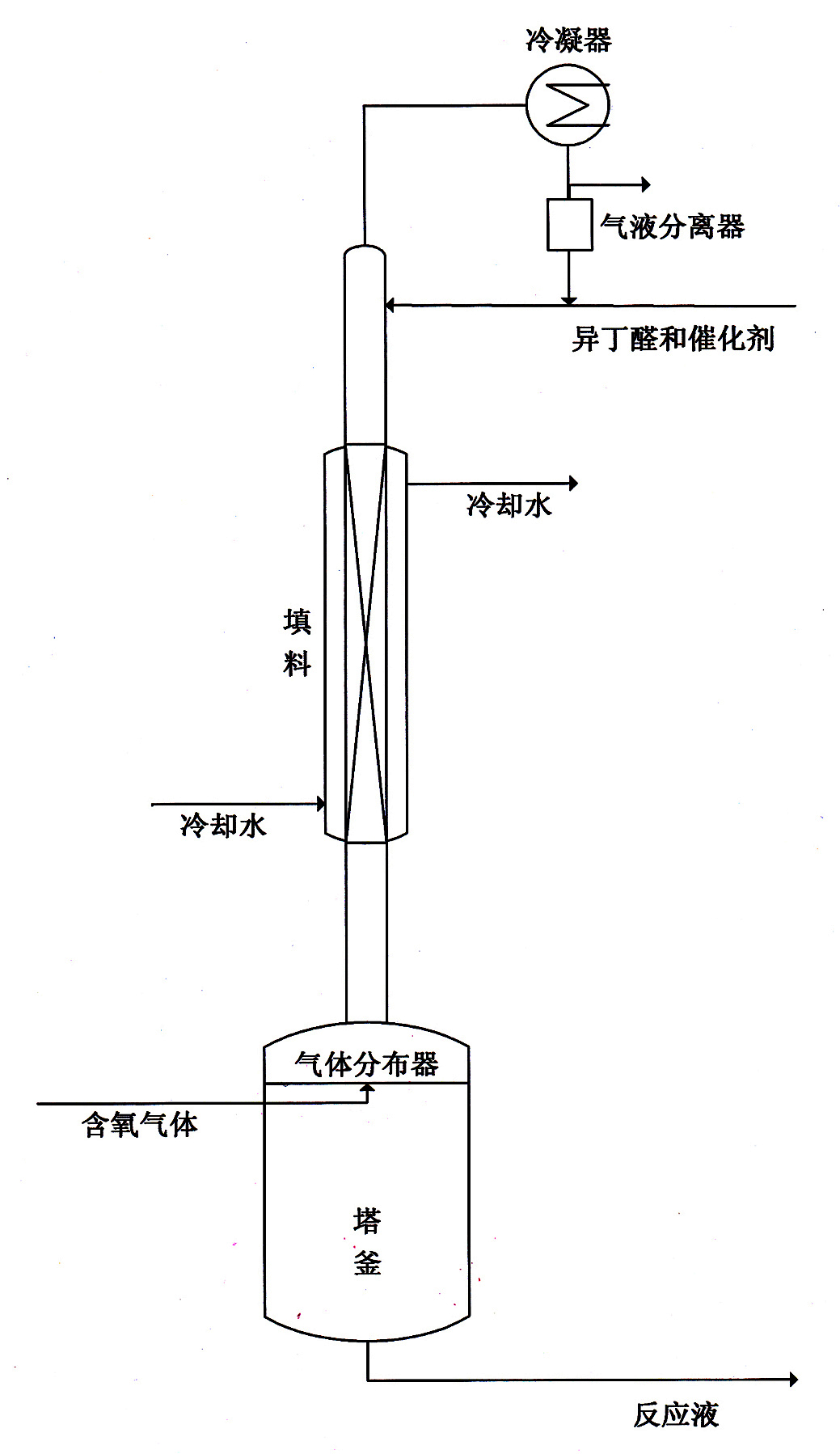

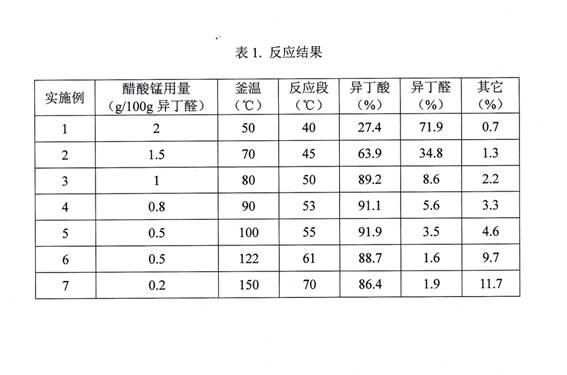

Process for continuously producing isobutyric acid

ActiveCN102010321AOrganic compound preparationCarboxylic compound separation/purificationOxygenDistributor

The invention discloses a process for continuously producing isobutyric acid, and belongs to the field of production of fine chemicals. In the process, a rectification mode is adopted for reaction; isobutylaldehyde and prepared catalyst solution serving as reaction raw materials are pumped from the upper part of a rectifying tower to flow from top to bottom; oxygen-containing gas is pumped from areaction kettle at the bottom of the tower; after the gas passes through a gas distributor, fine gas bubbles flow upwards in a backflow way; the middle part of the rectifying tower is a reaction section which accommodates a porcelain ring or a stainless steel filler; the isobutylaldehyde and the oxygen-containing gas are converged on a filler layer of the rectifying tower to react under the action of a catalyst; generated isobutyric acid which is enriched on a tower kettle is continuously discharged from the tower kettle; and the heat discharged by the reaction is removed by cooling water of a jacket. The continuous process is more environmental-friendly, saves energy and has high efficiency, isobutylaldehyde conversion rate of more than 90 percent and isobutyric acid selectivity of more than 95 percent.

