Patents

Literature

97 results about "Isobutyrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

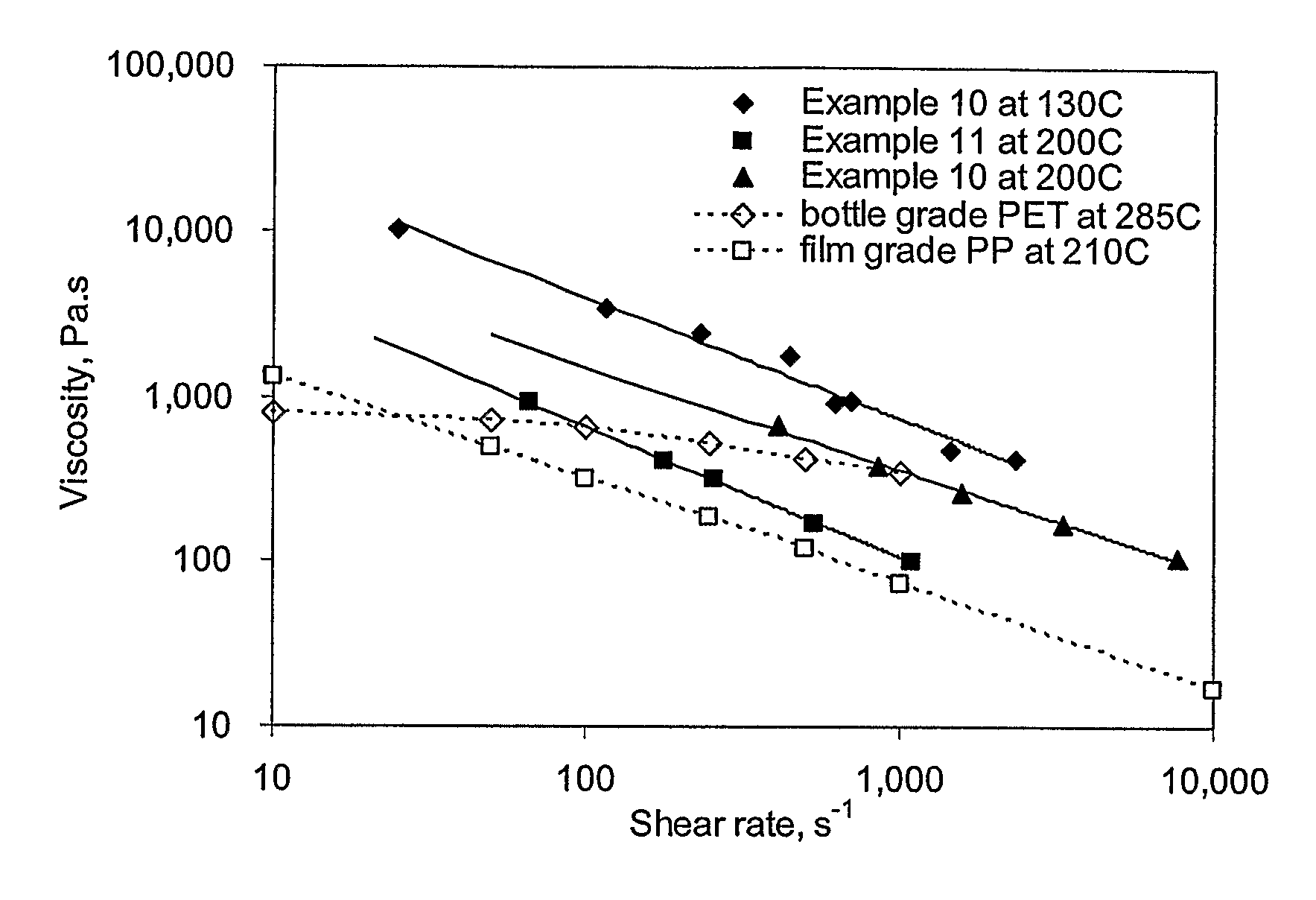

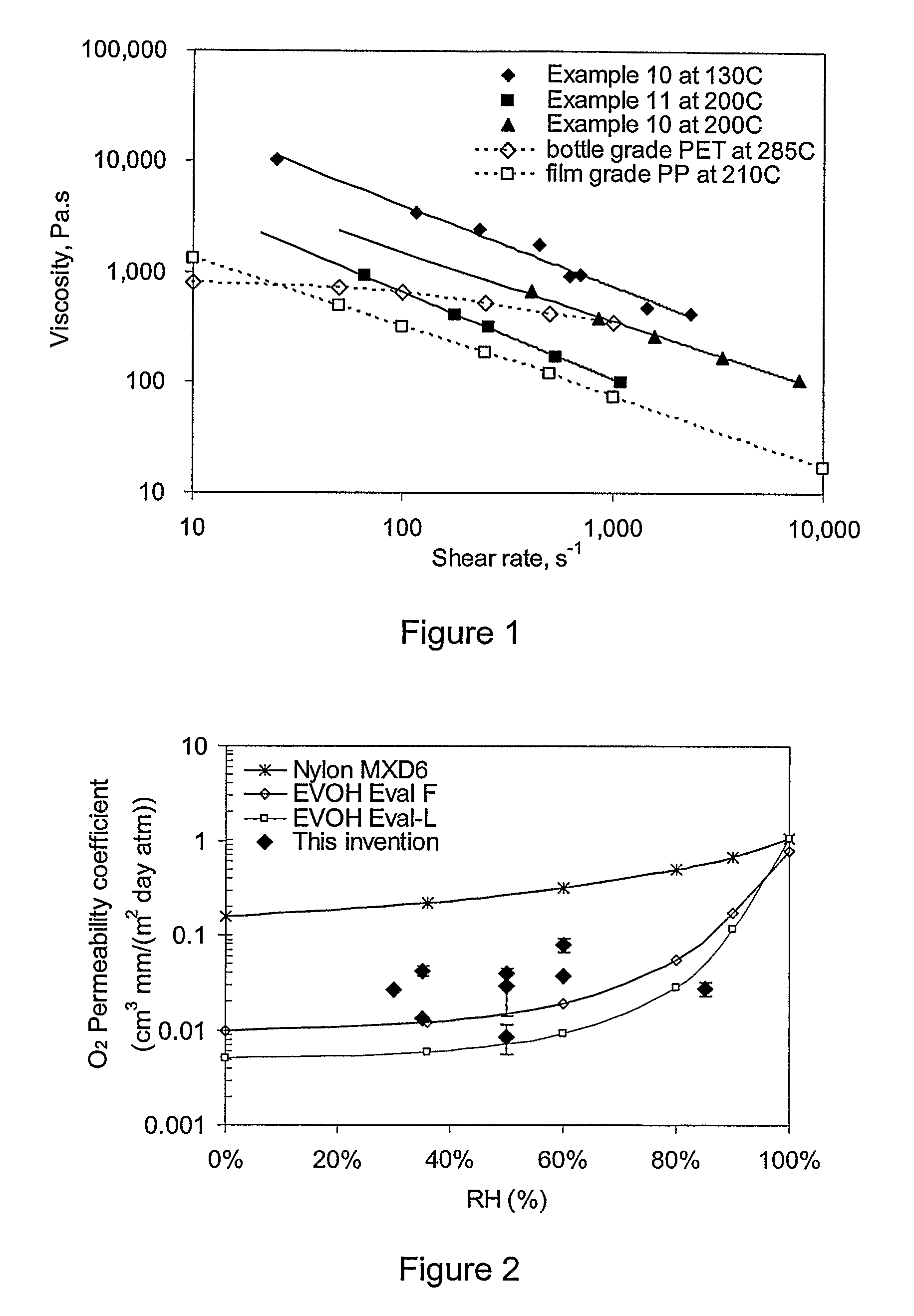

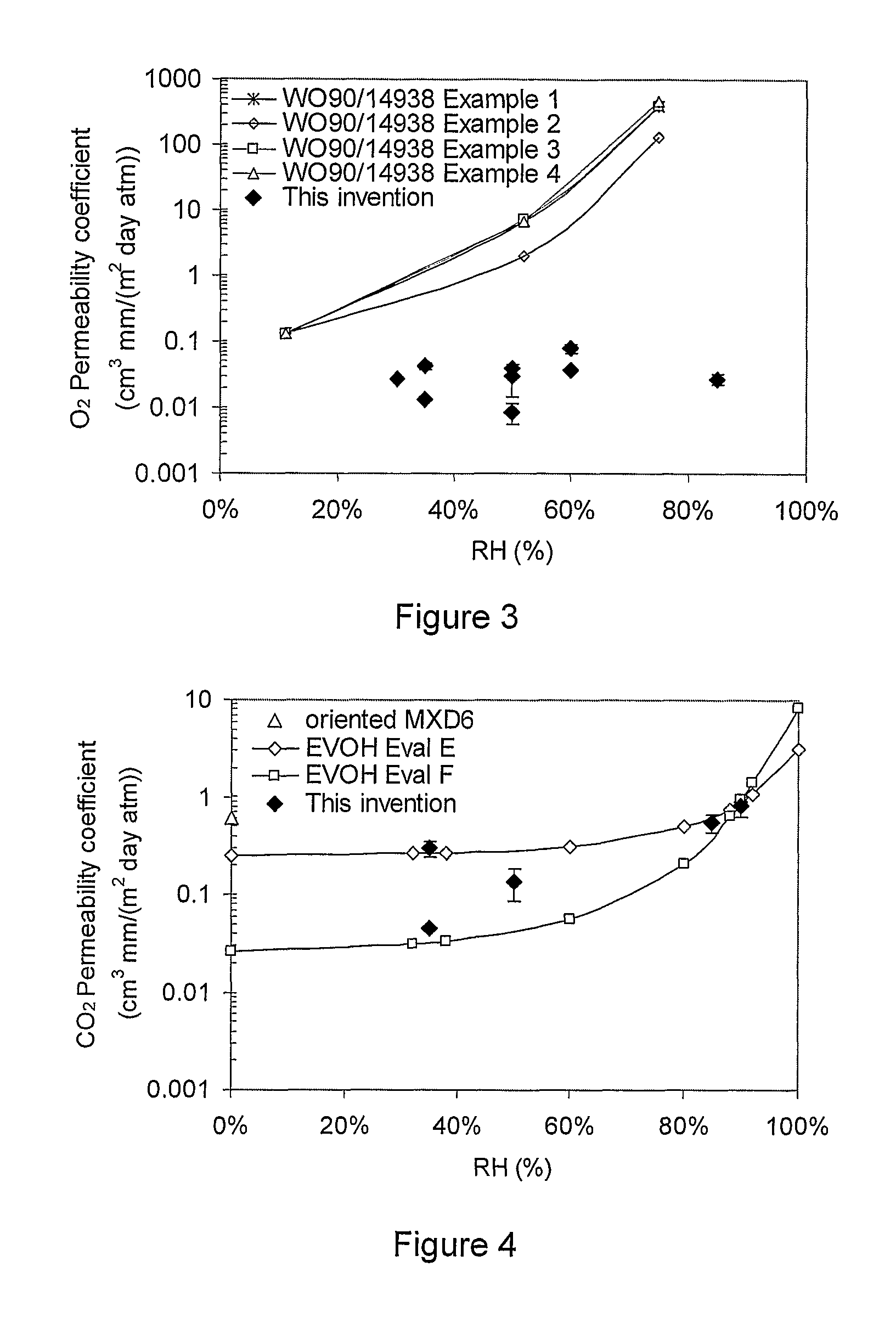

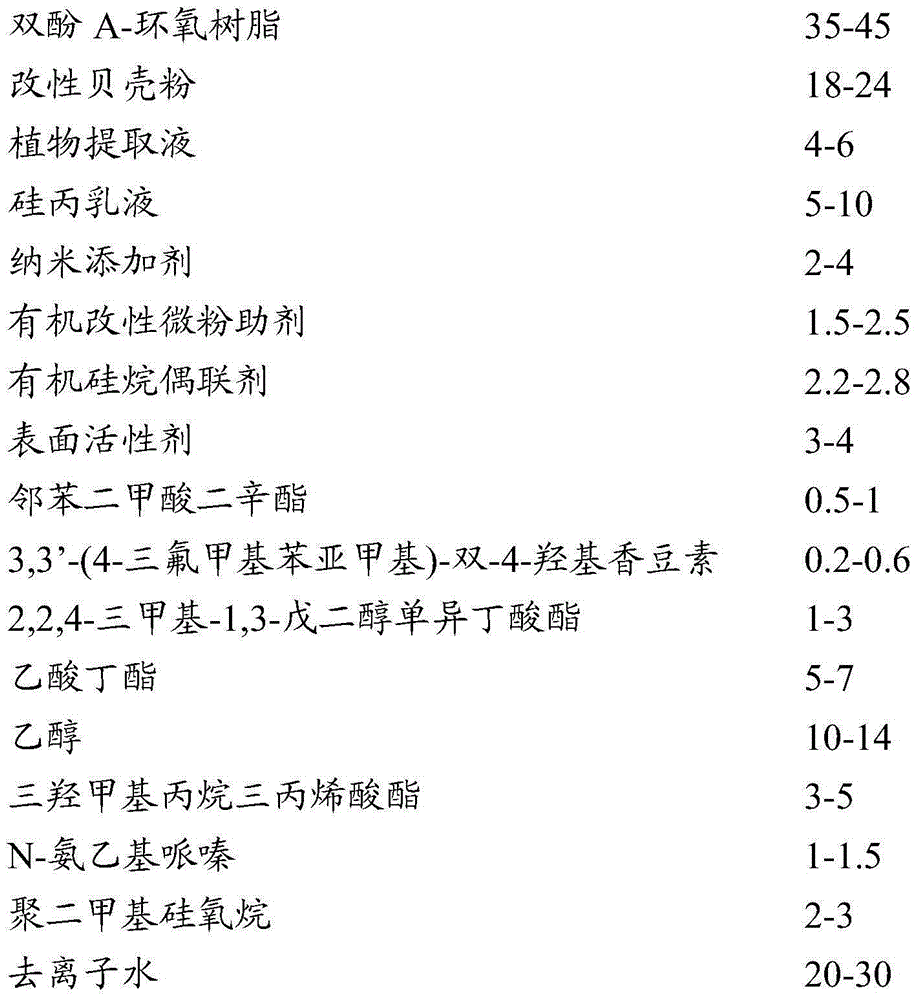

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

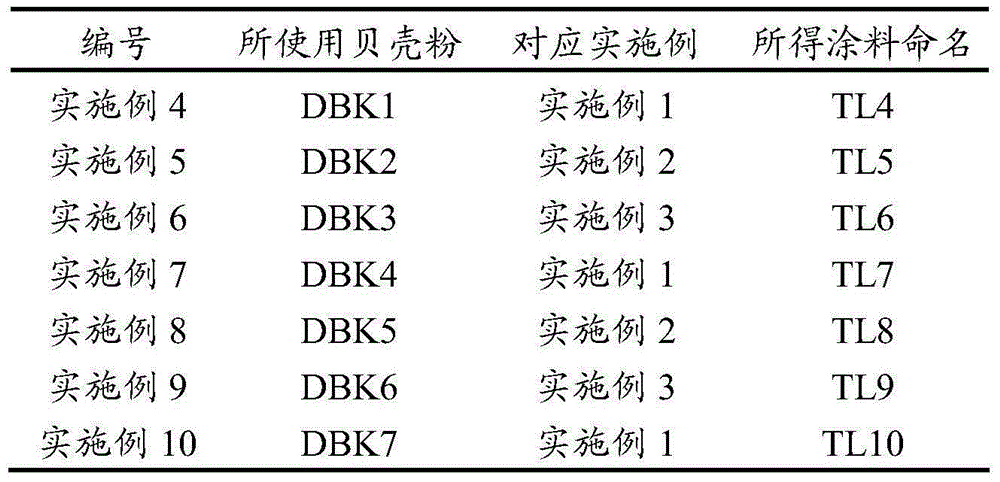

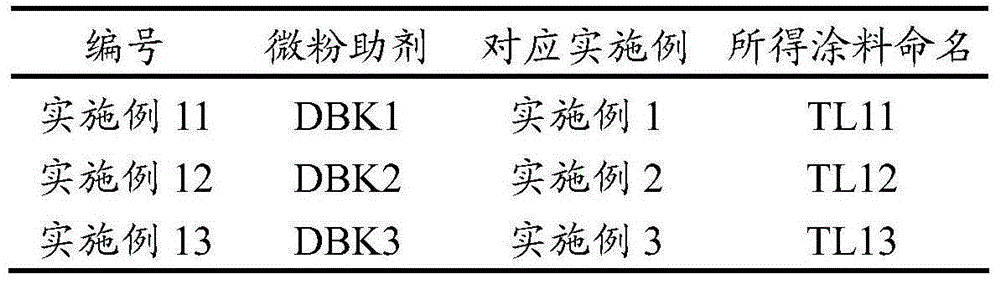

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

Injectable controlled release composition comprising high viscosity liquid carrier

Compositions may include a pharmaceutical active agent, a high viscosity liquid carrier material (HVLCM), a lactic acid-based polymer, and an organic solvent. Related compositions and methods are also disclosed. For instance, a carrier formulation for controlled release of injectable drugs is disclosed. The formulation may include a non-water soluble high viscosity liquid which may be sucrose acetate isobutyrate, a lactic-acid based polymer which may be a poly(lactic acid)(glycolic acid), and an organic solvent which maintains the composition in a monophasic form at 25° C. in one atmosphere. Drug in the formulation may be released upon administration such that less than 10% (e.g. 2-8%) of drug is released in the first 5 hours; 10% to 80% of the drug is released during a period of 5 hours to 7 days after administration; and 10% to 40% of the drug is released gradually over a period of 7 days to 28 days from initial administration. The drug may be an anti-schizophrenia agent delivered by injection.

