Light absorption material, preparation method thereof and photovoltaic cell

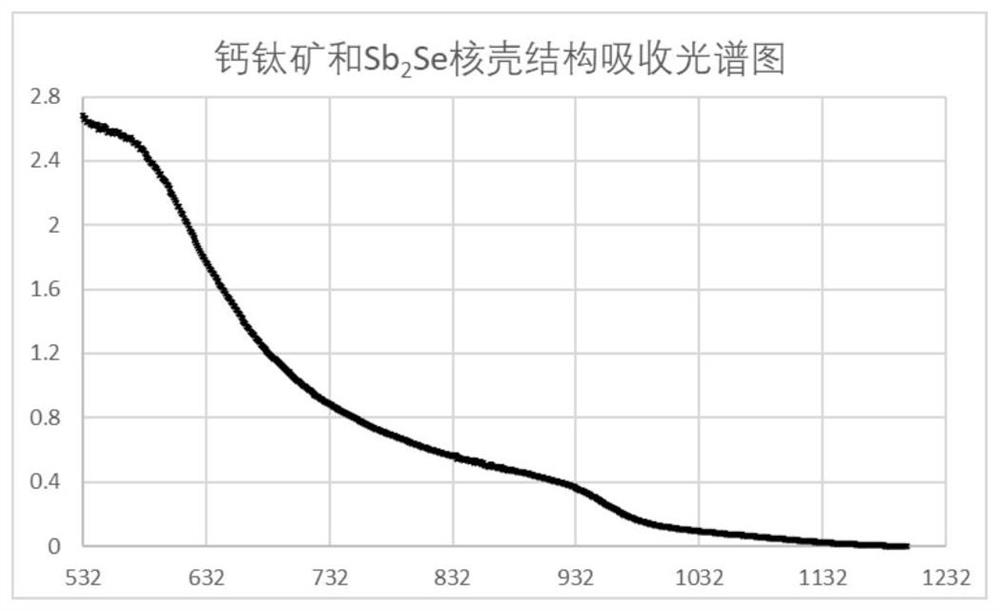

A technology of light-absorbing materials and photovoltaic cells, which is applied in the field of its preparation and light-absorbing materials, can solve problems such as the complexity of the preparation process, achieve the effects of simple preparation procedures, breaking through the efficiency limit, and broadening the spectral absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

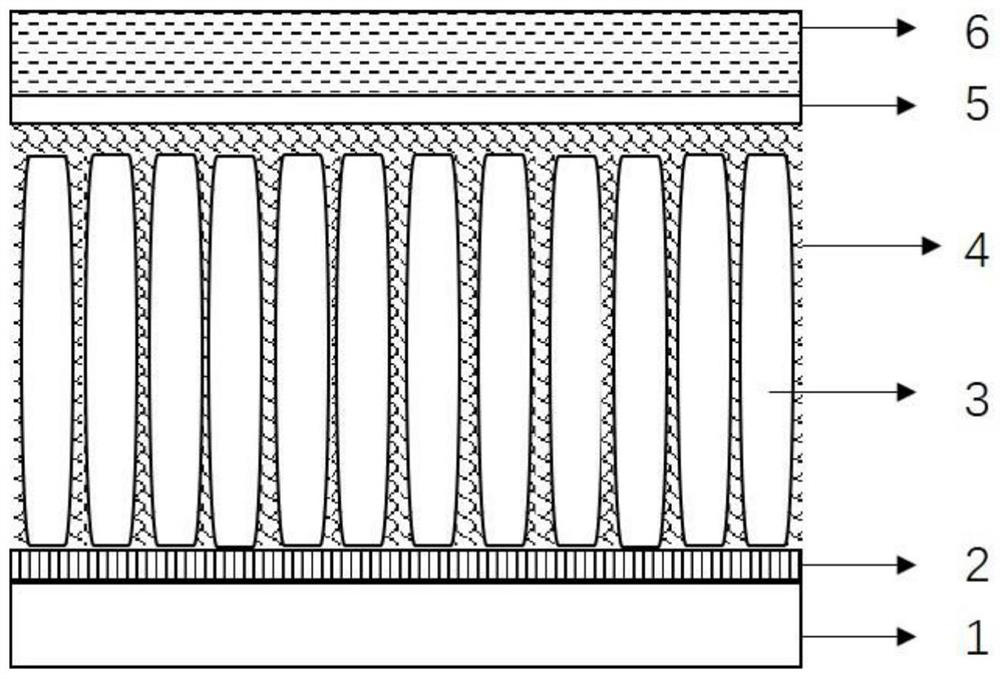

[0035] The present invention also provides a method for preparing the above-mentioned light-absorbing material, comprising: soaking antimony selenide nanorods in ABX doped with N-type dopant materials 3 In the perovskite precursor solution, a light absorbing layer is obtained; the ABX doped with an N-type dopant material 3 The perovskite precursor solution is prepared according to the following method: one or more of MAX, FAX and CsX and, BX 2 Mix with N-type dopant material in a solvent to obtain ABX doped with N-type dopant material 3 Perovskite precursor solution; wherein X is one or more of Cl, Br and I; the N-type dopant material includes Bi 3+ , Sb 3+ , Fe 3+ with Al 3+ one or more of.