Owner:YIXING HENGXING FINE CHEM +1

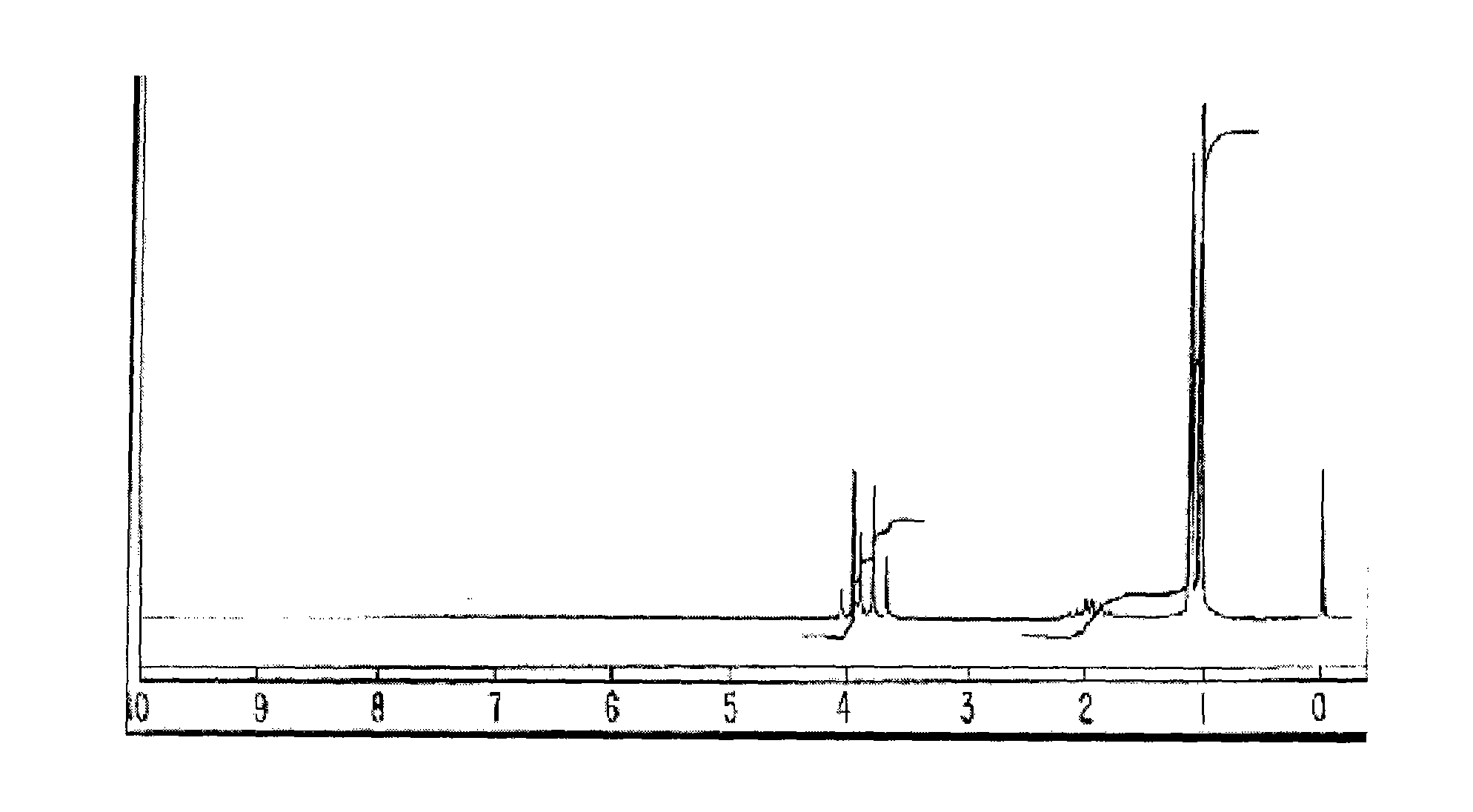

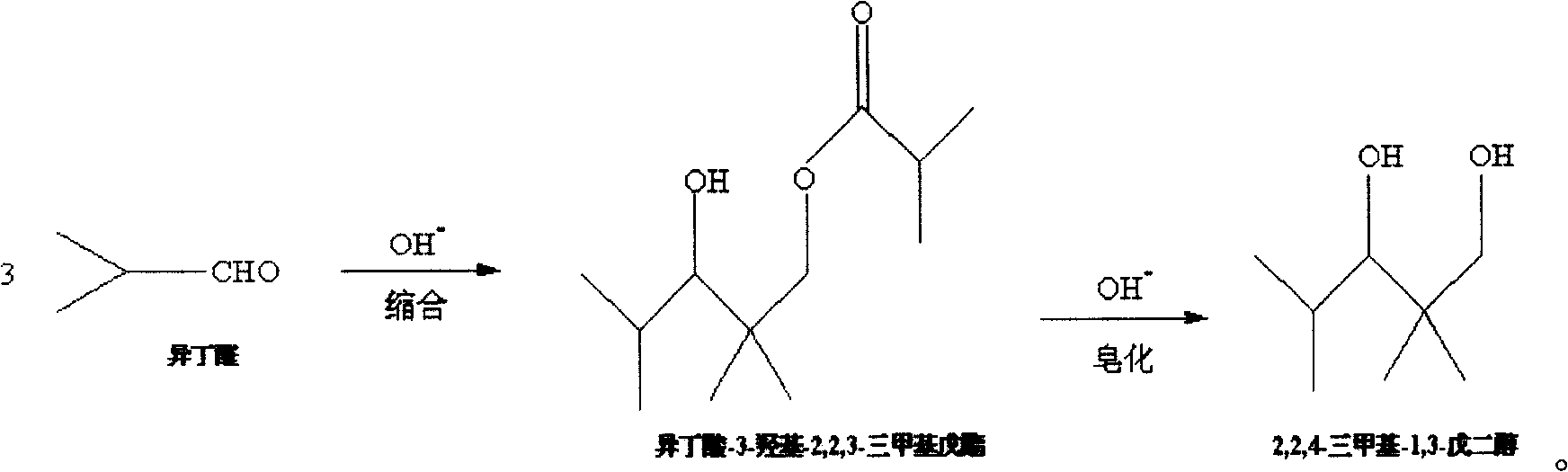

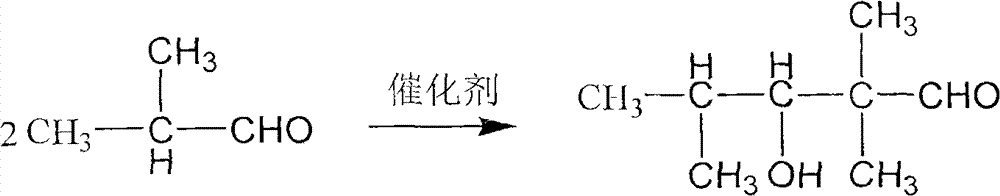

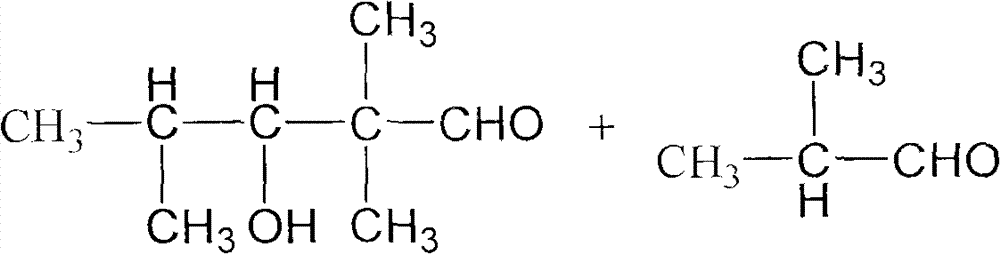

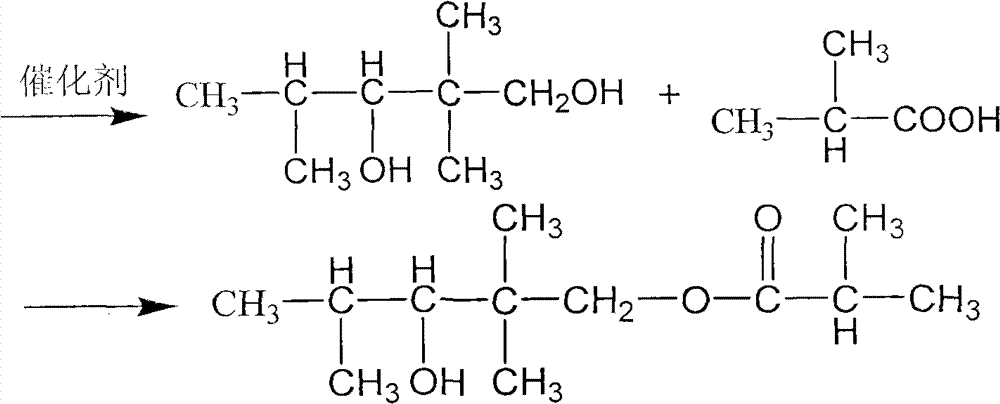

Continuous production method for 2,2,4-trimethyl-1,3-pentanediol isobutyrate

ActiveCN104072367AHigh selectivityIncrease productivityOrganic compound preparationHeterogenous catalyst chemical elementsIsobutyratesPtru catalyst

The invention discloses a continuous production method for 2,2,4-trimethyl-1,3-pentanediol isobutyrate. A two-step method fixed bed continuous reaction process and a solid catalyst are adopted, wherein the catalyst is a solid catalyst Cs-K / SiO2 which is prepared by taking spherical silicon oxide as a carrier to carry caesium-potassium double-alkali metal active components. The method comprises the following steps: adopting two serial tubular type fixed bed reactors, firstly feeding a preheated isobutyraldehyde raw material into a first tubular type fixed bed reactor for an aldol condensation reaction, subsequently feeding an obtained an aldol condensation product into a second tubular type fixed bed reactor for intramolecular Cannizzaro reaction, and continuously reacting so as to obtain a target product. Due to adoption of a two-step method fixed bed continuous reaction process, the method is not only high in isobutyraldehyde conversion rate and product selectivity, but also high in production efficiency, simple in reaction operation, beneficial for energy conservation and discharge reduction and has a large-scale continuous industrial production prospect.

Owner:德纳化工滨海有限公司 +1

Method for regenerating catalyst for the production of methacrylic acid and process for preparing methacrylic acid

InactiveCN101554594ARestore activityImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseCatalytic oxidation

A catalyst for the production of methacrylic acid comprising a heteropolyacid compound containing phosphorus and molybdenum is regenerated by a method comprising the steps of heat-treating a mixture containing a deactivated catalyst, water, a nitrate ion and an ammonium ion having a molar ratio to the nitrate ion of 1.3 or less at a temperature of at least 100 DEG C., drying the mixture to obtain a dried catalyst, and calcining the dried catalyst. The regenerated catalyst has substantially the same catalytic activity as a fresh catalyst in a gas phase catalytic oxidation reaction of methacrolein, isobutylaldehyde, isobutane or isobutyric acid to prepare methacrylic acid.