Owner:DURECT CORP

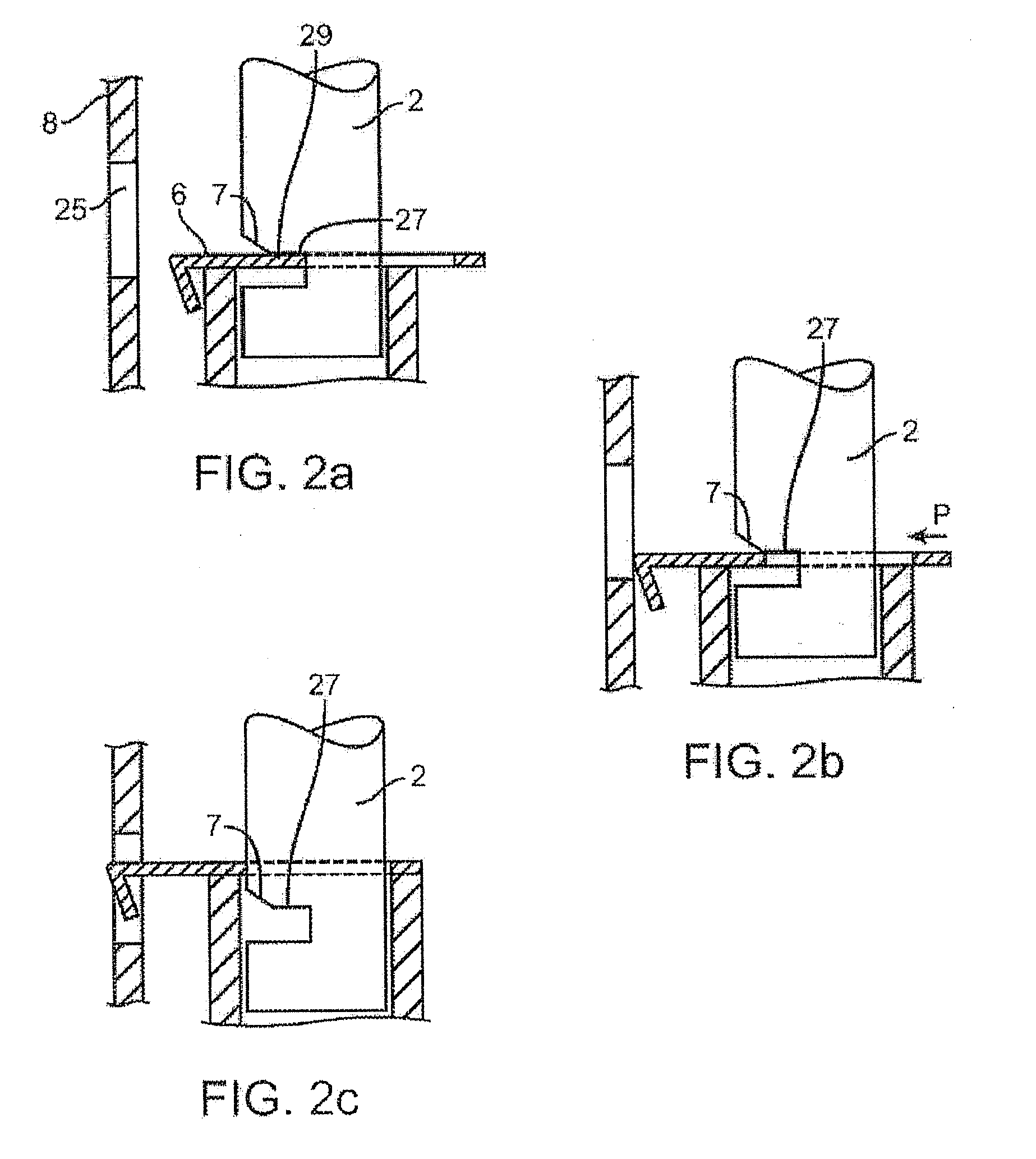

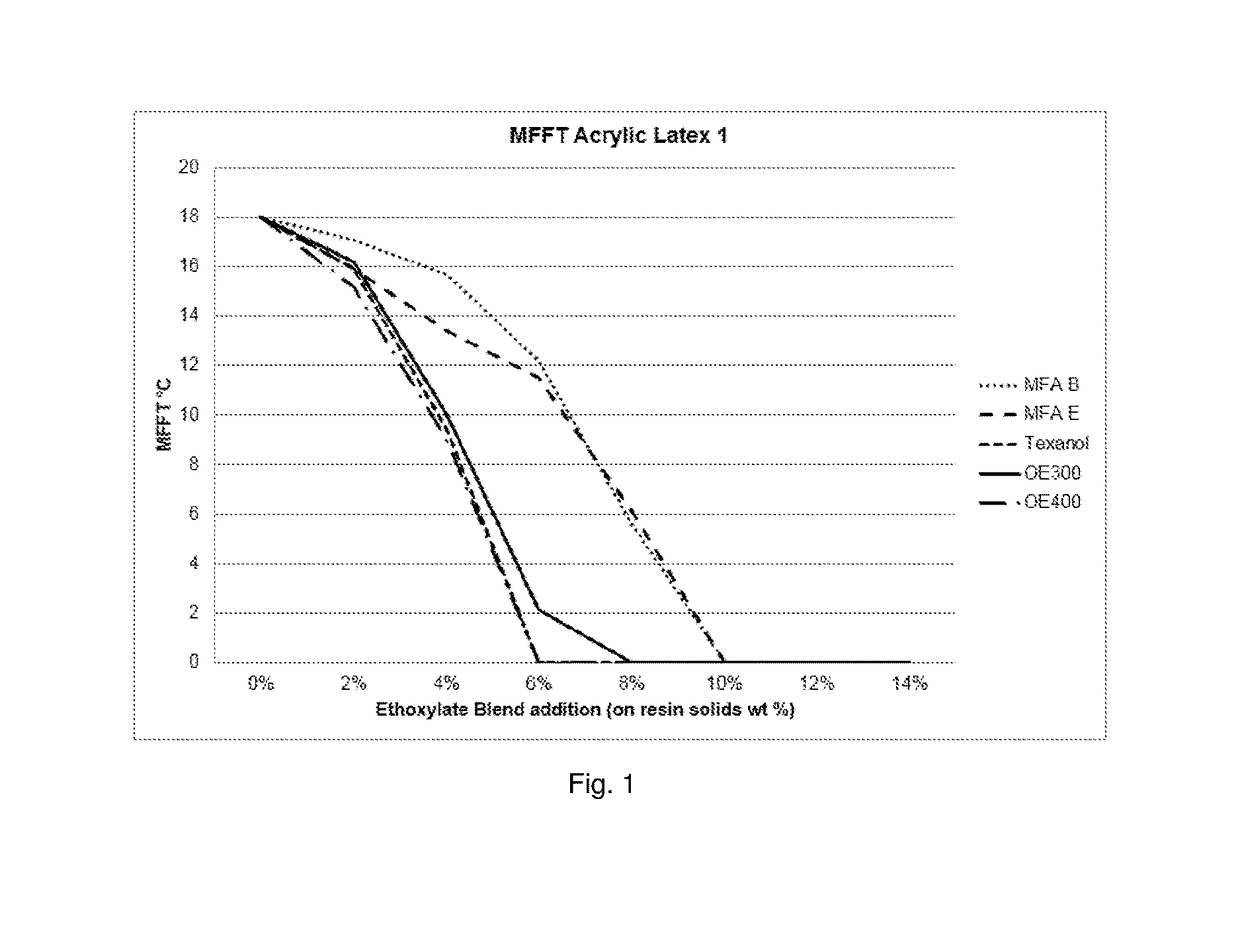

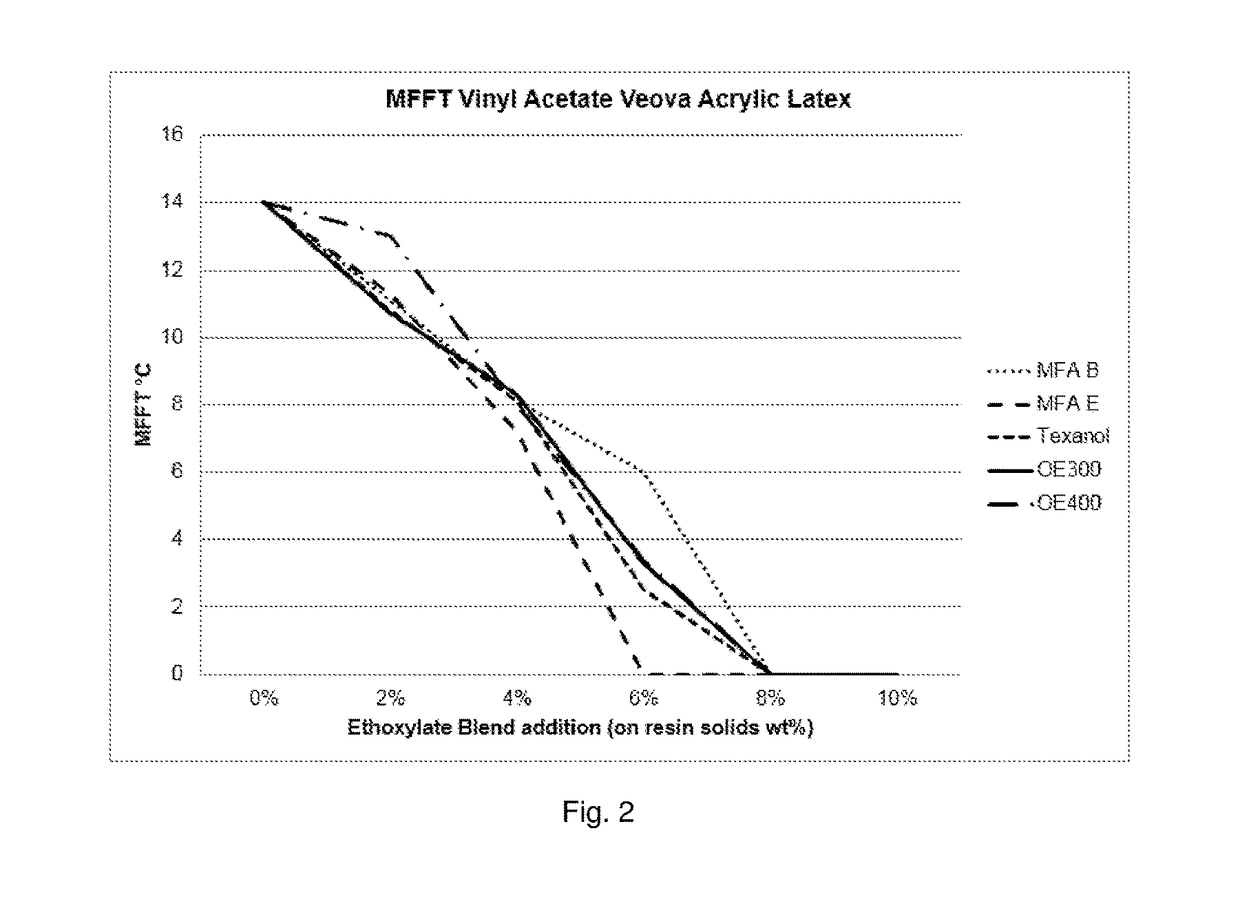

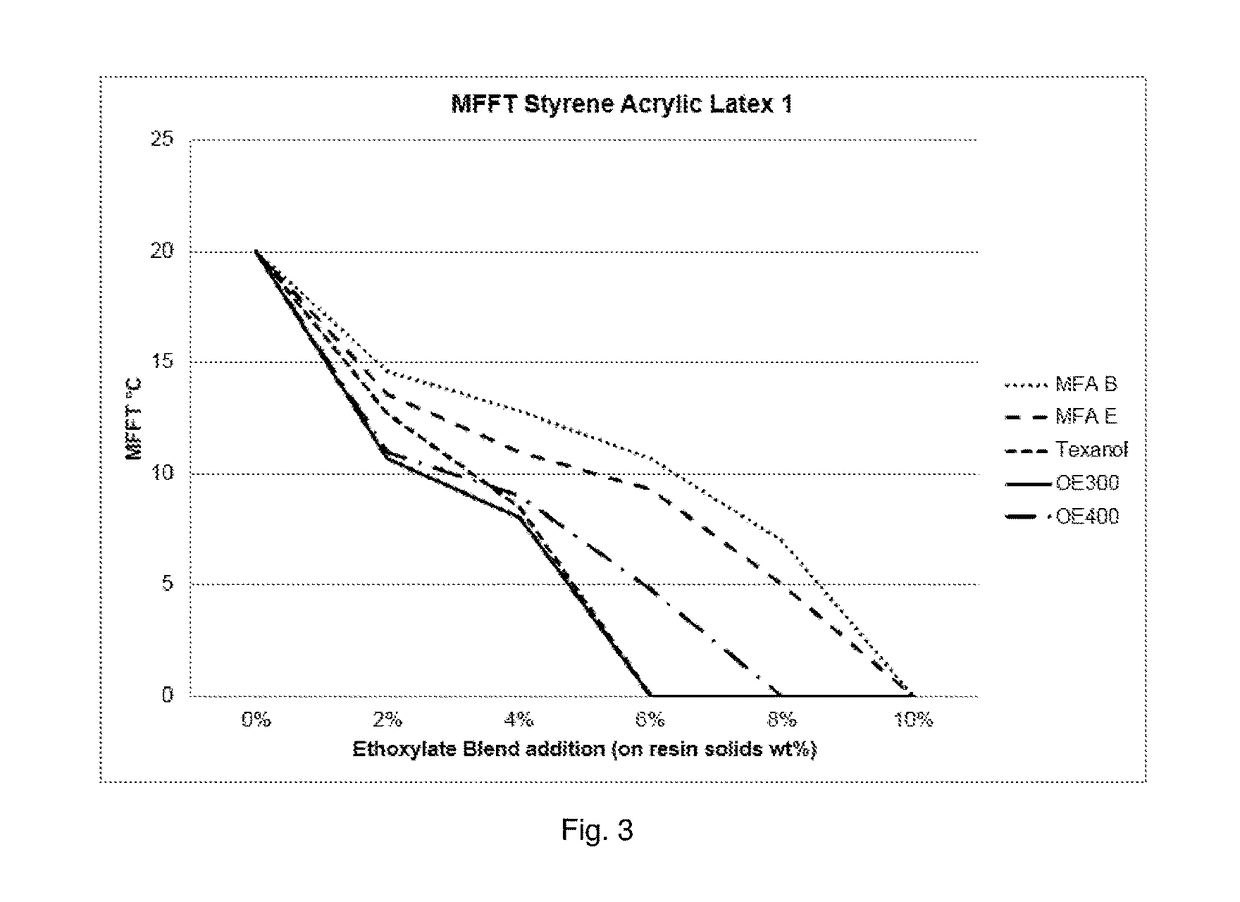

Coalescent and non-ionic surfactant blend

The invention is comprised of a coalescent and non-ionic surfactant blend additive for use in water-based architectural coating formulations. The dual-function blend is produced by reacting 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate with ethylene oxide in the presence of a basic catalyst and separating the desired ethoxylated coalescent and non-ionic surfactant blend from the reaction product.

