Patents

Literature

46results about How to "Efficient synthesis process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

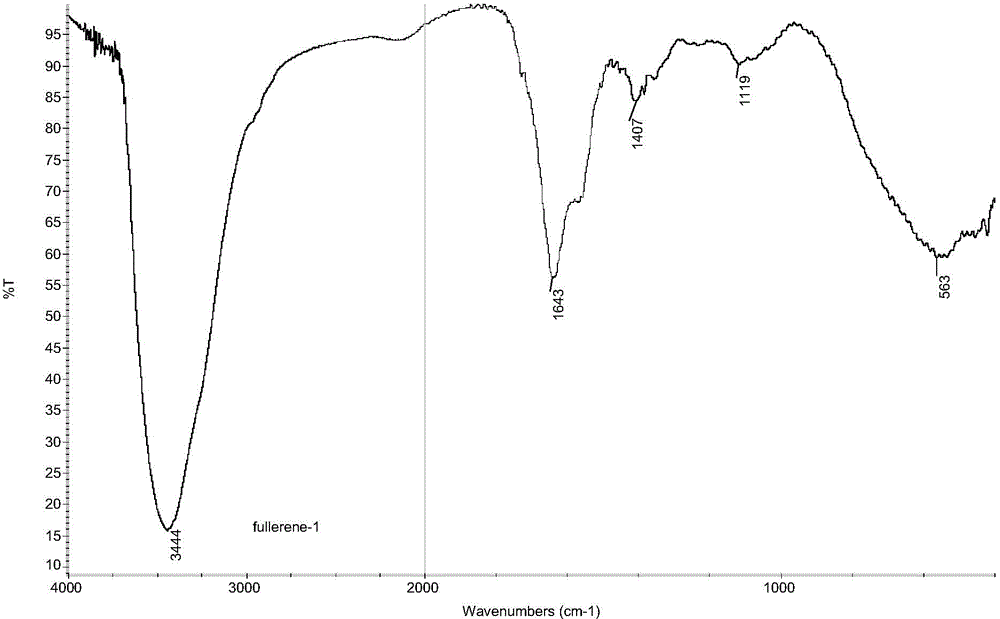

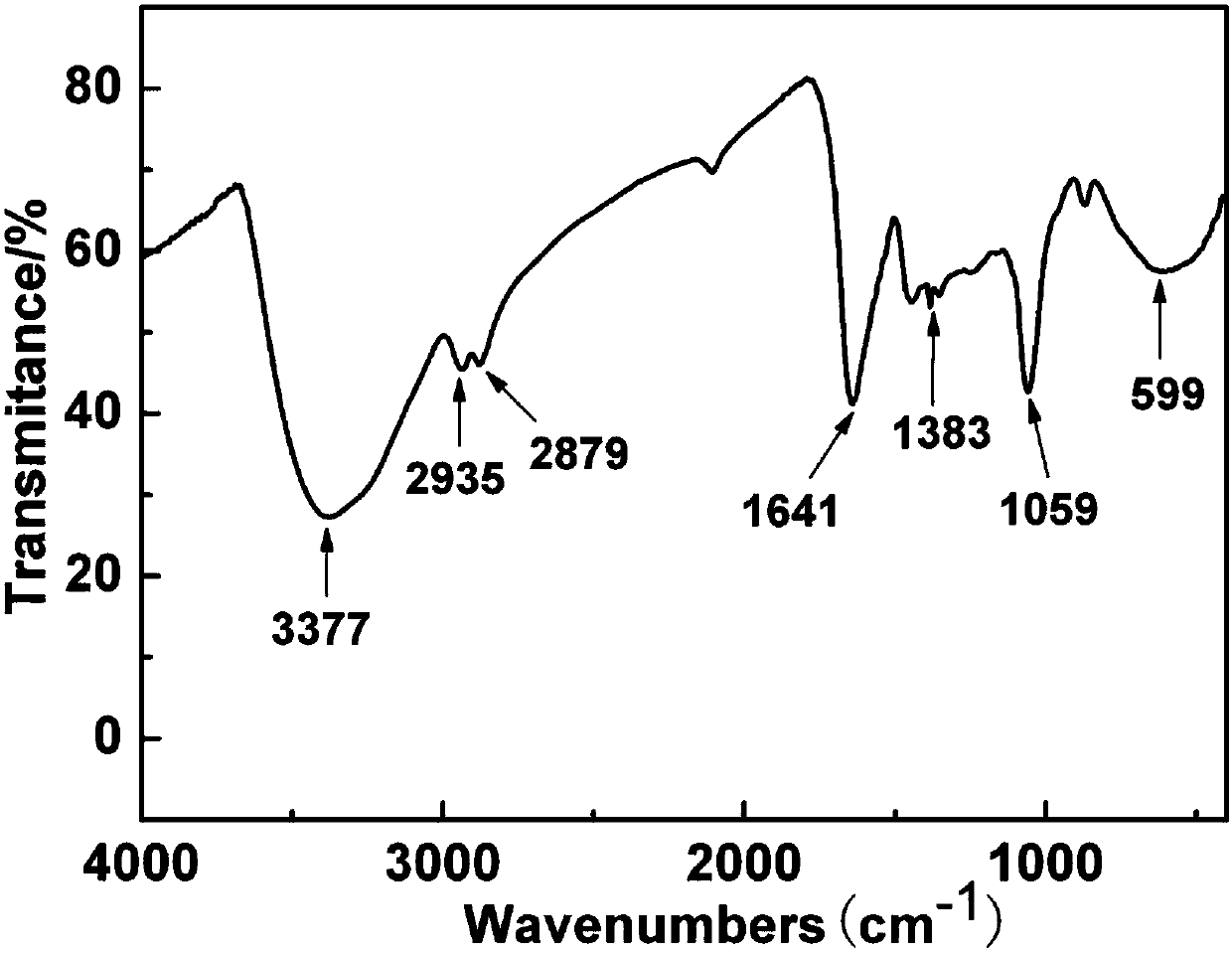

Preparation method of fullerol

ActiveCN104555977AThe synthesis process is simpleSimple Purification and Separation MethodOrganic solventRoom temperature

The invention discloses a preparation method of fullerol. The preparation method comprises the following steps: (1) dissolving fullerene in an organic solvent, wherein the organic solvent is selected from an organic matter which is higher than water in relative density, immiscible with water and can dissolve fullerene; then, respectively putting fullerene C2n which is dissolved in the organic solvent, a hydroxylation reagent aqueous solution with appointed concentration and a phase transfer catalyst into a reactor and layering, wherein a water phase is in the upper layer while the organic solvent in the lower layer; (2) opening a reaction system without isolating air, and after continuously stirring for 10-72 hours at room temperature, stopping reaction; (3) separating liquids, after washing the organic solvent with water, recovering for later use, and recovering the solvent from the water phase to obtain a cured fullerol coarse product; and (4) refining the fullerol coarse product to obtain solid pure fullerol. The synthetic process disclosed by the invention is simple, efficient, convenient to operate and easy for scaled production, and the prepared fullerol shows a good electron paramagnetic spinning property.

Owner:HENAN AGRICULTURAL UNIVERSITY

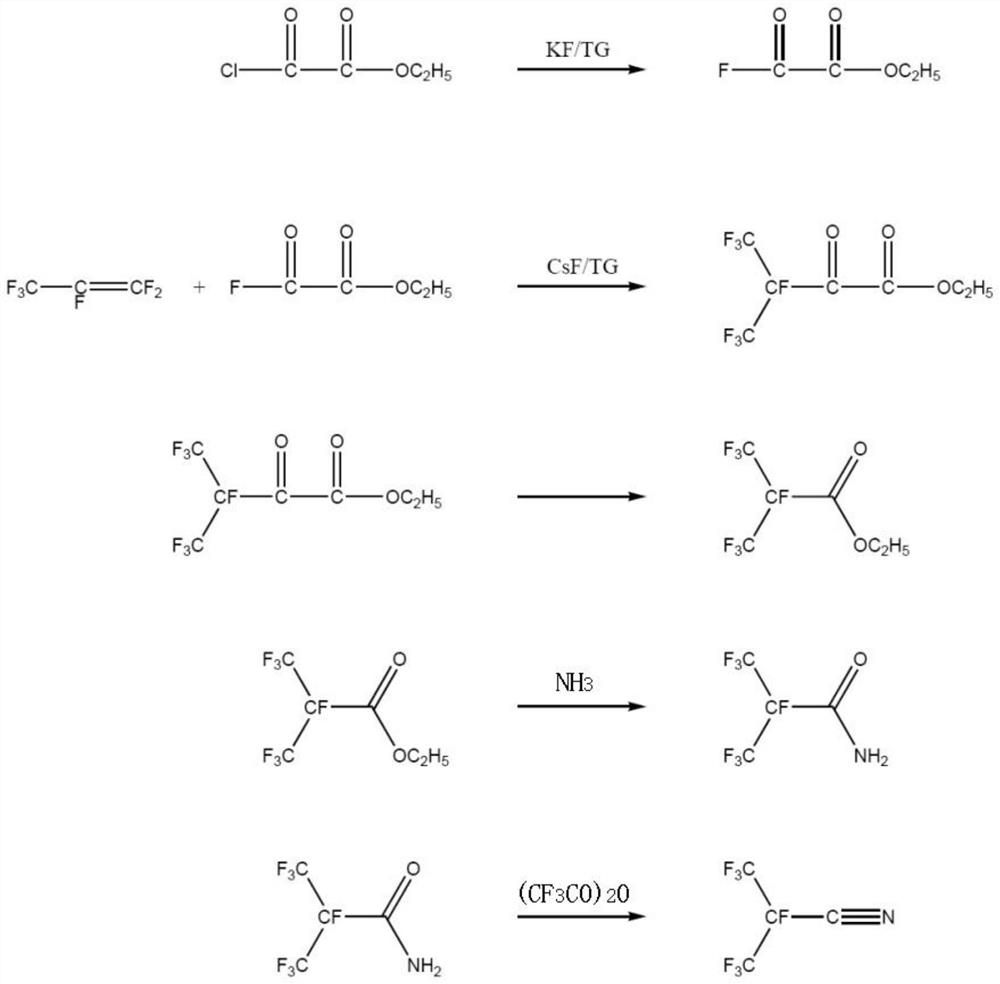

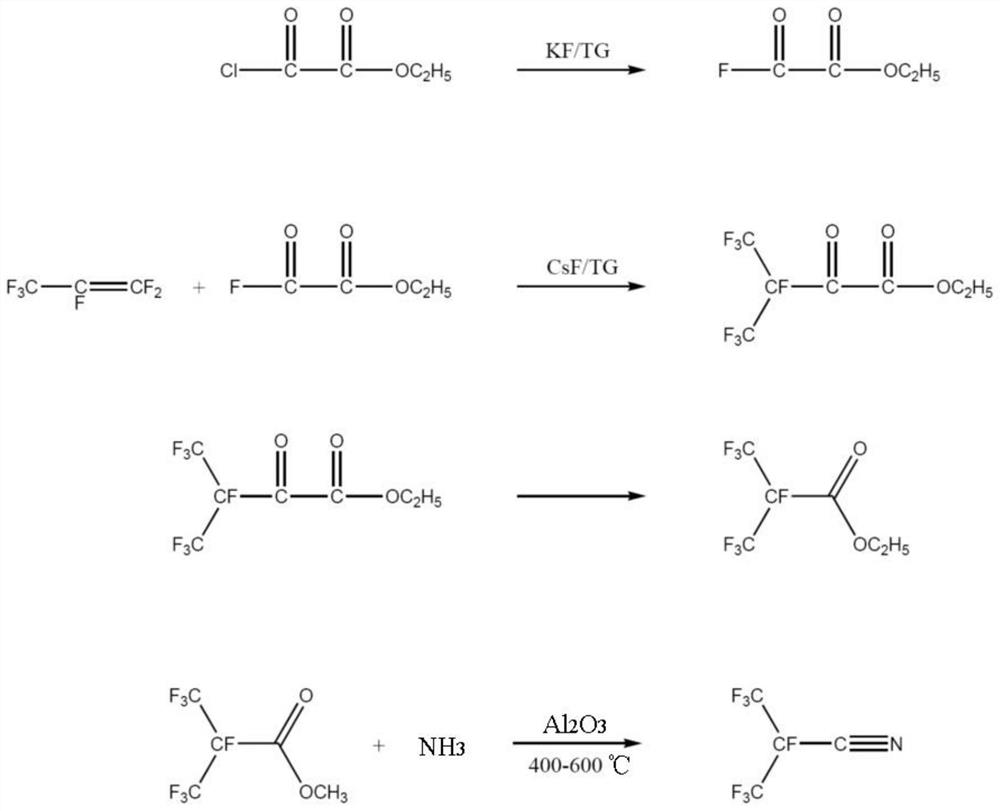

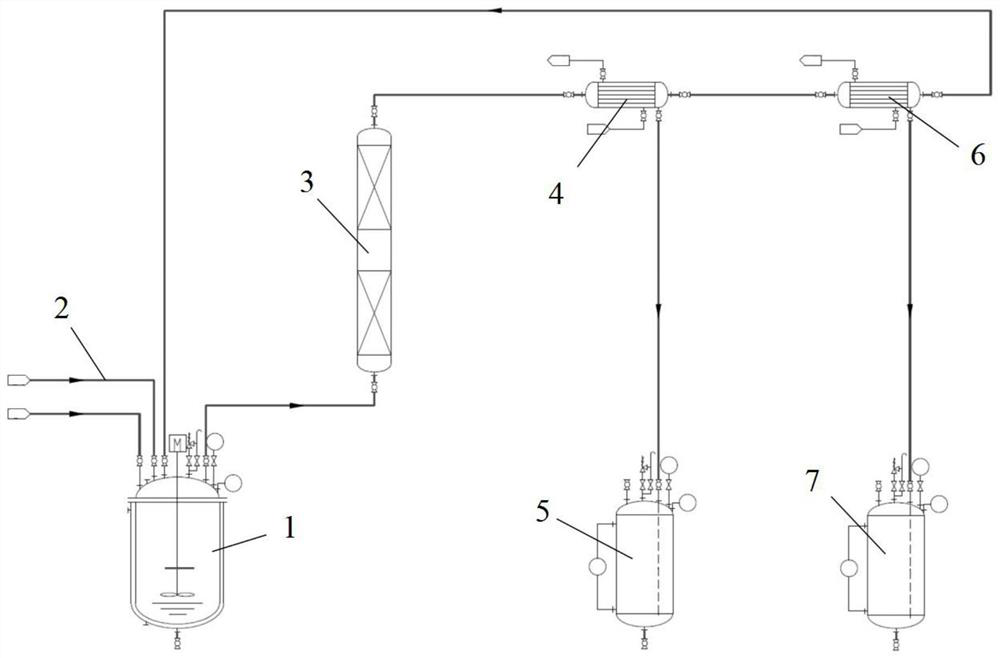

Synthetic method of perfluoroisobutyronitrile

PendingCN111825568ASynthetic process safetyEfficient synthesis processOrganic compound preparationCarboxylic acid esters preparationOxalyl fluoridePtru catalyst

Owner:福建省漳平市九鼎氟化工有限公司

Method for preparing cellulose carbamate through liquid-solid-phase reaction

The invention discloses a method for preparing cellulose carbamate through a liquid-solid-phase reaction. The method comprises the following step: performing esterification reaction on cellulose pulp or activated cellulose pulp and urea as raw materials in a high-boiling-point nonprotonic strong-polarity solvent such as dimethyl formamide (DMF), dimethylacetamide (DMAc), dimethyl sulfoxide (DMSO) or N-methylpyrrolidone (NMP) to synthesize cellulose carbamate. In the process of preparing cellulose carbamate by adopting a liquid-solid-phase method, the used solvent is low in toxicity and easy to recover; the preparation process is simple and convenient, environment-friendly, safe, and controllable; prepared cellulose carbamate can be dissolved in a NaOH solution to form a stable solution and can be used for preparing regenerated cellulose fibers, membranes and the like.

Owner:TIANJIN POLYTECHNIC UNIV

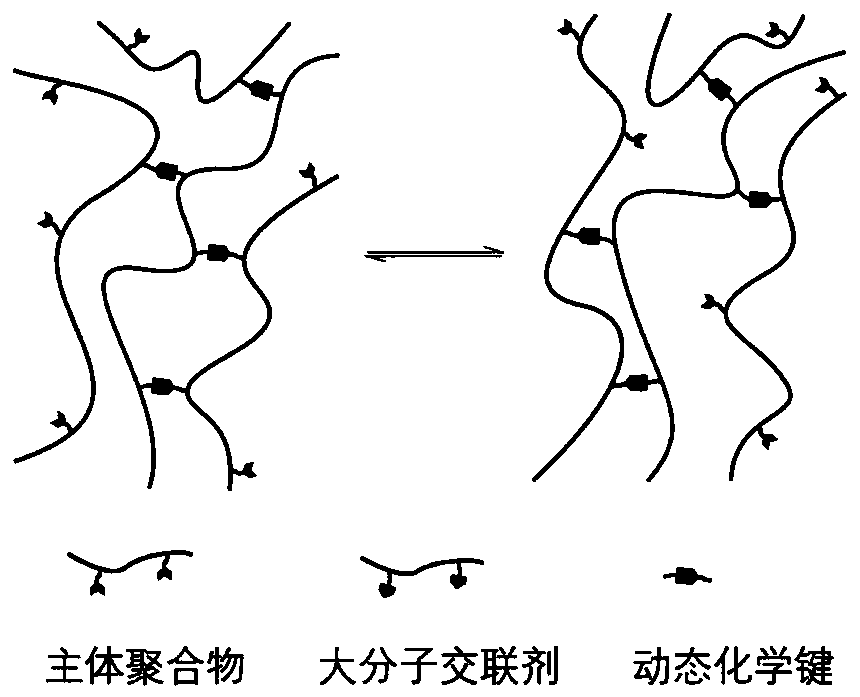

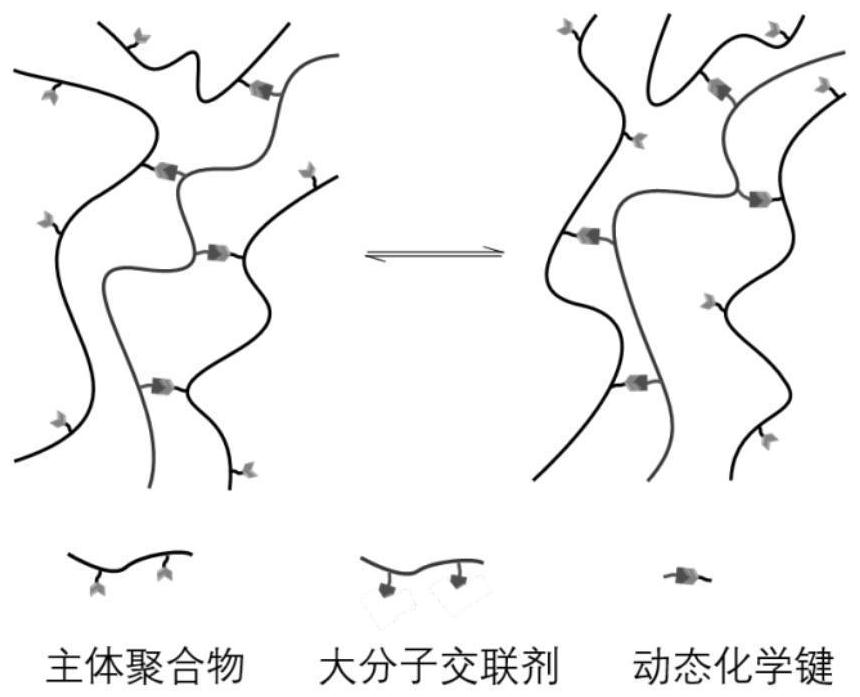

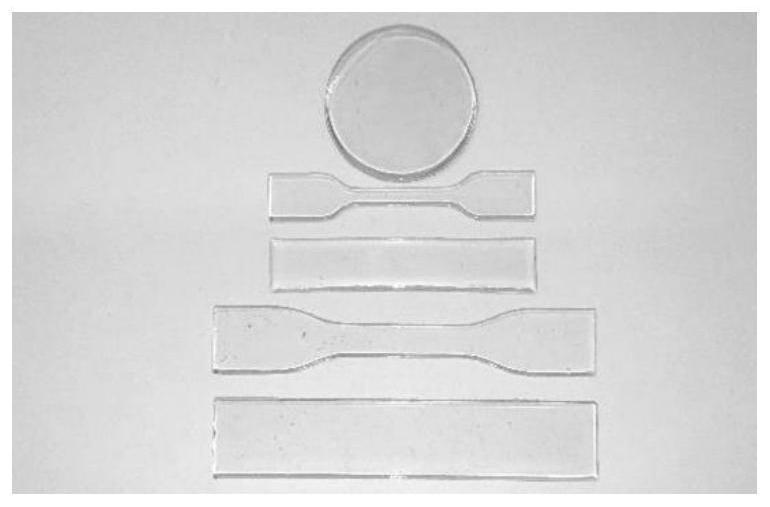

Synthesis method of reproceesable thermosetting polymer

ActiveCN110669225AImprove mechanical propertiesAvoid phase separationPerylene derivativesAcrylic acid

The invention belongs to the technical field of polymer synthesis, and in particular relates to a synthesis method of a reproceesable thermosetting polymer. The method adopts a macromolecular cross-linking agent and utilizes reversible cross-linking effect between macromolecular chains and macromolecular chains to synthesize a reproceesable cross-linked polymer. Specifically, the method includes two parts: synthesis of a functionalized copolymer and crosslinking and curing of the copolymer. The copolymer takes vinyl monomers such as (meth) acrylic acid (ester), acrylamide, styrene and derivatives thereof as main components and vinyl monomers having crosslinkable functional groups as secondary components; cross-linking and curing are realized through dynamic chemical bonds formed between functional groups. Compared with thermoplastic materials with similar chemical compositions, the material synthesized by the invention has better mechanical strength, solvent resistance, creep resistance, aging resistance and the like.