Owner:SUMITOMO CHEM CO LTD

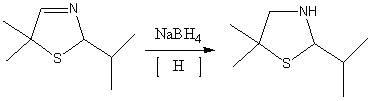

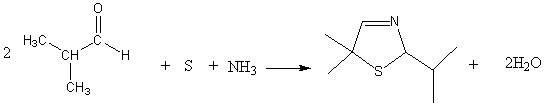

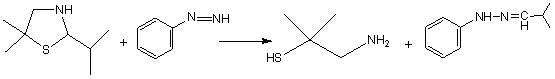

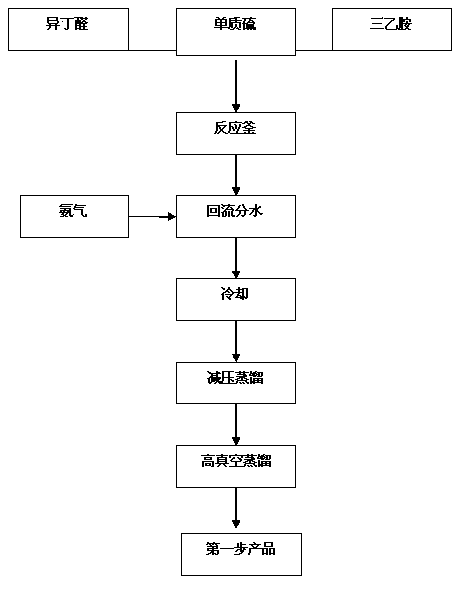

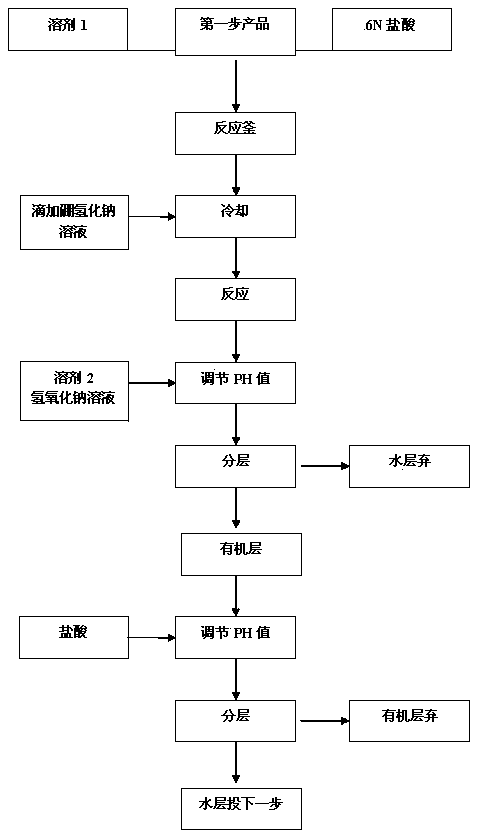

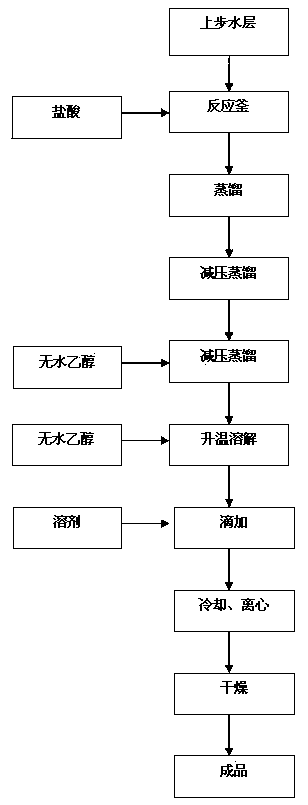

Synthetic method of dimethyl cysteamine hydrochloride

ActiveCN102432510AHigh purityReaction raw materials are readily availableThiol preparationThiazolineCYSTEAMINE HYDROCHLORIDE

The invention discloses a synthetic method of dimethyl cysteamine hydrochloride. The method comprises the following steps of: synthesizing 5,5-dimethyl-2-isopropyl thiazoline by taking isobutylaldehyde, element sulfur, ammonia gas and triethylamine as raw materials; reducing the 5,5-dimethyl-2-isopropyl thiazoline into 5,5-dimethyl-2-isopropyl thiazolidine under the actions of sodium borohydride and acid; and reacting the 5,5-dimethyl-2-isopropyl thiazolidine and phenyl hydrazine under the air insulating situation to obtain dimethyl cysteamine hydrochloride. The method has the advantages of readily-available reaction raw materials, easiness for operating the reaction process, low requirement on the reaction equipment, relatively mild reaction conditions, feeding of the product of every step of reaction into a next step reaction after refining and purifying, high yield and high purity, and the purity of the finally-obtained dimethyl cysteamine hydrochloride is close to 100 percent.

Owner:山东胜利生物工程有限公司

Process for preparing neopentyl glycol with calcium method

InactiveCN102701908ALow priceHigh hydroxyl valueCarboxylic acid salt preparationPreparation by oxygen reductionCalcium formateReaction temperature

The invention relates to a novel process for preparing neopentyl glycol by taking calcium hydroxide as a condensing agent. The neopentyl glycol is prepared by taking isobutylaldehyde, formaldehyde and calcium hydroxide as raw materials. A production process of the process comprises the following steps of: performing a condensation reaction, wherein the condensation ratio of isobutylaldehyde to formaldehyde to calcium hydroxide is 1:2.1:0.55 (molar ratio), the concentration of isobutylaldehyde is 97-98 percent, the concentration of formaldehyde is 37 percent, and the concentration of calcium hydroxide (suspension) is 10 percent, and the condensation process parameters are that: the reaction temperature is 25-75 DEG C, the feeding time is 2-4 hours, and the heat-preserving reaction time is 1-3 hours; separating calcium formate in a steam stripping way; and distilling. Due to the adoption of the process, the price of calcium hydroxide serving as a raw material is lower than that of sodium hydroxide, and the added value of calcium formate serving as a byproduct is high; and the hydroxyl value of a neopentyl glycol product is high, and the quality is good.

Owner:HENGYANG NORMAL UNIV

Synthetic method of dimethyl cysteamine hydrochloride

The invention relates to a synthetic method of dimethyl cysteamine hydrochloride, and belongs to the technical field of organic synthesis. The method comprises the following processing steps: synthesizing 5,5-dimethyl-2-isopropyl thiazoline by taking isobutylaldehyde, element sulfur, ammonia gas and triethylamine as raw materials; reducing the 5,5-dimethyl-2-isopropyl thiazoline into 5,5-dimethyl-2-isopropyl thiazolidine under the actions of sodium borohydride and acid; and reacting the 5,5-dimethyl-2-isopropyl thiazolidine with a hydrochloric acid solution under nitrogen production to obtain the dimethyl cysteamine hydrochloride. The synthetic method has the advantages that the reaction raw materials are easily obtained; the reaction process is simple in operation; the requirement for reaction equipment is low; the reaction conditions are relatively mild; and the yield and content are high, and the content of the finally obtained dimethyl cysteamine hydrochloride is greater than 99%.