Owner:EASTMAN CHEM CO

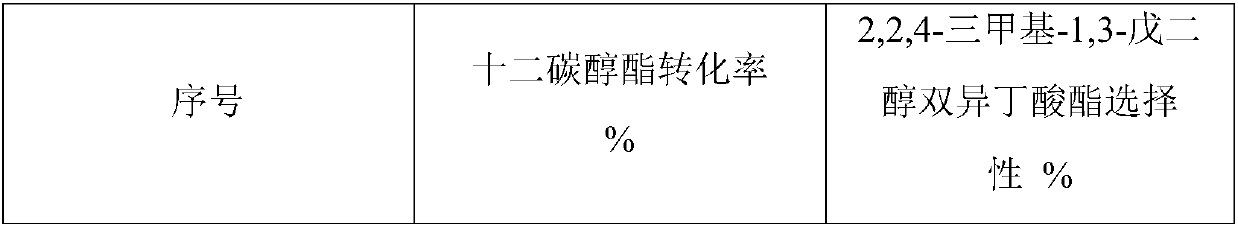

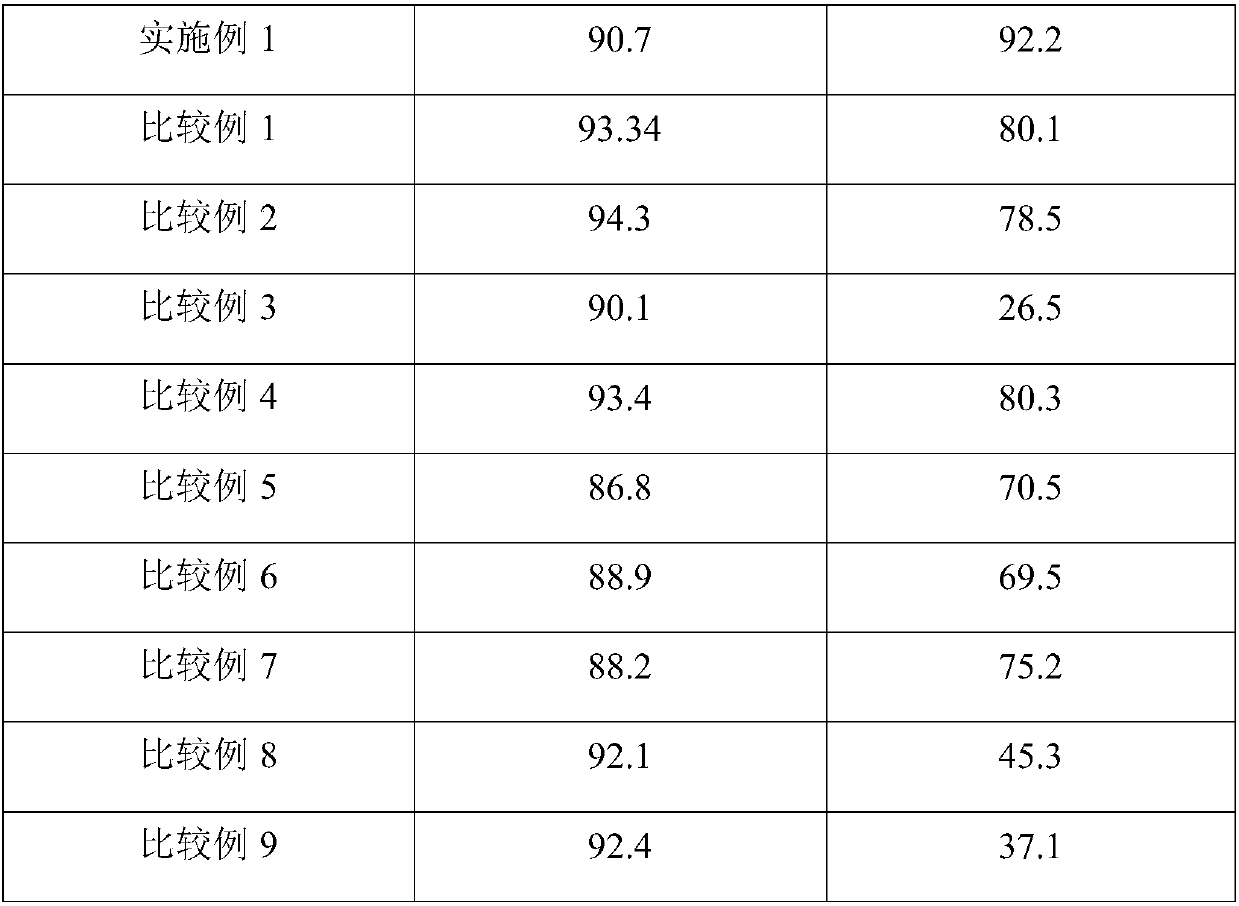

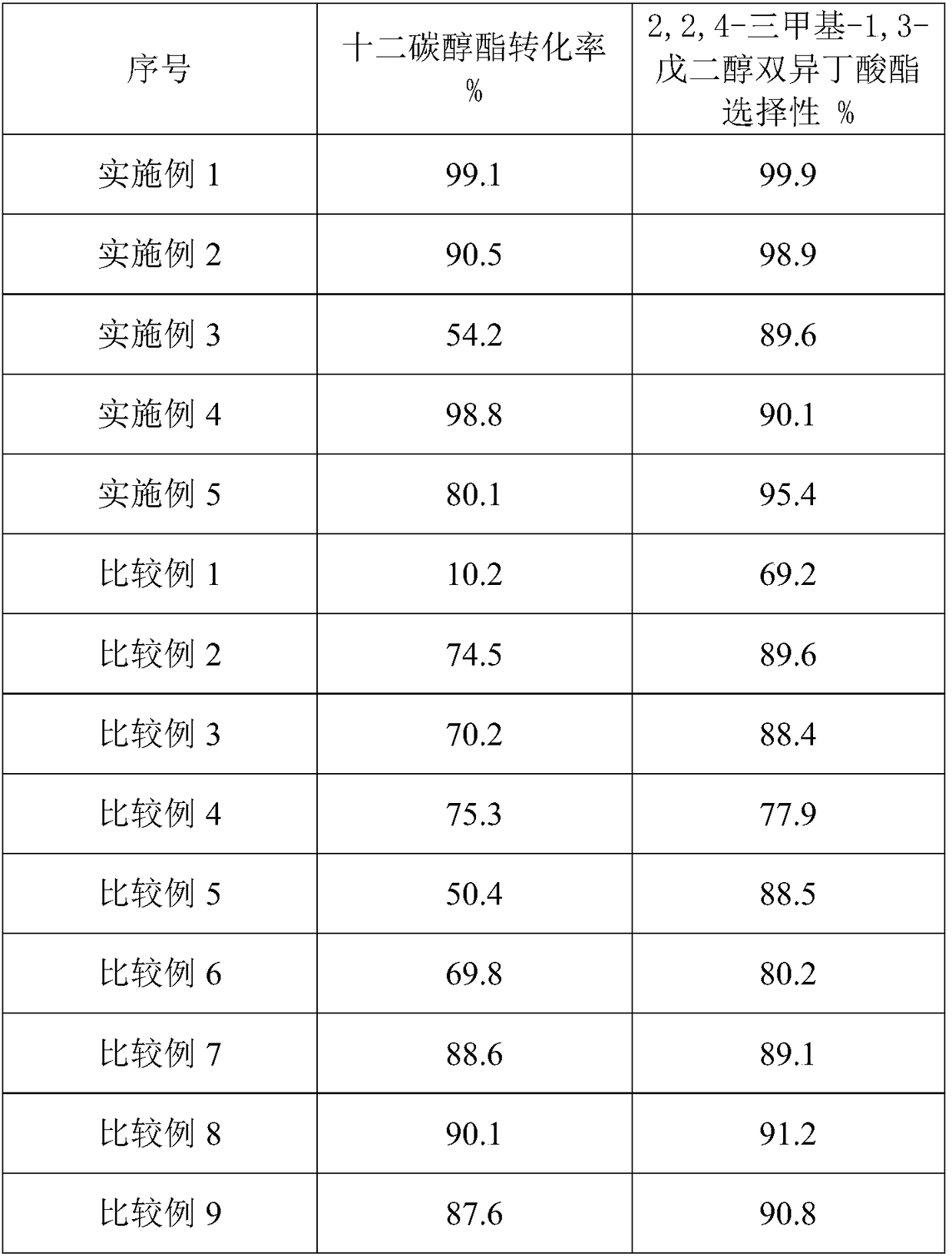

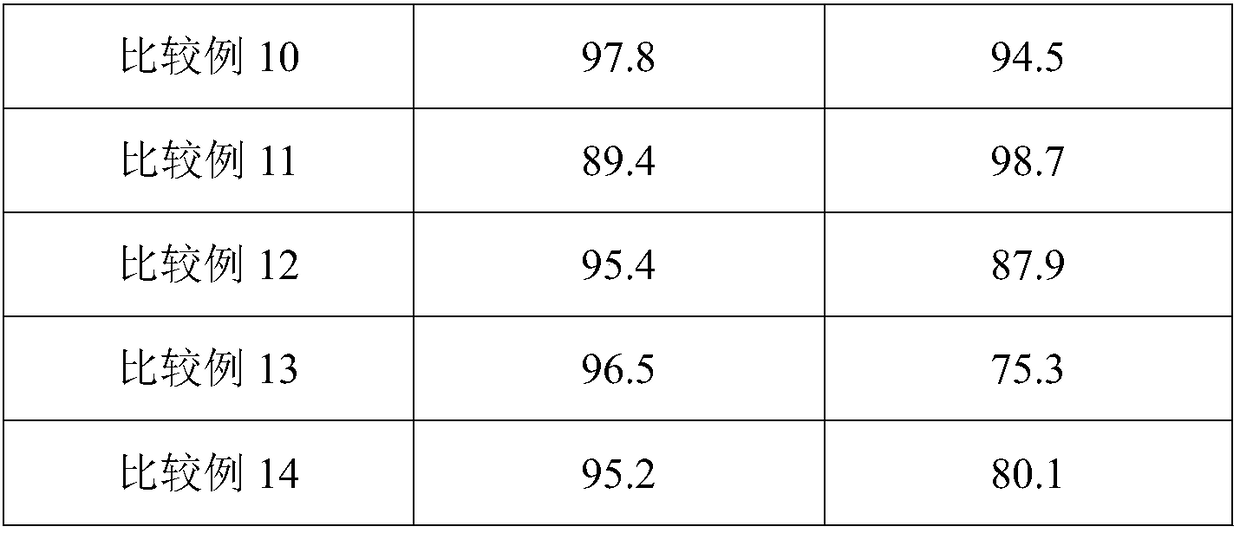

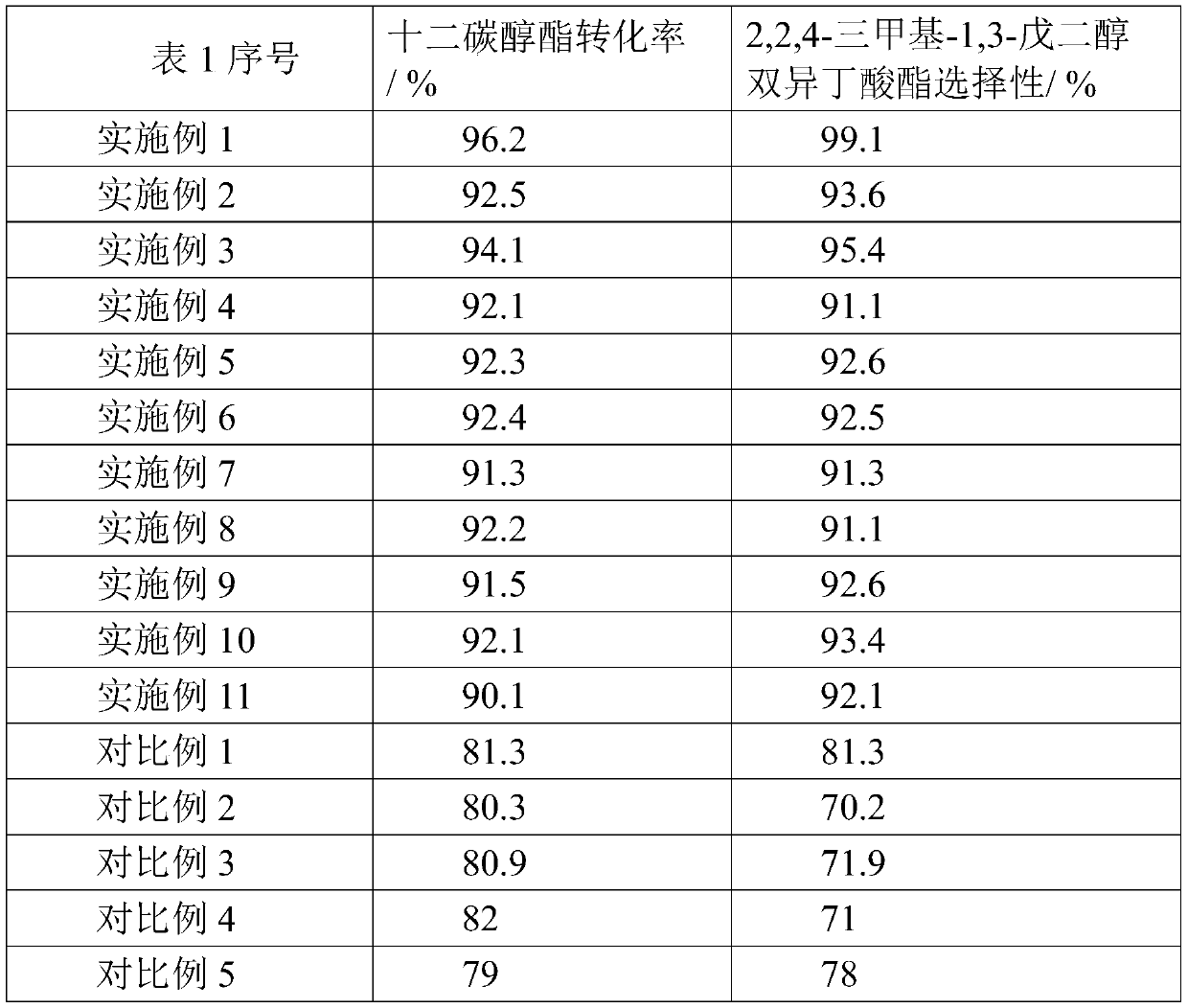

Preparation method of solid acid catalyst applied to producing of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate

InactiveCN107552074AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationFiltrationSolid acid

The invention relates to a preparation method of a solid acid catalyst applied to the producing of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate. The preparation method comprises the steps: firstly, preparing a TiO2-ZrO2 compound carrier; enabling the obtained TiO2-ZrO2 compound carrier to react with 0.5mol / L H2SO4; performing suction filtration to filter a solid product out; vacuum drying and roasting to obtain the solid acid catalyst. The method disclosed by the invention has the advantages of convenience and easiness in operation and lower cost; the catalyst has the characteristics of highactivity and selectivity, and reutilization; the defects of serious equipment corrosion, generation of a lot of effluent, environmental pollution and the like caused by using concentrated sulfuric acid as a catalyst are overcome; industrial prospect is very good.