Owner:FUDAN UNIV

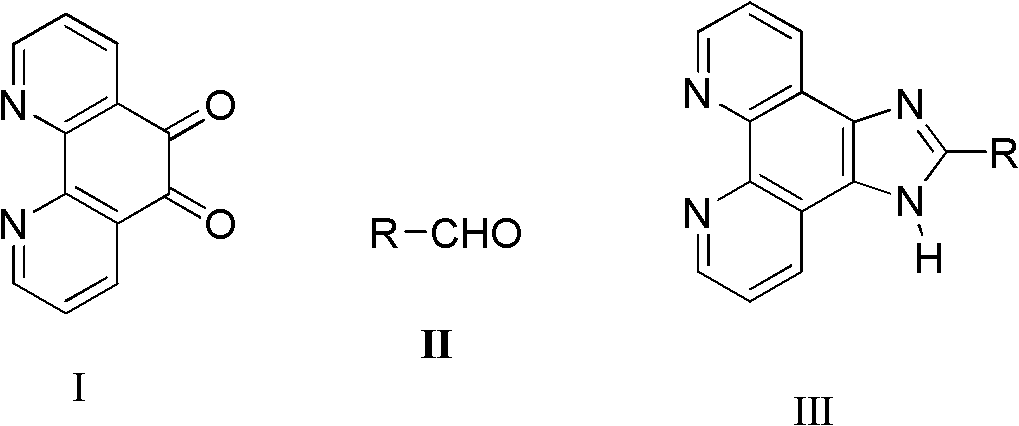

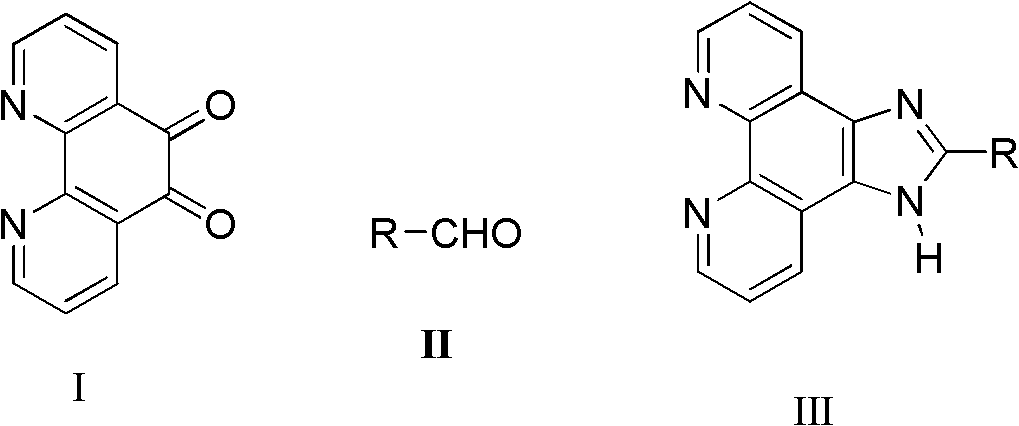

Synthetic process of imidazo phenanthroline compound

The invention discloses a synthetic process of an imidazo phenanthroline compound shown in a formula (III), which comprises the following steps: mixing phenanthroline diketone shown in a formula (I) with aldehyde and ammonium salt shown in a formula (II), and conducting condensation reaction after evenly grinding the mixture, thus obtaining the imidazo phenanthroline compound shown in the formula(III) after complete reaction. In the synthetic process, without the presence of catalyst acid, the synthesis of an imidazole ring is realized by grinding and reacting the phenanthroline diketone with the aldehyde and the ammonium salt under solvent-free conditions, so that the synthetic process has the characteristics of being green and efficient, and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

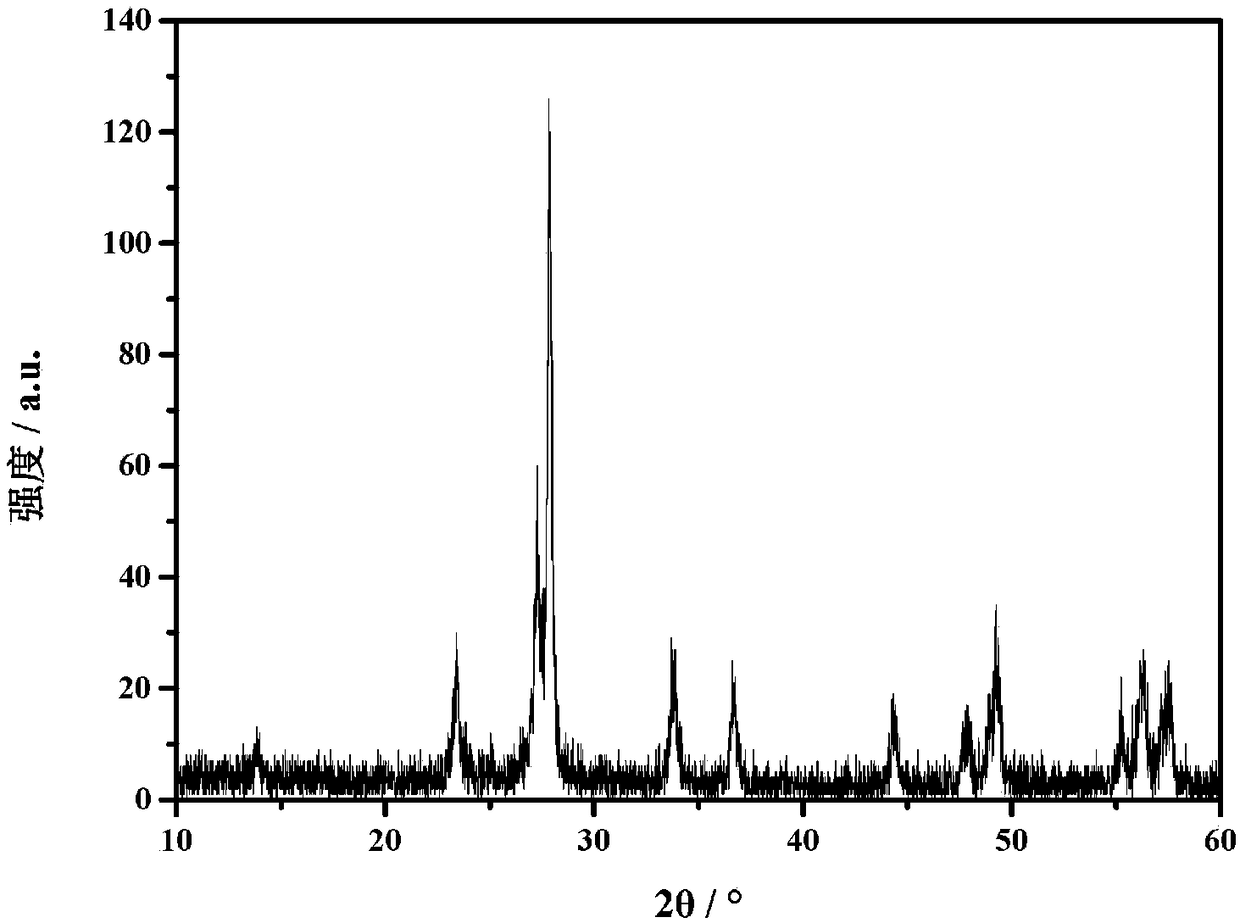

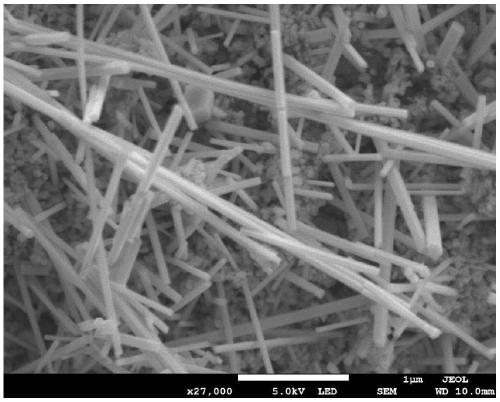

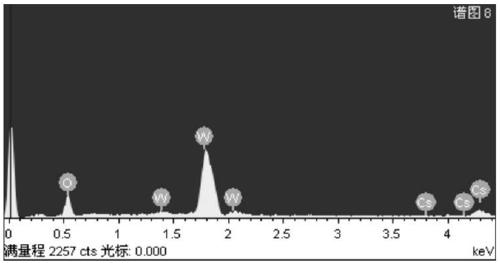

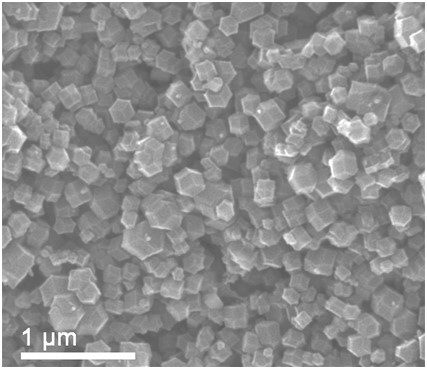

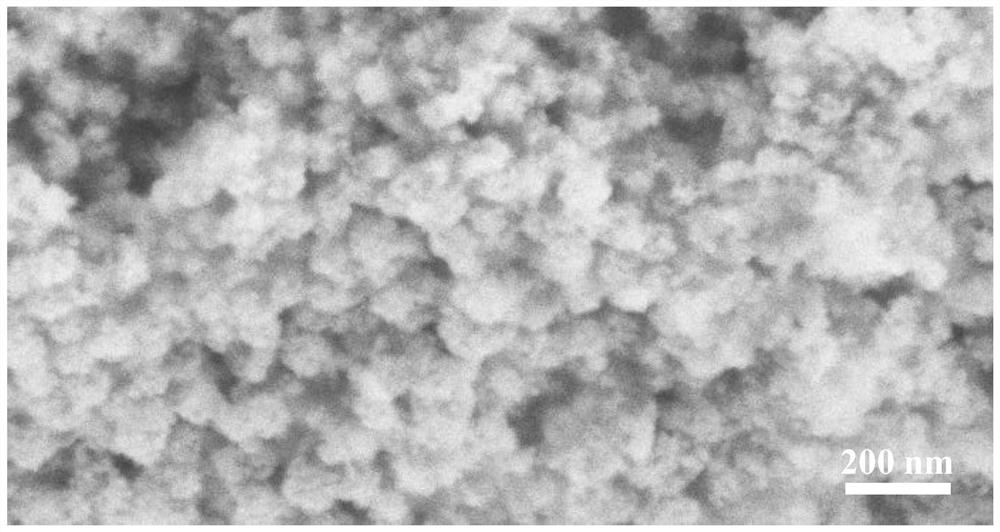

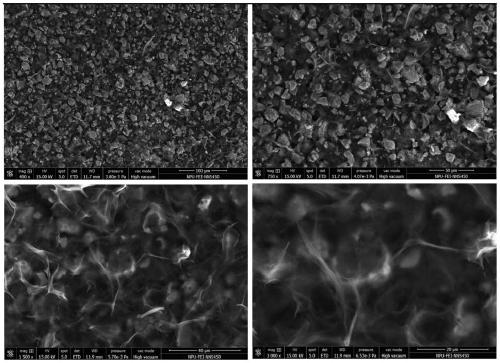

Alkali tungsten bronze nanorod and preparation method and application thereof

InactiveCN108946812ASmall particle sizeGood dispersionNanotechnologyCoatingsWater bathsCrystallinity

The invention relates to an alkali tungsten bronze nanorod, a preparation method and application thereof, and belongs to the technical field of nanometer materials. The preparation method of the alkali tungsten bronze nanorod comprises the following steps: dissolving tungsten powder in cold bath by using hydrogen peroxide, stirring till the tungsten powder completely reacts, filtering, stirring and heating in water bath to obtain sol; adding a dispersing agent to the sol, stirring uniformly, adding an alkali metal salt, continuing to stir uniformly to obtain the gel, drying the gel to obtain aprecursor, and calcining the precursor in a non-oxidizing atmosphere to obtain the alkali tungsten bronze nanorod. The alkali tungsten bronze nanorod prepared by the method has small particle size, good dispersion, good crystallinity and good reproducibility; the synthesis process of the alkali tungsten bronze nanorod is simple and efficient; the yield of the alkali tungsten bronze nanorod is great; raw materials are easily available; and the problem that alkali tungsten bronze nanometer materials cannot be industrialized is effectively solved.

