Modified attapulgite loaded with copper and silver ions and silver ions and preparation method thereof

A technology for modifying attapulgite and attapulgite, which is applied in the directions of separation methods, chemical instruments and methods, and other chemical processes to achieve the effects of expanding the spectral absorption range and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

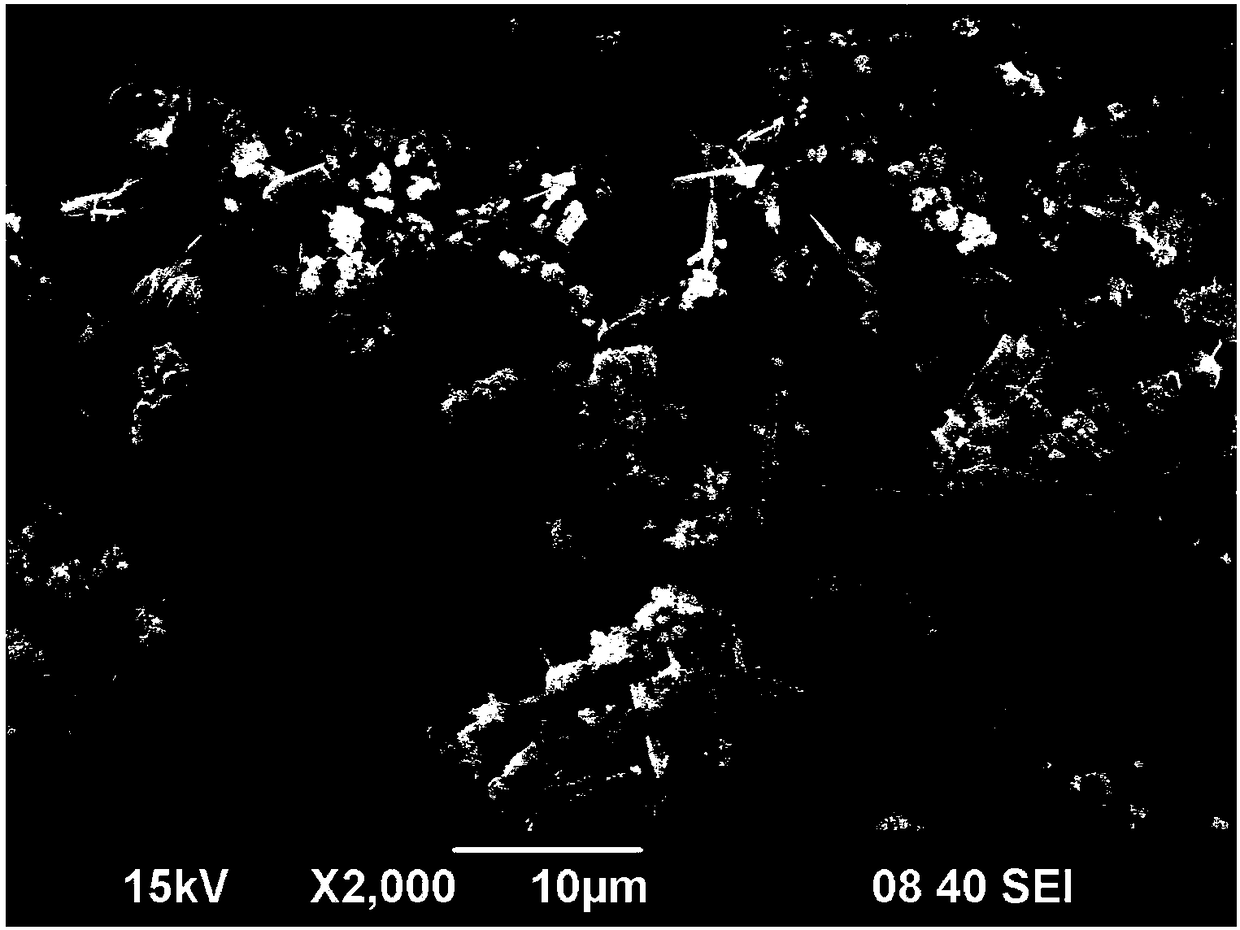

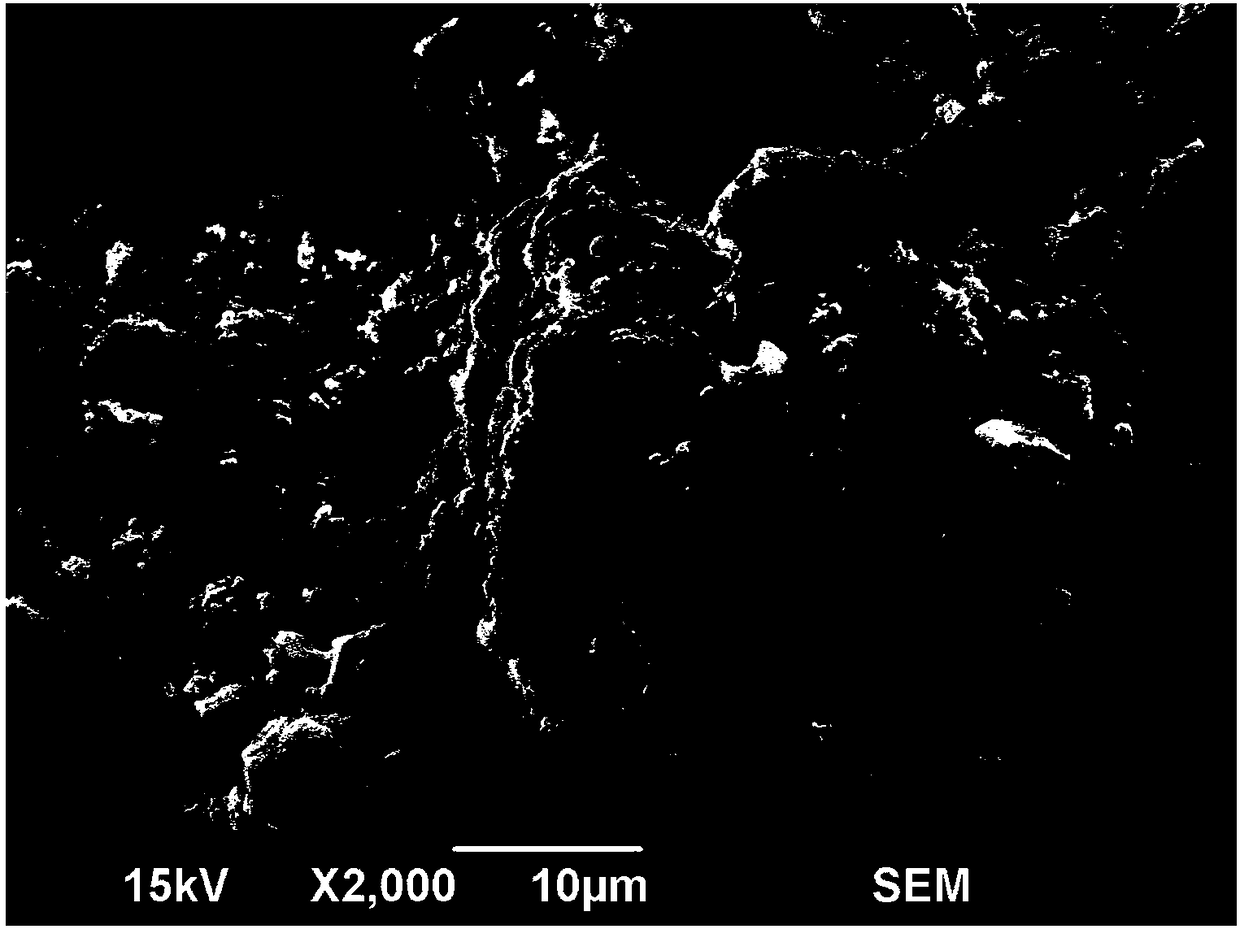