Owner:RUNTAI CHEM CO LTD

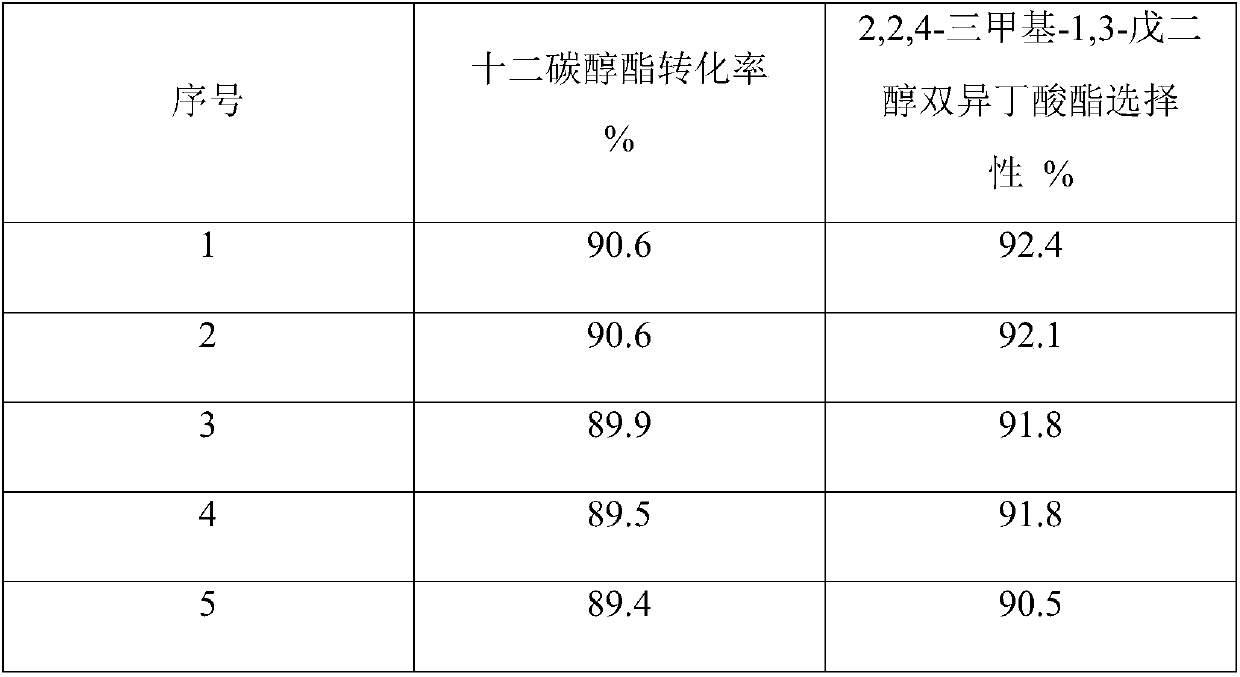

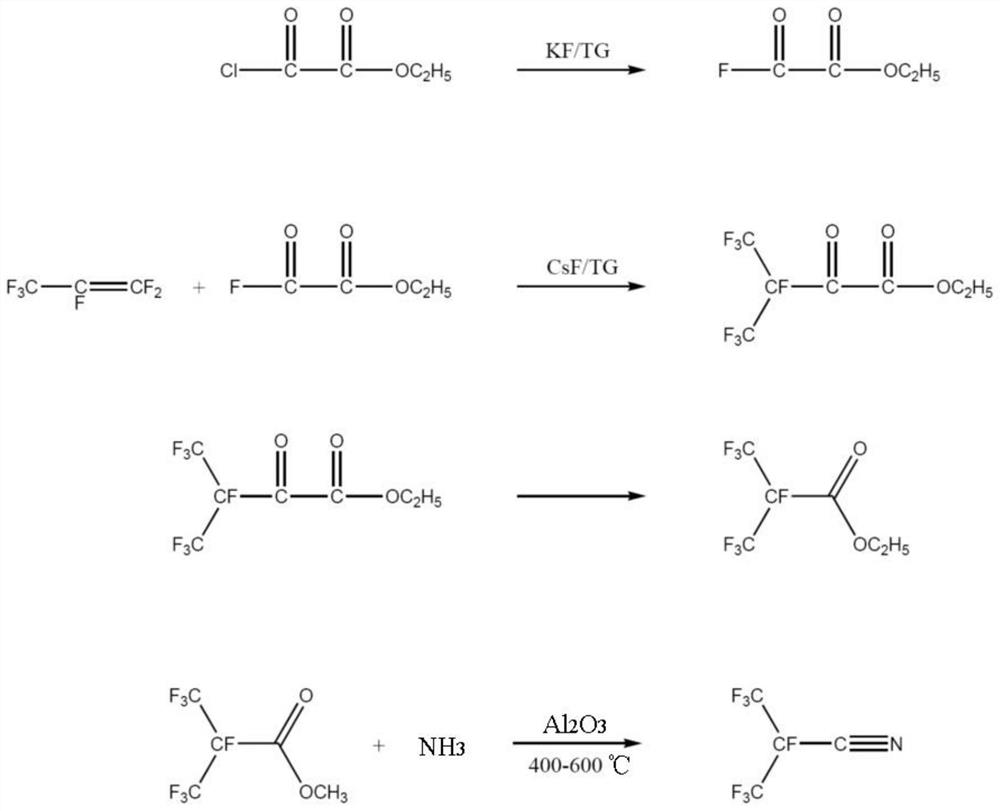

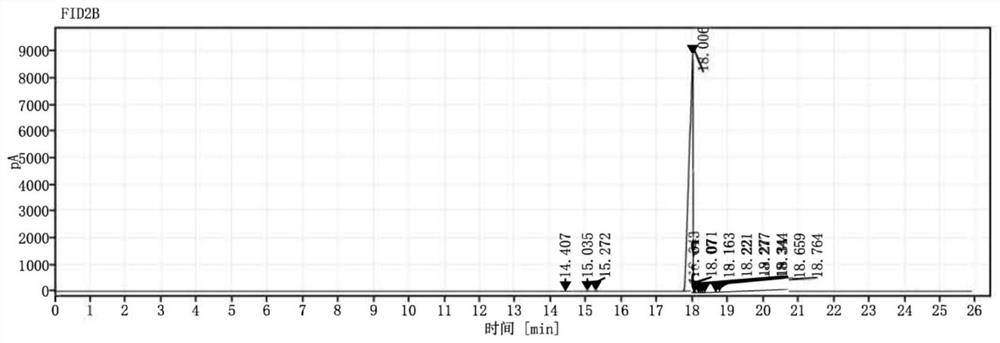

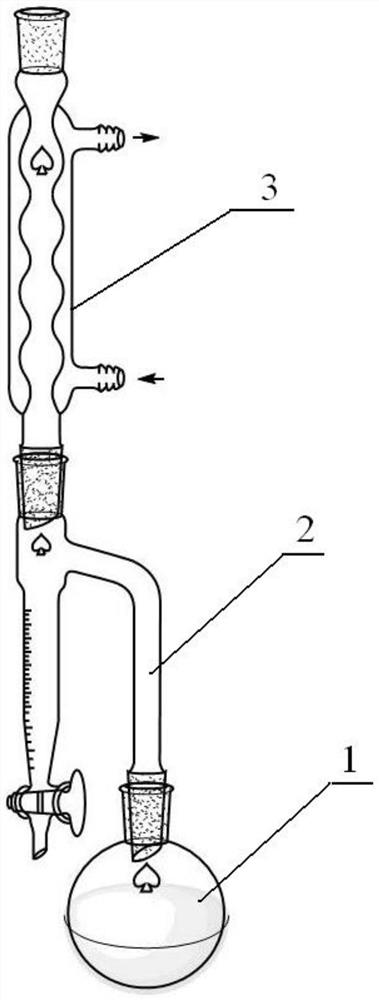

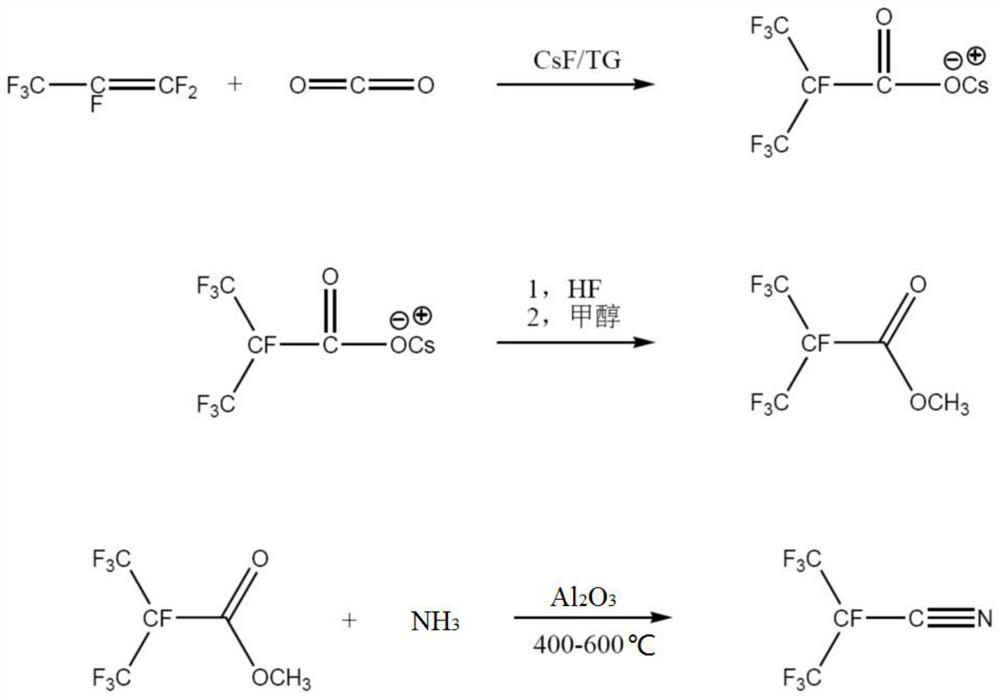

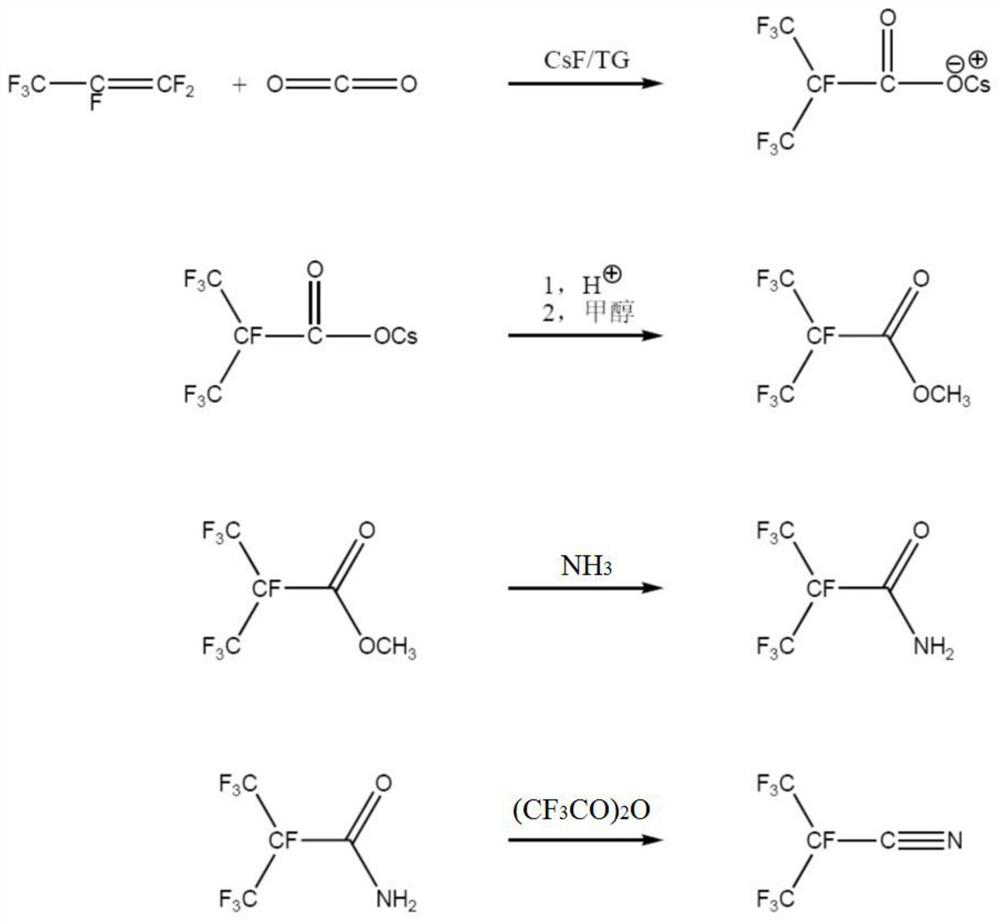

Synthetic method of perfluoroisobutyronitrile

PendingCN111825568ASynthetic process safetyEfficient synthesis processOrganic compound preparationCarboxylic acid esters preparationOxalyl fluoridePtru catalyst

Owner:福建省漳平市九鼎氟化工有限公司

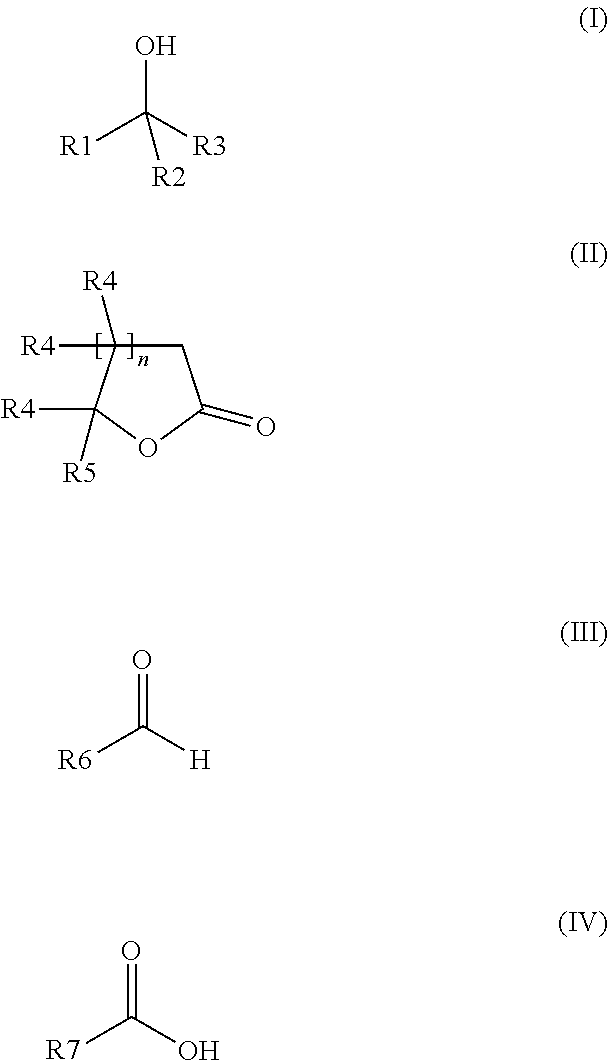

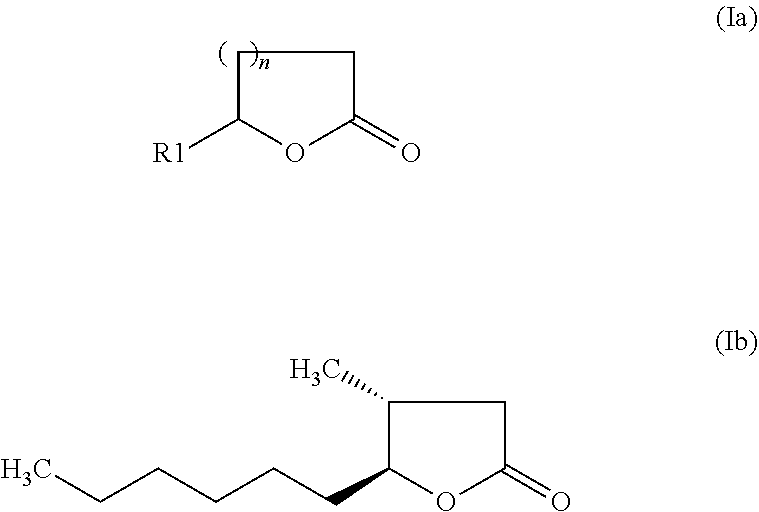

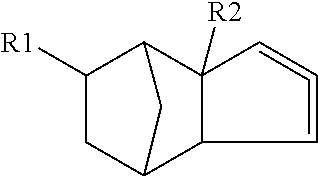

Composition for odour improvement

The invention relates to a preparation containing: (i) a composition containing (a) one, two or a plurality of compounds selected from the group consisting of (a1) alcohol monoterpenes of formula (I) in which R1 is H or methyl, R2 is H or C2-alkenyl, and R3 is a linear or branched, saturated or unsaturated hydrocarbon radical with 4 to 10 carbon atoms, and the enantiomers, diastereomers, racemates, solvates and physiologically compatible salts thereof, and / or (a2) bicyclic epoxy-monoterpenes, (b) at least two lactones of formula (II) in which R4 is H or methyl, R5 is a linear or branched, saturated or unsaturated hydrocarbon radical with 2 to 10 hydrocarbon atoms and n is the number 1 or 2, and the enantiomers, diastereomers and racemates thereof, (c) one, two or a plurality of solvents selected from the group consisting of ethanol, water, dipropylene glycol (DPG), diethyl phtalate (DEP), propylene glycol (PG), isopropyl myristate (IPM), isopropyl palmitate (IPP), triethyl citrate (TEC), triacetin (TRI), 1,2-Propanediol, 1,3-Propanediol, Propanethiol, Pentanediol, Hexanediol, Octanediol, Decanediol (SymClariol®), Dodecanol, 4-hydroxy-acetophenone (SymSave® H), glycerine, butylene glycol, pentylene glycol, hexylene glycol, decylene glycol, propylene carbonate, butylene carbonate, glycerine carbonate, 2-5 benzyl heptanol, lauryl alcohol, trimethyl-hydroxypentyl-isobutyrate, glyceryl-caprylate, ethylhexyl glycerine, benzyl benzoate (BB), and optionally (d) other flavouring agents or aromatic substances selected from the group consisting of 3-phenylbutanal (Trifernal), acetyl methyl carbinol, anethole, anisyl acetate, dihydroeugenol, linalyl formate, 2-methyldecanal, 2-benzyl-2-methylbut-3-ene nitrile (Ci-trowanil® B), 3-hexenyl acetate, styrallyl acetate, belanis, citronellal, cinnamyl acetate, rhubafuran, beta-ions, anther, prenyl acetate, 2-phenyl propanal, 4-(4-hydroxyphenyl)butan-2-one (Frambinon®), ethyl phenoxyacetate, isoralderine, gamma-terpinene, limonene, neocyclocitral, methyl lavender ketone, styrallyl propionate, phenyl ethyl propionate, limonenal, 4-isopentylcyclohexanol (Symrose®), 4-methyl-2-phenyl-3,6-dihydro-2H-pyran / 4-methylene-2-phenyl-tetrahydropyrane (Rosyrane super), hydrocitronitril, phenoxanol, isoamyl phenylacetate, damascone, silvial, nectaryl, ambroxide, acetyl pyrazine, trimethyl pyrazine, isoamyl acetate, para-cresyl methyl ether, filbertone, cyclohexyl acetate, heliotropin, acetophenone, anisaldehyde, para-methyl acetophenone, veratraldehyde, methyl anisate and vertoprenal; (ii) aldehydes of formula (III) in which R6 is a saturated or non-saturated, linear hydrocarbon radical; and / or (iii) free fatty acids of formula (IV), in which R7 is a linear or branched, saturated hydrocarbon radical.

Owner:SYMRISE GMBH & CO KG

Self-closing type polymer cement waterproof coating

The invention discloses a self-closing type polymer cement waterproof coating. The self-closing type polymer cement waterproof coating is prepared by mixing a powder material and a liquid material at a weight ratio of 1:1, wherein the powder material comprises the following components in parts by weight: 45 parts of cement, 45 parts of quartz powder, 40 parts of filler and 10 parts of active master batch FLW and the liquid material comprises the following components in parts by weight: 90 parts of acrylic emulsion, 0.5 part of wetting agent SILCOWET065, 5 parts of trimethyl pentanediol diisobutyrate, 0.5 part of silicone antifoaming agent, 0.5-0.8 part of water-retaining agent and 20 parts of water, wherein the water-retaining agent is alkyl biphenyl ether sulfonate, fatty alcohol polyoxyethylene ether sulfate or alkyl phenol ether sulfosuccinate ester salt. The self-closing time of the self-closing type polymer cement waterproof coating film is 4 hours, the initial setting time is more than 45 minutes, after coating is applied, the self-closing type polymer cement waterproof coating has good adhesive properties and the adhesive strength is 0.7MPa.

Owner:大岩(上海)建筑材料有限公司

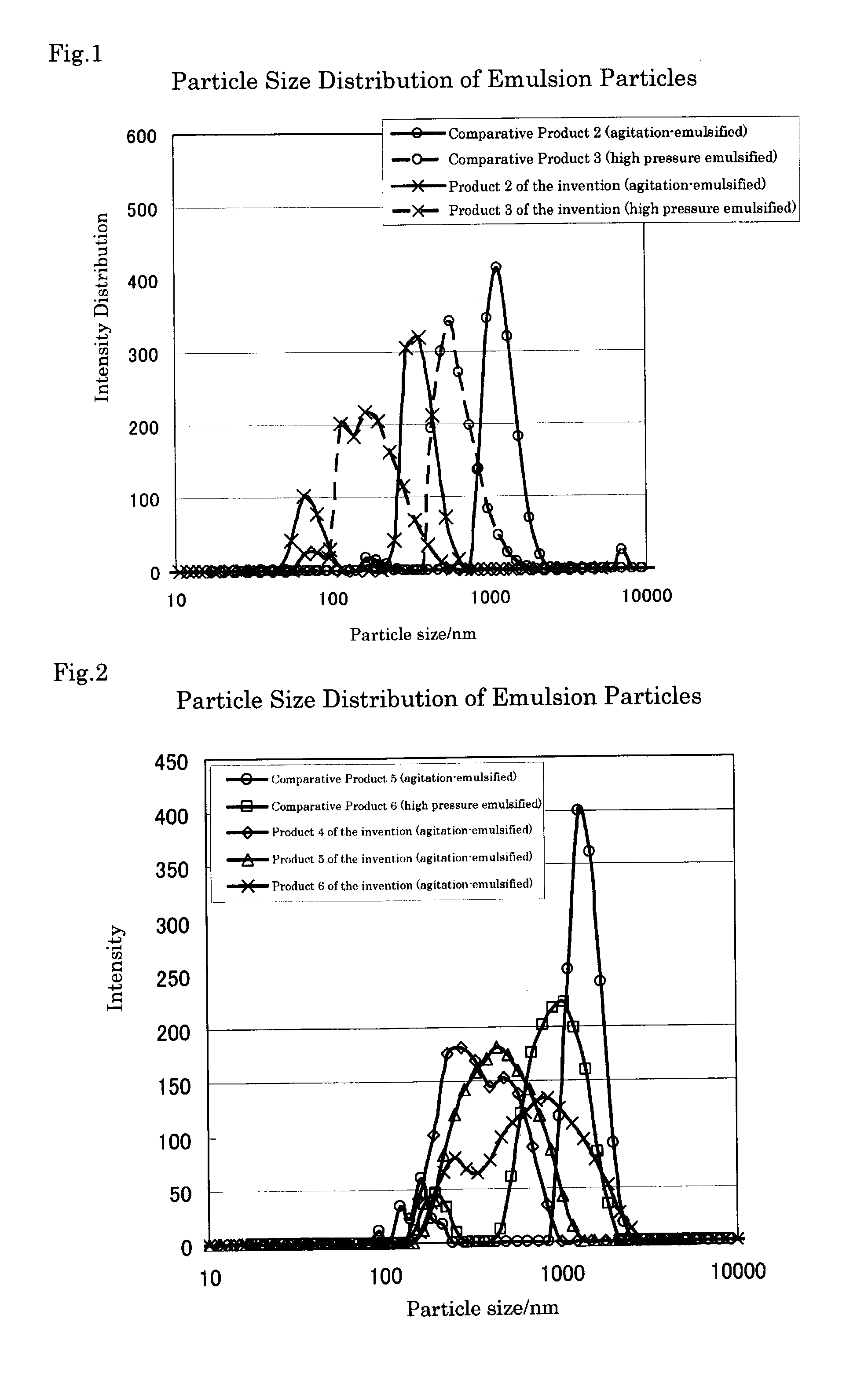

Emulsified composition, a method for preparing the same and food and drink containing the same

InactiveUS20130108763A1Stable and high qualityEasy to produceTransportation and packagingMixingSucroseEmulsion

This invention provides an emulsified composition comprising (A) edible oil material, (B) sucrose diacetate hexaisobutyrate (SAIB), (C) octenylsuccinic acid-modified gum arabic, (D) polyalcohol and (E) water, in which the particles are finer and more uniform than those in conventional emulsions prepared with gum arabic, and which is easy of preparation.

