Preparation method of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate

A technology of pentanediol monoisobutyrate and trimethyl is applied in the field of preparation of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and can solve the problem of decreasing catalytic activity , difficult distillation separation and other problems, to achieve the effect of less catalyst dosage, good selectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, comprising the following steps:

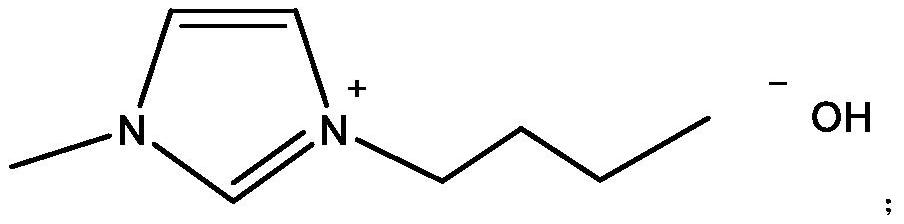

[0039] S1. In a 500ml three-neck flask equipped with a reflux condenser and a stirrer, add 100g isobutyraldehyde (1.389mol), and ionic liquid catalyst A, 10g, stir, and the reaction pressure is 0.5MPa;

[0040] S2. The temperature of the reaction system was raised to 65° C., and the stirring reaction was continued for 2 h.

[0041] S3. Cool the reaction system to room temperature, remove unreacted raw materials, and then separate by vacuum distillation to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

Embodiment 2

[0043] A preparation method of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, comprising the following steps:

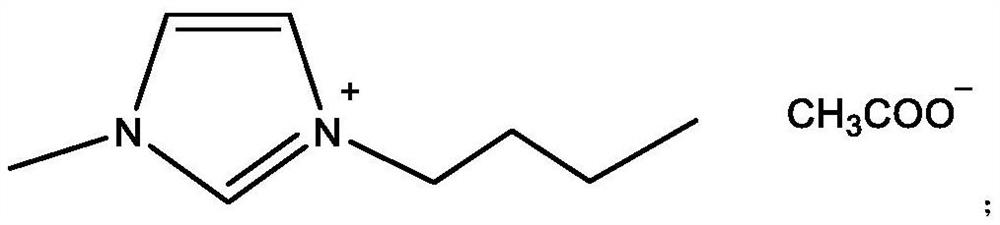

[0044] S1. In a 500ml three-neck flask equipped with a reflux condenser and a stirrer, add 100g isobutyraldehyde (1.389mol), and ionic liquid catalyst B, 12.7g, stir, and the reaction pressure is 0.5MPa;

[0045] S2. The temperature of the reaction system was raised to 65° C., and the stirring reaction was continued for 2 h.

[0046] S3. Cool the reaction system to room temperature, remove unreacted raw materials, and then separate by vacuum distillation to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

Embodiment 3

[0048] A preparation method of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, comprising the following steps:

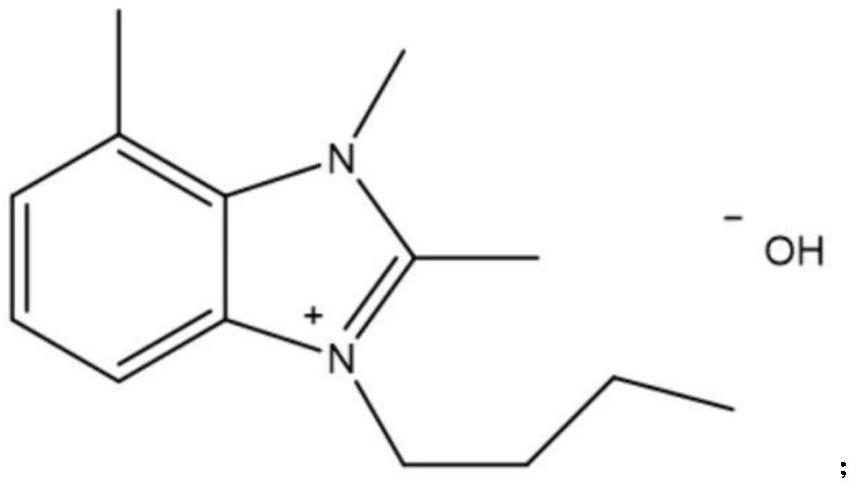

[0049] S1. In a 500ml three-neck flask equipped with a reflux condenser and a stirrer, add 100g isobutyraldehyde (1.389mol), and ionic liquid catalyst C, 20.3g, stir, and the reaction pressure is 0.5MPa;

[0050] S2. The temperature of the reaction system was raised to 65° C., and the stirring reaction was continued for 2 h.

[0051] S3. Cool the reaction system to room temperature, remove unreacted raw materials, and then separate by vacuum distillation to obtain 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com