Owner:SHENZHEN UNIV

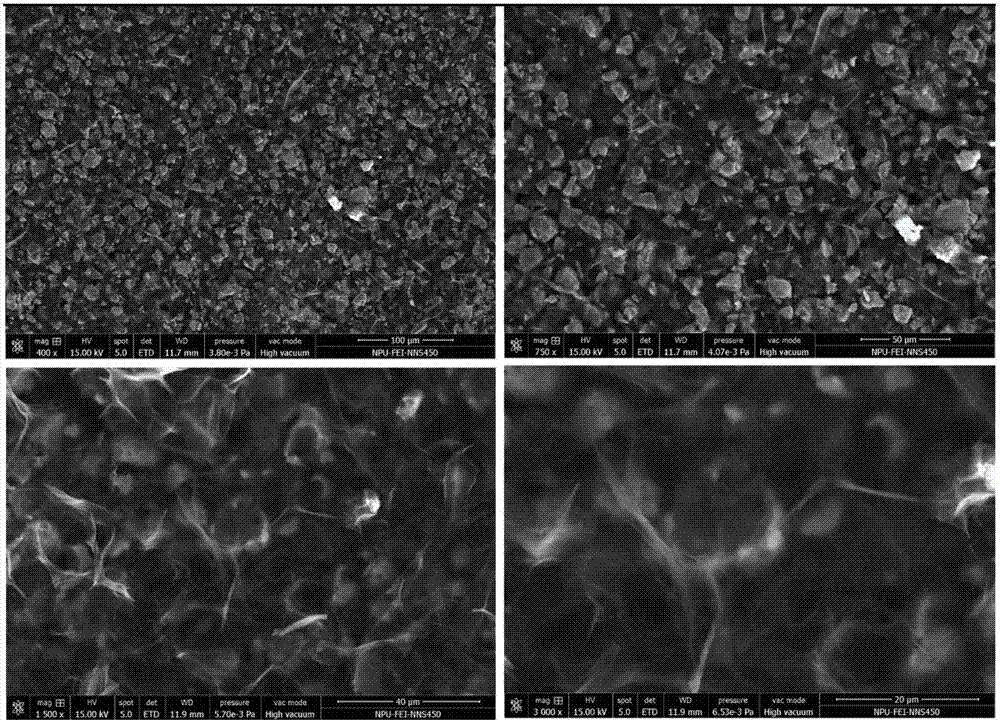

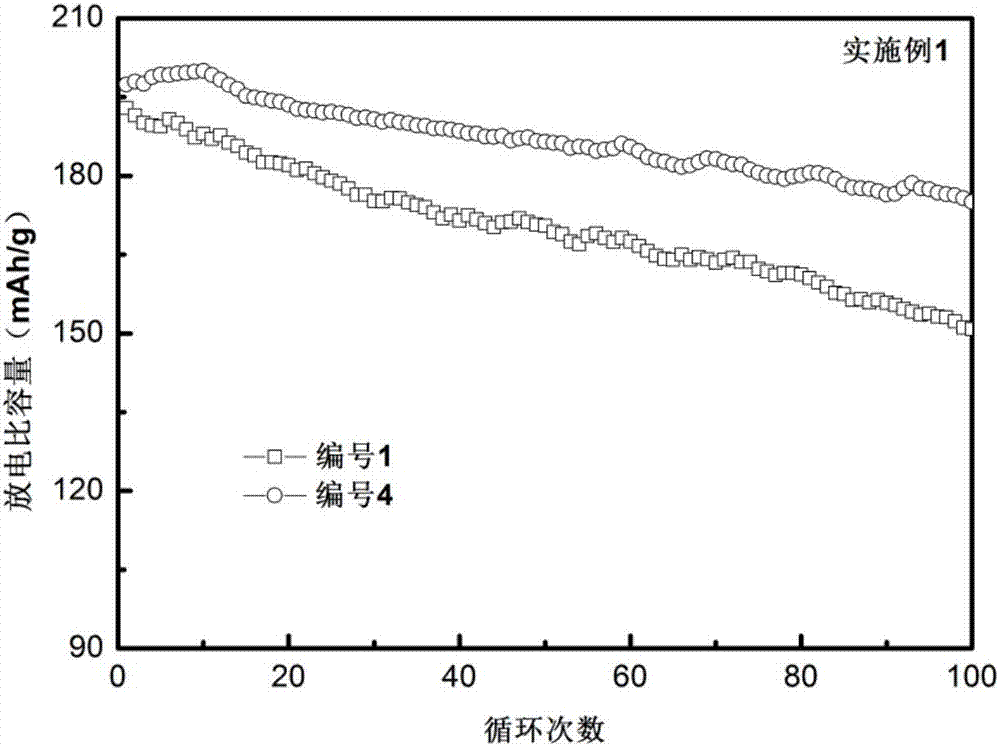

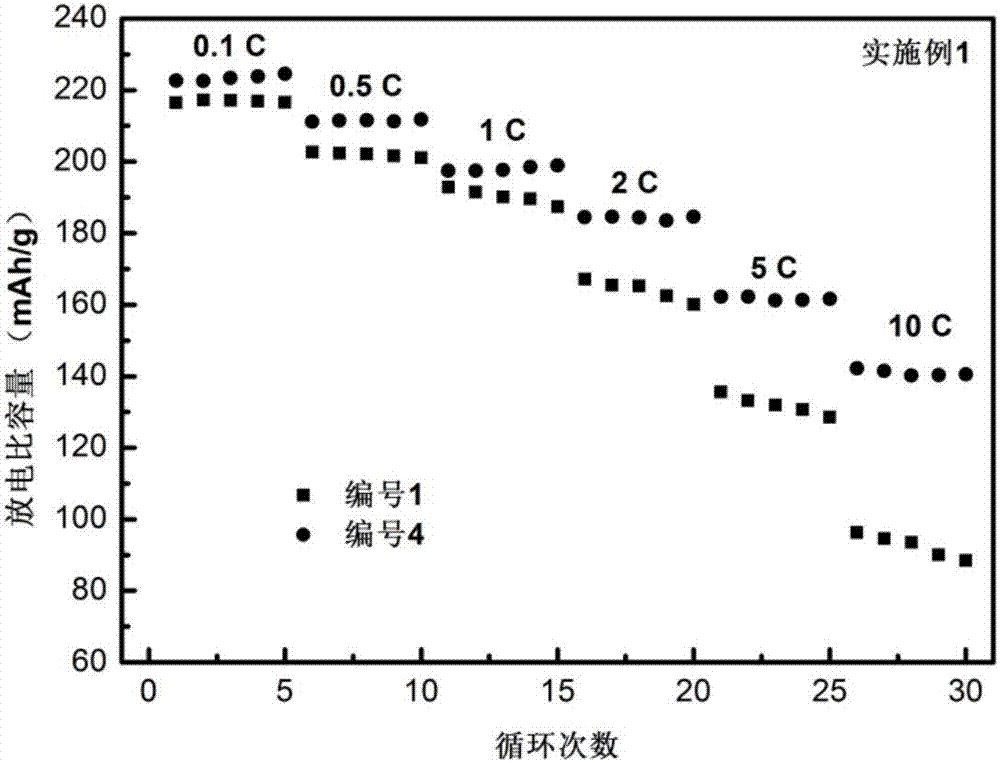

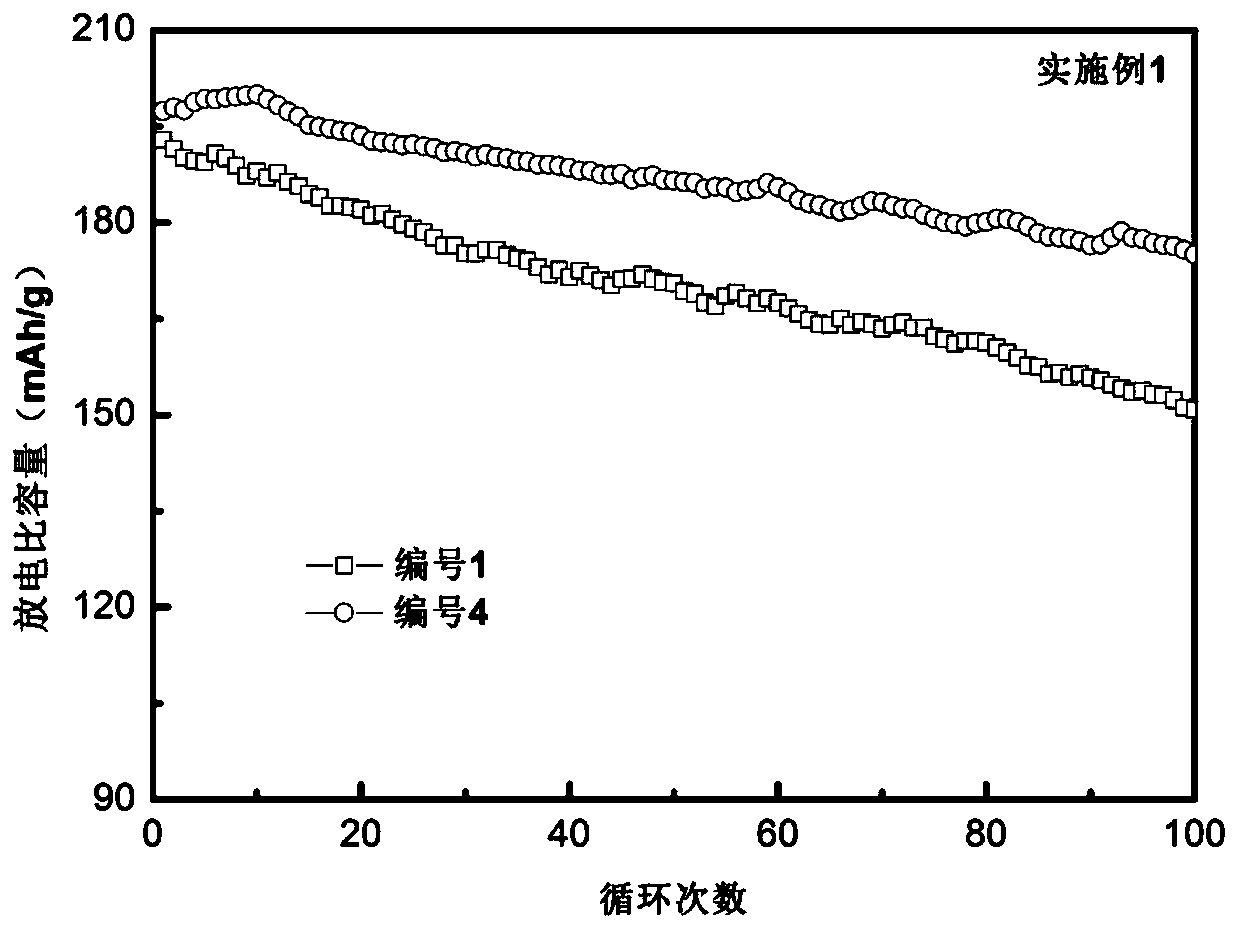

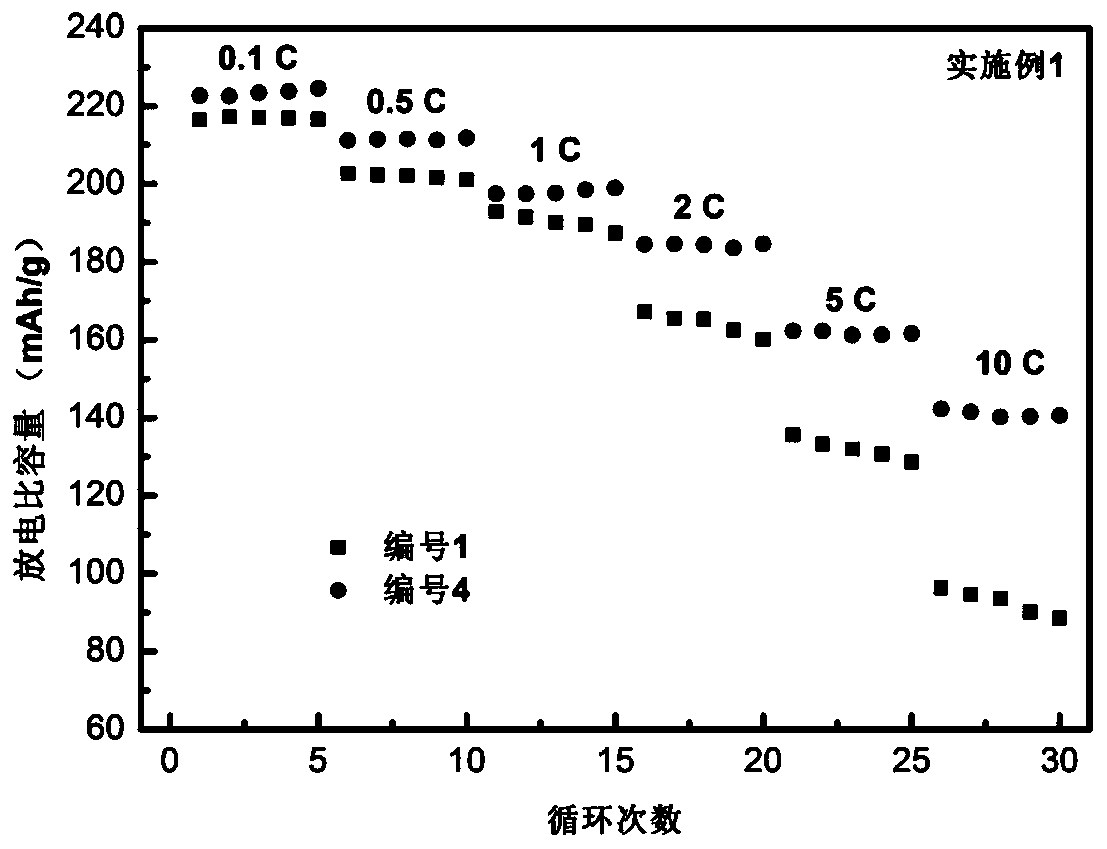

Lithium ion battery and preparation method thereof

ActiveCN107069043AShort processEasy to operateElectrode carriers/collectorsSecondary cellsButton batteryLithium-ion battery

The invention provides a lithium ion battery and a preparation method thereof. The preparation method of the lithium ion battery comprises the following steps: a ternary material is mixed with a conductive agent and a polymer binder, a mixture is applied to aluminum foil and dried, and a positive plate is obtained; graphene oxide is dispersed in a dispersing agent, a graphene oxide dispersion is obtained and applied to the positive plate, a graphene oxide coating is formed, and a graphene oxide modified positive plate is obtained; a button cell is formed by assembling the graphene oxide modified positive plate, a separator, an electrolyte, a lithium plate and a nickel net in a glove box; the button cell is subjected to electrochemical reduction, and the lithium ion battery is obtained. The positive pole of the lithium ion battery is graphene oxide modified positive pole made of the ternary material, the electronic conductivity is high, and cycle performance and rate capability are improved substantially.

Owner:湖南豪曼新能源科技有限公司

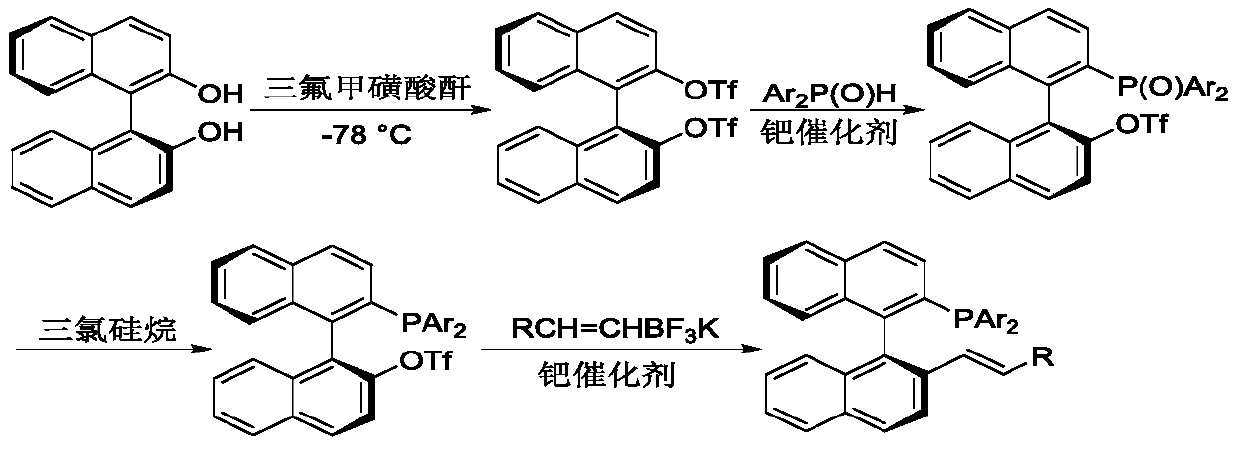

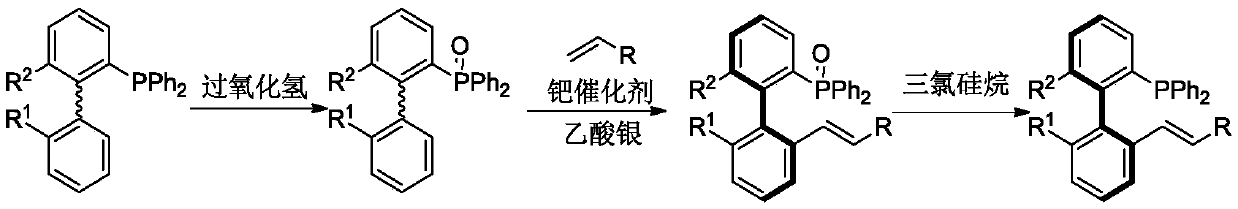

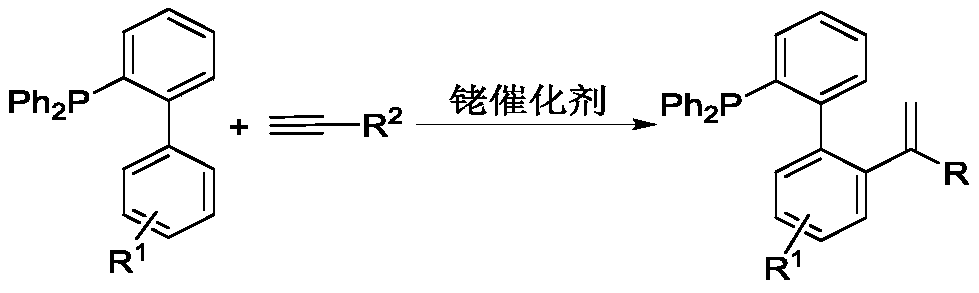

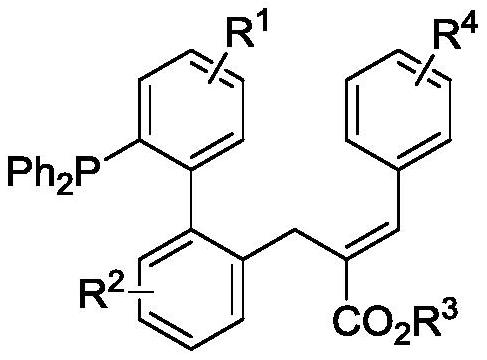

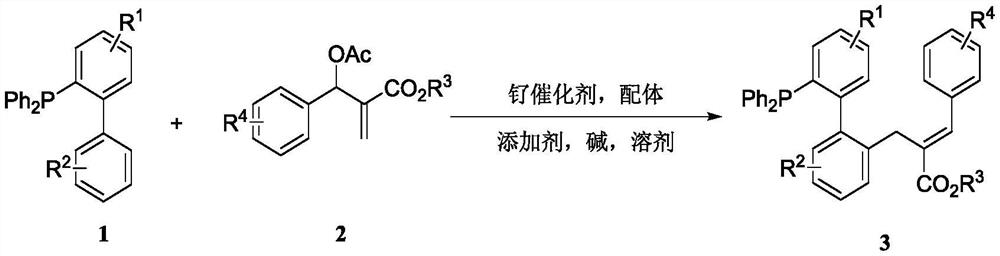

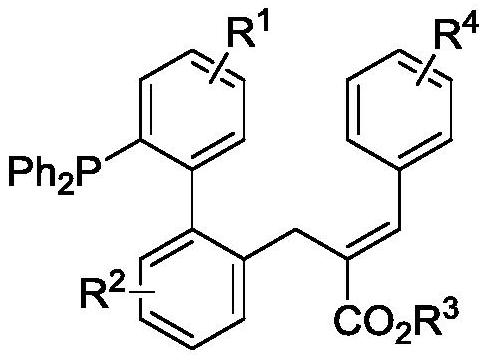

Synthesis method of bidentate phosphorene ligand

ActiveCN111592567AThe synthesis steps are simpleEfficient synthesis processGroup 5/15 element organic compoundsArylProcess equipment

The invention discloses a synthesis method of a bidentate phosphorene ligand, and belongs to the technical field of organic chemistry. Biaryl-2-(disubstituent) phosphine 1 and an alkenyl bromide 2 areadopted as raw materials, and react in an organic solvent at 40-180 DEG C in the presence of a ruthenium catalyst, a ligand and an alkali to obtain the bidentate phosphorene ligand 2-(disubstituent)phosphine-2'-olefin 3. The synthesis steps are simple, and the method can be completed only through one step, active functional groups or complex reaction steps do not need to be introduced to construct C-C bonds in the synthesis process, the synthesis process is efficient, and the operation process is simple; and raw materials are cheap and easy to obtain, the product yield reaches 93%, the requirement for process equipment is low, the reaction process is more environmentally friendly, and potential large-scale industrial production and application prospects are achieved.

Owner:HUBEI UNIV

Process for synthesizing ethyl chloride

ActiveCN106336341AAvoid it happening againAvoid pollutionPhysical/chemical process catalystsHalogenated hydrocarbon preparationDistillationReaction temperature

The invention discloses a process for synthesizing ethyl chloride. In a closed reactor, an ethyl chloride product can be obtained from ethanol and hydrogen chloride gas under the catalytic effect of AlCl3-ZnCl2 double component catalyst by gradually heating for reaction, releasing step by step and recovering. The high activity of AlCl3-ZnCl2 double component catalyst is used in the method, reaction temperature and by-product diethyl ether are reduced, and the yield of the ethyl chloride is increased to above 95%; by the use of the hydrogen chloride for replacement of industrial hydrochloric acid, mother liquor and distillate are directly continuously applied, energy consumption for distillation distillate recovery and hydrogen chloride loss are effectively reduced, environment pollution caused by production of a lot of high salt wastewater and organic waste acid can be avoided; in addition, by use of a closed staged heating reaction way, a catalytic substitution reaction is performed in a liquid phase system, substrate contact reaction time is increased, ethanol conversion rate reduction caused by too fast escaping of excessive hydrogen chloride from the reactor can be avoided, the consumption increase of the hydrogen chloride is avoided, and the atmospheric pollution is reduced.

Owner:ANHUI JINGHE IND

Synthesis method of alkyl phosphinic acid and aluminium salt thereof under normal-pressure mild condition

InactiveCN108864182AAvoid concentrationSimple and fast operationGroup 5/15 element organic compoundsSynthesis methodsPhosphoric acid

The invention discloses a synthesis method of alkyl phosphinic acid and aluminium salt thereof under a normal-pressure mild condition. A hypophosphorous acid solution and alcohol are adopted as raw materials, by means of an organic solvent which has an azeotropy point with water, through in-situ reaction of olefin, the alkyl phosphinic acid is synthesized, after reaction is completed, the pH is adjusted, an aluminium salt solution is added, and alkyl aluminum hypophosphite precipitates as a white precipitate. According to the synthesis method of the alkyl phosphinic acid and the aluminium saltthereof under the normal-pressure mild condition, operation is simple and convenient, concentration of the hypophosphorous acid solution is avoided, energy consumption is reduced, and the efficiencyis improved; the alcohol not only can be used as the raw material for in-situ reaction of the olefin, but also can promote homogeneous system generation of the reaction, so that inconvenience of easyauto-agglutination brought by using acetic acid as a solvent and using olefin as an oligomer is eliminated; by using the solvent co-boiling with water, the purposes of solvent recovery and recycle areachieved, and it is easier to obtain the high-quality salt-forming product; the method is implemented under the normal-pressure mild condition, a security coefficient is high, the reaction risk is small, a synthesis technology is more energy-saving, environmentally friendly and efficient, and industrial production is easier to achieve.