Owner:SULI PHARMA TECH JIANGYIN

Preparation method of 2, 2-dimethyl-3-hydroxy propionaldehyde

InactiveCN101863747AReaction control temperature is highHigh yieldOrganic compound preparationCarbonyl compound preparationDistillationSolvent

The invention discloses a preparation method of 2, 2-dimethyl-3-hydroxy propionaldehyde, which comprises the steps of: (1) adding paraformaldehyde and catalyst into solvent, heating to 60-85 DEG C, adding isobutylaldehyde, carrying out condensation reaction, and obtaining solution dissolved with reaction products; (2) carrying out reduced pressure distillation on the solution, removing low-melting-point substance, and obtaining viscous substance; (3) cooling the viscous substance to 10-0 DEG C, then adding distilled water into the cooled viscous substance, leading crystal to be fully separated out under stirring, and papering crystal-liquid mixture; (4) filtering the crystal-liquid mixture, and obtaining a filter cake; and (5) drying the filter cake under the condition of vacuum or inert gas protection, and obtaining the target product. The method has the advantages of high reaction control temperature, short reaction time, high yield and high purity.

Owner:ZIBO MINGXIN CHEM

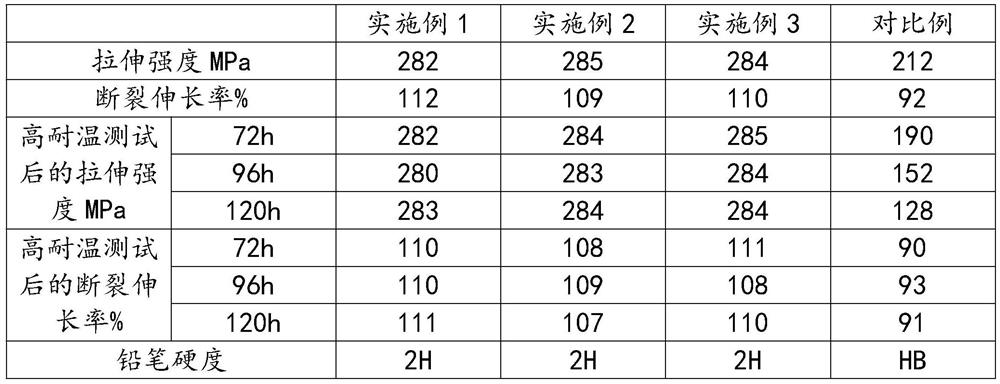

On-line coated three-layer co-extruded BOPET film with high temperature resistance and low precipitation

The invention discloses an on-line coated three-layer co-extruded BOPET film with high temperature resistance and low precipitation. The BOPET film comprises a PET base layer and layers having high temperature resistance and coating the surfaces of the two sides of the PET base layer on line, wherein the layers with high temperature resistance are made of paint with high temperature resistance; the paint with high temperature resistance uses organic silicon resin molecules and bisphenol A epoxy resin as raw materials, and organic silicon resin and epoxy resin both have good heat resistance; and a wear-resistant filler and a migration-resistant plasticizer are prepared at the same time, the wear-resistant filler coats the surface of graphene with nano-silica to improve the wear resistance of the BOPET film, and the migration-resistant plasticizer is prepared from isobutyraldehyde by conducting an aldol condensation reaction at first and a Tishchenko reaction next to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and subjecting 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and isocaprylic acid to an esterification reaction, so the service life of the BOPET film is prolonged.

Owner:GUANGDONG BAOJIALI COLOR PRINTING IND CO LTD

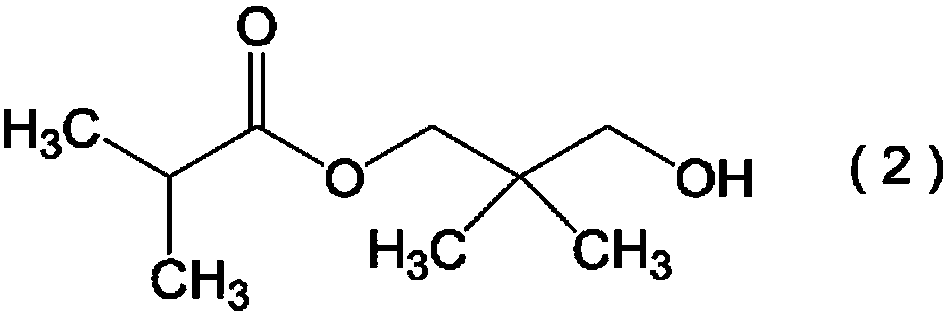

Preparation method of 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate

ActiveCN112430181AOrganic compound preparationCarboxylic acid esters preparationPtru catalystMethyl palmoxirate

The invention relates to a preparation method of 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, which comprises the following steps: (1) adding alkali metal hydroxide, alkaline earth metal oxideand alcohol ester-12 product into a reaction container, and uniformly stirring the materials; (2) adding isobutyraldehyde, controlling the feeding speed of isobutyraldehyde, controlling the temperature to be 20-70 DEG C, and carrying out a first-stage isobutyraldehyde condensation reaction to obtain an intermediate product; (3) after the isobutyraldehyde is completely added, controlling the temperature to be 40-70 DEG C, keeping the temperature for 1-5 hours, and carrying out a second-stage Canichalro reaction to obtain an alcohol ester-12 crude product; and (4) purifying the alcohol ester-12crude product to obtain an alcohol ester-12 finished product. According to the invention, alkali metal hydroxide is used as a catalyst, alkaline earth metal oxide is added to remove moisture in the material, and alcohol ester-12 is added and the feeding speed of isobutyraldehyde is controlled in the reaction process, so that the temperature of the condensation reaction of isobutyraldehyde is controlled, and the preparation method of alcohol ester-12 is enlarged to industrial production from laboratory lab test.