Owner:T HASEGAWA CO LTD

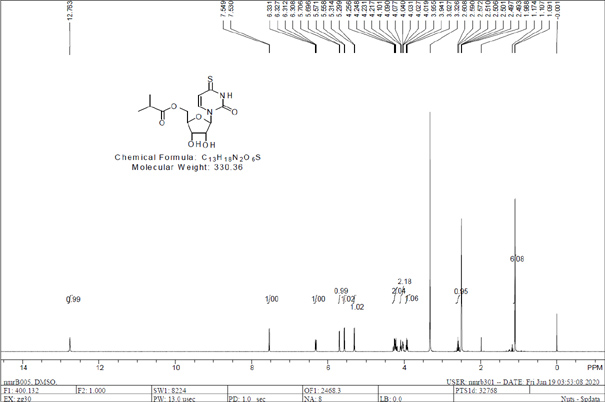

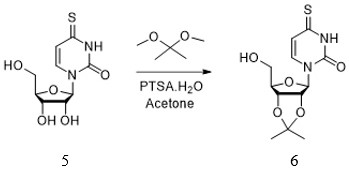

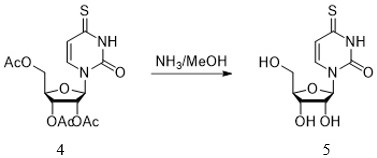

Anti-hepatitis B virus compound as well as preparation method and application thereof

ActiveCN112979733AInhibitory activityThe preparation method is mildOrganic active ingredientsSugar derivativesThio-Engineering

The invention provides an anti-hepatitis B virus compound and a preparation method and application thereof, the compound is 4-thiouridine isobutyrate, the molecular formula is C13H18N2O6S, and the structural formula is shown in the specification. The compound provided by the invention can effectively inhibit the activity of hepatitis B virus, can be used as a substitute drug for lamivudine and telbivudine, solves the problem of drug resistance of lamivudine and the like in the aspect of resisting hepatitis B virus, is high in drug effect, low in toxicity and low in price, and provides a direction for development of drugs for treating hepatitis B. In addition, the invention discloses a preparation method of the compound 4-thiouridine isobutyrate, and the preparation method is mild in condition, easy to synthesize and suitable for industrial production.

Owner:南京颐媛生物医学研究院有限公司 +1

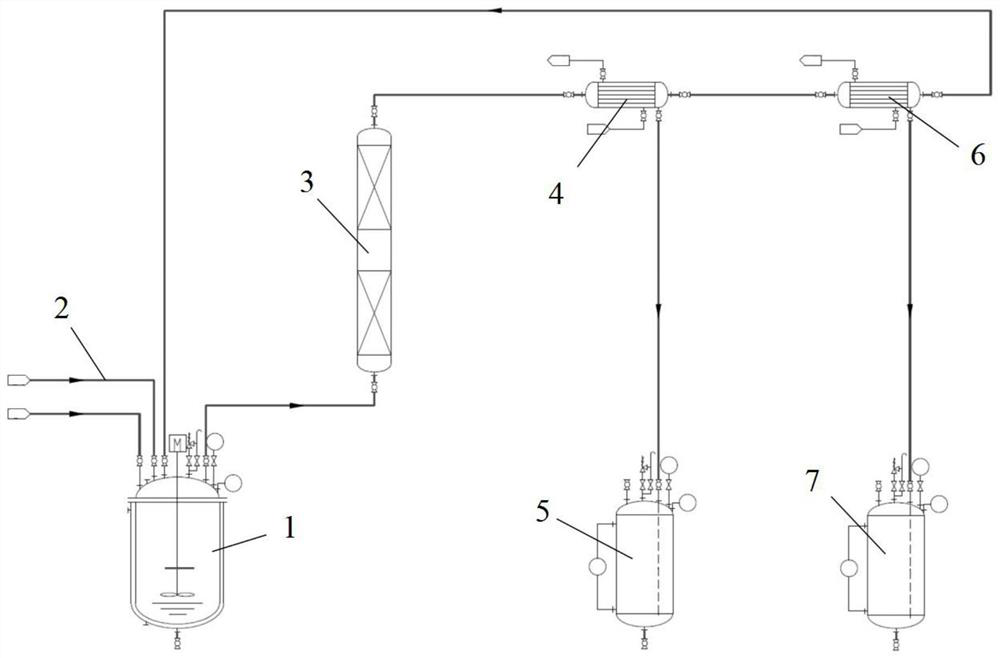

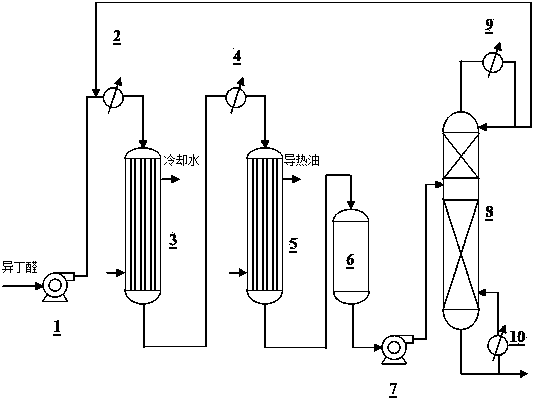

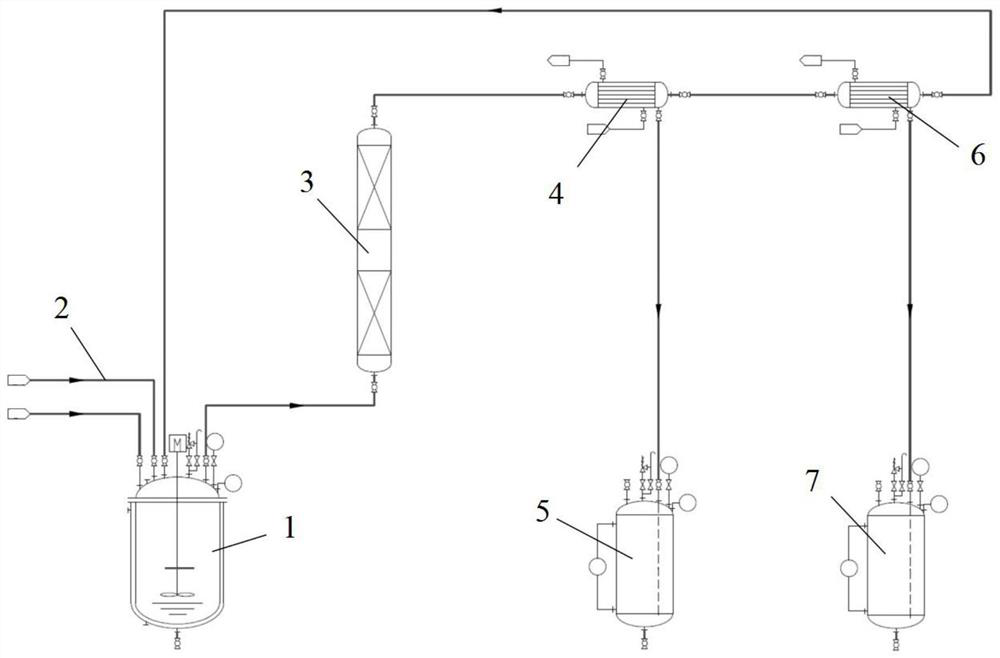

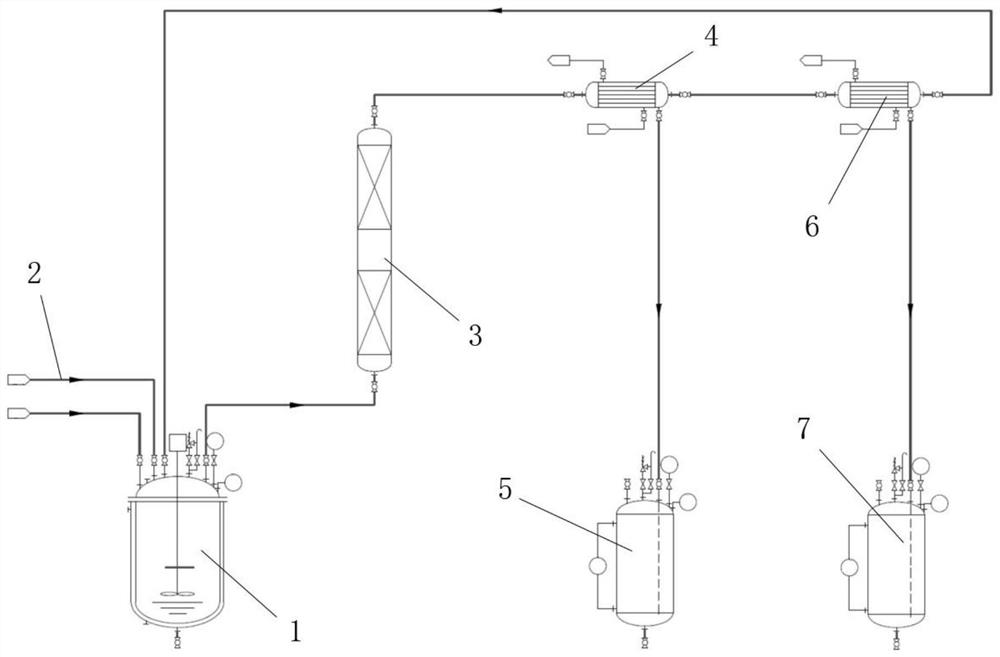

Continuous production method for 2,2,4-trimethyl-1,3-pentanediol isobutyrate

ActiveCN104072367AHigh selectivityIncrease productivityOrganic compound preparationHeterogenous catalyst chemical elementsIsobutyratesPtru catalyst

The invention discloses a continuous production method for 2,2,4-trimethyl-1,3-pentanediol isobutyrate. A two-step method fixed bed continuous reaction process and a solid catalyst are adopted, wherein the catalyst is a solid catalyst Cs-K / SiO2 which is prepared by taking spherical silicon oxide as a carrier to carry caesium-potassium double-alkali metal active components. The method comprises the following steps: adopting two serial tubular type fixed bed reactors, firstly feeding a preheated isobutyraldehyde raw material into a first tubular type fixed bed reactor for an aldol condensation reaction, subsequently feeding an obtained an aldol condensation product into a second tubular type fixed bed reactor for intramolecular Cannizzaro reaction, and continuously reacting so as to obtain a target product. Due to adoption of a two-step method fixed bed continuous reaction process, the method is not only high in isobutyraldehyde conversion rate and product selectivity, but also high in production efficiency, simple in reaction operation, beneficial for energy conservation and discharge reduction and has a large-scale continuous industrial production prospect.

Owner:德纳化工滨海有限公司 +1

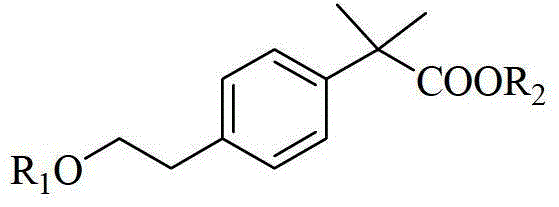

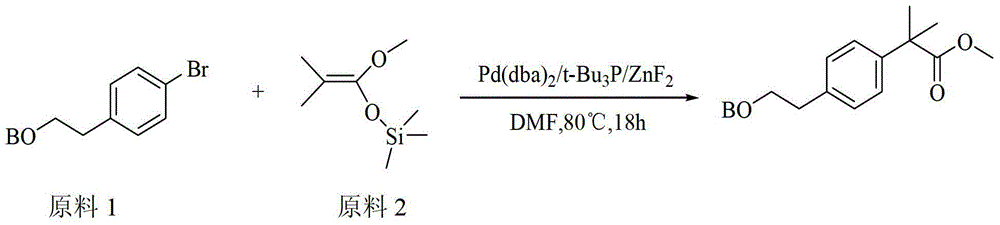

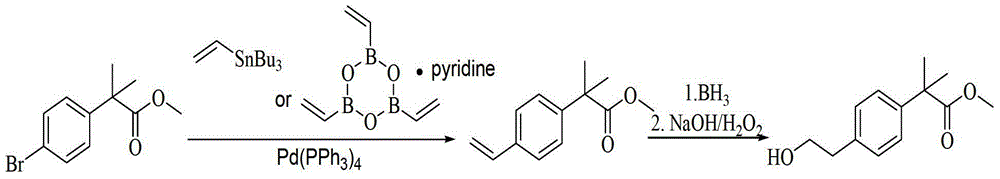

Method for synthesizing 2-methacrylate derivatives by use of ester compounds

InactiveCN104151160AReduce energy consumptionLow reaction temperatureGroup 4/14 element organic compoundsOrganic compound preparationIsobutyratesRoom temperature

The invention provides a method for synthesizing 2-methacrylate derivatives by use of ester compounds as one of raw materials. The method is characterized in that isobutyrates are creatively selected as one of reaction raw materials instead of alkene compounds in the prior art. The method is capable of obtaining the desired products through only one step of reaction, and is short in reaction time, and low in energy consumption and cost, the reaction can be carried out at a room temperature, and the raw material isobutyrates are easy to get; as a result, the method is greatly convenient for industrial production.

Owner:CHONGQING HUAPONT PHARMA

Esterified weak acid catalyst for synthesizing 2,2,4-trimethylpentanediol diisobutyrate

ActiveCN108940258AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationSolid acidVanadate

The invention discloses an esterified weak acid catalyst for synthesizing 2,2,4-trimethyl-1,3-pentanediol diisobutyrate and a preparation method thereof. The weakly acidic solid catalyst is prepared by compounding modified attapulgite and ammonium vanadate. The method disclosed by the invention is simple in catalyst preparation process and low in cost, the catalyst has the advantages of being highin activity and selectivity, easily recyclable, reusable and the like, the defects that the equipment corrosion is serious and the amount of product impurities is large when concentrated sulfuric acid and super-strong solid acid are used as the catalyst, lots of waste liquor is produced, the environment is polluted and the like are overcome, and the industrial prospects are excellent.

Owner:RUNTAI CHEM TAIXING CO LTD

On-line coated three-layer co-extruded BOPET film with high temperature resistance and low precipitation

The invention discloses an on-line coated three-layer co-extruded BOPET film with high temperature resistance and low precipitation. The BOPET film comprises a PET base layer and layers having high temperature resistance and coating the surfaces of the two sides of the PET base layer on line, wherein the layers with high temperature resistance are made of paint with high temperature resistance; the paint with high temperature resistance uses organic silicon resin molecules and bisphenol A epoxy resin as raw materials, and organic silicon resin and epoxy resin both have good heat resistance; and a wear-resistant filler and a migration-resistant plasticizer are prepared at the same time, the wear-resistant filler coats the surface of graphene with nano-silica to improve the wear resistance of the BOPET film, and the migration-resistant plasticizer is prepared from isobutyraldehyde by conducting an aldol condensation reaction at first and a Tishchenko reaction next to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and subjecting 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and isocaprylic acid to an esterification reaction, so the service life of the BOPET film is prolonged.