[0036] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0037] The antimony selenide nanorods are the same as described above, and will not be described in detail here; in the present invention, ...

Embodiment 1

[0056] 1) Select a stainless steel foil (1) with a thickness of 0.2mm, grind and polish, and then use deionized water, absolute ethanol and acetone to perform ultrasonic cleaning, and then N 2 blow dry;

[0057] 2) Preparation of the metal back electrode (2): Deposit Mo on the stainless steel foil (1) as the back electrode of the battery by magnetron sputtering, with a deposition thickness of 800 nm;

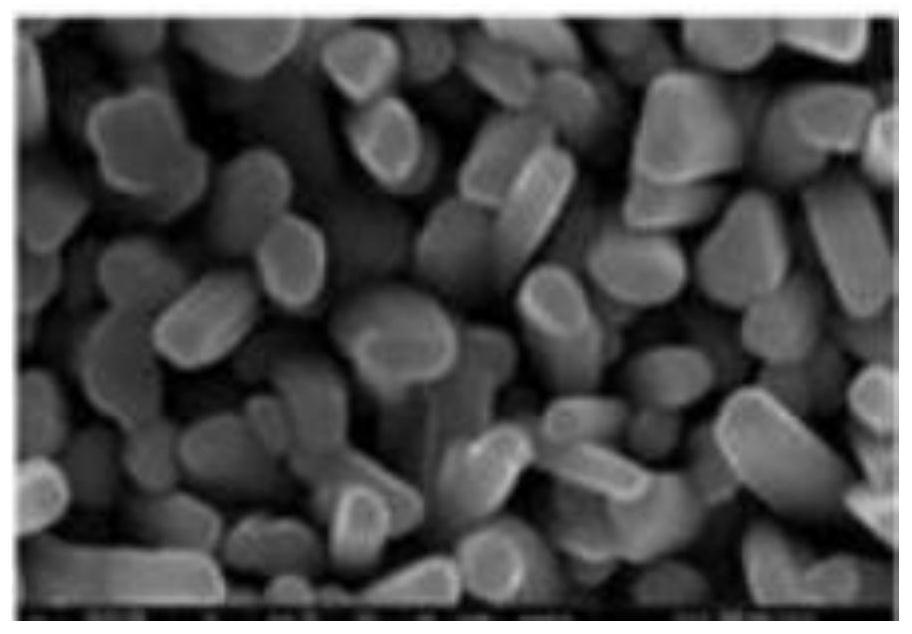

[0058] 3) Add 600mg of Se powder and 50mg of hydrazine hydrate to 100mL of NaOH solution with a pH value of 8, stir for 15min, add 1.16g of antimony chloride, and transfer the mixed solution to the reaction kettle with the base of the composite back electrode In 150 ℃ reaction for 24h to get the substrate composited with antimony selenide nanorods.

[0059] 4) Prepare N-type perovskite material solution, wherein the solute is SnI 2 , PbI 2 , CsBr, FAI, wherein the molar ratio of CsBr to FAI is 0.15:0.85, SnI 2 with PbI 2 The molar ratio is 0.3:0.7. (SnI 2 +PbI 2 ) to (Cs...

Embodiment 2

[0068] 1) Select FTO-coated glass (1) with a thickness of 2mm, and use deionized water, absolute ethanol and acetone to carry out ultrasonic cleaning, and then N 2 Stream dry.

[0069] 2) Preparation of the metal back electrode (2): Deposit Mo on the stainless steel foil (1) as the back electrode of the battery by magnetron sputtering, with a deposition thickness of 800 nm;

[0070] 3) Add 600mg of Se powder and 50mg of hydrazine hydrate to 100mL of NaOH solution with a pH value of 8, stir for 15min, add 1.16g of antimony chloride, and transfer the mixed solution to the reaction kettle with the base of the composite back electrode In the reaction at 150℃ for 24h, antimony selenide nanorods were obtained.

[0071] 4) Prepare N-type perovskite material solution, wherein the solute is SnI 2 , PbI 2 , MAI, FAI, wherein the molar ratio of MAI to FAI is 0.05:0.85, SnI 2 with PbI 2 The molar ratio is (0.2 ~ 0.5): (0.5 ~ 0.8). (SnI 2 +PbI 2 ) to (MAI+FAI) in a molar ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com