BaTiO3/BiOIO3 composite material as well as preparation method and application thereof

A composite material and dosage ratio technology, applied in the field of photocatalysis, can solve the problems of low solar energy conversion efficiency, achieve the effects of expanding the spectral absorption range, promoting the separation of photogenerated carriers, and inhibiting electron-hole recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A BaTiO 3 / BiOIO 3 The preparation method of composite material comprises the following steps:

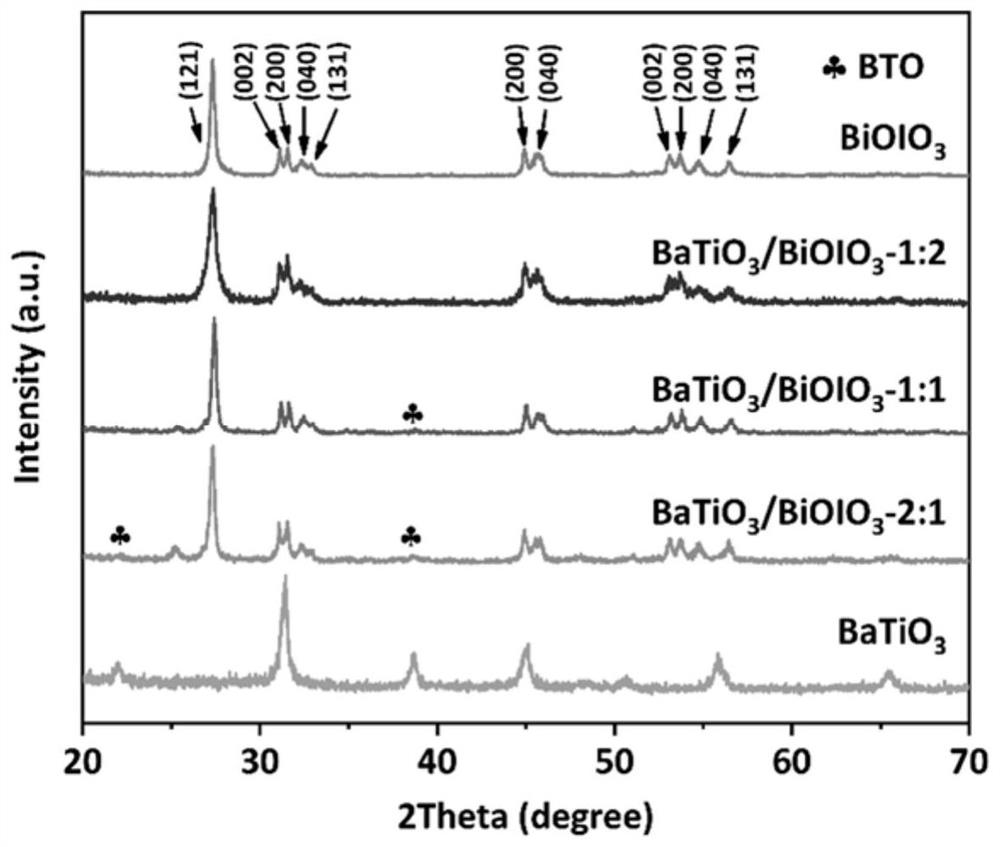

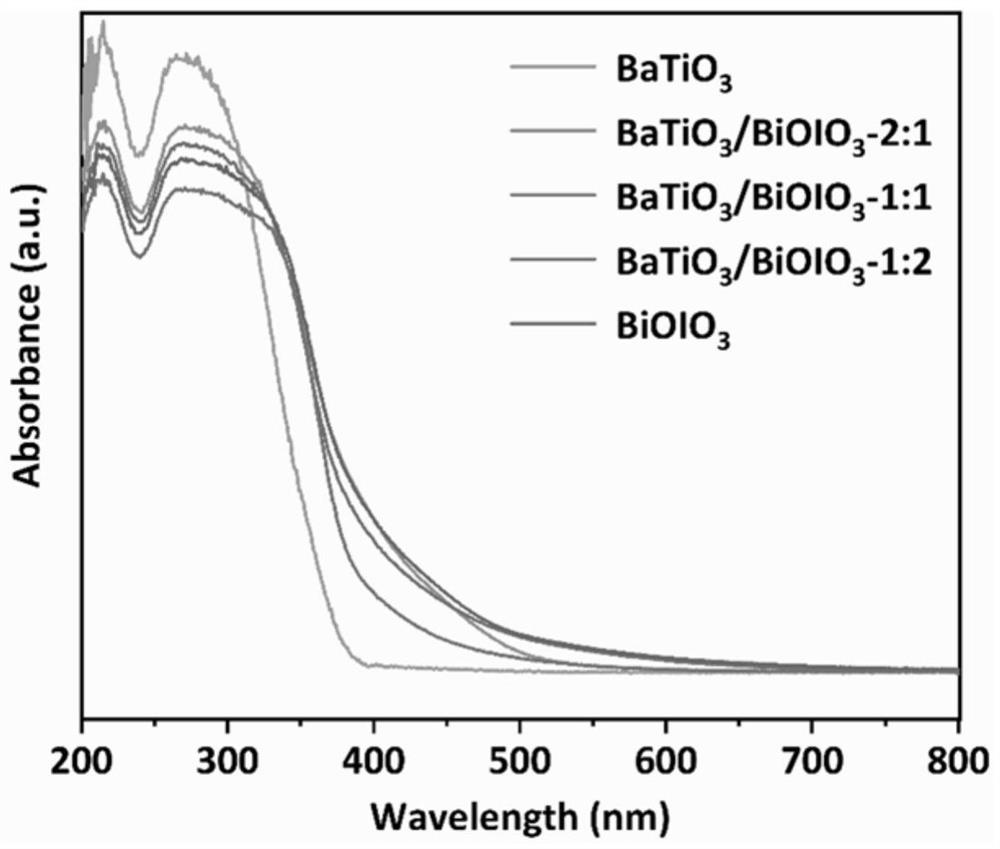

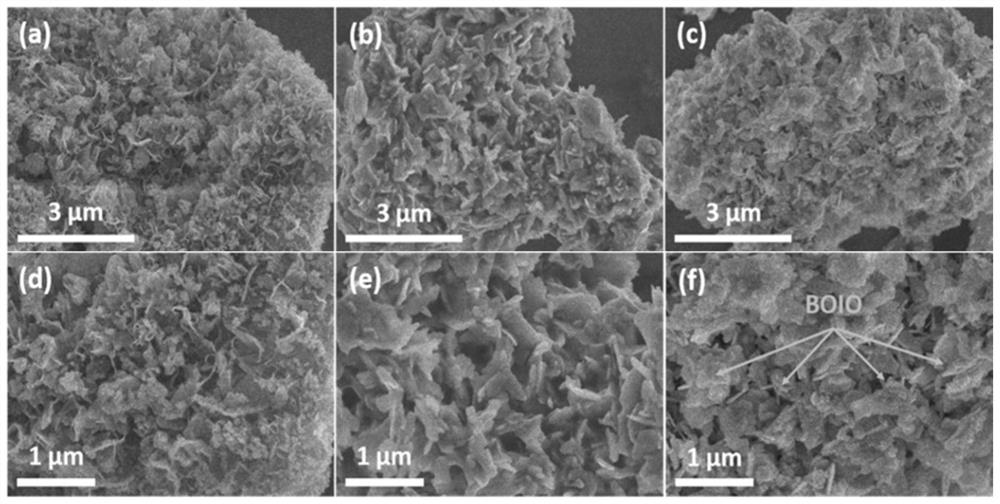

[0039] 3 mmol of BaTiO 3 Powder and 1.5mmol of Bi(NO 3 ) 3 ·5H 2 Add 30ml of distilled water, stir for 0.5h to form a suspension, then add 1.5mmol of NaIO to the suspension 3 , after stirring for 0.5h, a mixed solution was obtained, and the mixed solution was transferred to a 50ml polytetrafluoroethylene-lined reaction kettle, and the hydrothermal reaction was carried out at 150 ° C. After 6h of heat preservation, a powder product was obtained. Washed with ethanol and dried at 60°C under vacuum to obtain BaTiO 3 and BiOIO 3 BaTiO with a molar ratio of 2:1 3 / BiOIO 3 composite material.

Embodiment 2

[0041] A BaTiO 3 / BiOIO 3 The preparation method of composite material comprises the following steps:

[0042] 1.5 mmol of BaTiO 3 Powder and 1.5mmol of Bi(NO 3 ) 3 ·5H 2 Add 30ml of distilled water, stir for 0.5h to form a suspension, then add 1.5mmol of NaIO to the suspension 3 , after stirring for 0.5h, a mixed solution was obtained, and the mixed solution was transferred to a 50ml polytetrafluoroethylene-lined reaction kettle, and the hydrothermal reaction was carried out at 150 ° C. After 6h of heat preservation, a powder product was obtained. Washed with ethanol and dried at 60°C under vacuum to obtain BaTiO 3 and BiOIO 3 BaTiO with a molar ratio of 1:1 3 / BiOIO 3 composite material.

Embodiment 3

[0044] A BaTiO 3 / BiOIO 3 The preparation method of composite material comprises the following steps:

[0045] Put 0.75 mmol of BaTiO 3 Powder and 1.5mmol of Bi(NO 3 ) 3 ·5H 2 Add 30ml of distilled water, stir for 0.5h to form a suspension, then add 1.5mmol of NaIO to the suspension 3 , after stirring for 0.5h, a mixed solution was obtained, and the mixed solution was transferred to a 50ml polytetrafluoroethylene-lined reaction kettle, and the hydrothermal reaction was carried out at 150 ° C. After 6h of heat preservation, a powder product was obtained. Washed with ethanol and dried at 60°C under vacuum to obtain BaTiO 3 and BiOIO 3 BaTiO with a molar ratio of 1:2 3 / BiOIO 3 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com