Owner:GUANGDONG BAOJIALI COLOR PRINTING IND CO LTD

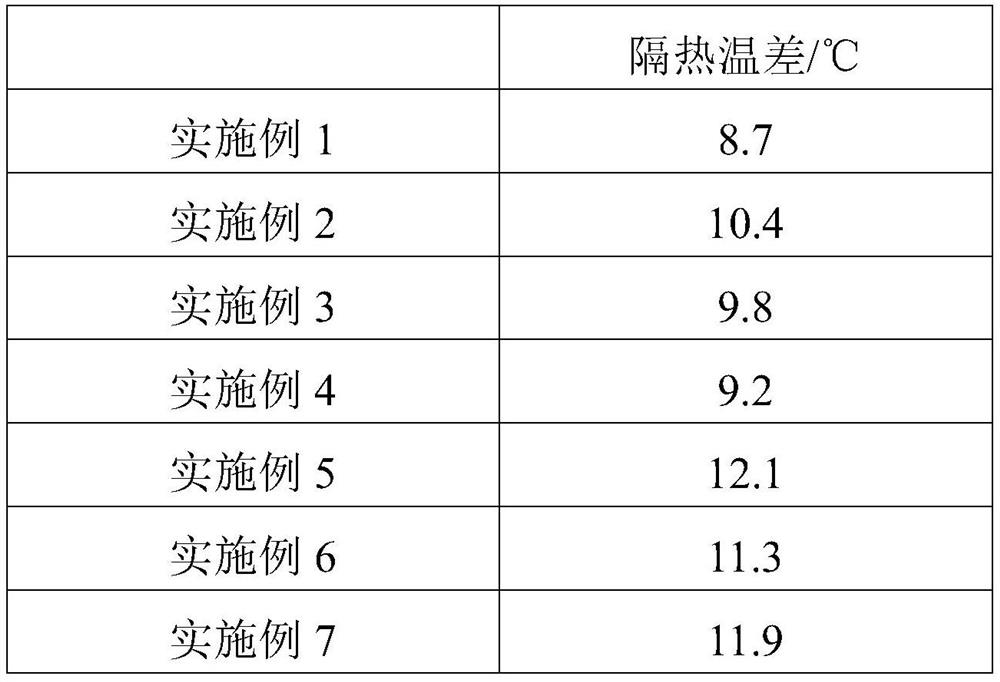

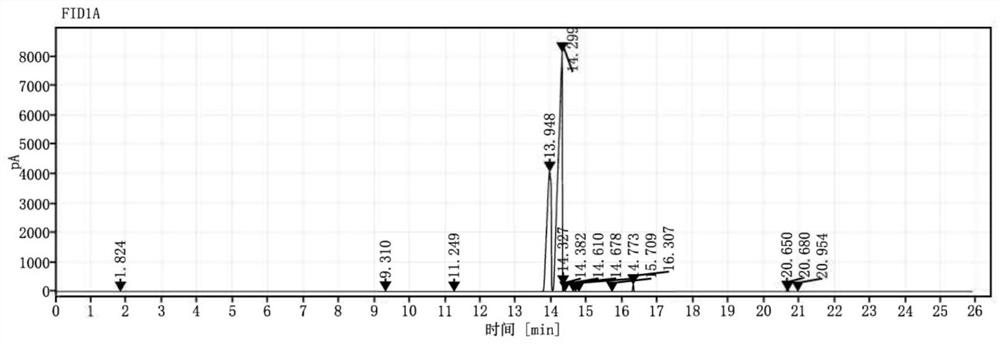

Heat-preservation and heat-insulation coating and preparation method thereof

PendingCN113502102AImprove thermal insulation performanceImprove waterproof performanceReflecting/signal paintsCellulosePolymer science

The invention discloses a heat-preservation and heat-insulation coating and a preparation method thereof. The heat-preservation and heat-insulation coating is prepared from a fluorosilicone modified acrylate emulsion, a styrene-acrylate emulsion, 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, carboxymethyl cellulose sodium, nonylphenol polyoxyethylene ether, a functional filler, 3, 3-diaminodiphenyl sulfone, polytrifluoropropyl methyl siloxane, methylsilsesquioxane, a functional montmorillonite compound, polyimide microspheres, nano titanium carbide and water. The heat-preservation and heat-insulation coating has good heat-preservation and heat-insulation performance and waterproof performance, and is good in adhesive force and not prone to cracking.

Owner:贵州广毅节能环保科技有限公司

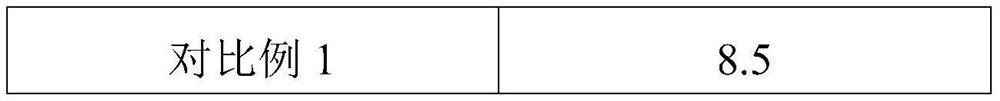

Preparation method of 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate

ActiveCN112430181AOrganic compound preparationCarboxylic acid esters preparationPtru catalystMethyl palmoxirate

The invention relates to a preparation method of 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, which comprises the following steps: (1) adding alkali metal hydroxide, alkaline earth metal oxideand alcohol ester-12 product into a reaction container, and uniformly stirring the materials; (2) adding isobutyraldehyde, controlling the feeding speed of isobutyraldehyde, controlling the temperature to be 20-70 DEG C, and carrying out a first-stage isobutyraldehyde condensation reaction to obtain an intermediate product; (3) after the isobutyraldehyde is completely added, controlling the temperature to be 40-70 DEG C, keeping the temperature for 1-5 hours, and carrying out a second-stage Canichalro reaction to obtain an alcohol ester-12 crude product; and (4) purifying the alcohol ester-12crude product to obtain an alcohol ester-12 finished product. According to the invention, alkali metal hydroxide is used as a catalyst, alkaline earth metal oxide is added to remove moisture in the material, and alcohol ester-12 is added and the feeding speed of isobutyraldehyde is controlled in the reaction process, so that the temperature of the condensation reaction of isobutyraldehyde is controlled, and the preparation method of alcohol ester-12 is enlarged to industrial production from laboratory lab test.

Owner:广州联普新材料科技有限公司

Wood coating and preparation method thereof

The invention relates to a wood coating and a preparation method thereof, belonging to the technical field of coatings. The wood coating is prepared from the following raw materials in parts by weight: 40-50 parts of polyacrylic emulsion, 0.3-0.5 part of sodium hexametaphosphate, 2-12 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 1-5 parts of hydroxy fluoro-carbon resin, 0.5-2.5 parts of pentachlorodiphenyl, 0.3-5 parts of triethanolamine, 0.05-0.20 part of a defoaming agent, 15-20 parts of deionzied water, 1-1.5 parts of a thickening agent, 15-25 parts of titanium dioxide and 10-15 parts of light calcium carbonate. Aiming at the internal structural characteristics of wood, the wood coating which is applicable to coating on the surface of wood is prepared by taking polyacrylic emulsion as base resin on the basis of design of a comprehensive coating formula, and a good coating effect is achieved on the surface of wood.

Owner:CHENGDU JINHUI TECH

Mixed organic solvent for preparing high-temperature sintered conductive paste

ActiveCN112133469AHigh affinityImprove solubilityNon-conductive material with dispersed conductive materialPhotovoltaic industryPhenyl Ethers

The invention relates to a mixed organic solvent for preparing high-temperature sintered conductive paste, and belongs to the technical field of oily organic solvents. The mixed organic solvent comprises 10-60 wt% of fatty acid ester containing a phenyl ether structure, 10-60 wt% of butyl carbitol acetate, 0.1-10 wt% of at least one of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, 10-30 wt% of dimethyl adipate, 0.1-0.5 wt% of gamma-methacryloxypropyltrimethoxysilane and 0.5-1.5 wt% of silicone oil. The mixed organic solvent has the advantages that the solvent has the characteristics of good resin solubility, good wettability to metal particles, no volatilization at room temperature, stable volatilization at high temperature and the like, various types of resin commonly used by photovoltaic front silver paste can be well dissolved, and experiments prove that compared with a traditional single solvent system, the solvent is more suitablefor the requirements of silver paste printing and sintering; and the solvent is simple in reaction condition and high high product yield, and has favorable application prospects in the photovoltaic industry and electronic conductive paste related fields.

Owner:CHANGCHUN GOLD RES INST

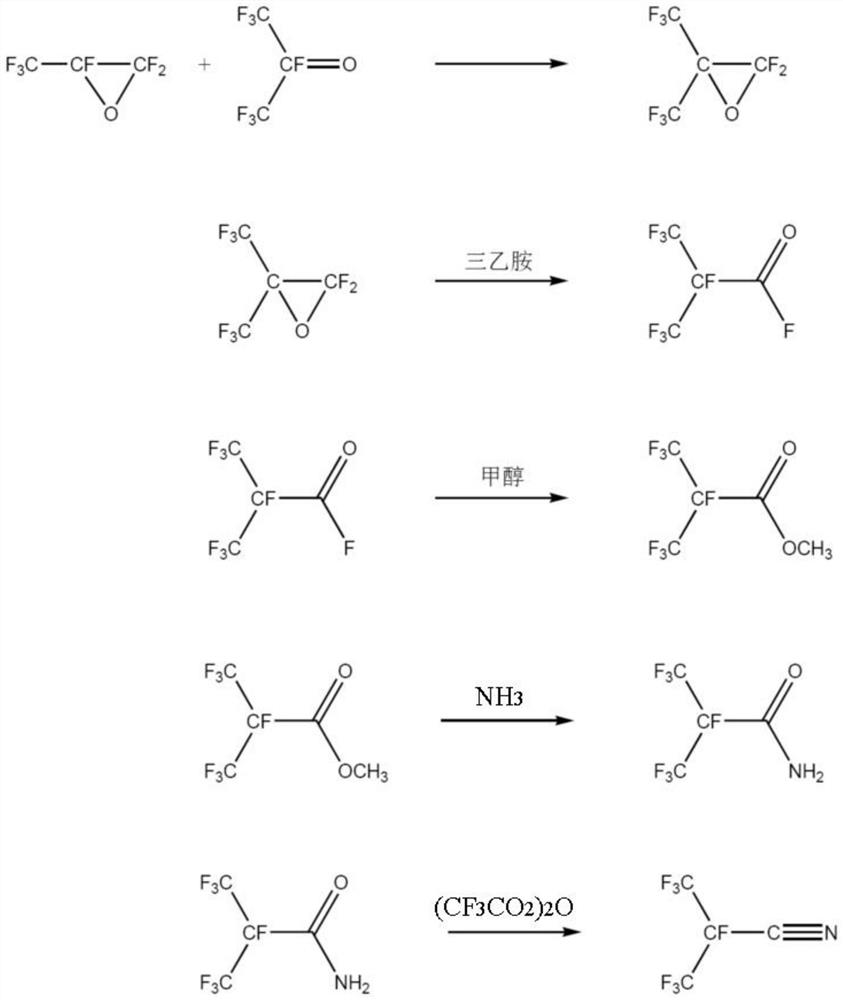

Synthetic method of perfluoroisobutyronitrile

PendingCN111848444AMild reaction conditionsHigh reaction conversion ratePreparation from carboxylic acid halidesOrganic compound preparationIsomerizationHexafluoropropylene oxide

The invention discloses a synthetic method of perfluoroisobutyronitrile. The synthetic method comprises the following steps of: (1) taking hexafluoropropylene oxide and hexafluoroacetone as raw materials to react to prepare perfluoroepoxyisobutane; (2) carrying out catalytic isomerization on the perfluoroepoxyisobutane to obtain heptafluoroisobutyryl fluoride; (3) carrying out esterification reaction on heptafluoroisobutyryl fluoride and alcohol to obtain heptafluoroisobutyrate; and (4) reacting heptafluoroisobutyrate with ammonia, and performing dehydrating to obtain perfluoroisobutyronitrile. The synthesis method has the advantages of easily available raw materials, low raw material cost, few byproduct, mild reaction conditions, high reaction conversion rate and yield, short synthesis route, simple and safe process and easy industrial production.

Owner:福建省漳平市九鼎氟化工有限公司

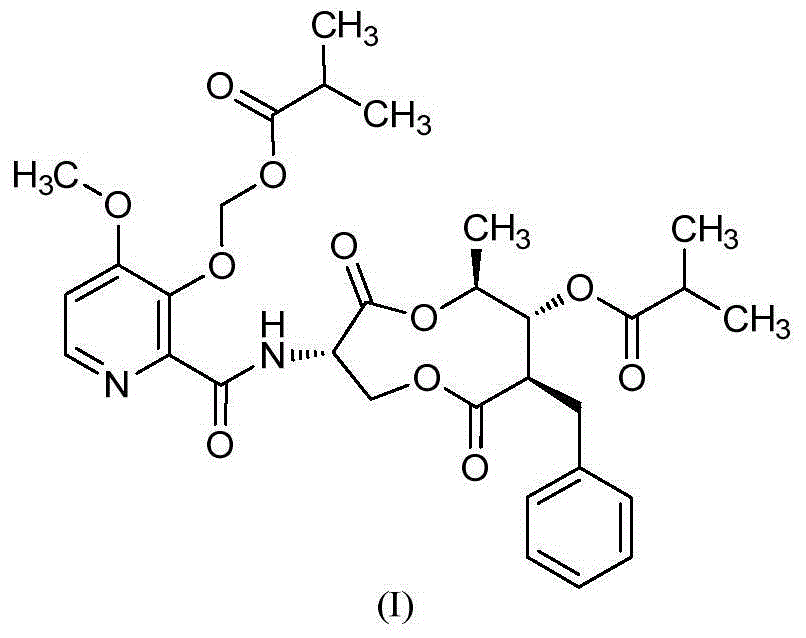

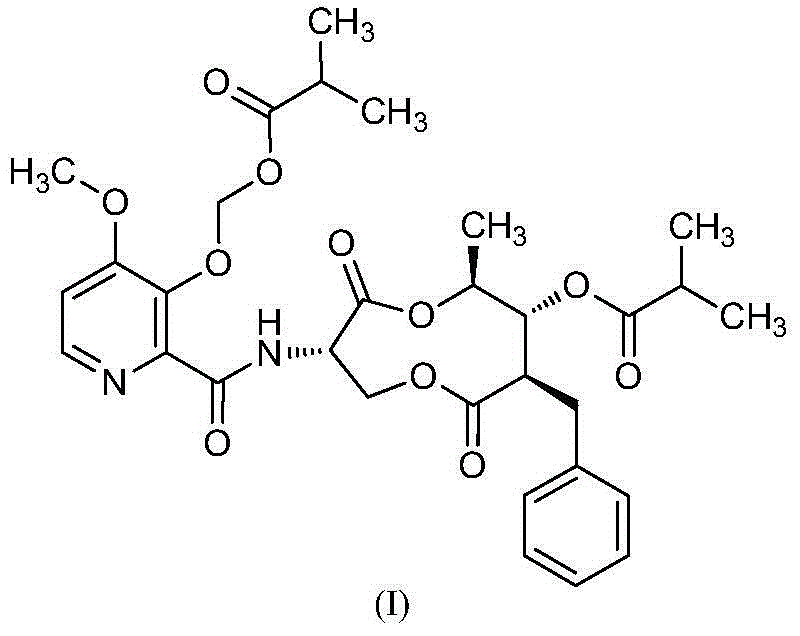

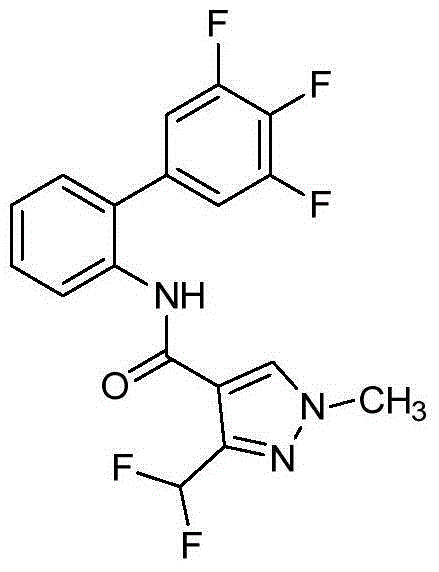

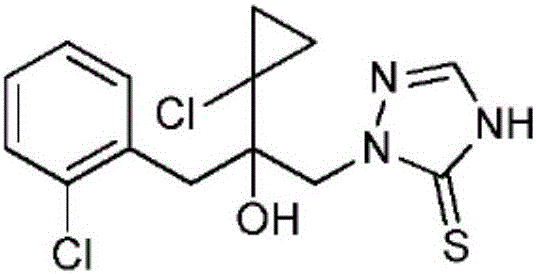

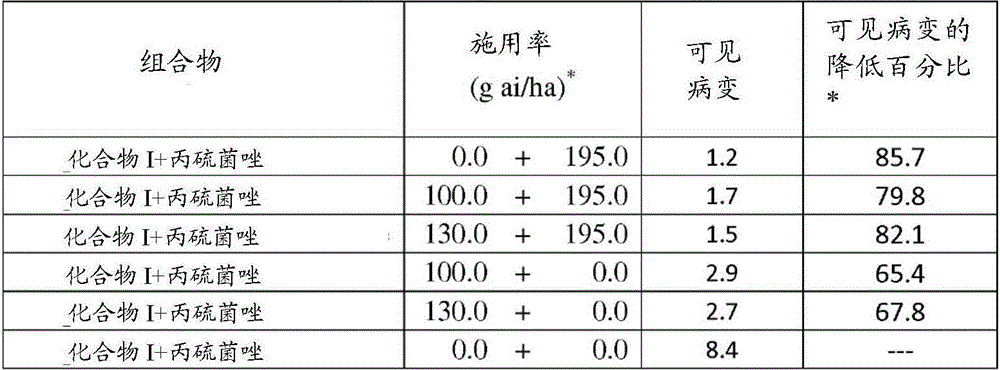

Synergistic fungicidal mixtures for fungal control in cereals

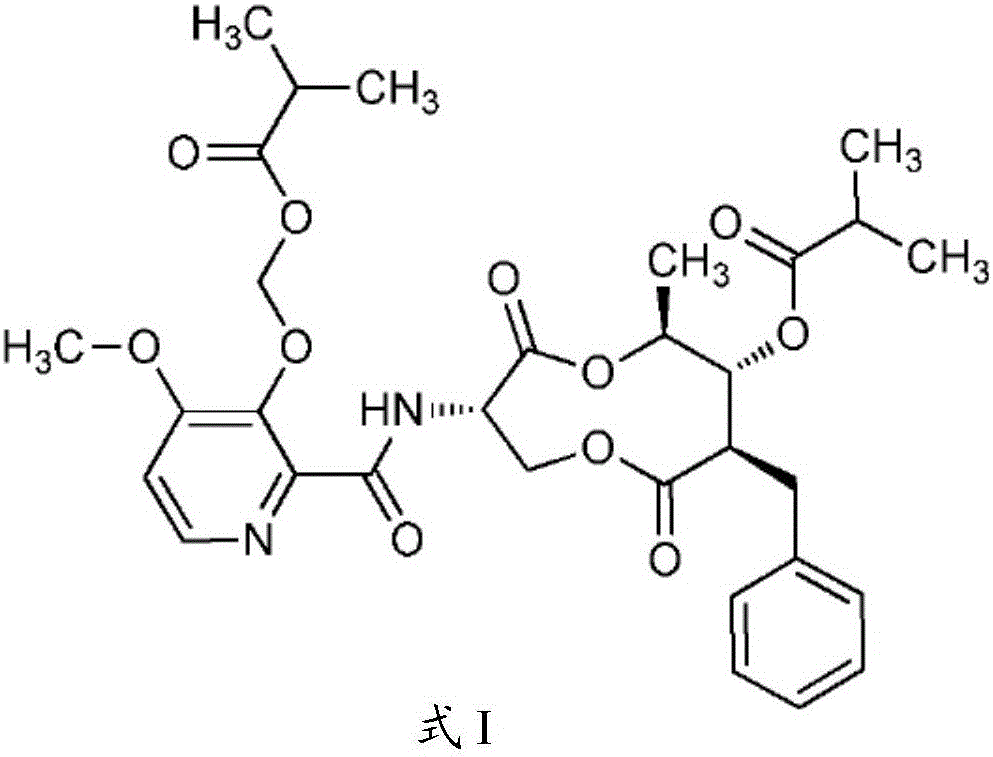

A fungicidal composition containing a fungicidally effective amount of (a) the compound of Formula I, (3S,6S,7R,8R)-8-benzyl-3-(3-((isobutyryloxy)methoxy)-4-methoxypicolinamido)-6-methyl-4,9-dioxo-1,5-dioxonan-7-yl isobutyrate, and (b) fluxapyroxad, provides synergistic control of selected fungi.

