Heat-preservation and heat-insulation coating and preparation method thereof

A technology for thermal insulation and coating, applied in the field of coatings, can solve problems such as the lack of in-depth research on the waterproofness and adhesion of coatings, and achieve the effects of good thermal insulation, good water repellency, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

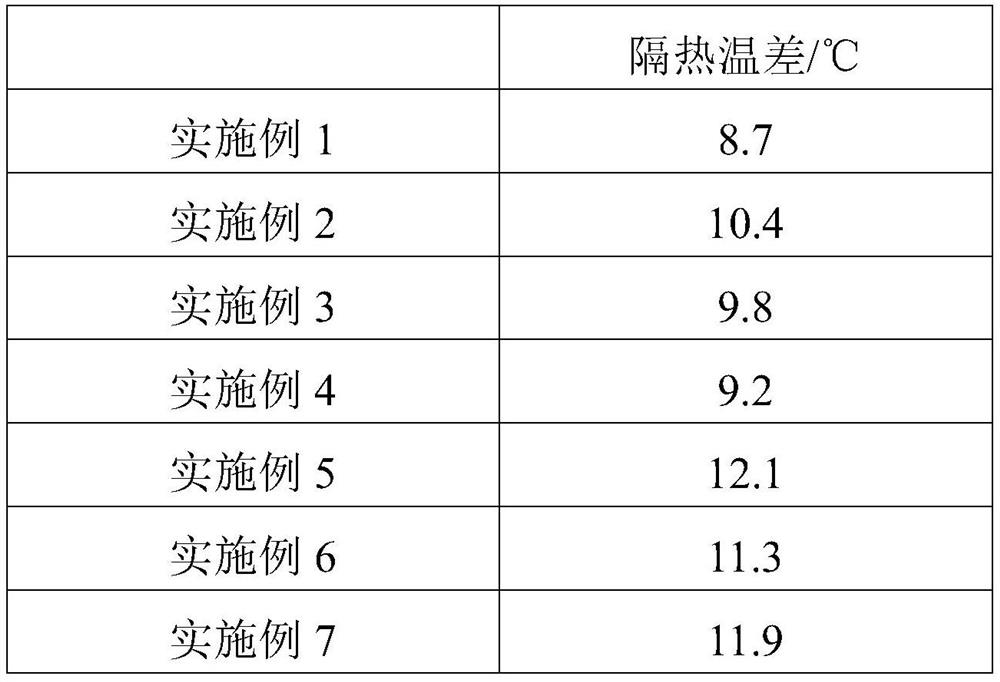

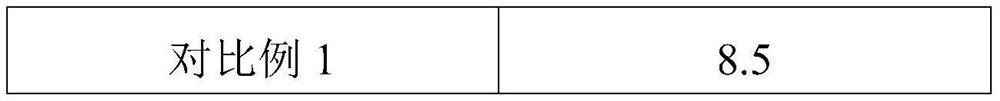

Examples

Embodiment 1

[0041] A thermal insulation coating, which is composed of the following raw materials in parts by weight: 100 parts by weight of fluorosilicon modified acrylate emulsion, 15 parts by weight of styrene-acrylate emulsion, 10 parts by weight of 2,2,4-trimethyl-1, 3-pentanediol monoisobutyrate, 3 parts by weight of sodium hydroxymethylcellulose, 2 parts by weight of nonylphenol polyoxyethylene ether, 20 parts by weight of functional filler, 2 parts by weight of 3,3-diaminodiphenyl Sulfone, 1.5 parts by weight of polytrifluoropropylmethylsiloxane, 0.5 parts by weight of methylsilsesquioxane, 5 parts by weight of montmorillonite, 10 parts by weight of polyimide microspheres, 8 parts by weight of nano titanium carbide , 40 parts by weight of water.

[0042] The functional filler is silica airgel and activated carbon mixed in a mass ratio of 2:1.

[0043] The preparation method of the thermal insulation coating comprises the following steps:

[0044] Add nonylphenol polyoxyethylene ...

Embodiment 2

[0048] A thermal insulation coating, which is composed of the following raw materials in parts by weight: 100 parts by weight of fluorosilicon modified acrylate emulsion, 15 parts by weight of styrene-acrylate emulsion, 10 parts by weight of 2,2,4-trimethyl-1, 3-pentanediol monoisobutyrate, 3 parts by weight of sodium hydroxymethylcellulose, 2 parts by weight of nonylphenol polyoxyethylene ether, 20 parts by weight of functional filler, 2 parts by weight of 3,3-diaminodiphenyl Sulfone, 1.5 parts by weight of polytrifluoropropylmethylsiloxane, 0.5 parts by weight of methylsilsesquioxane, 5 parts by weight of montmorillonite, 10 parts by weight of polyimide microspheres, 8 parts by weight of nano titanium carbide , 40 parts by weight of water.

[0049] The functional filler is a mixture of modified silica airgel and activated carbon at a mass ratio of 2:1. The preparation method of the modified silica airgel comprises the following steps: drying and pulverizing the silica airge...

Embodiment 3

[0053] It is basically the same as Embodiment 2, the only difference is:

[0054] The preparation method of the modified silica airgel comprises the following steps: drying and pulverizing the silica airgel through a 100-mesh sieve to obtain silica airgel powder; , Add the silane coupling agent into the ethanol aqueous solution and mix evenly, carry out ultrasonic treatment for 2 hours, the ultrasonic power is 800W, the ultrasonic frequency is 20kHz, centrifuge to collect the precipitate, dry, and obtain the modified silica airgel, the silica airgel The mass ratio of powder, silane coupling agent, and ethanol aqueous solution is 15:2:60; the ethanol aqueous solution is mixed with absolute ethanol and water at a mass ratio of 40:18. The silane coupling agent is N-(2-aminoethyl)-3-aminopropyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com