Production process of feed-grade manganese glutamate

A technology of manganese glutamate and production process, applied in the field of production technology of feed-grade manganese glutamate, can solve problems such as being difficult to apply to actual production, and achieve the effects of low equipment cost, few components and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

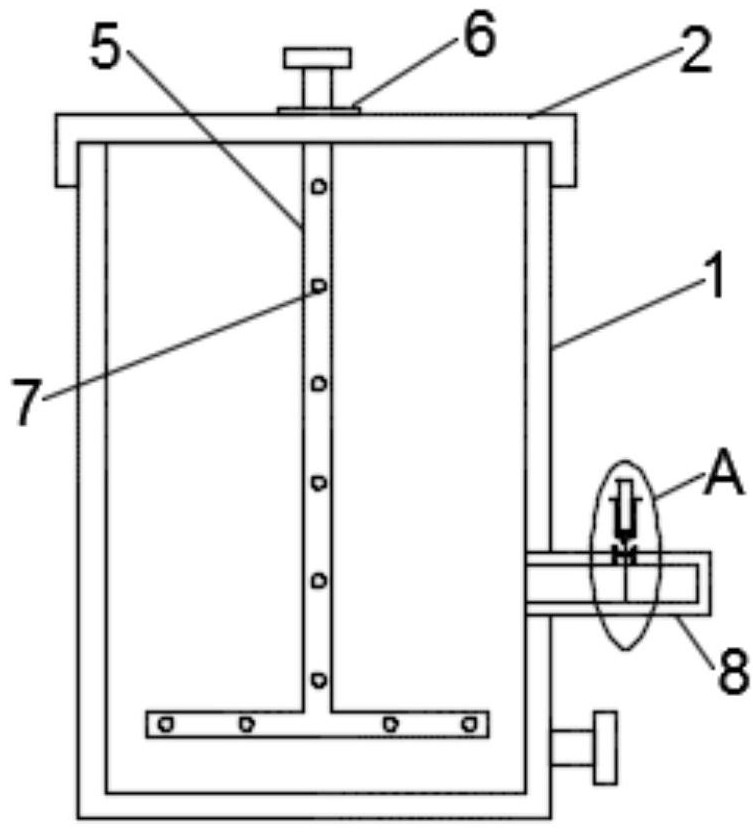

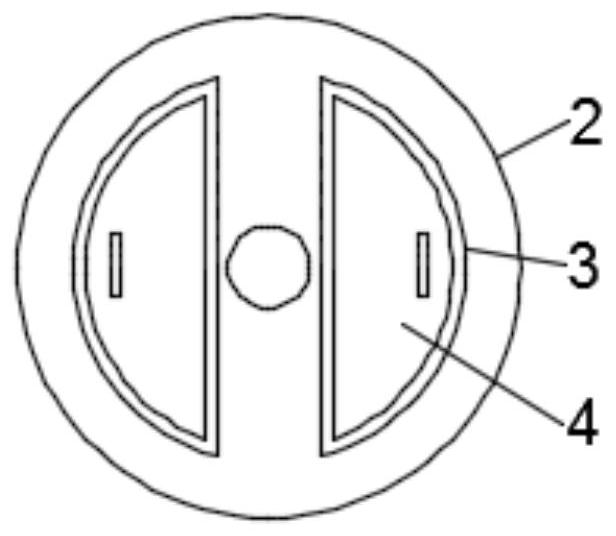

[0025] see Figure 1-3 :

[0026] (1) Open the cover plate 4 to feed the material to the feed port 3, first add deionization;