Owner:CORTEVA AGRISCIENCE LLC

High-stability wood door water-based epoxy resin coating

InactiveCN107955489AImprove dispersion stabilityImprove adhesionEpoxy resin coatingsWater basedEpoxy

The invention discloses a high-stability wood door water-based epoxy resin coating which comprises first materials and second materials. The first materials comprise, by weight, 70-110 parts of main materials, 2-8 parts of aluminum nitride, 1-5 parts of melamine resin, 1-4 parts of magnesium hydroxide, 2-6 parts of expanded perlite, 1-4 parts of diatomite, 1-4 parts of mica powder, 0.5-1.2 parts of zinc oxide, 2-6 parts of composite dispersing agents, 3-7 parts of plasticizers, 1-2 parts of defoaming agents, 1-2 parts of wetting agents and 1-2 parts of leveling agents. The second comprise, byweight, 5-9 parts of aminoethyl piperazine, 1-3 parts of propanediol butyl ether, 2-4 parts of 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyl acid ester and 20-40 parts of deionized water. According tothe high-stability wood door water-based epoxy resin coating, adhesive force between the coating and a coating substrate is good, toughness and hardness can be balanced, mechanical properties are excellent, and the dispersion stability of the coating is good when the coating stands for a long time.

Owner:合肥林邦门业有限公司

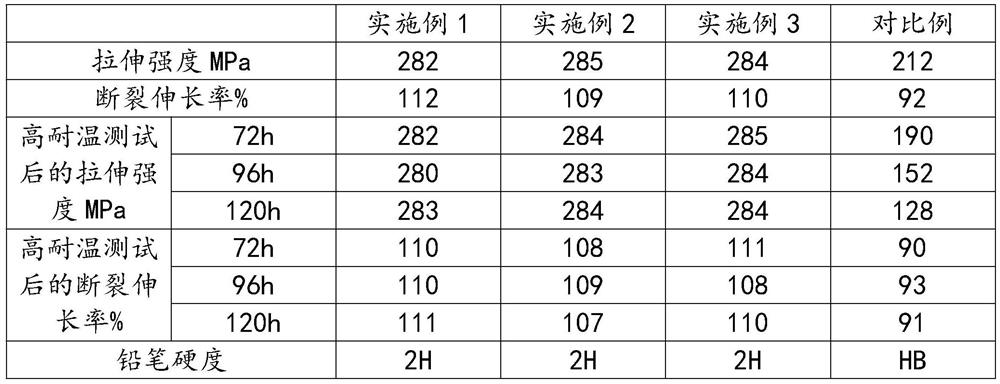

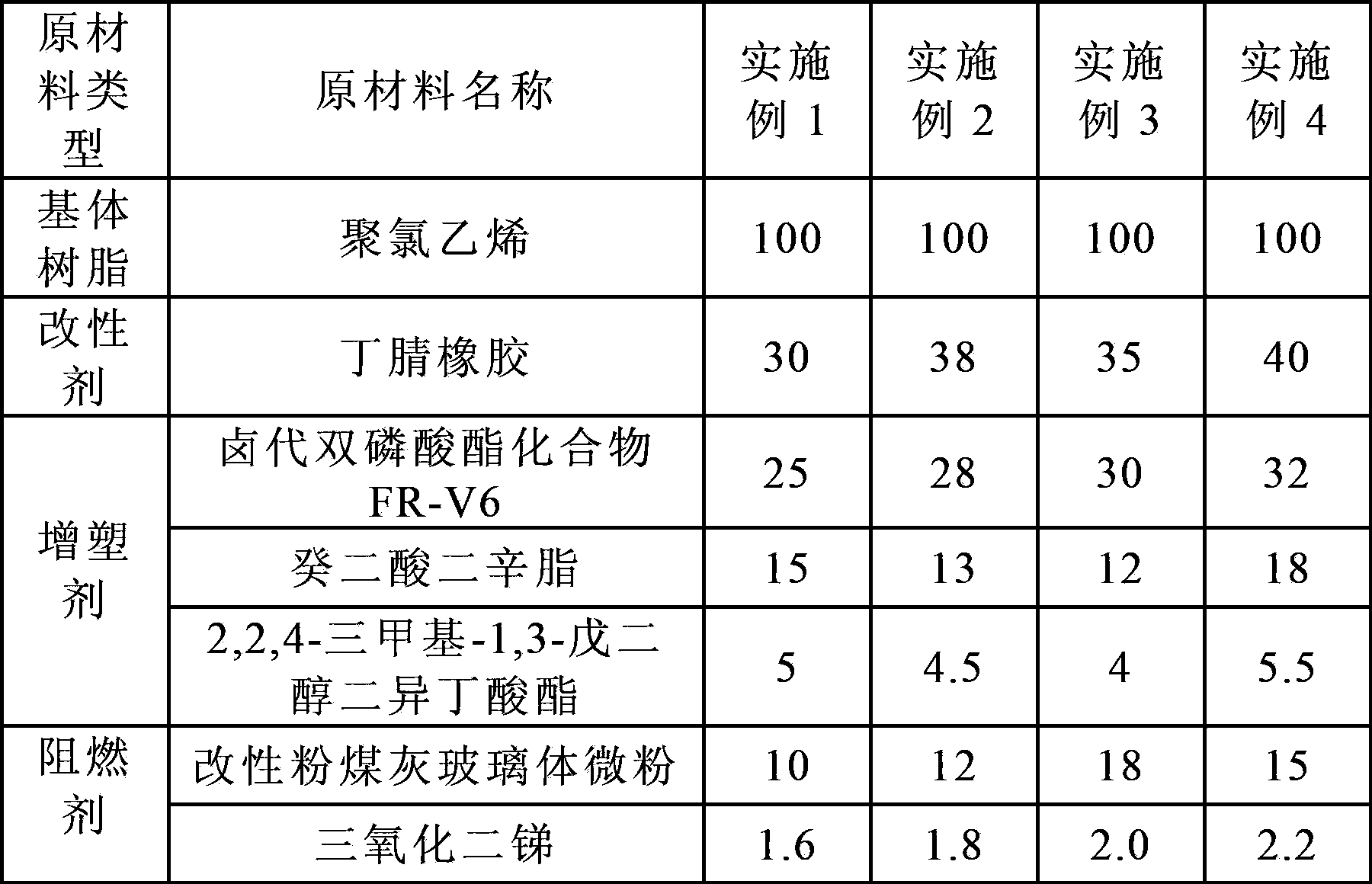

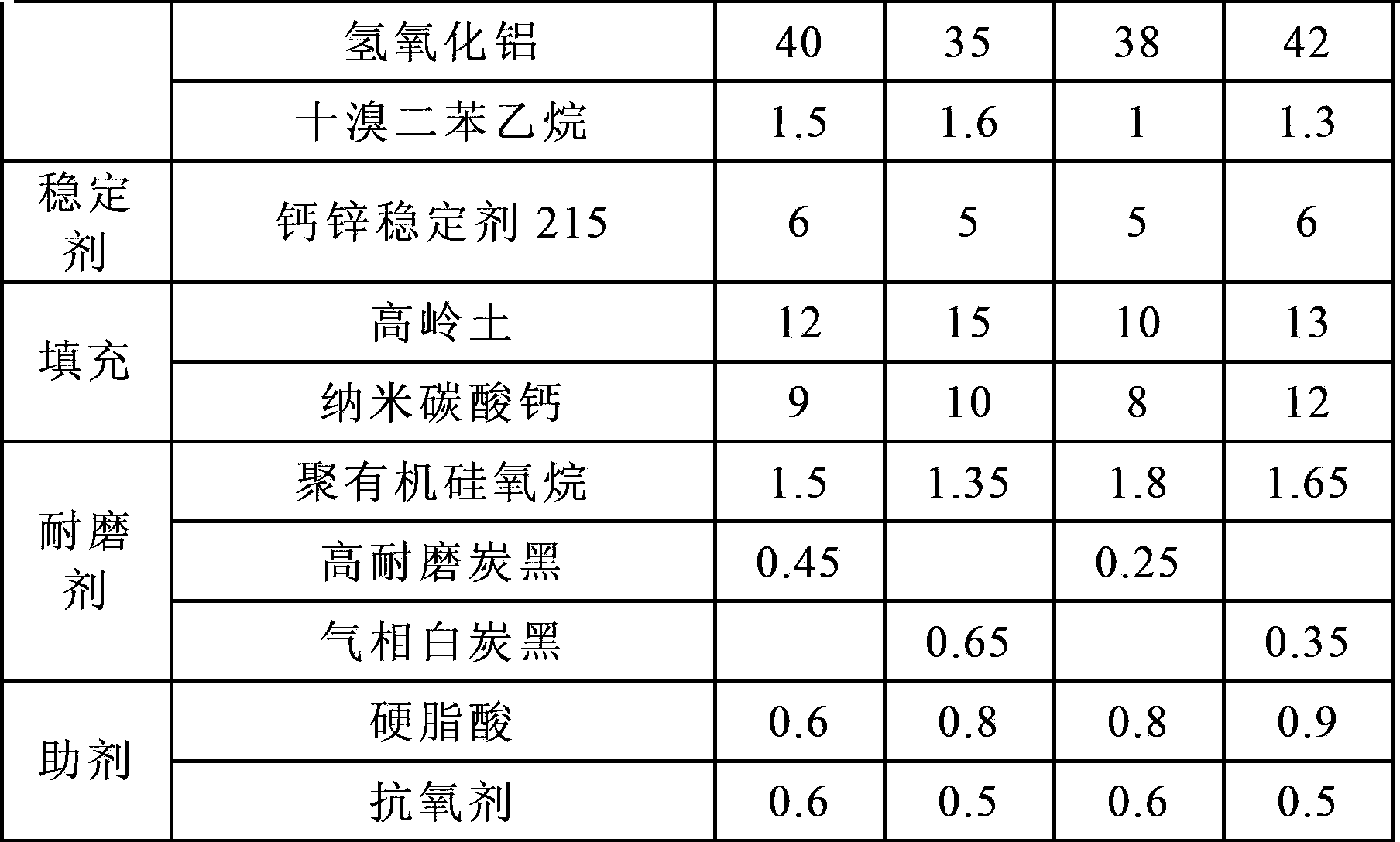

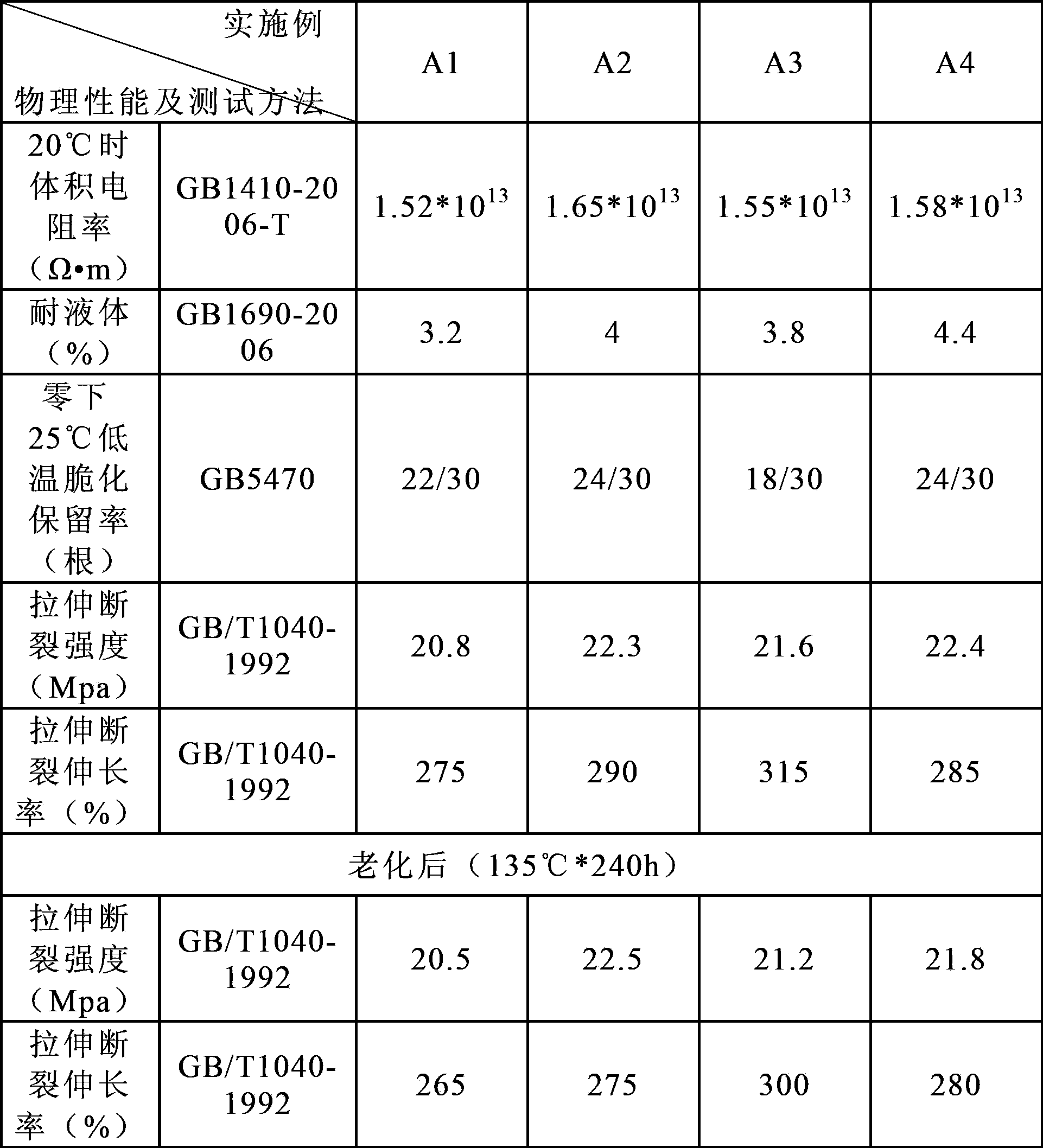

Thin-wall insulated electric wire material for automobile and preparation method of electric wire material

ActiveCN102964724BCompatibility is reasonableImprove physicsPlastic/resin/waxes insulatorsInsulated cablesCombustionWear resistant

The invention relates to a thin-wall insulated electric wire material for an automobile and a preparation method of the electric wire material, belonging to the technical field of materials, and solving the problem that cable wires cannot meet long-time ageing resistance, low-temperature resistance, high-temperature resistance, high physical performance, no drop during combustion, good liquid resistance and the like simultaneously in the prior art. The cable material comprises the following ingredients in parts by weight: 100 parts of matrix resin, 30-40 parts of modifier, 40-60 parts of plasticizer, 15-25 parts of filler, 50-60 parts of flame retardant, 5-10 parts of stabilizer, 1-5 parts of wear-resistant agent, and 1-5 parts of auxiliaries, wherein the plasticizer is the mixture of halogenated biphosphate compound FR-V6, dihexyl sebacate and 2,2,4-trimethyl-1,3-pentanediol di-isobutyrate in a weight ratio of (5-10): (3-6): 1. The thin-wall insulated electric wire material for the automobile disclosed by the invention is good in physical performance, resistant to long-time ageing, and low in cost.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Temporary removable solvent based protective coating

InactiveUS20140018280A1Easy to disassembleEasy to wearDetergent compounding agentsTemporary coatingsDiacetone alcoholAcetic acid

This invention is for a composition of clear or pigmented coating that is temporary and removable. It is especially designed to protect the surface of an automobile from the damaging effects of the environment and also from damage caused by normal daily use. The coating is a composition of 40 to 80% of cellulose acetate butyrate ester, 15 to 60% of an acrylic polymer and 2 to 10% of a sucrose acetate isobutyrate. The remover is a combination of tetrahydrofurfuryl alcohol, dibasic ester, diacetone alcohol, ethyl 3 ethoxypropionate; 2,2,4 trimethyl-1,3 pentanoldiol Monoisobutyrate, and White Mineral Oil.

Owner:OCONEE COATING TECH LLC

Sucrose acetate isobutyrate formulation

InactiveUS20070104850A1Food preparationFood ingredient as emulsifierSolid substrateSucrose acetate isobutyrate

The present invention provides a process for producing a solid sucrose acetate isobutyrate (SAIB) formulation, by combining sucrose acetate isobutyrate in an amount from about 1 weight percent to about 80 weight percent based on the total weight percent of the total solid formulation; and a solid substrate that is soluble in water or oil, wherein the substrate is present in an amount from about 99 weight percent to about 30 weight percent based on the weight of the formulation, wherein the formulation produced is pourable in less than about 20 seconds according to ASTM method D1895-96. The solid SAIB formulation is useful in beverage applications.