Owner:JINAN TAIXING FINE CHEM

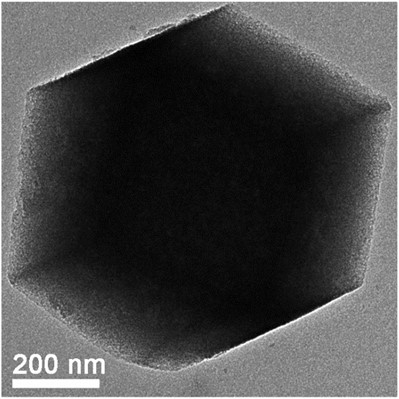

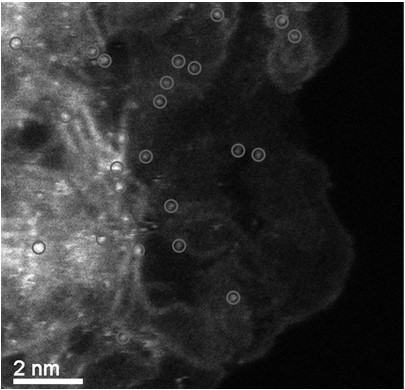

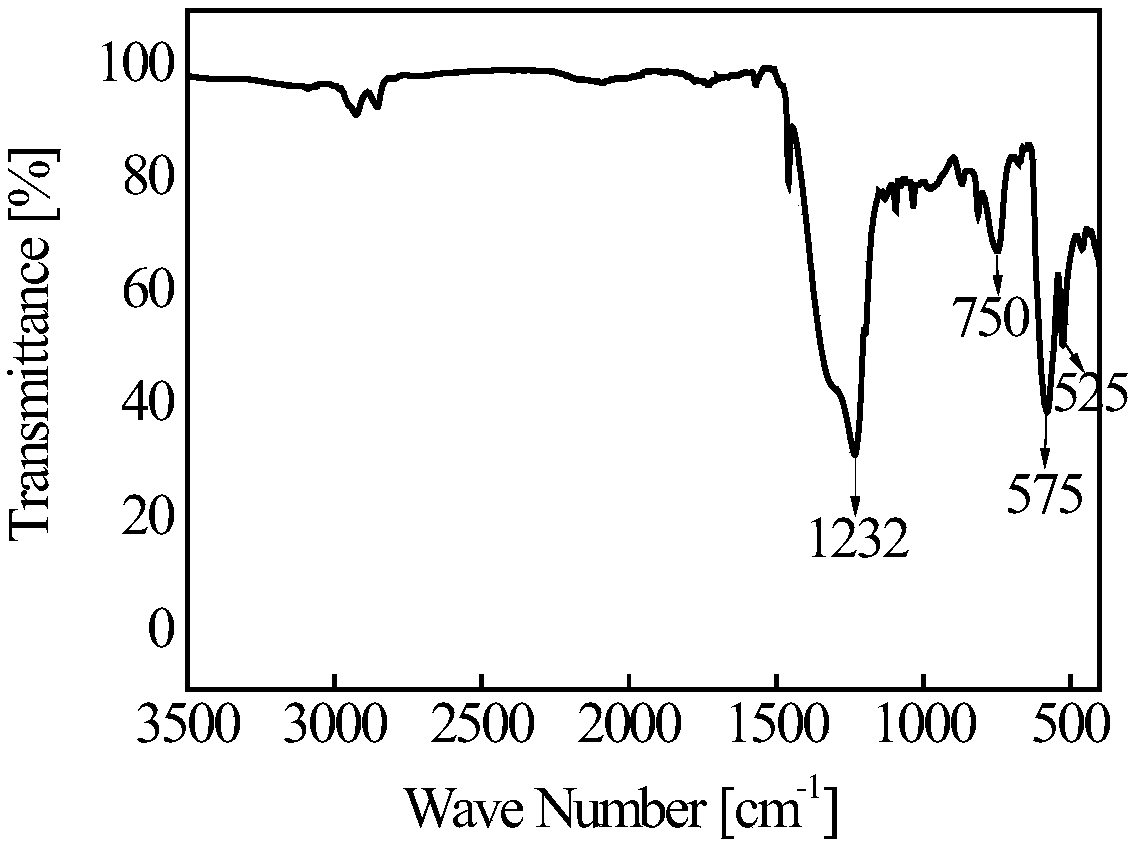

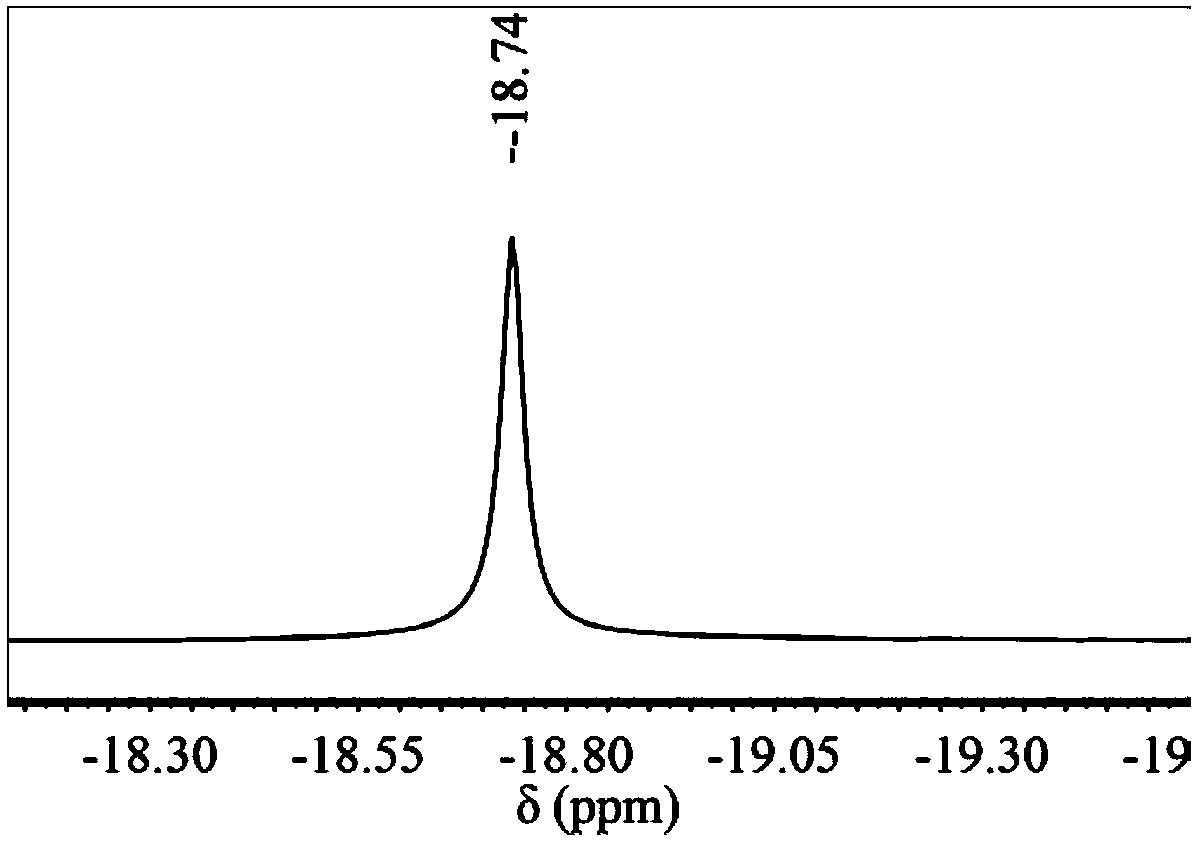

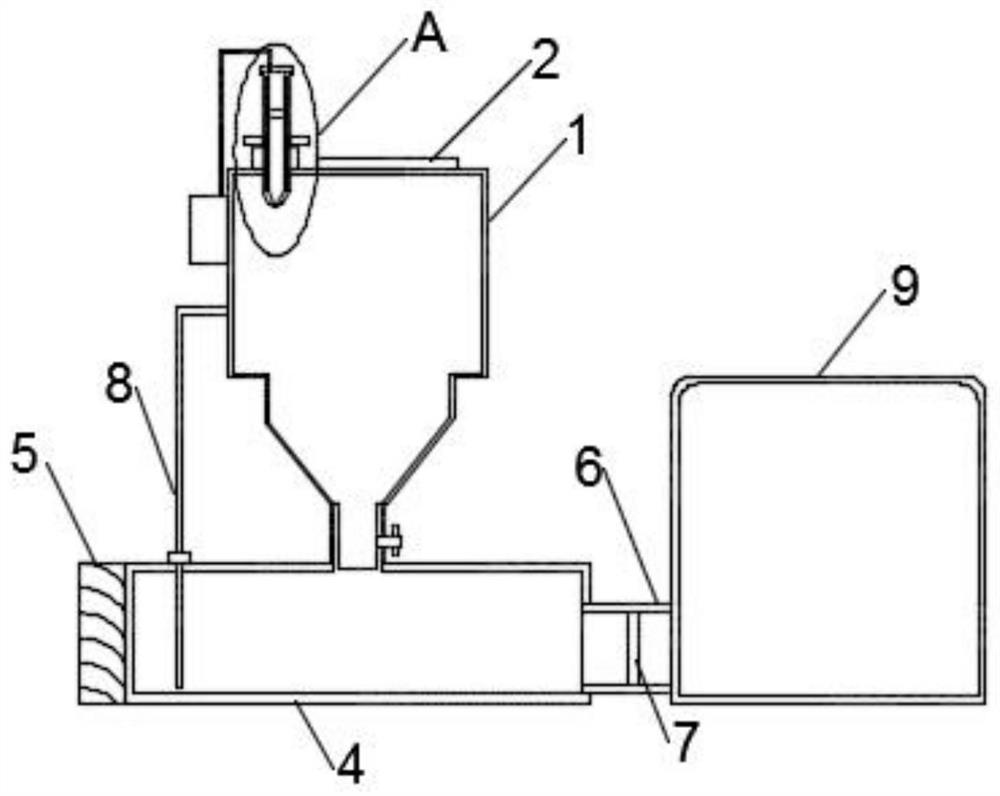

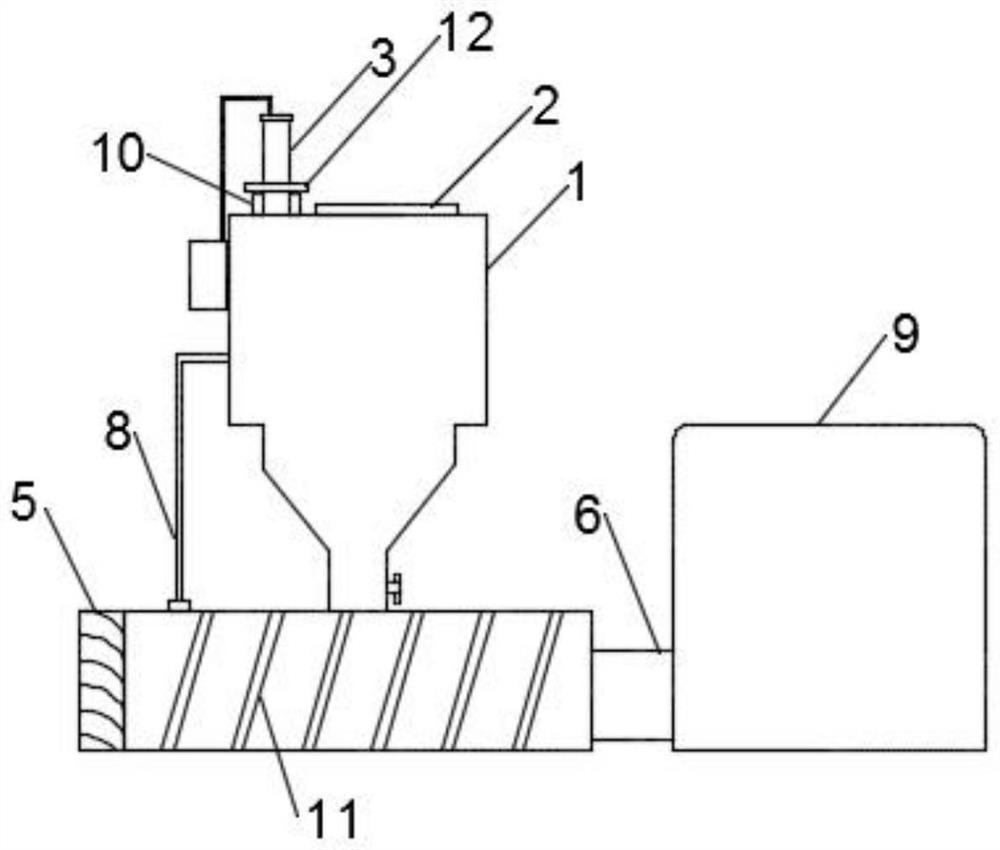

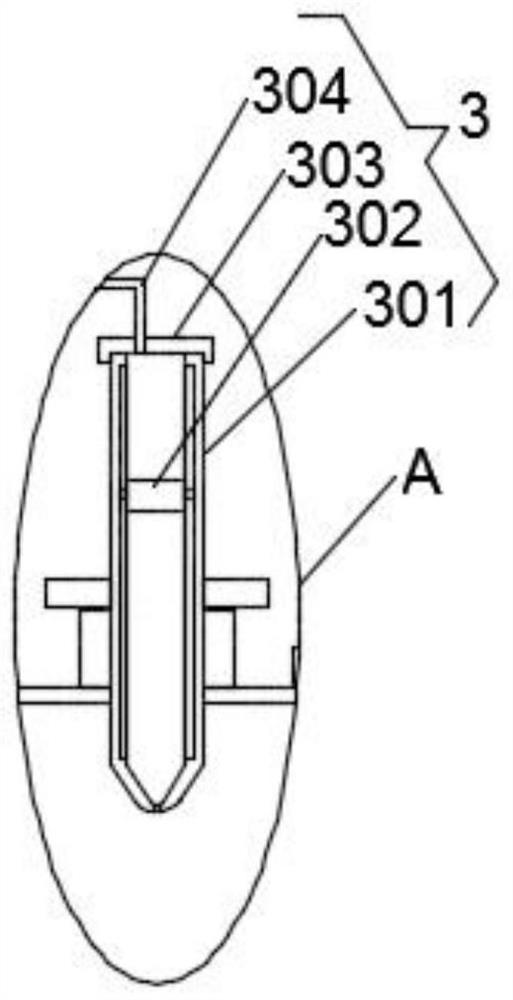

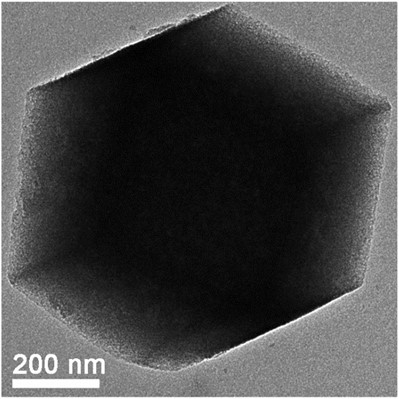

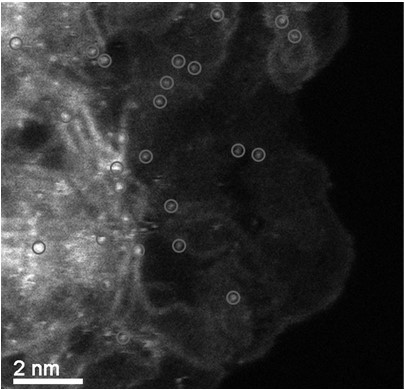

Preparation method of Mn monatomic-loaded N-doped carbon polyhedral catalyst

The invention relates to a preparation method of an Mn monatomic-loaded N-doped carbon polyhedral catalyst, which comprises the following steps: (1) stirring and dissolving manganese salt and zinc nitrate in a solvent to obtain a solution A, stirring and dissolving an N-containing organic ligand in the solvent to obtain a solution B, stirring and mixing the solution A and the solution B, standing and aging, centrifuging, filtering and washing, and freeze-drying; (2) carrying out primary heat treatment under the protection of inert atmosphere; (3) dispersing in a manganese salt solution, stirring, and freeze-drying; and (4) carrying out secondary heat treatment under the protection of an inert atmosphere to obtain the Mn monatomic-loaded N-doped carbon polyhedral catalyst. The catalyst obtained through the method is good in dispersion, the metal Mn is dispersed in an atomic scale, Mn, N and C elements are evenly distributed, the electro-catalytic oxygen reduction performance is good, the rate performance is superior to that of a commercial Pt / C catalyst, and the catalyst is simple in synthesis process, efficient, low in cost, high in universality and suitable for industrial production.

Owner:CENT SOUTH UNIV

Method for preparing linear chlorophosphoronitrile

InactiveCN108439357ASimple and fast operationShorten heating timePhosphonitrilic dihalidesLiquid wasteFiltration

The invention discloses a method for preparing linear chlorophosphoronitrile. Ammonium chloride, phosphorus pentachloride, a composite catalyst and a solvent are adopted as raw materials, and all thecomponents are added into a reactor to be mixed; under nitrogen protection, a reaction is carried out for 4-5 hours, and cooling is gradually carried out after the reaction is finished; undissolved substances are subjected to extraction filtration, the filtrate is added into normal heptane, centrifugation is carried out, and a gelatineous linear chlorophosphoronitrile product is obtained. According to the method, the two-step reaction is completed through one step of catalyzing, the technological process is simplified, and the reaction time of the whole process is shortened; energy consumptionis reduced, generated liquid waste is reduced, and compared with a previous synthetic method, the method is a more energy-saving, environment-friendly and efficient synthetic process.

