Method for preparing linear chlorophosphoronitrile

A chlorophosphazene and linear technology, which is applied in the field of preparation of linear polydichlorophosphazene, can solve the problems of high energy consumption, complicated operation, and many waste liquids, and achieves the advantages of simplified process flow, high-efficiency synthesis process and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 0.1g of calcium sulfate dihydrate, 0.22g of ferric chloride, 17g of NH 4 Cl (0.32mol), 60g ground PCl 5 (0.26mol) and 300mL of 1,2,4-trichlorobenzene, stirred and protected by nitrogen, gradually heated up to 190 degrees, reacted for 5 hours, the reaction solution became viscous, cooled to 50 degrees, quickly filtered out insolubles, and the filtrate was added to normal Heptane, a colloidal precipitate was obtained, and centrifuged several times to obtain a colloidal product, linear chlorophosphazene. Yield 40%, total preparation time 7 hours.

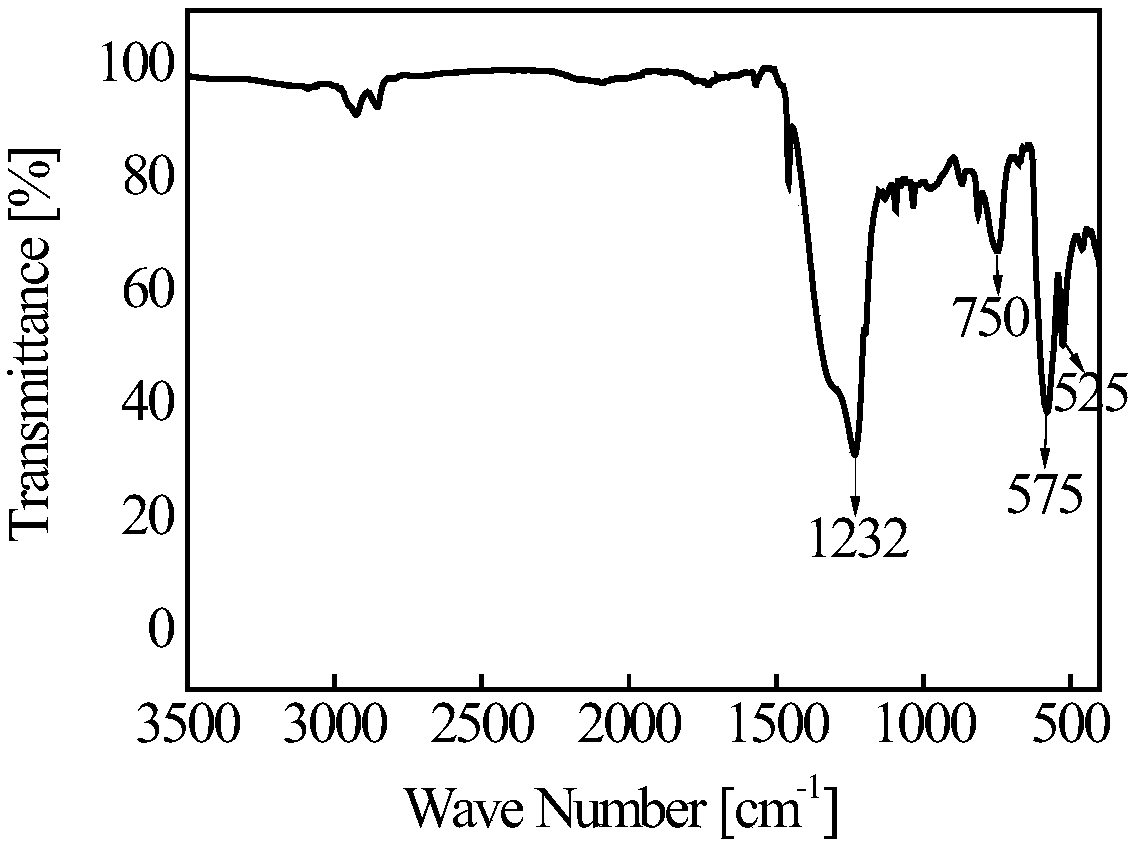

[0020] figure 1 Shown is the infrared spectrum of the product, where 1232cm-1 is the stretching vibration peak of the P=N bond, 750cm-1 is the stretching vibration peak of the P-N bond, and 525cm-1 and 575cm-1 are the P-Cl bond stretching vibration peak. The product was judged to be polydichlorophosphazene.

