Composite solid acid catalyst for preparing 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyrate and preparation method

A technology of pentanediol diisobutyrate and solid acid catalyst is applied in chemical instruments and methods, physical/chemical process catalysts, preparation of carboxylate, etc., and can solve the problem of low conversion rate of alcohol ester, low product selectivity, Produce industrial wastewater and other problems, achieve the effects of good stability, high activity and uniform pore channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

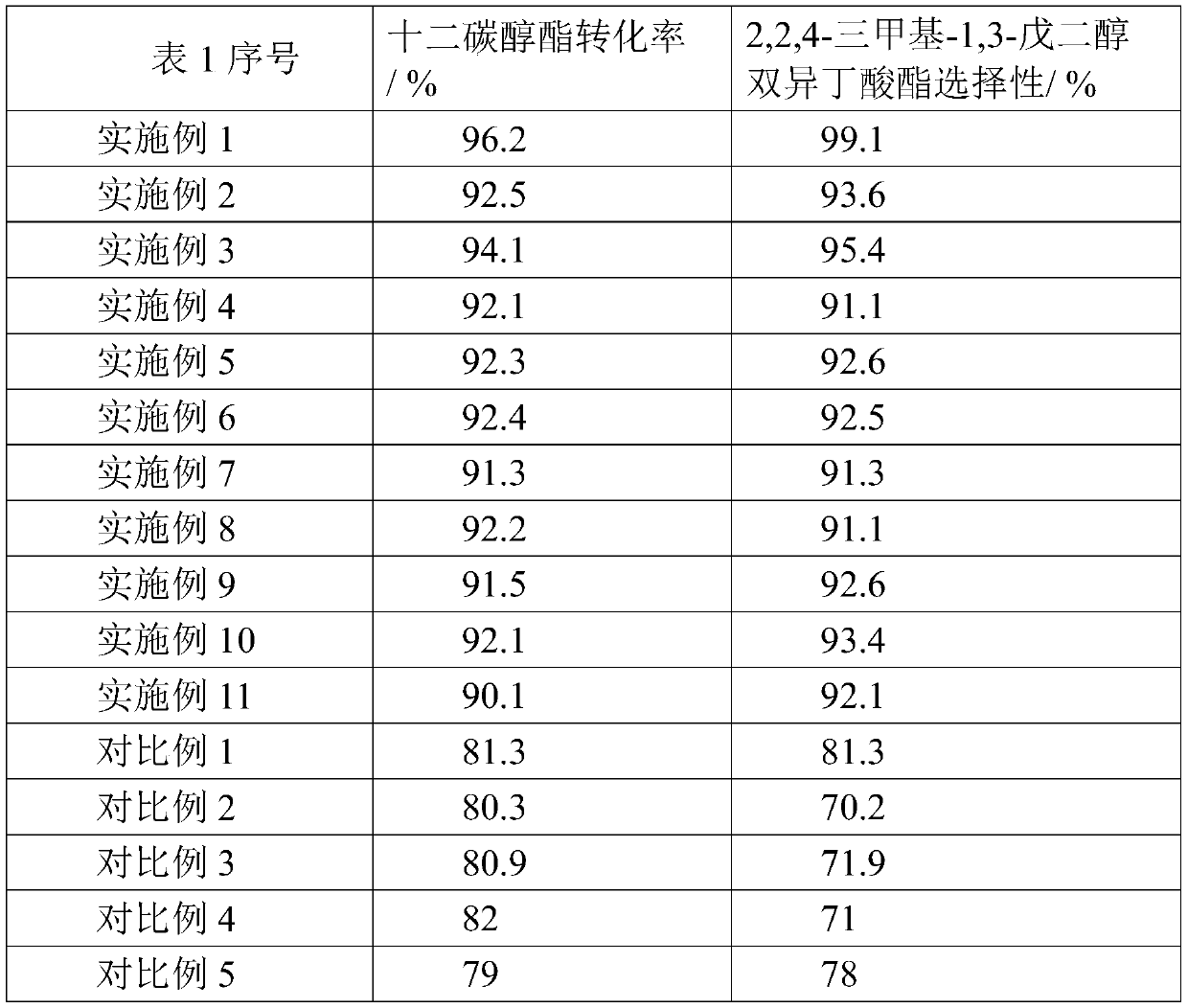

Examples

Embodiment 1

[0025] 1. Preparation of supported composite solid acid catalyst:

[0026] (1) Weigh ZrCl 4 (0.233g, 1.0mmol) and PTA (0.166g, 1.0mmol) were dissolved in DMF (50mL) to form a solution, and the mixture was stirred at room temperature in a flask for 30 minutes;

[0027] (2) Place the prepared solution in step (1) in a lined autoclave, and keep it in an oven at 120°C for 48 hours;

[0028] (3) Obtain a solid sample by filtration, and fully wash 3 times with DMF and ethanol to obtain a white powder;

[0029] (4) Dry the obtained white powder in a vacuum oven at 100°C overnight to finally obtain UiO-66;

[0030] (5) Weigh 0.5g of titanium nitrate and dissolve it in 5ml of deionized water, drop it into the UiO-66 prepared in step (4), and ultrasonicate for 30 minutes;

[0031] (6) Let it stand for 12 hours, and then dry it at 110°C to obtain the precursor;

[0032] (7) The precursor passes through the continuous NH 3 Heating from room temperature to 700 °C at a heating rate of ...

Embodiment 2

[0037] The titanium nitrate in embodiment 1 step (5) is changed into ferric nitrate, prepares catalyst, and uses ZrO 2 -Fe 2 o 3 @NC instead of ZrO in Example 1 2 -TiO 2 @NC, the rest of the steps are the same as in Example 1.

Embodiment 3

[0039] Change the titanium nitrate in embodiment 1 step (5) into copper nitrate, prepare catalyst, and use ZrO 2 -CuO@NC instead of ZrO in Example 1 2 -TiO 2 @NC, the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com