Owner:JINAN TAIXING FINE CHEM

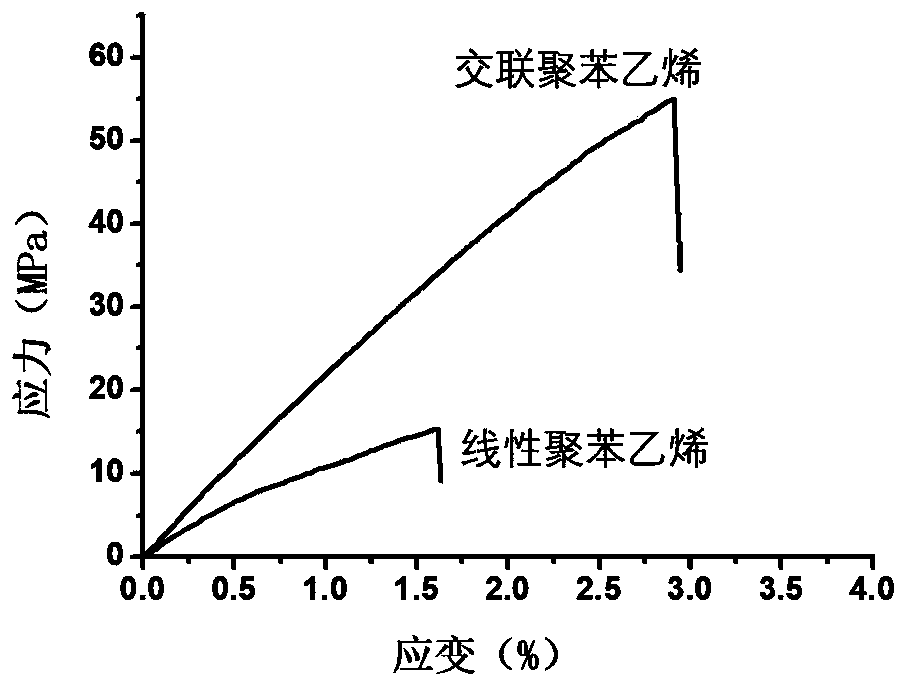

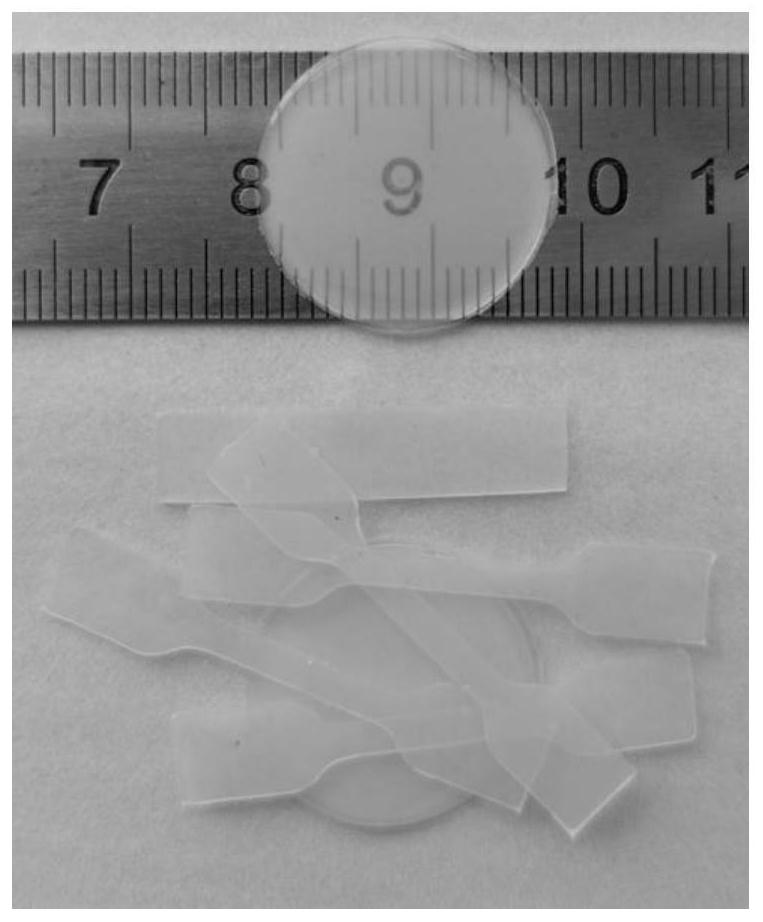

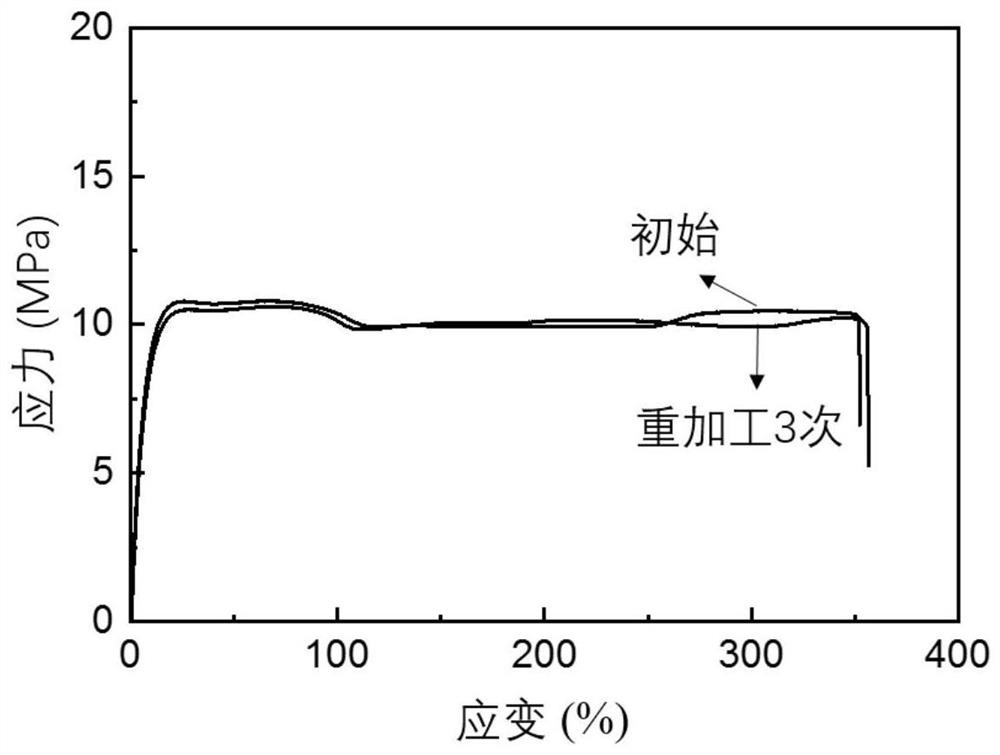

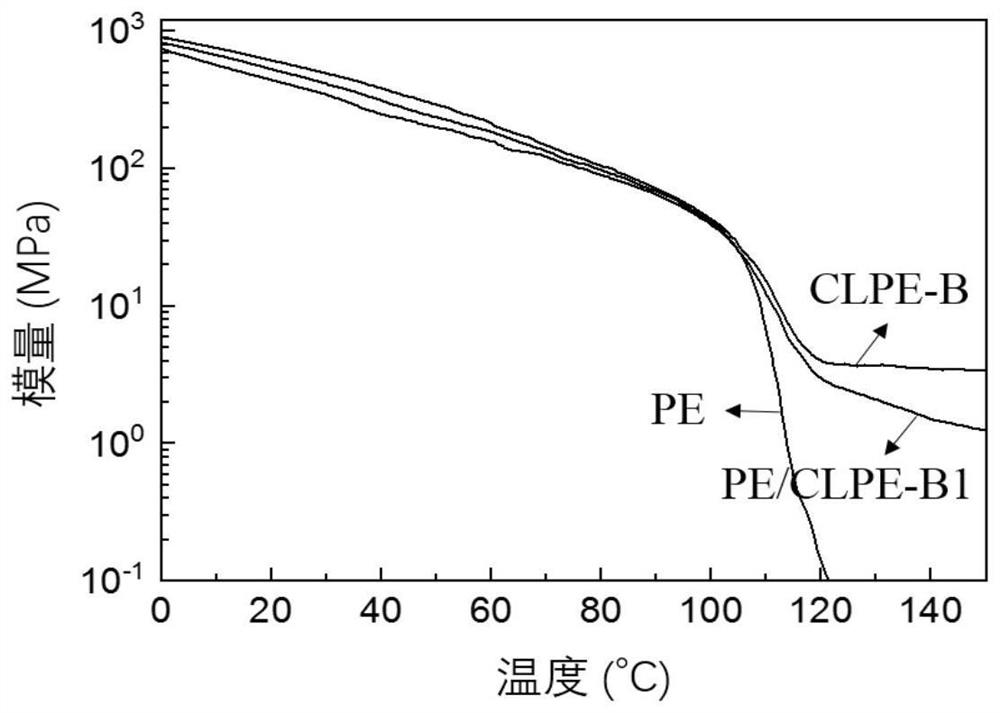

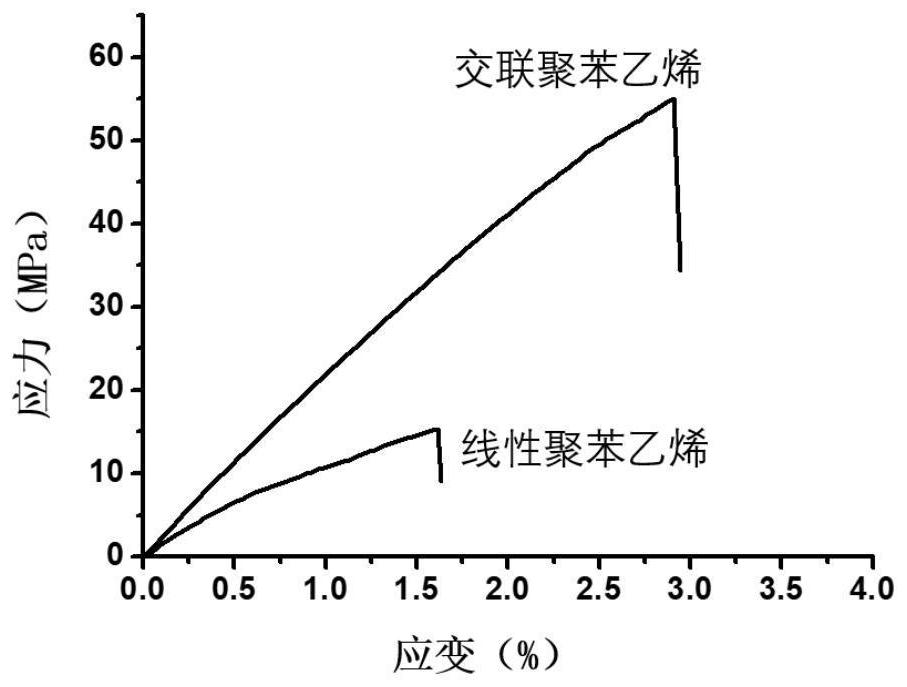

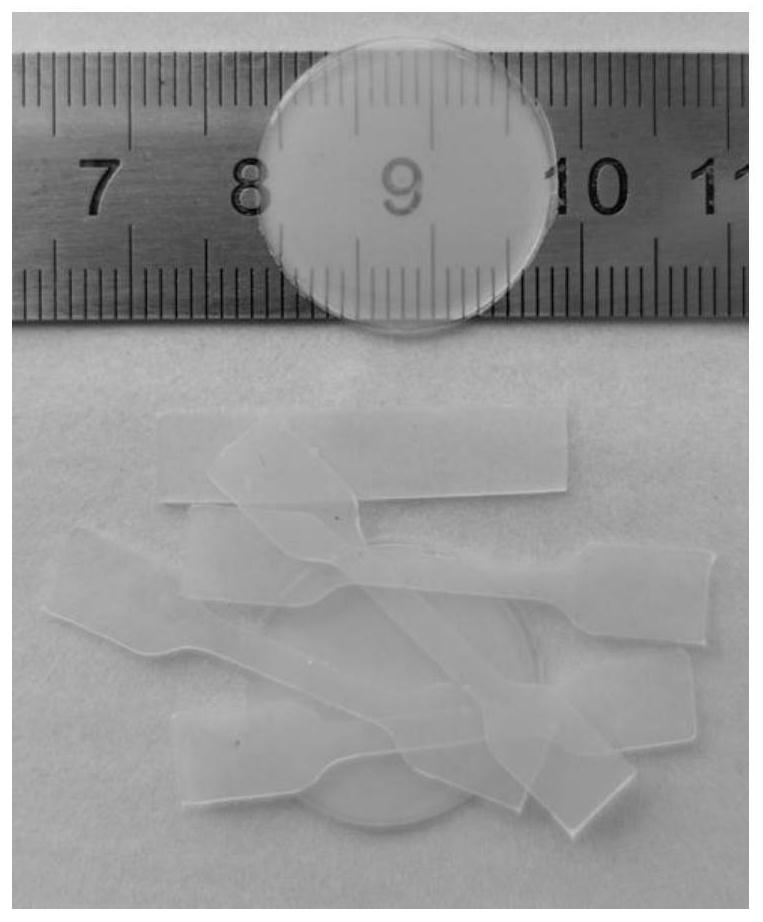

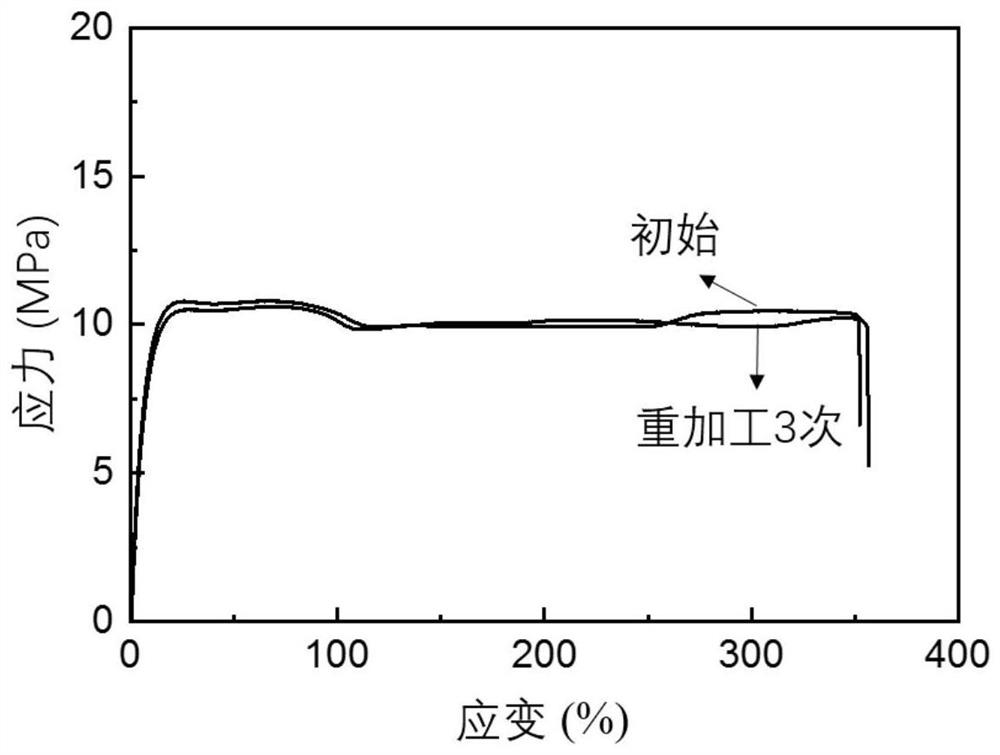

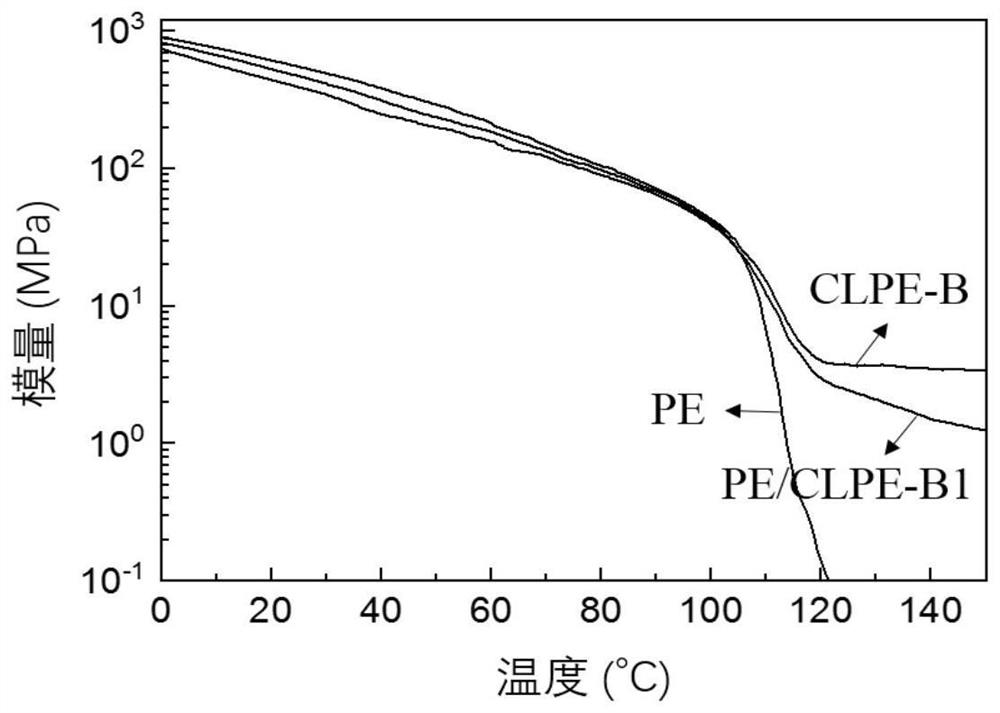

Dynamic covalent cross-linking material for enhancing polyethylene performance and preparation method and application thereof

ActiveCN112358631AImprove mechanical propertiesImprove creep resistancePolymer sciencePolymer network

The invention belongs to the technical field of high polymer materials, and particularly relates to a dynamic covalent cross-linking material for enhancing polyethylene performance and a preparation method and application thereof. The dynamic covalent cross-linking material is prepared from linear polyethylene with a borate group and a borate cross-linking agent through a borate exchange reaction,wherein the borate cross-linking agent is prepared from polybasic boric acid molecules and 1, 2-diol molecules or 1, 3-diol molecules through a dehydration condensation reaction; according to the dynamic covalent cross-linking polyethylene material, conversion and recombination of a polymer network can be realized through reversible exchange reaction among different borate groups. The dynamic covalent cross-linking polyethylene is added into commercial thermoplastic polyethylene to synthesize a polyethylene / dynamic cross-linked polyethylene composite polymer material; the mechanical properties (such as tensile strength and Young's modulus), creep resistance, solvent resistance, heat resistance and the like of the composite polymer material are remarkably enhanced, and the composite polymer material can be used for repeated processing, repeated shaping and 3D printing.

Owner:FUDAN UNIV

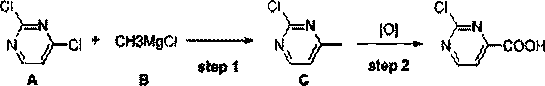

Continuous synthesis method of 2-chloropyrimidine-4-formic acid compound

ActiveCN110642789AImprove reaction efficiency and yieldLower synthesis costOrganic chemistryPyrimidineFormic acid

The invention provides a continuous synthesis method of a 2-chloropyrimidine-4-formic acid compound. The 2-chloropyrimidine-4-formic acid compound has a structure represented by a formula I, wherein in the formula I, R1 and R2 are respectively and independently selected from hydrogen, alkoxy, aryl, benzyl or fluorine. The synthesis method comprises the following steps: S1, under the action of a non-noble metal catalyst, carrying out continuous methylation reaction on a compound A and a methyl Grignard reagent B to obtain a compound C, wherein the compound A is a compound shown in the specification, the compound C is a compound shown in the specification, R1 and R2 are respectively and independently selected from hydrogen, alkoxy, aryl, benzyl or fluorine, and the non-noble metal catalyst is one or more of ferric salt, cobalt salt and nickel salt; and S2, carrying out continuous oxidation reaction on the compound C under the action of oxygen, an oxidation catalyst and an additive, and thus obtaining the 2-chloropyrimidine-4-formic acid compound. By adopting the process provided by the invention to synthesize the 2-chloropyrimidine-4-formic acid compound, the aspects of cost, yield,environmental friendliness and the like can be considered.

Owner:TIANJIN ASYMCHEM PHARMA

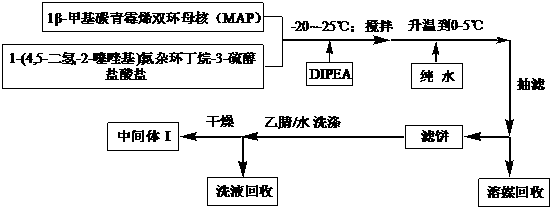

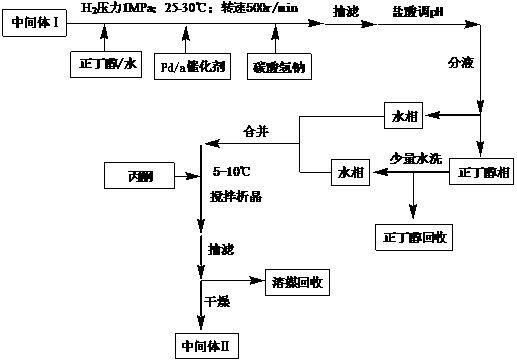

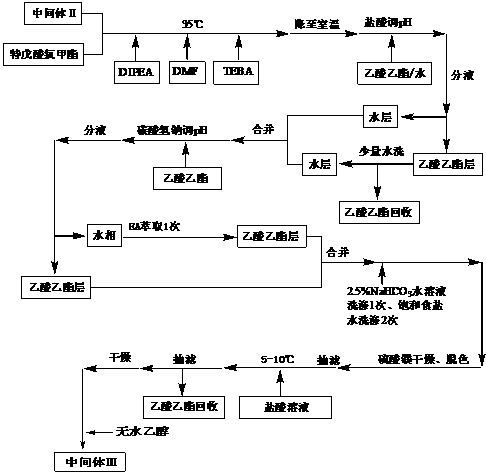

The preparation method of tipipenem ester

The invention provides a preparation method of tebipenem pivoxil, and relates to the technical field of pesticide synthesis. The preparation method of the tebipenem pivoxil comprises the following steps that 1-(4,5-dihydro-2-thiazolyl) azetidine-3-thiol hydrochloride and 1 beta-methyl vinyl phosphate are used as raw materials to take a reaction under the existence of diisopropylethylamine, and an acetonitrile water solution is used for washing to obtain an intermediate I; the intermediate I, an n-butyl alcohol water solution, a palladium-carbon catalyst and sodium bicarbonate take a mixed reaction, and treatment is performed to obtain an intermediate II; the intermediate II and chloromethyl pivalate take a reaction through phase transfer catalyst catalysis under the existence of diisopropylethylamine and dimethylformamide to obtain an intermediate III; the intermediate III and a sodium bicarbonate water solution are mixed, ethyl acetate is added, and reaction and refining are performed to prepare the tebipenem pivoxil. The preparation method has the advantages that the purity and the yield of the intermediates are obviously improved; the purity of the final product of the tebipenem pivoxil reaches 99.21 to 99.78 percent; the yield reaches 88.7 to 92.1 percent.