Owner:广州联普新材料科技有限公司

Method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate through condensation of isobutylaldehyde

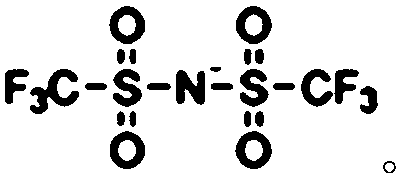

ActiveCN109305912AHigh yieldGood miscibilityPreparation by aldehyde oxidation-reductionCarboxylic acid esters separation/purificationChemical reactionCannizzaro reaction

The invention relates to a method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate through condensation of isobutylaldehyde. The method takes the isobutylaldehyde as a raw material; the raw material and a catalyst are mixed and commonly heated so that the raw material is subjected to two chemical reaction processes including aldol condensation reaction and cannizzaro reaction in one section of reaction, wherein the catalyst is ionic liquid. The method provided by the invention has the advantages of moderate reaction conditions, less impurity content and high yield; the ionic liquid can be recycled and a synthesis technology is environmentally friendly. By adopting the method provided by the invention, a product can be purified and the product with the purity greater than or equal to 99.5 percent is obtained.

Owner:ZHONGRONG TECH CORP LTD

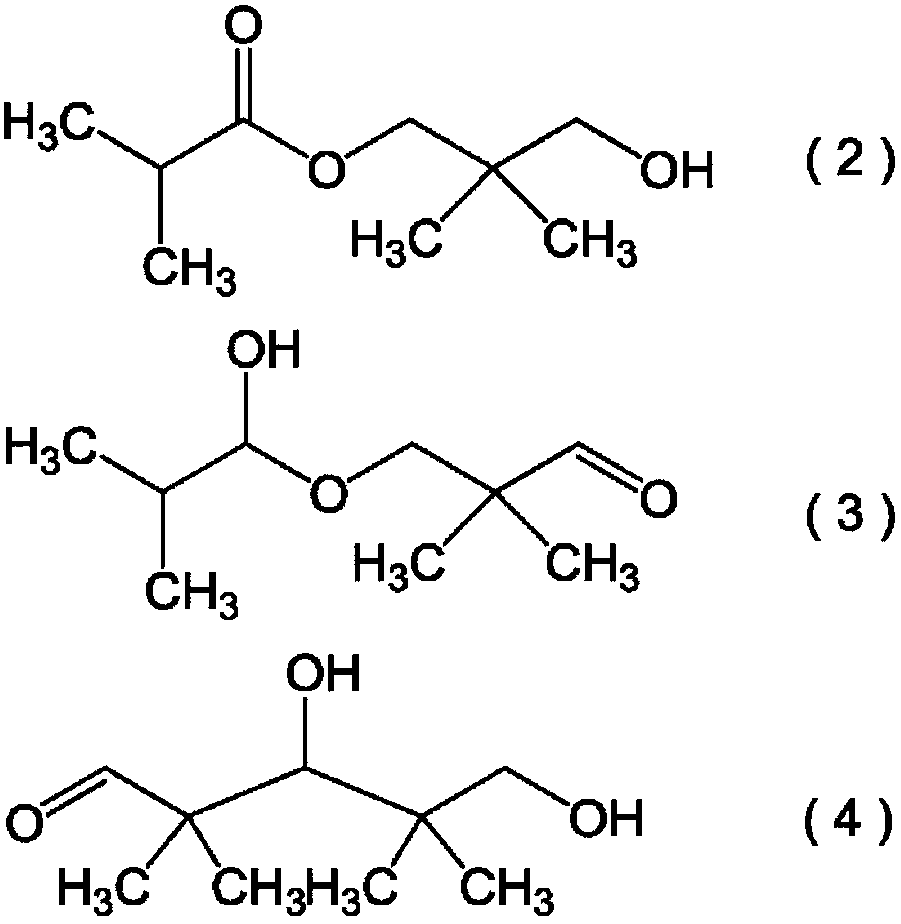

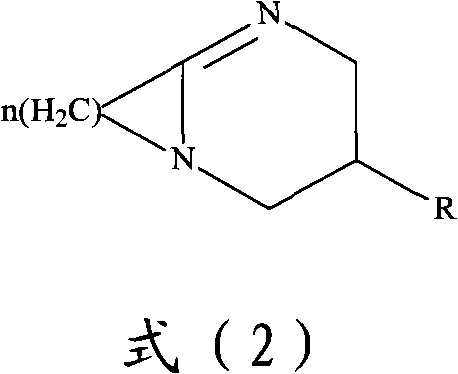

Hydroxypivalaldehyde production method

ActiveCN108463451AReduce contentHigh recovery rateOrganic compound preparationCarbonyl compound separation/purificationDistillationSolvent

A hydroxypivalaldehyde (HPA) production method, comprising steps (i) to (iii) as mentioned below in this order, wherein the distillation step (iii) is a step of carrying out distillation in the co-presence of an extract and water, and the amount of water to be subjected to the distillation is 100 to 2,000 parts by mass inclusive relative to the total amount, i.e., 100 parts by mass, of isobutylaldehyde (IBAL) derived from the raw material in the extract to be subjected to the distillation and an aldehyde solvent represented by formula (1). A production method can be provided, whereby it becomes possible to produce HPA in a large amount and it also becomes possible to improve the rate of collection of HPA while selectively removing non-water impurities, particularly IBAL and the like, contained in HPA. According to the above-mentioned HPA production method, it also becomes possible to reduce the contents of specific impurities that are produced secondarily as by-products from HPA, i.e.,neopentyl glycol-isobutyric acid ester, isobutylaldehyde-hydroxypivalaldehyde-acetal and isobutylaldehyde-hydroxypivalaldehyde-aldol. Step (i): a reaction step of reacting IBAL with FA to produce a reaction solution containing HPA, step (ii): an extraction step of extracting the reaction solution with an aldehyde solvent represented by formula (1) under basic conditions to produce an extract containing HPA, and step (iii): a distillation / collection step of distilling the extract and then collecting HPA from the residue. (In formula (1), R represents a saturated alkyl group having 3 to 7 carbon atoms inclusive.)