Owner:COOK PHILLIP MICHAEL +2

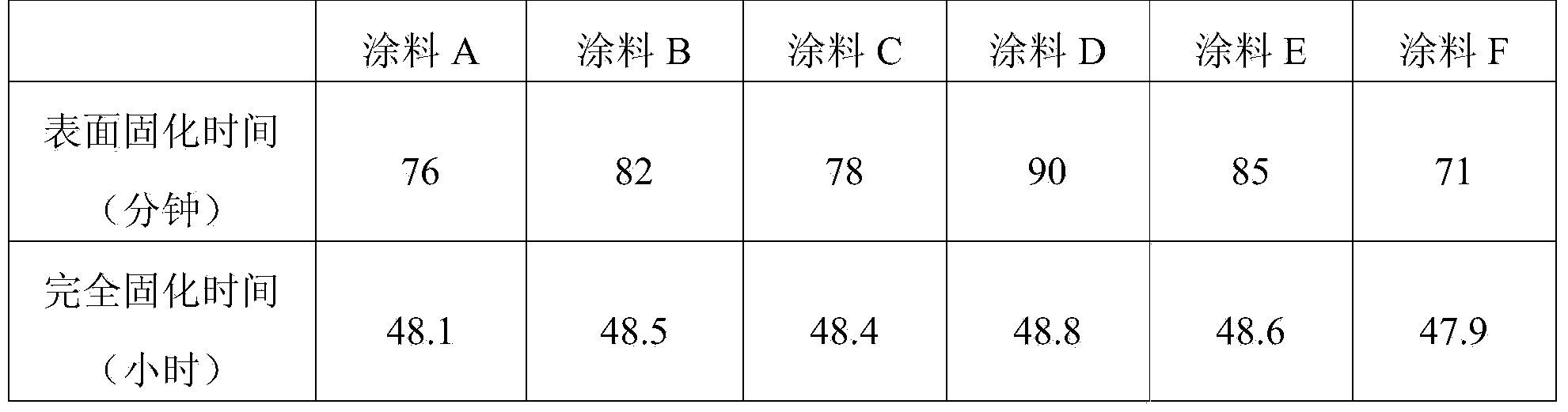

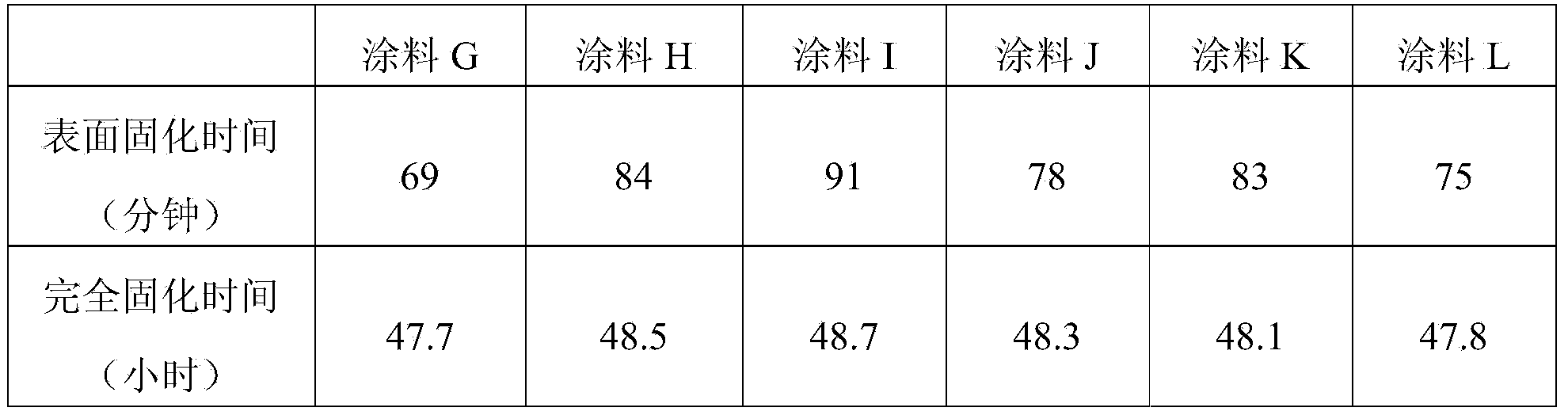

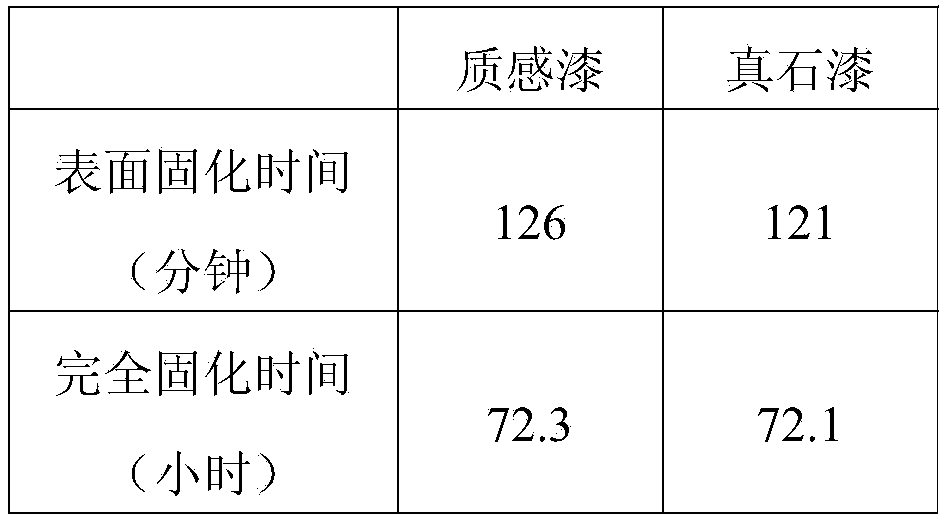

Catalyzing-curing film-forming agent special for texture paint and real stone paint and preparation and use methods thereof

ActiveCN103756398AFast film formationShorten the construction periodEmulsion paintsPolyester coatingsAlcoholLacquer

The invention provides a catalyzing-curing film-forming agent special for texture paint and real stone paint and preparation and use methods thereof. The catalyzing-curing film-forming agent special for the texture paint and the real stone paint consists of the following components in parts by weight: 20-40 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 5-25 parts of phenoxy-1-propanol, 5-25 parts of ethylene glycol butyl ether, 5-20 parts of glycol ether and 5-20 parts of ethyl alcohol. By adopting the catalyzing-curing film-forming agent special for the texture paint and the real stone paint, coating, particularly coating such as texture paint or real stone paint with a thick paint film can become films rapidly, the construction period is shortened, and the construction cost is reduced.

Owner:SHENYANG SHIFENG CHEM BUILDING MATERIAL

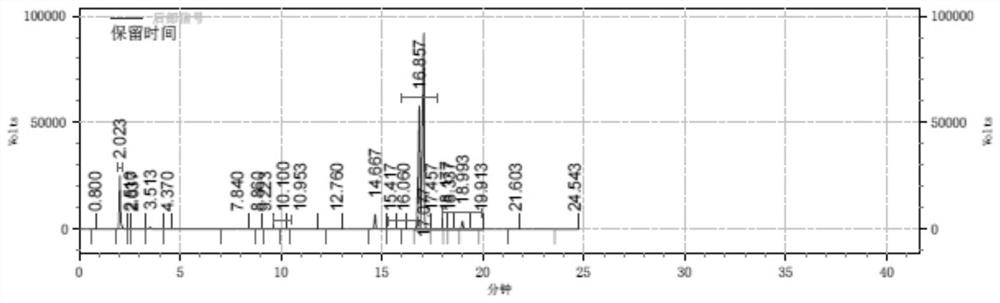

Preparation method of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate

InactiveCN111875498AReduce dosageAvoid Bumping HazardsOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by aldehyde oxidation-reductionPtru catalystOrganic synthesis

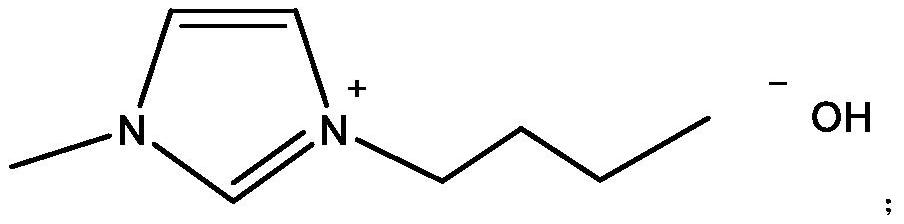

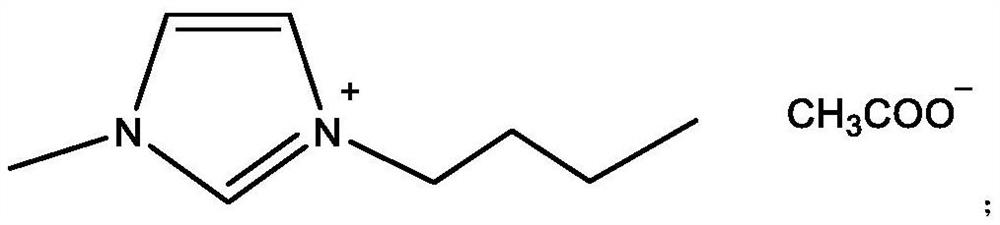

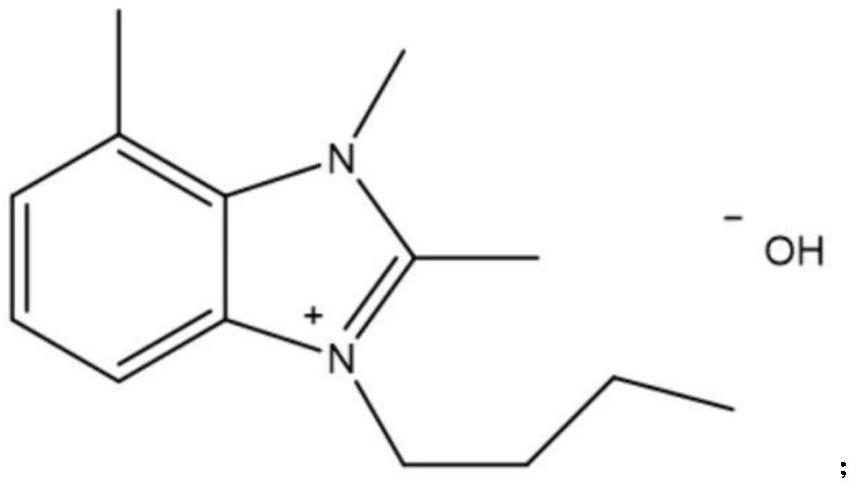

The invention relates to the technical field of organic synthesis, in particular to a method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate. According to the method, isobutyraldehyde issubjected to a condensation reaction in the presence of an ionic liquid catalyst to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate. An ionic liquid the cation of which is alkyl imidazole cations or benzimidazole cations and the anion of which is at least one of hydroxyl ions and acetate ions is adopted as the catalyst. The 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.is prepared through one step, the reaction conditions are mild, the reaction conversion rate is high, selectivity is good, and subsequent products are easy to separate.

Owner:武汉昱鼎科技有限公司

Synergistic fungicidal mixtures for fungal control in cereals

A fungicidal composition containing a fungicidally effective amount of a compound of Formula I, (3S,6S,7R,8R)-8-benzyl-3-(3-((isobutyryloxy)methoxy)-4- methoxypicolinamido)-6-methyl-4,9-dioxo-1,5-dioxonan-7-yl isobutyrate, and at least one fungicide selected from the group consisting of prothioconazole, epoxiconazole, cyproconazole, myclobutanil, prochloraz, metconazole, difenconazole, tebuconazole, tetraconazole, fenbuconazole, propiconazole, fluquinconazole, flusilazole, flutriafol, and fenpropimorph.

Owner:DOW AGROSCIENCES LLC

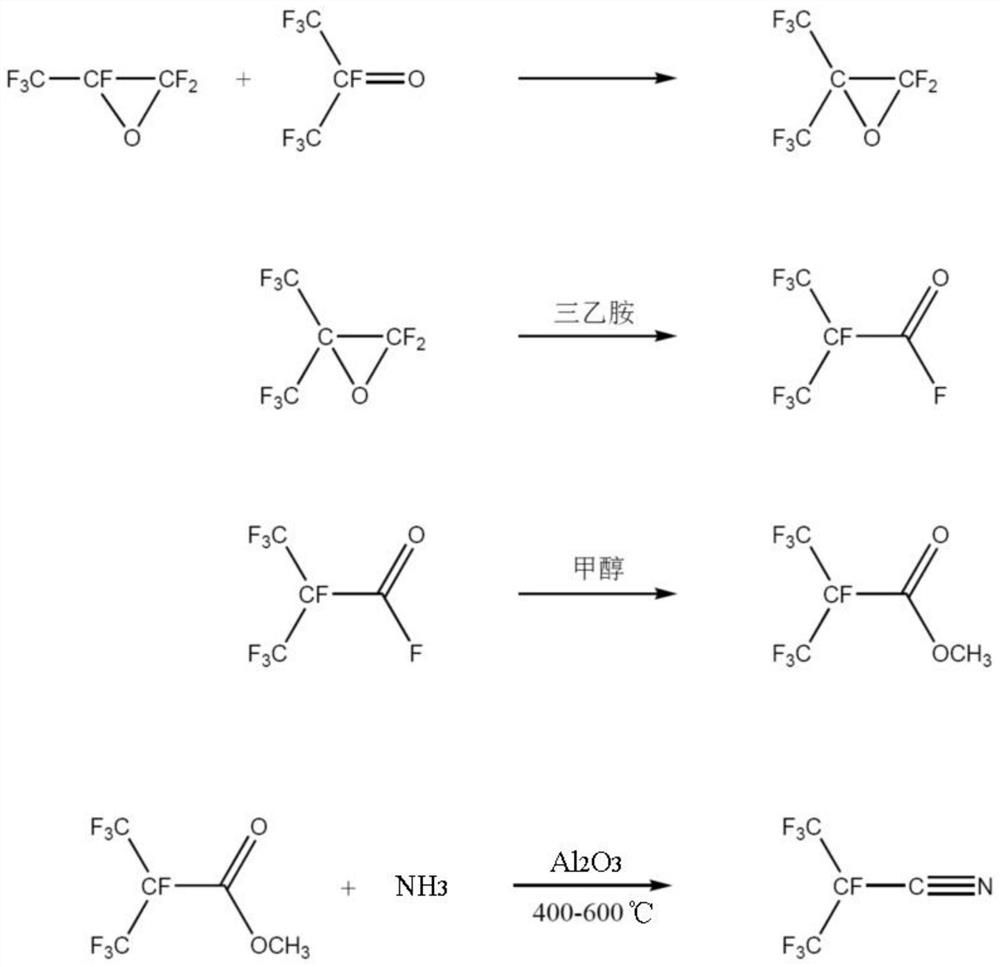

Synthesis method of heptafluoroisobutyronitrile

InactiveCN111777503AHigh purityEasy to separatePreparation from carboxylic acid saltsOrganic compound preparationHexafluoropropyleneHydrochloric acid

The invention discloses a synthesis method of heptafluoroisobutyronitrile, which comprises the following steps: (1) reacting hexafluoropropylene with carbon dioxide under the catalysis of fluoride salt to obtain heptafluoroisobutyrate; (2) acidifying the obtained heptafluoroisobutyric acid, and then carrying out esterification reaction with alcohol to obtain heptafluoroisobutyrate; and (3) reacting the obtained heptafluoroisobutyrate with ammonia, and dehydrating to obtain heptafluoroisobutyronitrile. The synthesis method has the advantages of easily available raw materials, mild reaction conditions, high reaction conversion rate and yield, easy separation and purification, simple and safe process operation, short synthesis route and low cost.

Owner:福建省漳平市九鼎氟化工有限公司

Mouldable biodegradable polymer

InactiveUS8697245B2Synthetic resin layered productsCellulosic plastic layered productsPolyethylene oxidePolyvinyl alcohol

A biodegradable injection mouldable polymer composition including on a dry weight basis from 45-85% w / w by weight of a starch and / or a modified high amylose starch, from 2-15% w / w by weight of a water soluble polymer preferably selected from polyvinyl alcohol, polyvinyl acetate and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch components, and from 5-45% w / w by weight of one or more polyol plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500, and still more preferably 100-400 and preferably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, polyglycerol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol; more preferably glycerol, maltitol, sorbitol, erythritol and xylitol. The composition is preferably substantially soluble in water.

Owner:PLANTIC TECH

Composite solid acid catalyst for preparing 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyrate and preparation method

PendingCN111389445AIncrease surface areaHigh nitrogen contentPhysical/chemical process catalystsOrganic compound preparationPtru catalystHeteropoly acid

The invention belongs to the technical field of catalysts, and particularly provides a composite solid acid catalyst for preparing 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyrate and a preparation method. According to the preparation method, firstly a metal organic framework is prepared, then metal ions are loaded, and then pyrolysis under ammonia gas flow is carried out to prepare nitrogen-containing mesoporous carbon with uniform pore channels, the organic metal framework can enable metal particles to be dispersed more uniformly, and the nitrogen element is successfully introduced under theaction of the ammonia gas flow, so that the metal surface area of the catalyst is large, and the nitrogen content is greatly increased, and finally, strong acid, super acid and heteropolyacid are loaded. The prepared catalyst is high in esterification reaction activity, good in stability and free of pollution, is a green catalyst, and has a good application prospect.

Owner:RUNTAI CHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com