Owner:HENAN QUANYU PHARMA CO LTD

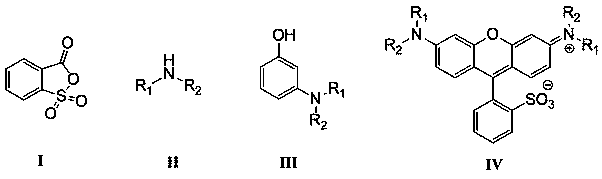

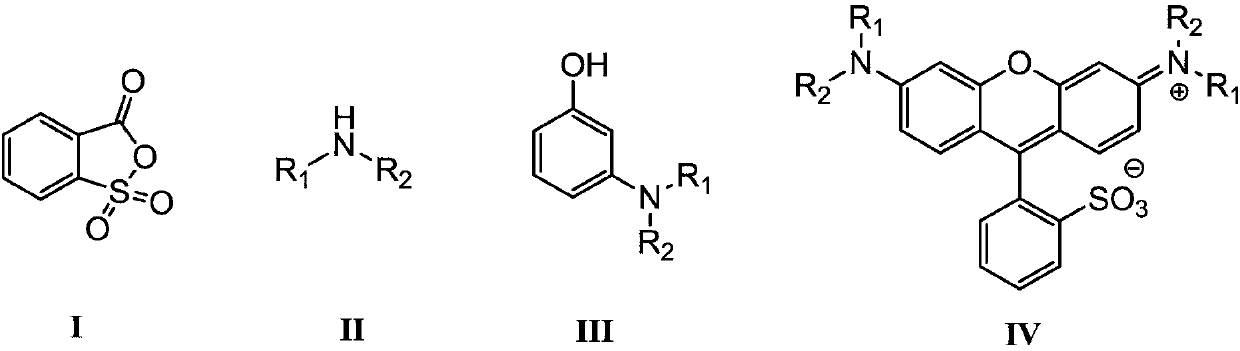

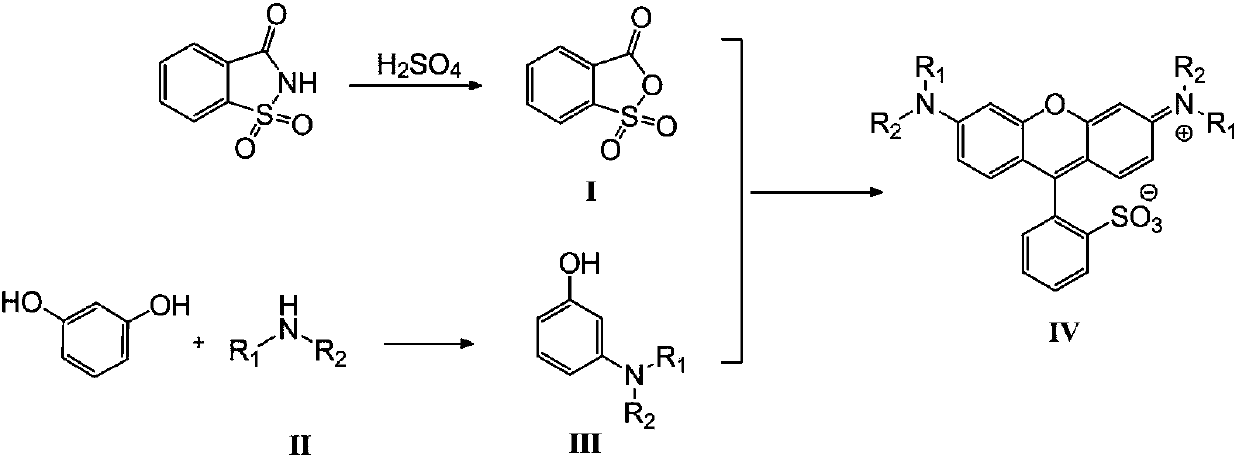

Synthesis process of sulfonic-group rhodamine compound

InactiveCN109608429AImprove separation efficiencyReduce usageOrganic chemistryNitrogenStructural formula

The invention discloses a synthesis process of a sulfonic-group rhodamine compound. The process comprises the steps: mixing saccharin and a protonic acid catalyst, performing heating for a reaction soas to obtain a compound shown in a formula (I), performing a reaction between a compound shown in a formula (II) and resorcinol through heating under the action of the protonic acid catalyst so as toobtain a compound shown in a formula (III), performing a reaction between the compound of the formula (I) and the compound in the formula (III) through heating under the action of a Lewis acid catalyst under the conditions of nitrogen protection and light shielding so as to obtain the sulfonic-group rhodamine compound shown in a formula (IV). Through the synthesis process, the use of thionyl chloride in a conventional process is avoided, the operation is simplified, the production safety is improved, the pollution to the environment is little, the reaction can be carried out under normal pressure, and the reaction has a high selectivity; and the chemical structural formulas of the compounds represented separately by the formula (I), the formula (II), the formula (III) and the formula (IV)are shown.

Owner:ZHEJIANG UNIV OF TECH

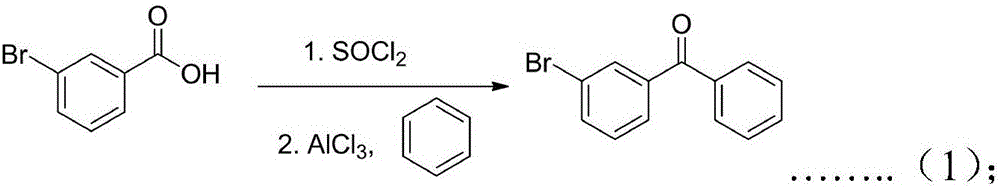

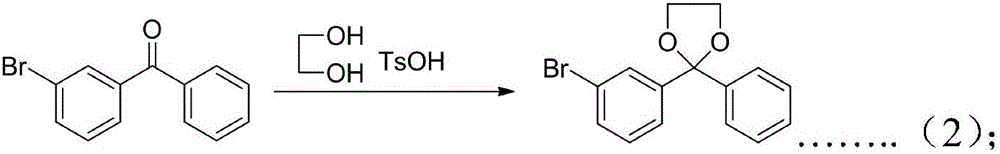

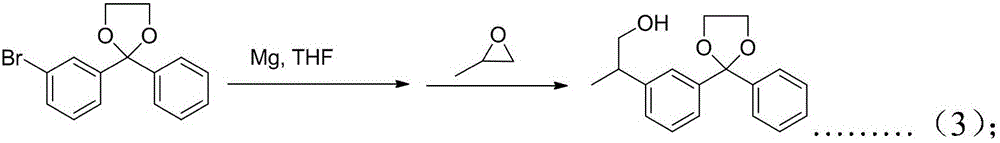

Preparation method of ketoprofen

InactiveCN106748723ACheap and easy to getSimple processOrganic compound preparationCarbonyl compound preparation by condensationBenzeneGrignard reagent

The invention discloses a preparation method of ketoprofen. The method takes m-bromobenzoic acid and benzene as starting raw materials, and the ketoprofen is prepared through the steps of acylating, protecting a carbonyl group, taking a Grignard reagent, reacting with propylene oxide, oxidizing, de-protecting and the like. The method disclosed by the invention has the characteristics of short reaction route, easiness of obtaining the raw materials, high yield and low cost.

Owner:IANGSU COLLEGE OF ENG & TECH

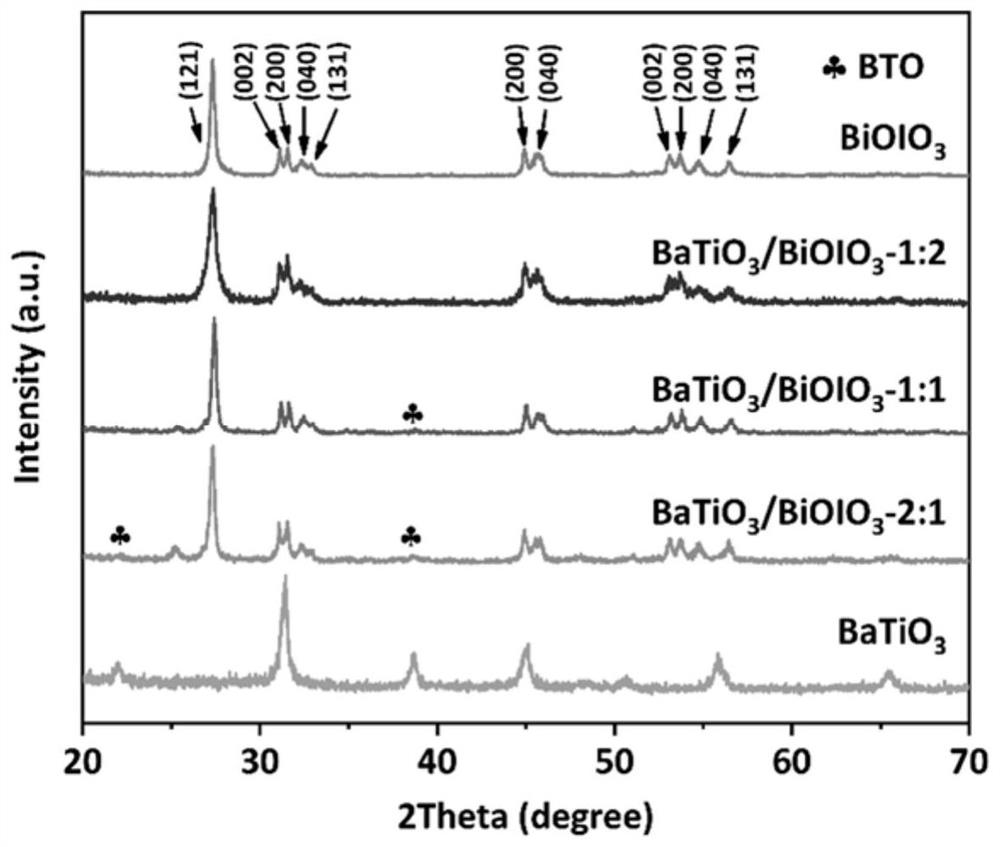

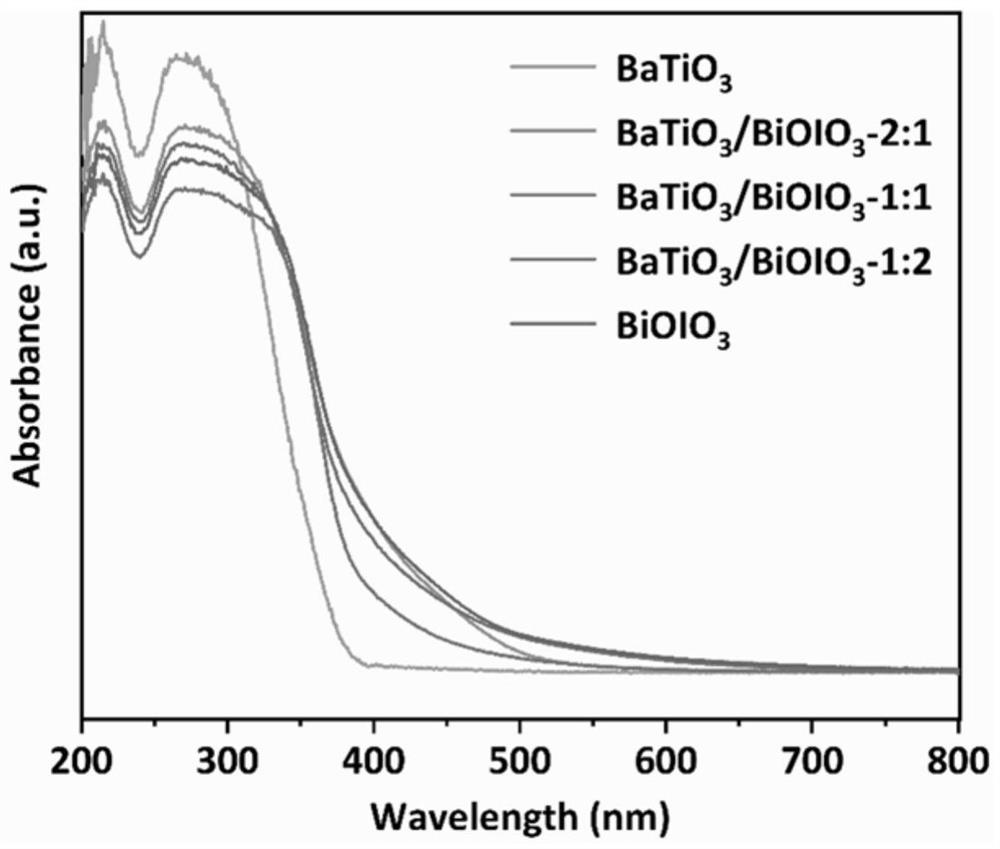

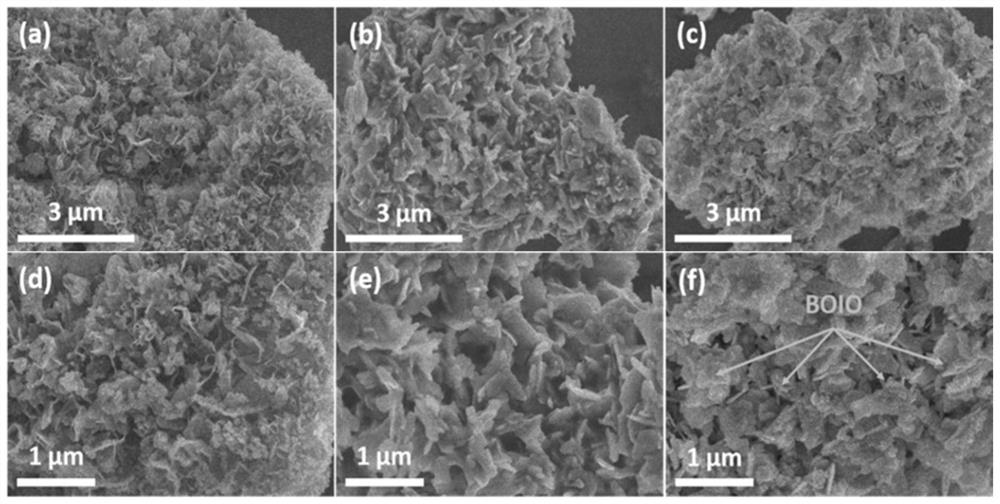

BaTiO3/BiOIO3 composite material as well as preparation method and application thereof

PendingCN114849744ABroaden the spectral absorption rangeEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationPhoto catalyticPhotocatalytic reaction

The invention discloses a BaTiO3 / BiOIO3 composite material as well as a preparation method and application thereof, belongs to the technical field of photocatalysis, and solves the technical problems that an existing catalytic material is low in solar energy conversion efficiency, only responds to a part of light and the like during photocatalytic reaction. According to the preparation method of the BaTiO3 / BiOIO3 composite material disclosed by the invention, BiOIO3 and BaTiO3 with proper energy band structures are selected, a hydrothermal method is adopted, BiOIO3 is introduced to the surface of BaTiO3 powder to prepare and construct the composite material, the hydrothermal reaction condition is mild, the time is short, and the preparation method is suitable for industrial production; the photodegradation efficiency of the obtained BaTiO3 / BiOIO3 composite material is far higher than that of pure-phase BaTiO3 and BiOIO3, and the BaTiO3 / BiOIO3 composite material is expected to be applied to the fields of sewage treatment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synthesizing Nitro-PAPS

InactiveCN108558746AThe synthesis process is simpleEfficient synthesis processOrganic chemistryM-aminophenolSynthesis methods

The invention discloses a method for synthesizing Nitro-PAPS. The chemical structural formula of the Nitro-PAPS is shown in the description. The Nitro-PAPS serves as commercialized hypersensitive colorimetric reagent for detecting Fe(II) in serum, and is also used for detecting zinc in the serum, has the advantages of high sensitivity, good accuracy, simple and stable reagent, small interference,rapid, simple and convenient operation and the like, and is widely used in biochemical detection. The price of the Nitro-PAPS is expensive, and the literature and patent reports for the synthesis method of the Nitro-PAPS are few, therefore, the invention provides a simple efficient synthesis method with high yield, mild reaction condition and very suitable for industrialized production. Accordingto the method, cheap m-aminophenol serves as a raw material, the m-aminophenol, bromopropane and 1,3-propane sultone are subjected to two-step nucleophilic substitution reaction, lastly, the m-aminophenol and diazonium salt of 2-amino-5-nitropyridine are coupled, and the Nitro-PAPS is synthesized by three steps with a high yield. The whole synthesis technology is simple and efficient, has low cost, and is an economically feasible industrialized production method.

Owner:HUNAN NORMAL UNIVERSITY

A Synthetic Method for Reproducible Thermoset Polymers

The invention belongs to the technical field of polymer synthesis, in particular to a method for synthesizing a repeatable thermosetting polymer. The present invention uses a macromolecular cross-linking agent to utilize the reversible cross-linking effect between polymer chains and polymer chains to synthesize cross-linked polymers that can be processed repeatedly; specifically, it includes two parts: the synthesis of functionalized copolymers and the cross-linking and curing of copolymers. ; The copolymer is mainly composed of vinyl monomers such as (meth)acrylic acid (ester), acrylamide, styrene and its derivatives, and vinyl monomers with crosslinkable functional groups as secondary components; crosslinking and curing through The dynamic chemical bond formed between functional groups is realized. Compared with thermoplastic materials with similar chemical composition, the material synthesized by the invention has better mechanical strength, solvent resistance, creep resistance, aging resistance and the like.

Owner:FUDAN UNIV

Allylated monophosphine ligand and preparation method thereof

PendingCN114478627AThe synthesis steps are simpleEfficient synthesis processGroup 5/15 element organic compoundsCombinatorial chemistryOrganic solvent

The invention relates to an allylated monophosphine ligand and a preparation method thereof, and belongs to the technical field of organic chemistry. A compound 1 and a compound 2 are used as raw materials and react in an inert atmosphere at 60-140 DEG C in the presence of a ruthenium catalyst, a ligand, alkali, an additive and an organic solvent, and the novel allylated monophosphine ligand is prepared after treatment. The preparation method disclosed by the invention is simple in synthesis step, can be completed by only one step, has the advantages of easily available raw materials, simple and convenient process operation, high efficiency, rapidness, reduction of production cost and requirements on equipment and the like, is high in product yield, and is easy to realize industrial large-scale production.