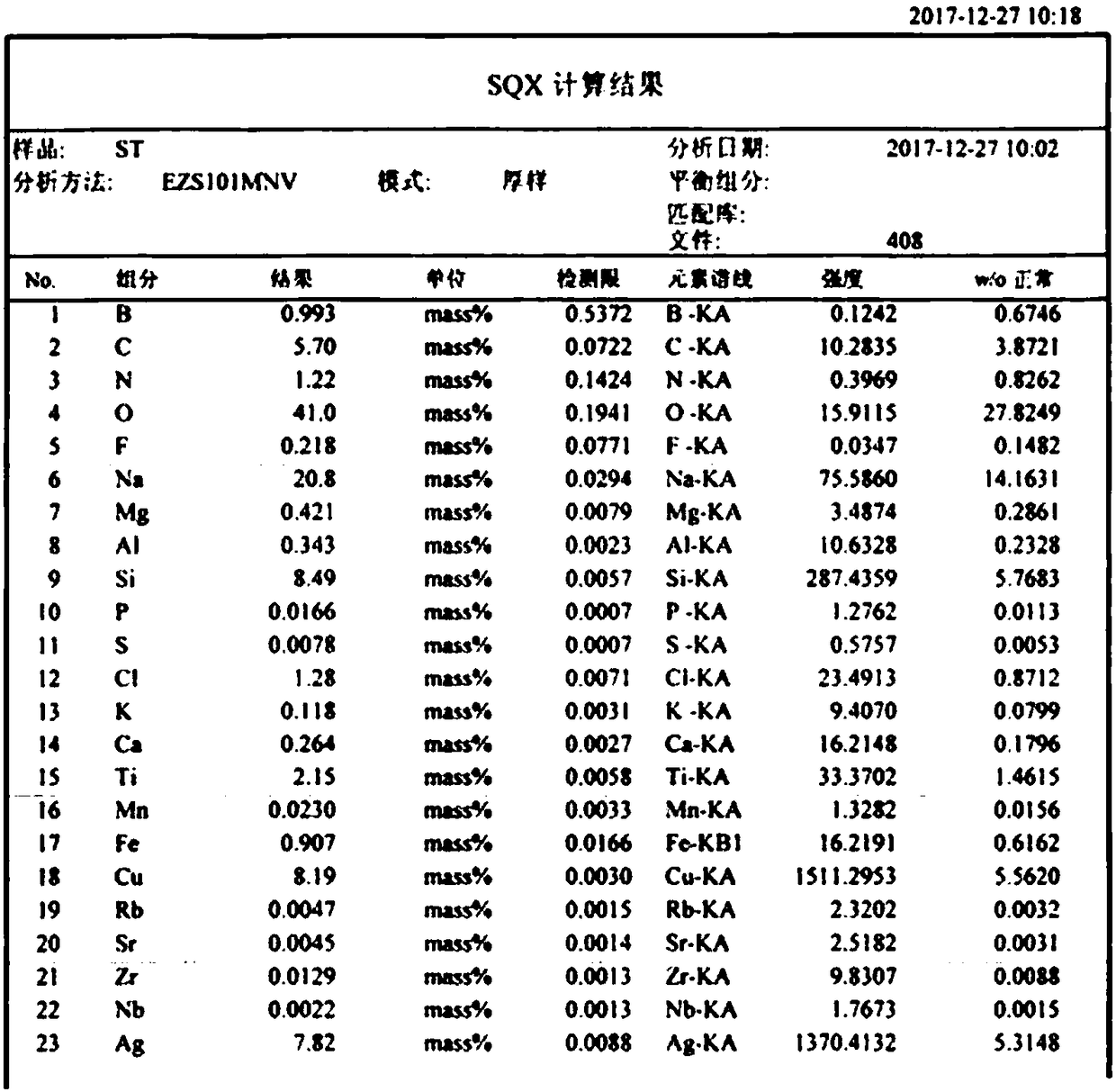

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] A modified attapulgite loaded with copper and silver ions is prepared through the following steps:

[0021] (1) When weighing sodium silicate with a mass ratio of 1-5:1 and distilled water to form a uniform suspension, add attapulgite with a particle size of about 1-200 μm and keep stirring. Mix until it forms a semi-dry viscous shape, make spherical granules, and let it dry naturally for later use.

[0022] (2) In the uniform sodium silicate suspension, add titanium dioxide powder at a ratio of 0.01-0.99 g / ml, and stir while adding until the titanium dioxide is evenly mixed.

[0023] (3) Put the prepared attapulgite spherical carrier into the viscous liquid in (2), and stir until the attapulgite spherical carrier is evenly loaded with titanium dioxide. After it is dried naturally, it is then calcined at 250°C for 0.5-4h, and after natural cooling, it is washed repeat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com