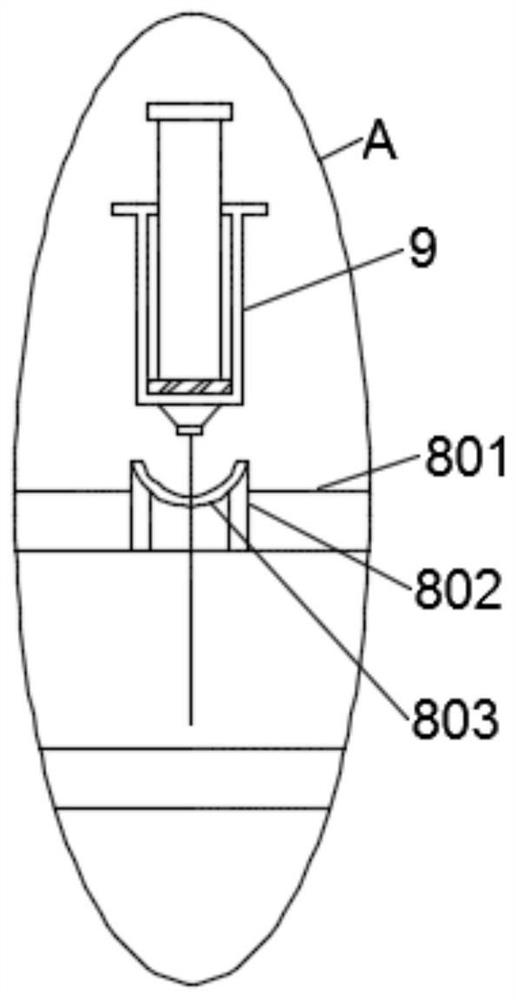

[0027] (2) Add feed grade glutamic acid then, ventilate to vent pipe 5, gas overflows along pore 7, produces air flow in the material in reactor 1, plays stirring effect to material, and reactor 1 is warmed up to 55 ℃ during stirring process. ℃, slowly add manganese sulfate, the connecting pipe 8 is connected to the reaction kettle 1, and the materials in the reaction kettle 1 enter the connecting pipe 8 at the same time. During the process of adding manganese sulfate, use the sampler 9 to insert into the connecting pipe 8 to extract the reaction kettle 1. For materials, detect the manganese sulfate content and glutamic acid content in the material, and control the molar ratio of the total manganese sulfate content to glutamic acid to be 1:1;

[0028] (3) After the feeding is completed, continue to heat up, control the reaction temperature to 75°C, ...

Embodiment 2

[0036] see Figure 1-3 :

[0037] (1) Open the cover plate 4 to feed the material to the feed port 3, first add deionization;

[0038] (2) Add feed grade glutamic acid then, ventilate to ventilation pipe 5, gas overflows along pore 7, produces air flow in the material in reactor 1, plays stirring effect to material, and reactor 1 is warmed up to 60 ℃ during stirring process ℃, slowly add manganese sulfate, the connecting pipe 8 is connected to the reaction kettle 1, and the materials in the reaction kettle 1 enter the connecting pipe 8 at the same time. During the process of adding manganese sulfate, use the sampler 9 to insert into the connecting pipe 8 to extract the reaction kettle 1. For materials, detect the manganese sulfate content and glutamic acid content in the material, and control the molar ratio of the total manganese sulfate content to glutamic acid to be 1:1;

[0039] (3) After the feeding is completed, continue to heat up, control the reaction temperature to ...

Embodiment 3

[0047] see Figure 1-3 :

[0048] (1) Open the cover plate 4 to feed the material to the feed port 3, first add deionization;

[0049] (2) Add feed grade glutamic acid then, ventilate to vent pipe 5, gas overflows along pore 7, produces airflow in the material in reactor 1, plays stirring effect to material, and reactor 1 is warmed up to 65 ℃ in stirring process. ℃, slowly add manganese sulfate, the connecting pipe 8 is connected to the reaction kettle 1, and the materials in the reaction kettle 1 enter the connecting pipe 8 at the same time. During the process of adding manganese sulfate, use the sampler 9 to insert into the connecting pipe 8 to extract the reaction kettle 1. For materials, detect the manganese sulfate content and glutamic acid content in the material, and control the molar ratio of the total manganese sulfate content to glutamic acid to be 1:1;

[0050] (3) After the feeding is completed, continue to heat up, control the reaction temperature to 85°C, and k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com