Owner:HUBEI UNIV

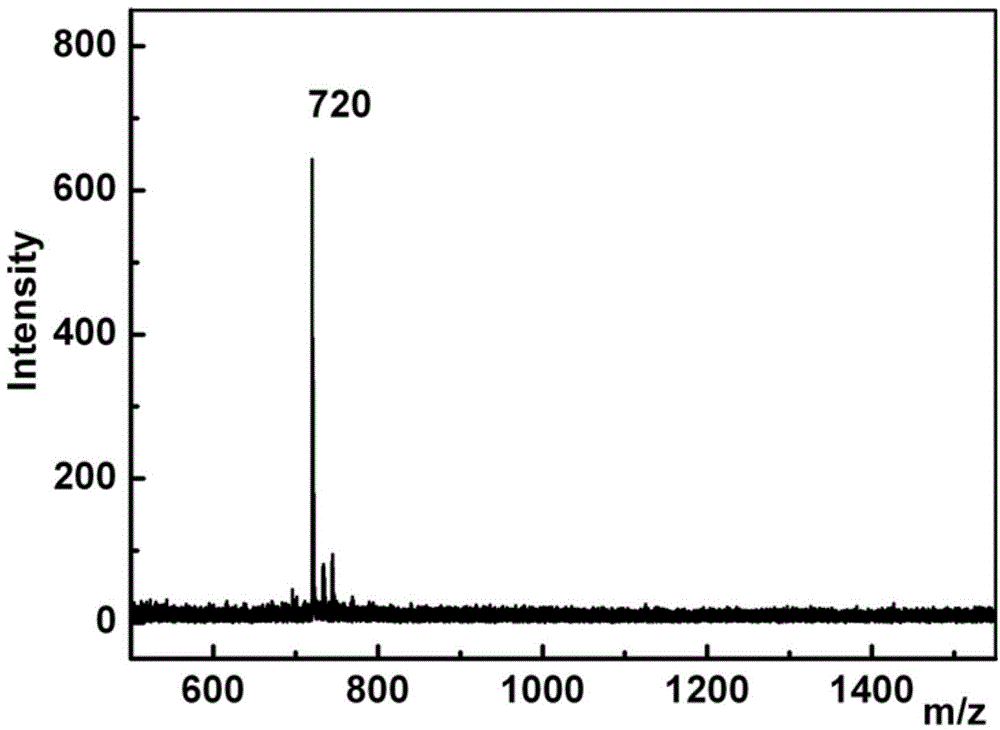

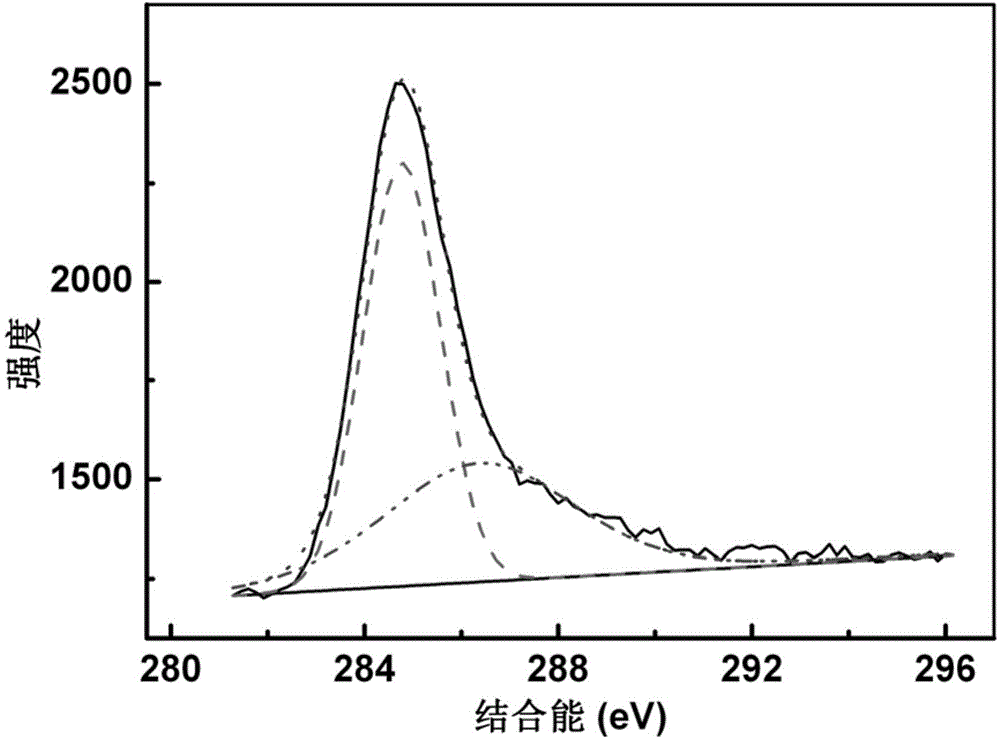

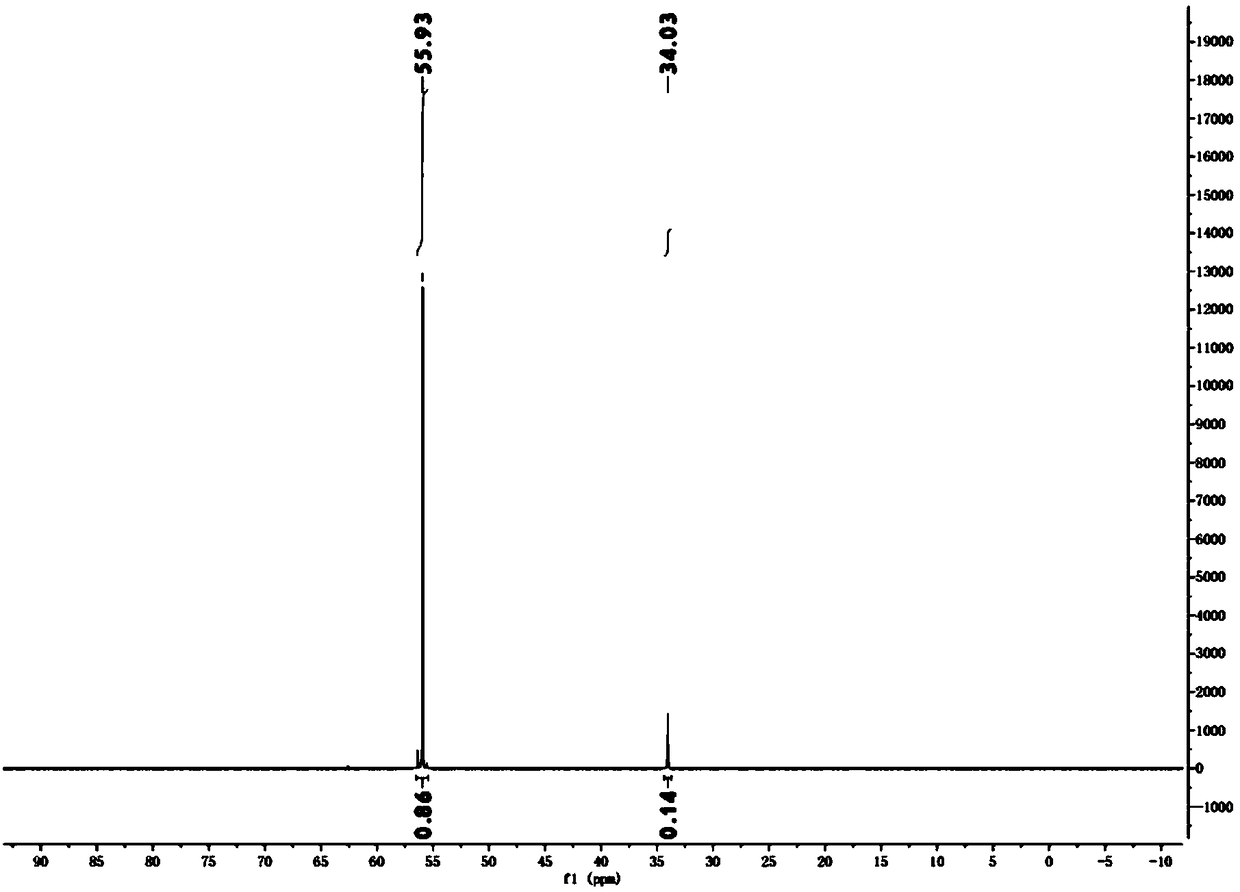

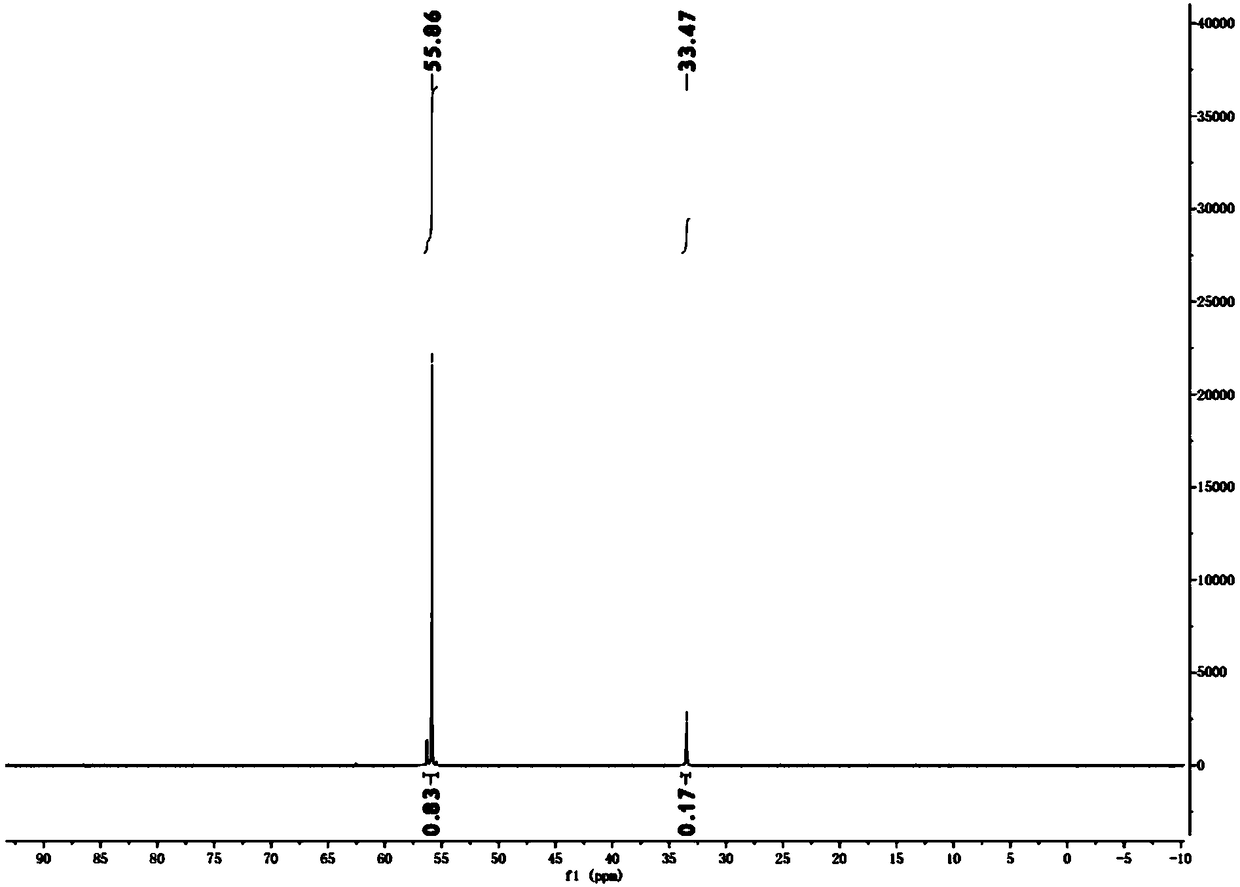

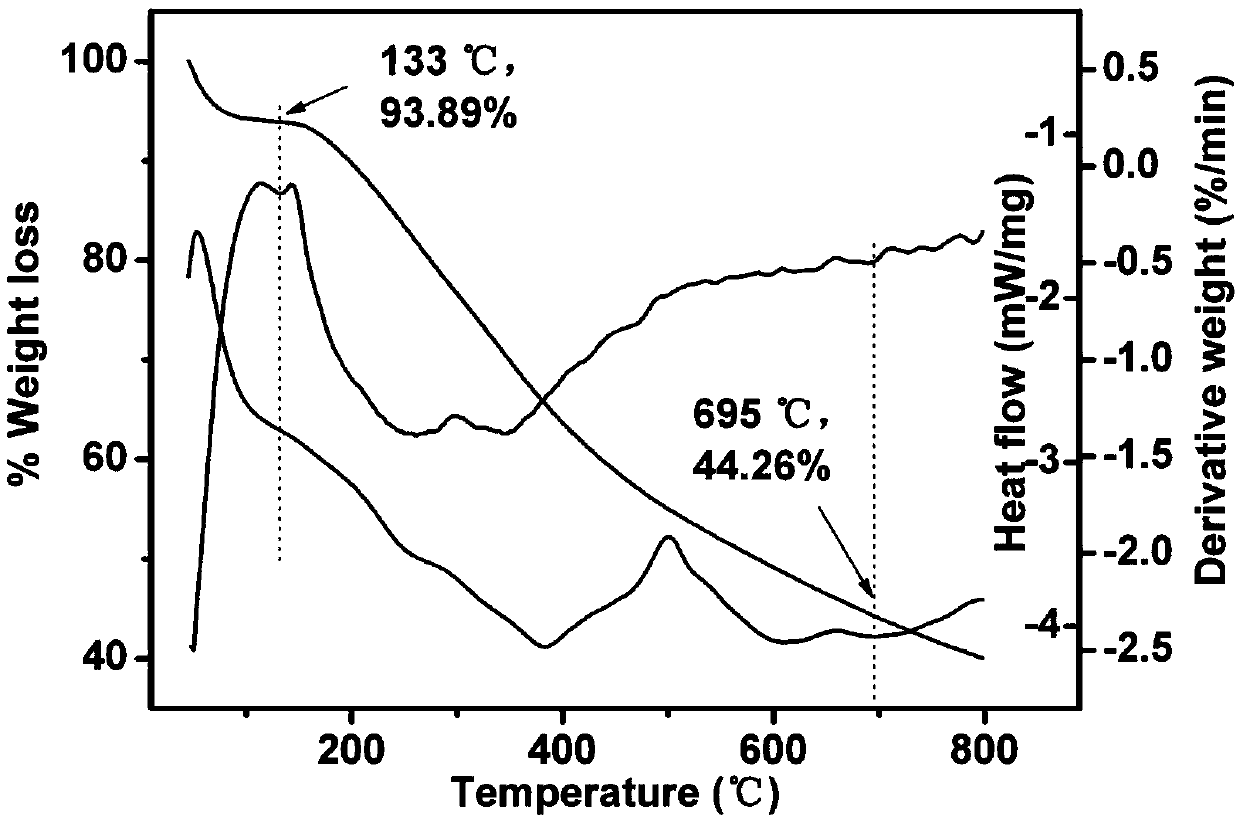

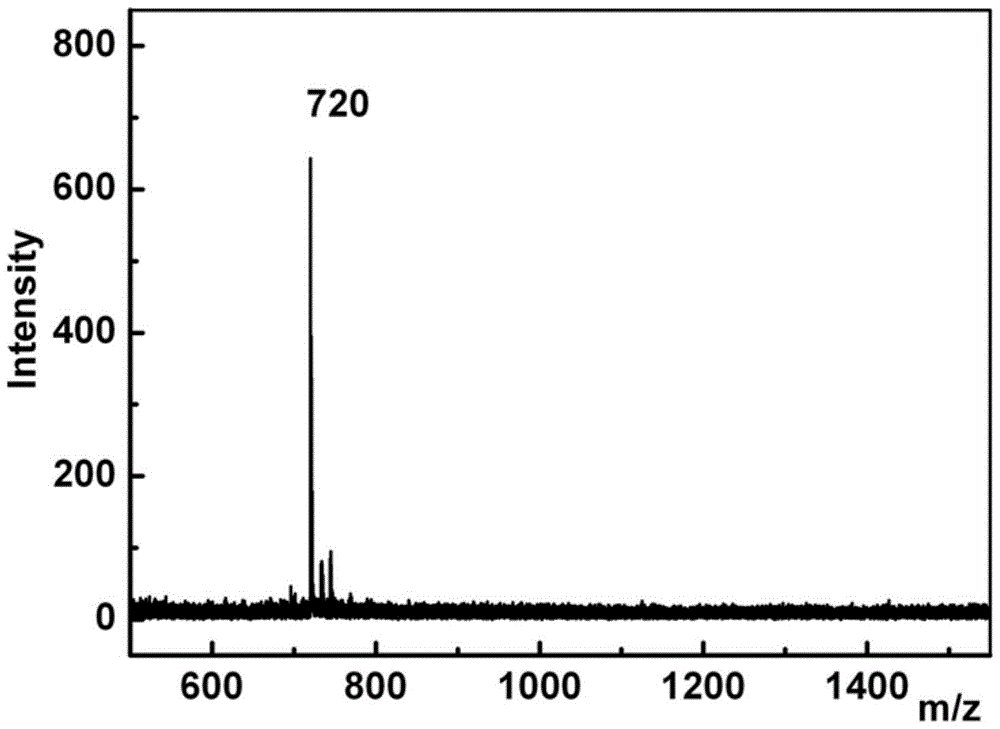

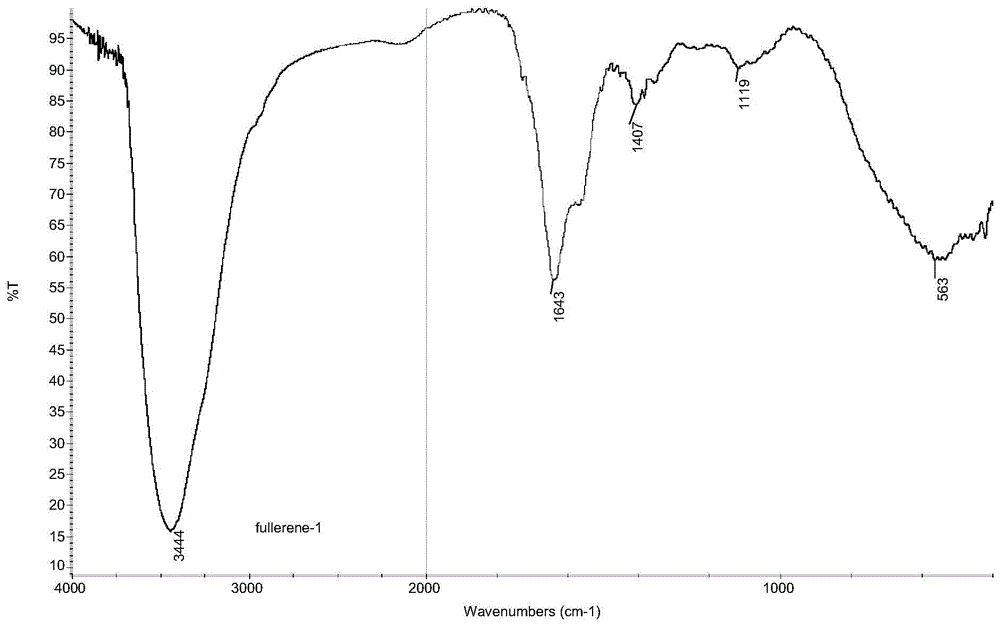

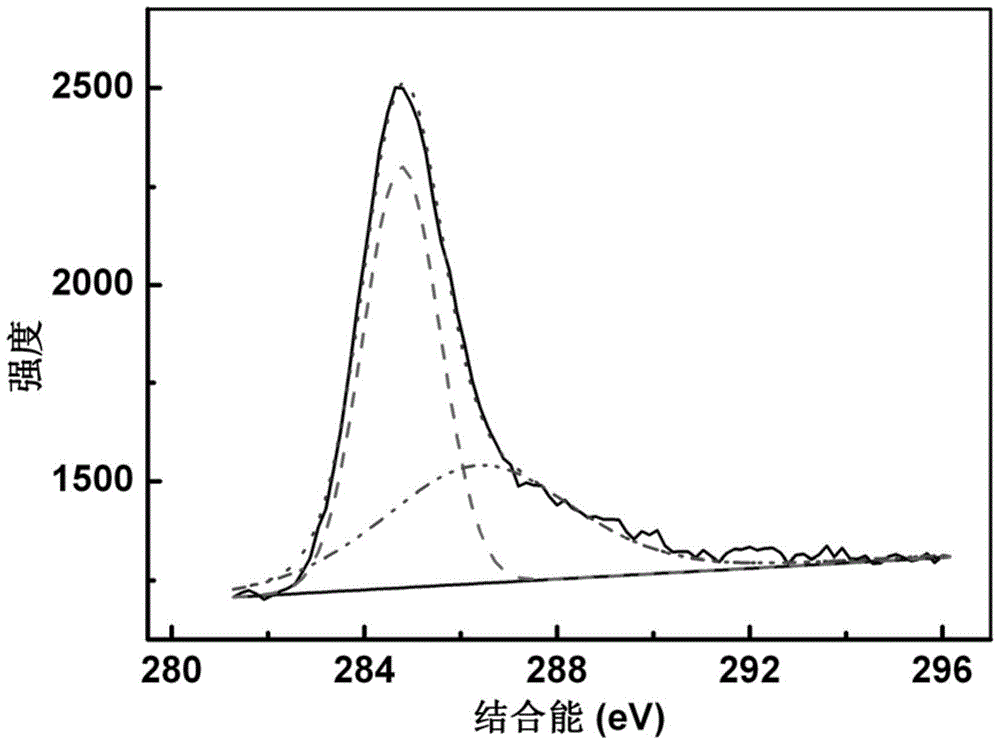

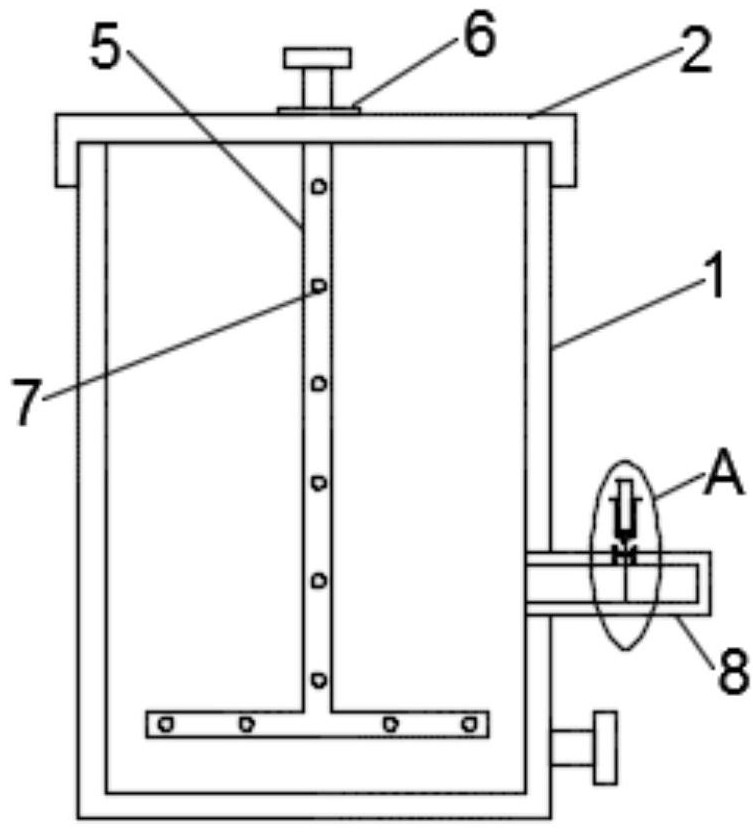

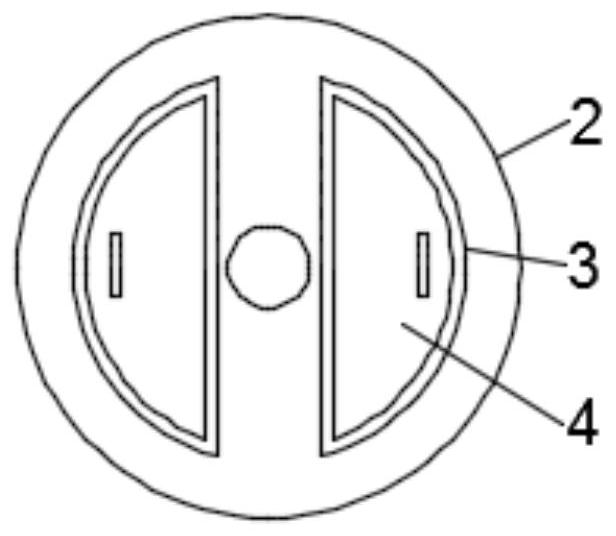

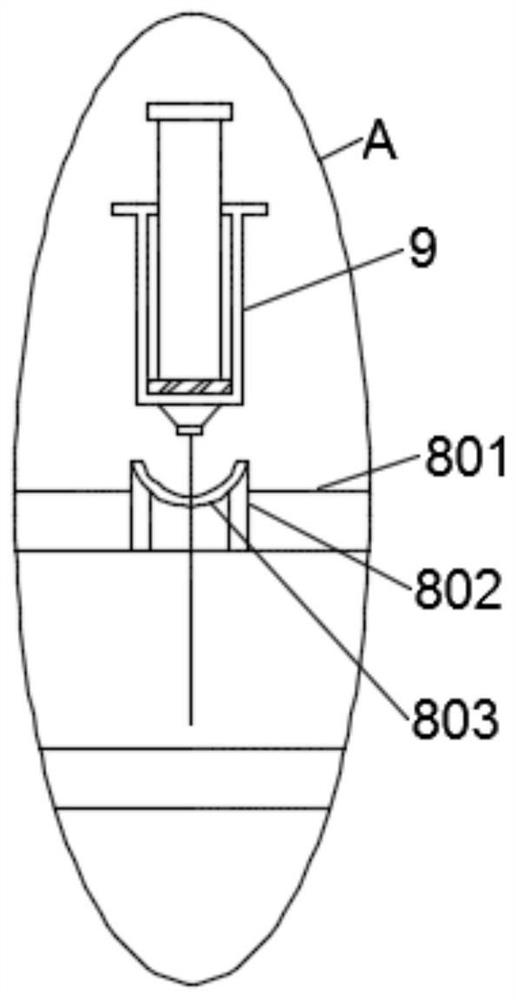

A kind of preparation method of fullerene polyaza bridge water-soluble derivative