Owner:MITSUBISHI GAS CHEM CO INC

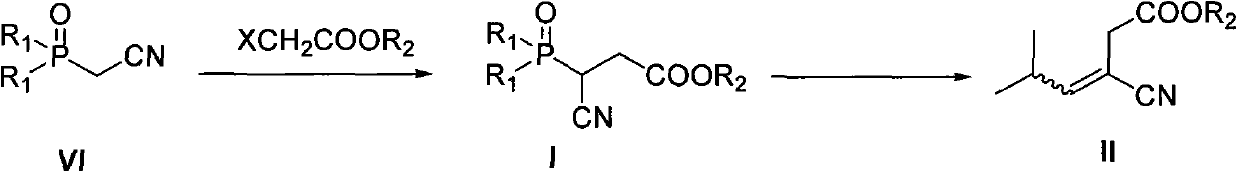

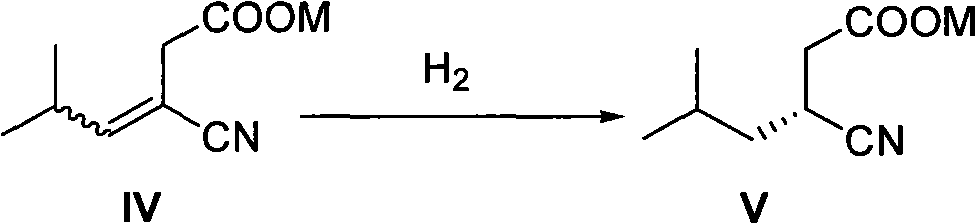

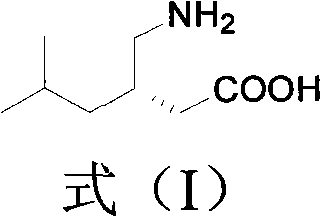

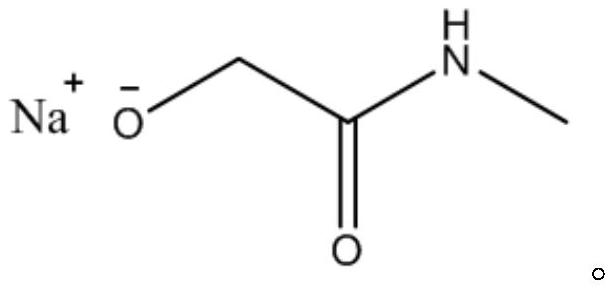

Preparation method of intermediate compound of pregabalin

ActiveCN102464594AImprove conversion rateHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationArylHydrogen

The invention discloses a preparation method for preparing an intermediate compound II of pregabalin. The preparation method of the intermediate compound II comprises the following steps of: (1) undergoing an SN2 substitution reaction on a compound VI and XCH2COOR2 to obtain a compound I; and (2) undergoing a Wittig-Hornor reaction on the compound I obtained in the step (1) and isobutylaldehyde, wherein R1 is alkoxyl with 1-6 carbon atoms or aryl with 6-10 carbon atoms; X is halogen; and R2 is alkyl with 1-6 carbon atoms. The invention further relates to a preparation method for preparing an intermediate compound V of pregabalin. The preparation method of the intermediate compound V comprises the following step of: undergoing an asymmetric hydrogenation reaction on the compound IV and hydrogen gas in a solvent under the action of [Rh((Sc,Rp)-Duanpos)(COD)]BF4, wherein M is H, alkyl with 1-6 carbon atoms or t-BuNH<3+>.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

Preparation method of grafted catalyst for continuous catalytic synthesis of isobutyl isobutyrate

ActiveCN111992247ALow priceLower conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by aldehyde oxidation-reductionPtru catalystReaction temperature

The invention relates to the technical field of catalysts, in particular to a preparation method of a grafted catalyst for continuous catalytic synthesis of isobutyl isobutyrate. An active center of the grafted catalyst prepared by the method belongs to a molecular form uniformly grafted on a carrier and is higher. Isobutyraldehyde is used as a reactant and reacts under the action of a grafting catalyst to prepare isobutyl isobutyrate, the reaction steps are few, byproducts are avoided, the reaction temperature is low, and the defects that the catalyst is inactivated and is difficult to separate from the product are overcome; besides, no byproducts except water are generated in the reaction process, the influence of water on the product is eliminated, and large-scale production can be achieved. The content of isobutyl isobutyrate in the prepared product is greater than 90%, and the requirements of industrial products are met.

Owner:RUNTAI CHEM TAIXING CO LTD

Preparation method of 2, 2-dimethyl-3-hydroxy propionaldehyde

InactiveCN101863747BReaction control temperature is highHigh yieldOrganic compound preparationCarbonyl compound preparationDistillationSolvent

Owner:ZIBO MINGXIN CHEM

Method for preparing 2,2-dimethyl-3-hydroxy propanal

ActiveCN102153456BReduce dosageEasy to recycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCondensation reactionIsobutylaldehyde

The invention provides a method for preparing 2,2-dimethyl-e-hydroxy propanal. The method is characterized by comprising the following step of: catalyzing a condensation reaction between isobutylaldehyde and formaldehyde by taking a compound having a structure shown in the specifications as a catalyst to obtain 2,2-dimethyl-e-hydroxy propanal, wherein n is equal to 2-11, m is equal to 2-6, and R is H or alky of C1-C8. In the preparation method, the consumption of the catalyst is small, and the catalyst is easy to recycle. Moreover, the reaction condition is mild, and the post treatment is simple. The transformation rate of the isobutyl aldehyde is over 99 percent, and the selectivity of hydroxyl pivalaldehyde is over 98 percent.