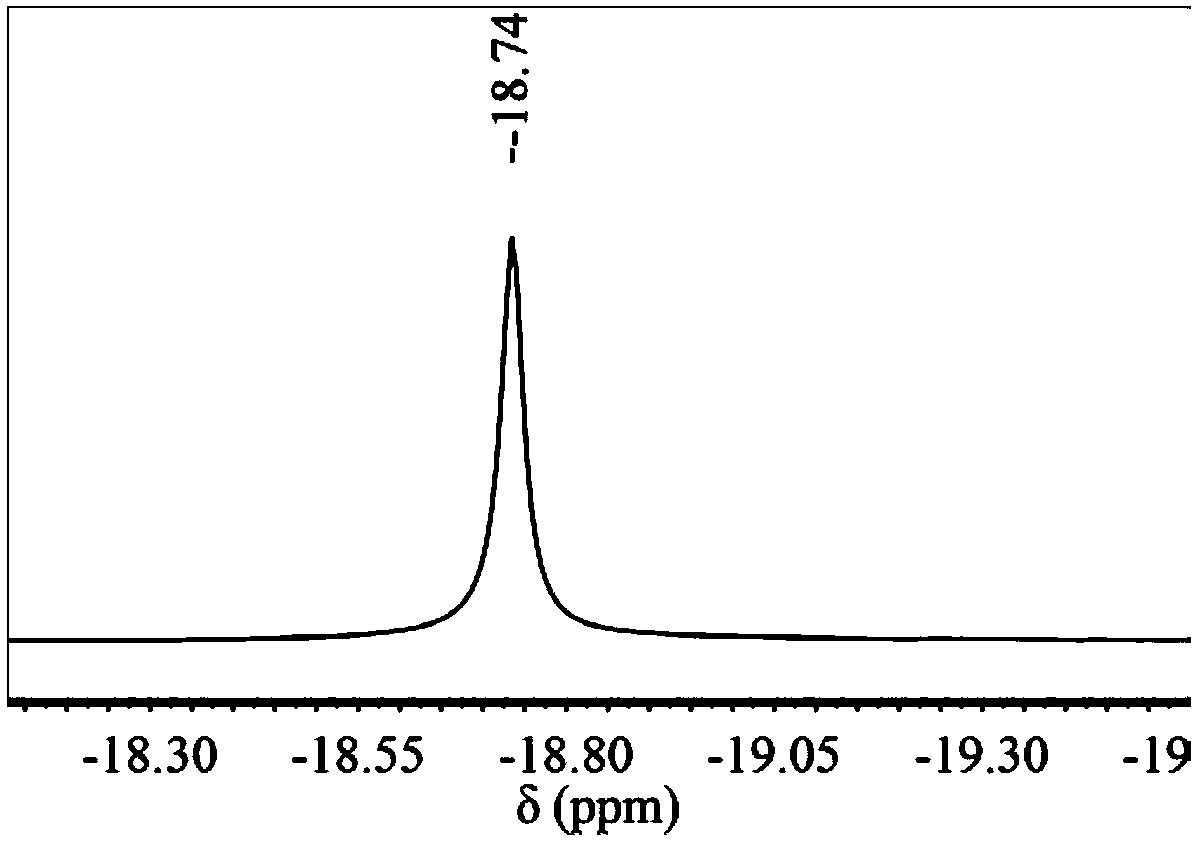

[0021] figure 2 shown for the product 31 In the P-NMR spectrum, the single peak that appears at the chemical ...

Embodiment 2

[0023] Put 0.2g calcium sulfate dihydrate, 0.2g aluminum trichloride, 15g NH 4 Cl (0.28mol) 60g ground PCl 5 (0.26mol) and 600mL of 1,2,4-trichlorobenzene, stirred and protected by nitrogen, gradually heated up to 190 degrees, reacted for 5 hours, the reaction solution became viscous, cooled to 50 degrees, quickly filtered out insolubles, and added 350ml of filtrate n-heptane, to obtain a gel-mounted precipitate, which was centrifuged several times to obtain a linear chlorophosphazene product. Yield 48%, total preparation time 7 hours.

Embodiment 3

[0025] Put 0.3g calcium sulfate dihydrate, 0.2g p-toluenesulfonic acid, 20.9g NH 4 Cl (0.39mol) 60g ground PCl 5 (0.26mol) and 500mL chlorinated naphthalene, stirring and nitrogen protection, gradually warming up to 180 degrees, reacted for 5 hours, the reaction solution became viscous, cooled to 50 degrees, rapidly filtered out insolubles, and the filtrate was added with 400ml n-heptane to obtain Precipitate in glue, centrifuge several times to obtain the linear phosphazene product, the yield is 42%, and the preparation time is 7 hours in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com