ActiveCN106810462BThe synthesis process is simpleEfficient synthesis processAmino compound purification/separationOrganic compound preparationSolventOrganic compound

The invention discloses a method for preparing water-soluble derivatives of fullerene polyaza bridges, which comprises the following steps: (1) feeding fullerene and liquid azide organic compounds at room temperature into a reactor without adding The organic solvent is directly mechanically stirred under an inert gas atmosphere, and the ratio of the amount of the two materials fed is 1:50 to 100; one end of the carbon chain of the azide organic compound is linked to a hydrophilic functional group; (2) the reaction system Heat up to reflux, keep warm for 12 to 72 hours, then stop heating; (3) Evaporate part of the unreacted azide organic compound, wash the residue with an organic solvent, then extract it with a solvent, filter the extract and remove the solvent to obtain a solidified (4) refining the crude product to obtain a solid product of pure fullerene polyaza bridge water-soluble derivatives. The invention provides a new method which is convenient in a liquid phase system, avoids adding organic solvents and can prepare water-soluble derivatives of fullerene polyaza bridges on a large scale.

Owner:HENAN AGRICULTURAL UNIVERSITY

A kind of preparation method of fullerene alcohol

ActiveCN104555977BThe synthesis process is simpleSimple Purification and Separation MethodOrganic solventRoom temperature

Owner:HENAN AGRICULTURAL UNIVERSITY

Dynamic covalent cross-linked material for enhancing polyethylene performance, its preparation method and application

ActiveCN112358631BImprove mechanical propertiesImprove mechanical properties (e.g. tensile strengthPolymer sciencePolymer network

Owner:FUDAN UNIV

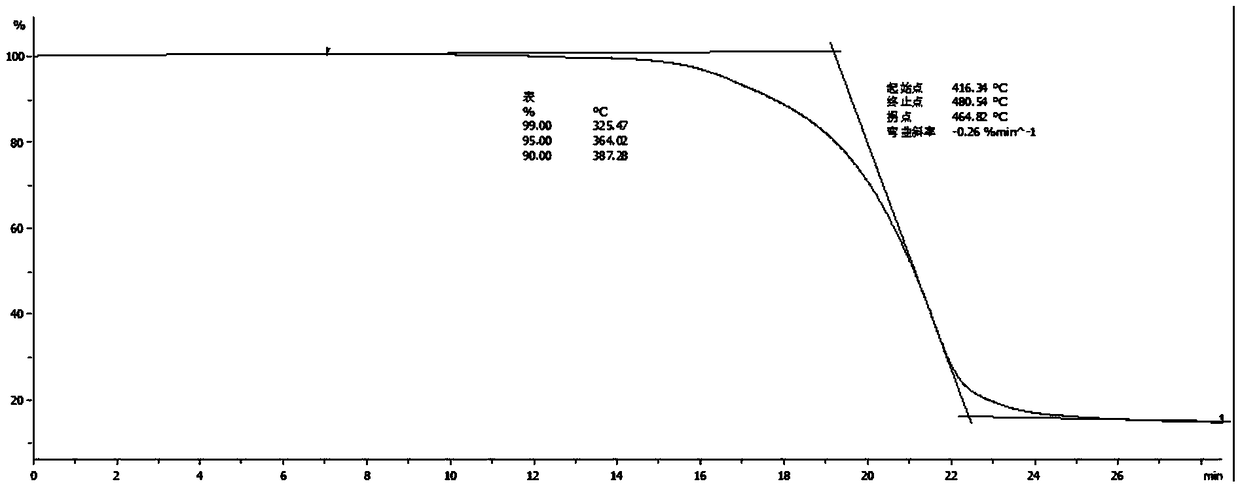

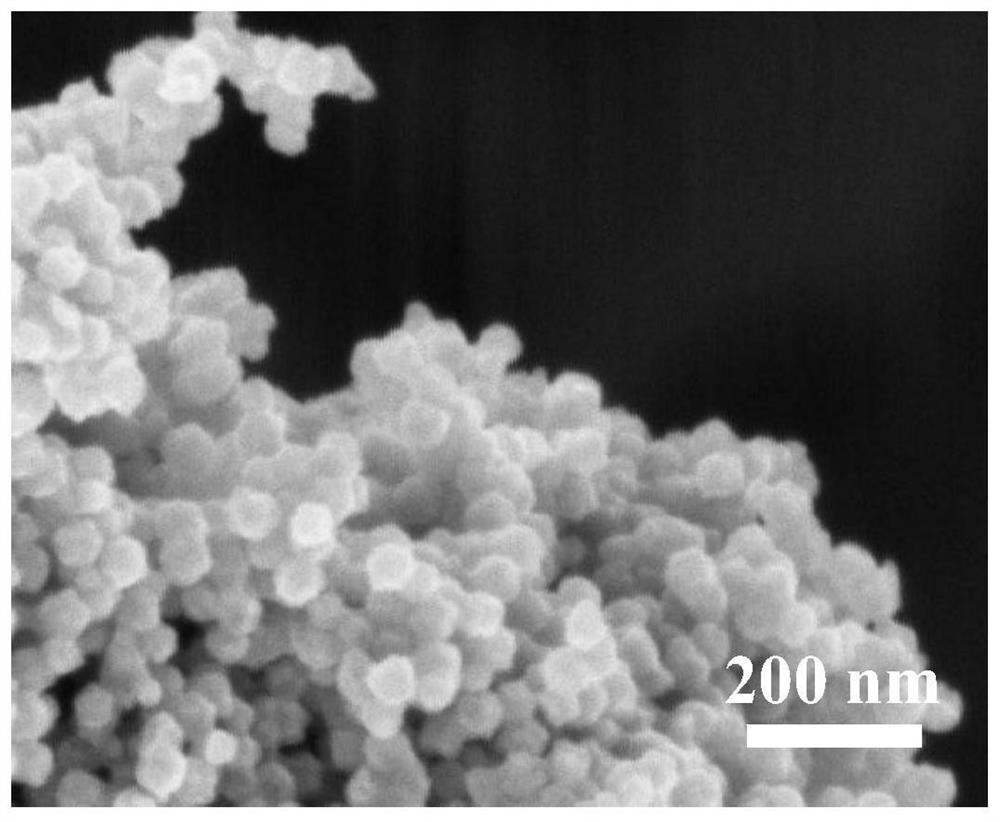

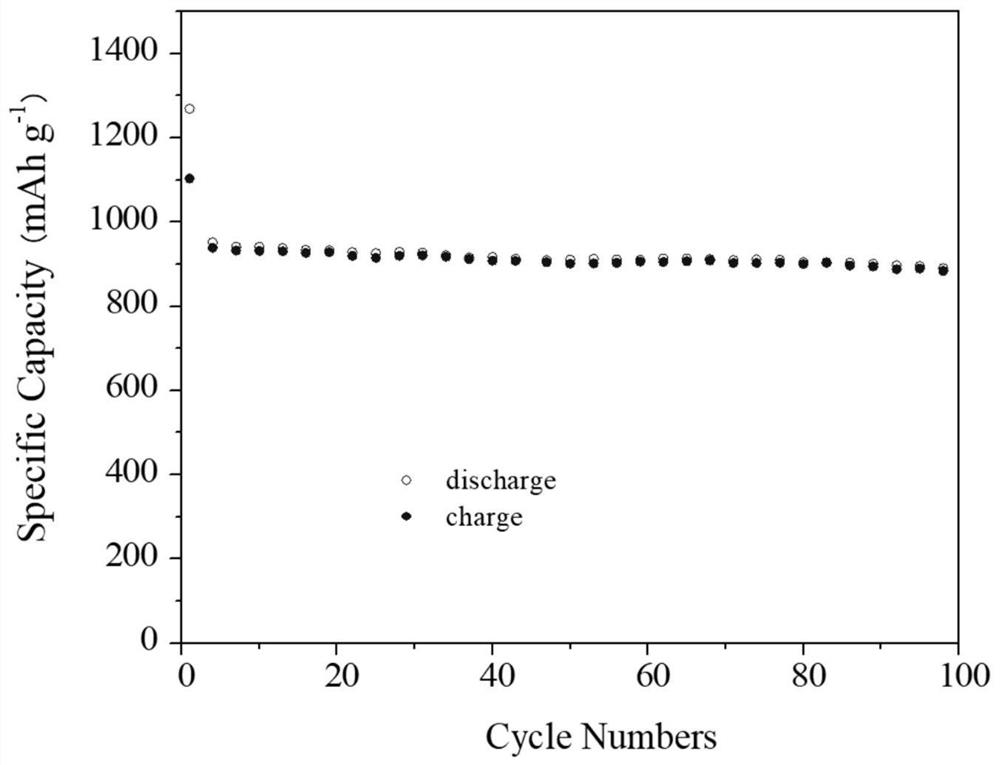

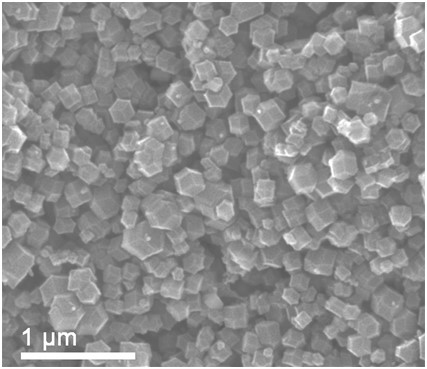

Carbon assembled zinc sulfide hollow nanopolyhedral honeycomb material and its preparation and application

ActiveCN112366312BImprove conductivityImprove structural stabilityMaterial nanotechnologyCell electrodesPyrrolidinonesHoneycomb like

The invention discloses a carbon-assembled zinc sulfide hollow nano-polyhedron honeycomb material. The zinc sulfide hollow nano-polyhedron is assembled into a three-dimensional honeycomb structure through carbon, and the carbon is amorphous carbon formed by carbonization of polyvinylpyrrolidone. The invention also discloses a method for preparing the carbon-assembled zinc sulfide hollow nano-polyhedral honeycomb material. First, the zinc MOF material ZIF-8 is synthesized, and then ZIF-8 is densely assembled with polyvinylpyrrolidone, and then through one-step gas phase vulcanization and carbonization method to obtain the final product. The invention can improve the electrical conductivity, structural stability and cycle stability of the zinc sulfide, so that the zinc sulfide has high specific capacity and stable cycle performance. Carbon-assembled zinc sulfide hollow nanopolyhedral honeycomb materials have important application value as anode materials for lithium-ion batteries.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Lithium ion battery and preparation method thereof

ActiveCN107069043BShort processEasy to operateElectrode carriers/collectorsSecondary cellsButton batteryLithium-ion battery

The invention provides a lithium ion battery and a preparation method thereof. The preparation method of the lithium ion battery comprises the following steps: a ternary material is mixed with a conductive agent and a polymer binder, a mixture is applied to aluminum foil and dried, and a positive plate is obtained; graphene oxide is dispersed in a dispersing agent, a graphene oxide dispersion is obtained and applied to the positive plate, a graphene oxide coating is formed, and a graphene oxide modified positive plate is obtained; a button cell is formed by assembling the graphene oxide modified positive plate, a separator, an electrolyte, a lithium plate and a nickel net in a glove box; the button cell is subjected to electrochemical reduction, and the lithium ion battery is obtained. The positive pole of the lithium ion battery is graphene oxide modified positive pole made of the ternary material, the electronic conductivity is high, and cycle performance and rate capability are improved substantially.

Owner:湖南豪曼新能源科技有限公司

Production process of feed-grade manganese glutamate

PendingCN113845435ANothing producedReduce processing energy consumptionOrganic compound preparationTransportation and packagingManganese sulphateSurface moisture

The invention relates to the technical field of production of manganese glutamate, and particularly discloses a production process of feed-grade manganese glutamate. The process adopts a wet synthesis process and comprises the following steps: reacting manganese sulfate with glutamic acid in a solution to obtain a manganese glutamate solution by controlling the reaction temperature and the reaction time, cooling and crystallizing to obtain a manganese glutamate product, performing drying to remove surface moisture, and then screening to remove large-particle products so as to obtain the feed-grade manganese glutamate. The process is low in energy consumption, green and environment-friendly, and does not generate substances polluting the environment, and various indexes such as the product content and heavy metals can meet the quality requirements of the feed-grade manganese glutamate; as only heating and stirring are needed in the production process, complex operations such as ultrasonic are not needed, and the equipment cost is low; the synthesis process is carried out in water, no harmful by-product is generated, mother liquor can be recycled, organic solvent extraction is not needed, the process is green and environment-friendly, post-treatment is simple, and no three wastes are generated; and the synthesis process is environment-friendly, economical and efficient.

Owner:GUANGHAN LONGDA FEED

Production process of feed-grade zinc glutamate

PendingCN113666836AReduce processing energy consumptionThe synthesis process is green and environmentally friendlyFeeding-stuffOrganic compound preparationOrganic solventReaction temperature

The invention relates to the technical field of zinc glutamate production, and particularly discloses a production process of feed-grade zinc glutamate, which comprises the following steps: adopting a wet synthesis process, adopting zinc and glutamic acid to react in a solution, obtaining a zinc glutamate solution by controlling the reaction temperature and the reaction time, obtaining a zinc glutamate product by cooling crystallization, through drying, removing surface moisture, and screening to remove large-particle products, thereby obtaining the feed-grade zinc glutamate. The process is low in energy consumption, green and environment-friendly, and does not generate substances polluting the environment, and various indexes such as product content and heavy metals can meet the quality requirements of feed-grade zinc glutamate; as only heating and stirring are needed in the production process, complex operations such as ultrasonic are not needed, and the equipment cost is low; the synthesis process is carried out in water, no harmful by-product is generated, mother liquor can be recycled, organic solvent extraction is not needed, the process is green and environment-friendly, post-treatment is simple, and no three wastes are generated; and the synthesis process is environment-friendly, economical and efficient.

Owner:GUANGHAN LONGDA FEED

A kind of preparation method of n-doped carbon polyhedron catalyst supporting mn single atom

A preparation method of an N-doped carbon polyhedral catalyst supporting Mn single atoms, comprising the following steps: (1) Stirring and dissolving manganese salt and zinc nitrate in a solvent to obtain solution A, stirring and dissolving an N-containing organic ligand in In the solvent, get solution B, then stir and mix solution A and solution B, let it stand for aging, centrifuge, filter and wash, freeze-dry; (2) conduct a heat treatment under the protection of an inert atmosphere; (3) disperse in manganese salt solution, stirred, and freeze-dried; (4) Under the protection of an inert atmosphere, a second heat treatment is performed to obtain an N-doped carbon polyhedral catalyst supporting Mn single atoms. The catalyst obtained by the method of the present invention is well dispersed and metal Mn is dispersed at the atomic level, Mn, N, and C elements are evenly distributed, the electrocatalytic oxygen reduction performance is good, the rate performance is better than that of commercial Pt / C catalysts, and the synthesis process is simple, efficient, and low in cost. The utility model has strong versatility and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

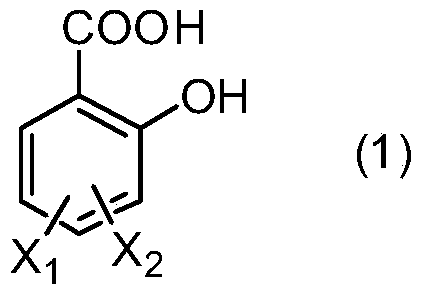

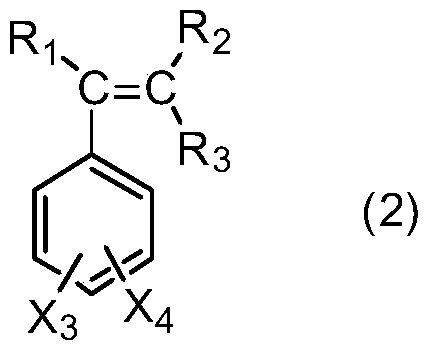

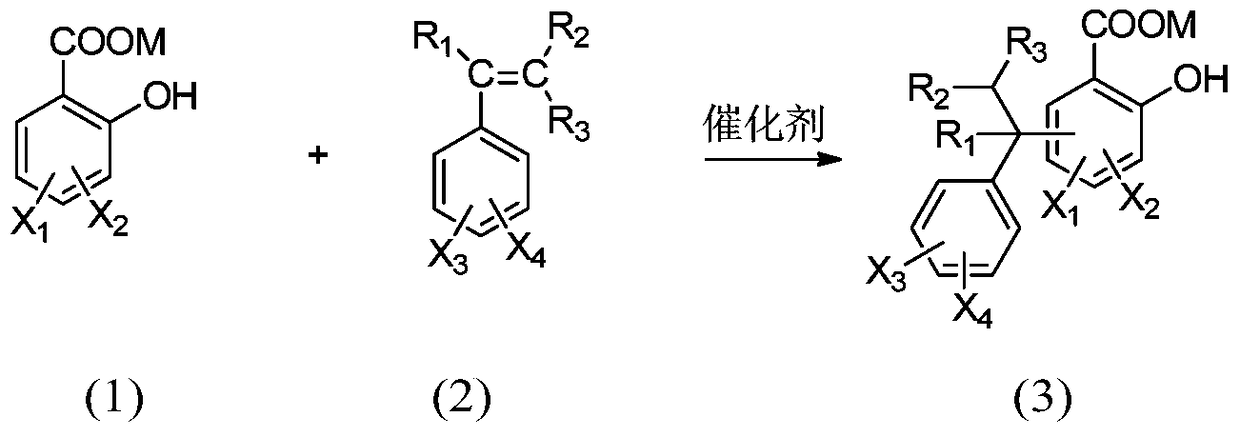

A kind of preparation method of aralkyl salicylic acid derivative

ActiveCN105294429BEfficient synthesis processSynthetic process greenOrganic compound preparationCarboxylic acid esters preparationSalicylic acid synthesisAcid derivative

The invention provides a preparation method of an aralkyl salicylic acid derivative. The method is characterized in that styrene or a derivative thereof reacts with salicylic acid or a derivative thereof in the presence of an ionic liquid catalyst. The method overcomes the disadvantages of present aralkyl salicylic acid synthesis technologies, and is an efficient and green aralkyl salicylic acid synthesis technology. The catalyst adopted in the invention settles to the bottom of a reactor after the reaction ends, is convenient to separate, and also has the advantages of multi-time repeated use, no emission of waste acids, and environment protection benefiting in case of guaranteeing good yield.

Owner:锦州康泰润滑油添加剂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com