Owner:WANHUA CHEM GRP CO LTD

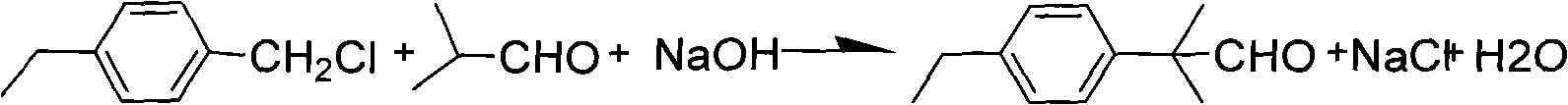

Preparation technology of alpha, alpha-dimethyl-ethide phenylpropyl aldehyde

InactiveCN101525280AReduce pollutionEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcid waterGas phase

The invention discloses a preparation technology of alpha, alpha-dimethyl-ethide phenylpropyl aldehyde. The preparation technology is as follows: ethide benzyl chloride and isobutylaldehyde are taken as major raw materials, aromatic hydrocarbon is a solvent under the condition of alkalescence and is added with a catalytic agent, the aromatic hydrocarbon is stirred and heated under the temperature of 60-95 DEG C to be reacted, and then the aromatic hydrocarbon is washed by protonic acid water under the temperature of 50-95 DEG C to eliminate enol ether so as to obtain the alpha, alpha-dimethyl-ethide phenylpropyl aldehyde. The preparation technology not only has simple operation and reduces the environment pollution, but also has high yield coefficient of products; in addition, the content of the gas phase chromatography of obtained products is 80-95 percent.

Owner:孙玉明

Preparation method and application of bifunctional catalyst for high-selectivity preparation of isobutyraldehyde by propylene hydroformylation

ActiveCN112169829AAvoid self-polymerizationPrevent sinteringMolecular sieve catalystsOrganic compound preparationCarbon layerPtru catalyst

The invention belongs to the technical field of catalysis, and particularly relates to a preparation method and application of a bifunctional catalyst for high-selectivity preparation of isobutyraldehyde by propylene hydroformylation. According to the characteristics of an isobutyraldehyde product, propylene is firstly adsorbed on a rare earth modified acidic carrier to generate secondary positivecarbon ions, then the secondary positive carbon ions are subjected to addition with CO on active center cobalt carbide, and finally the product is generated through addition with active hydrogen. Thebifunctional catalyst is prepared by the steps of dipping cobalt salt and a nitrogen-containing compound precursor into acidic molecular sieve pores, carbonizing at a relatively high temperature, generating active center cobalt carbide highly dispersed in the molecular sieve pores in situ, and generating an N-modified carbon layer on the surface of the cobalt carbide. The carrier in the catalystplays an acidic role, and cobalt carbide activates CO and H2 at the same time. The prepared catalyst enables the yield of isobutyraldehyde to be as high as 79%. The catalyst prepared by the method islow in cost, high in activity, good in catalyst stability and high in isobutyraldehyde selectivity, and has a good industrial prospect.

Owner:RUNTAI CHEM TAIXING CO LTD

Process method for synthesizing isobutyric acid by using microchannel reactor

PendingCN113501756AReduce consumptionReduce the risk of oxidation reactionsOrganic compound preparationChemical/physical/physico-chemical microreactorsPtru catalystOxygen delivery

The invention discloses a process method for synthesizing isobutyric acid by a microchannel reactor, the process method comprises the following steps: S1, setting a reaction device which comprises a mixing module and at least four reaction modules; s2, mixing the materials, and enabling the materials to enter the reaction modules of the reaction device for reaction; s3, obtaining a product at the tail end of the reaction device; in the step S1, the reaction device is a micro-channel reactor; in the step S2, material mixing comprises the following steps: step S201, dissolving a catalyst in isobutyraldehyde to obtain a liquid-phase mixture; and step S202, conveying the liquid-phase mixture obtained in the step S201 and oxygen into a mixing module. According to the method, the risk of oxidation reaction is reduced, the one-time conversion rate of the reaction is improved, and isobutyric acid with the content of 70% or above can be directly obtained; the reaction selectivity is improved, byproducts are few, and the consumption of raw materials is reduced; the method does not occupy a large area, is high in heat and mass transfer and good in mixing effect, and can realize efficient and continuous work.

Owner:上海和创化学股份有限公司

Preparation method for isobutylidene diurea water-retention sustained-release fertilizer

InactiveCN106242765AAdjust water retentionRegulatory characteristicsSolid/semi-solid fertilisersUrea compound fertilisersHydrophilic monomerCross-link

The invention belongs to the field of water-retention sustained / controlled-release fertilizers and particularly discloses a preparation method for an isobutylidene diurea water-retention sustained / controlled-release fertilizer. According to the preparation method, isobutylidene diurea with extensive application is produced through a reaction between isobutylaldehyde and urea, so that the utilization ratio of a nitrogen fertilizer is increased, and material wasting and environmental pollution are reduced. During the synthesis of isobutylidene diurea, hydrophilic monomers, a cross-linking agent and an initiator are simultaneously added, a hydrophilic polymer network is formed through heating-up polymerization, and the isobutylidene diurea water-retention sustained / controlled-release fertilizer is prepared by a one-pot method. The water-retention sustained / controlled-release fertilizer not only has good sustained-release performance, but also has certain water retention property, and the preparation method is simple and is wide in application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate

ActiveCN101948386BAvoid high quality requirementsReduce dosagePreparation by aldehyde oxidation-reductionAlcoholOrganic synthesis

The invention discloses a method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, which relates to the technical field of organic synthesis. In the invention, isobutylaldehyde is used as a raw material, aldol condensation and Cannizzaro reactions are completed by a one-step reaction process in the presence of a catalyst, and the process adopts sodium alcoholate as the catalyst; and the isobutylaldehyde is used to form alcohol ester-12 in the presence of the sodium alcoholate catalyst, so the complex and high-energy consumption drawbacks of a two-step reaction process using an inorganic alkali as a catalyst are overcome, the drawbacks of toxic catalyst and high quality requirement on the isobutylaldehyde raw material of a one-step reaction process using Ba(OH)2 as a catalyst are overcome, and simple process, high single-pass yield, small catalyst dosage, low energy consumption, safety and environmental protection are realized.

Owner:YIXING HENGXING FINE CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com