Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

A technology of functional coatings and shell powder, which is applied in the field of coatings and can solve the problems that the comprehensive performance needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

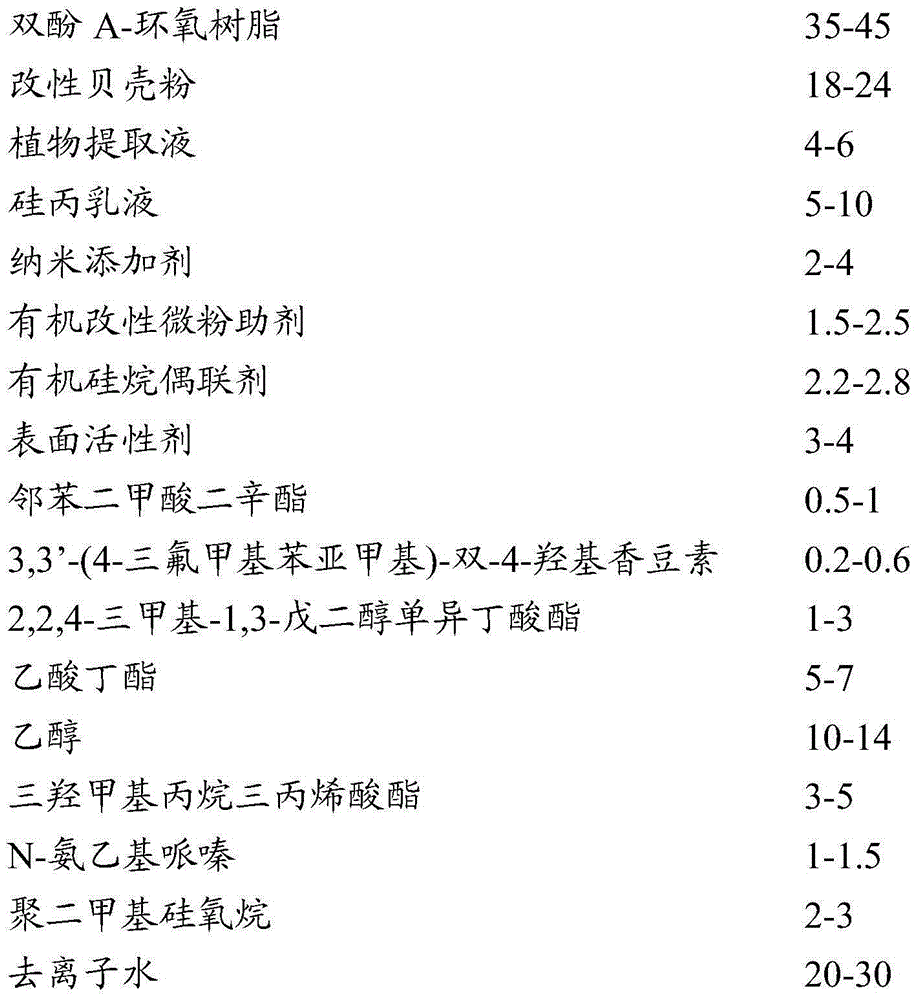

Method used

Image

Examples

preparation example 1

[0074] Preparation Example 1: Preparation of Modified Shell Powder

[0075] (1) The washed oyster shells are sequentially calcined in a three-stage gradient. The specific calcining operation is: calcining at 400°C for 12 minutes, then raising the temperature to 500°C at a heating rate of 10°C / min, and heating at this temperature Calcining at low temperature for 22 minutes; finally, heating up to 700°C at a heating rate of 5°C / min, and holding and calcining at this temperature for 35 minutes; after the calcination, naturally cool to room temperature to obtain calcined shells;

[0076] (2) crushing and grinding the calcined shells, and passing through a 300-mesh sieve to obtain shell powder;

[0077] (3) Add diethanolamine and absolute ethanol to n-butyl titanate (wherein the molar ratio of n-butyl titanate to diethanolamine is 1:0.15, the amount of absolute ethanol can be properly selected), to obtain a solution, Then ultrasonically disperse for 25 minutes to obtain a transpar...

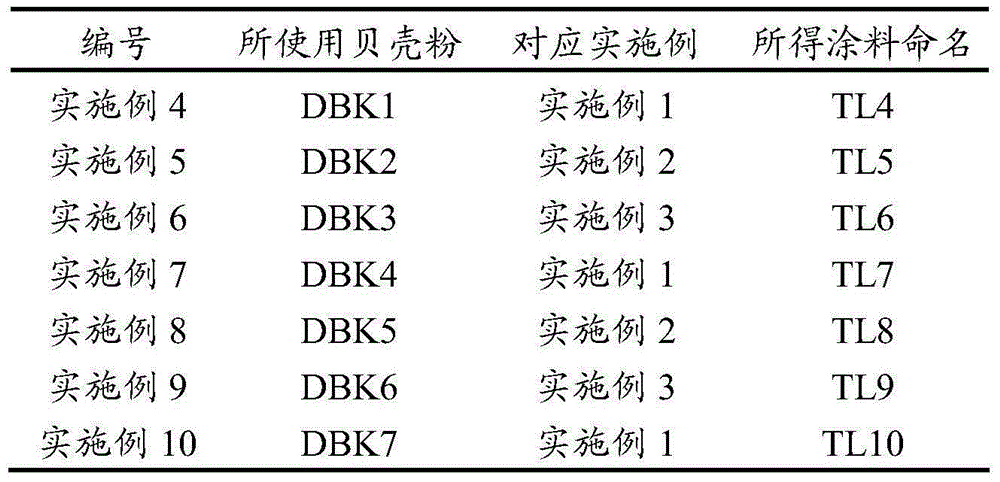

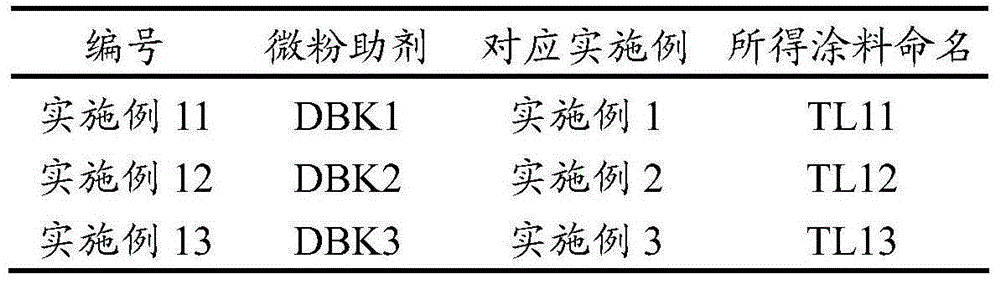

preparation example 11-17

[0079] Preparation Example 1.1-1.7: Preparation of Modified Shell Powder

preparation example 11

[0080] Preparation Example 1.1: Except modifying step (1) of Preparation Example 1 to "calcine the cleaned oyster shells, the specific calcining operation is: calcining at 400°C for 119 minutes; after the calcination, cool naturally to room temperature to obtain Except for the "shell" after calcination, other operations were unchanged, that is, the three-stage gradient calcination was not carried out, but only the original total time of calcination at 400 ° C. The obtained modified shell powder was named DBK1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com