A kind of preparation method of n-doped carbon polyhedron catalyst supporting mn single atom

A carbon polyhedron and catalyst technology, which is applied in the field of preparation of N-doped carbon polyhedron catalysts, can solve the problems of low metal single atom loading, easy agglomeration of carbon supports, and reduced mass transfer efficiency, so as to improve ORR stability and activity, The effect of optimizing the reaction path and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

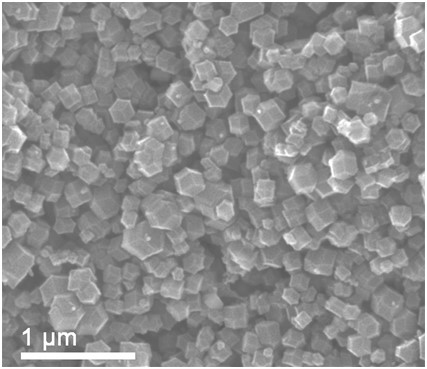

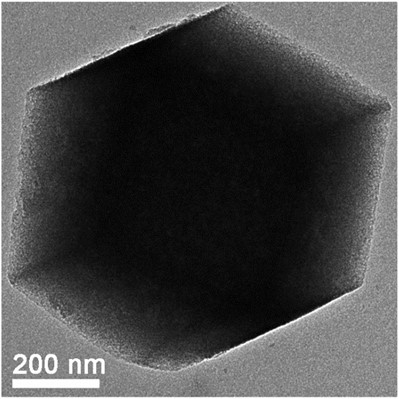

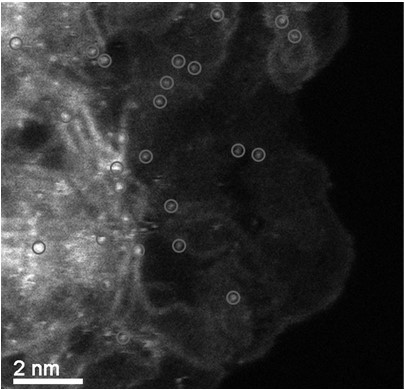

[0057] (1) First, 10.0 mg of carbonyl manganese and 1190 mg of zinc nitrate were dissolved in 30 mL of methanol solution at room temperature with stirring for 10 min to obtain solution A, and 1380 mg of dimethylimidazole was dissolved in 30 mL of methanol solution at room temperature with stirring for 10 min , get solution B, and then mix solution A and solution B at room temperature for 2 hours, then at room temperature, let stand for aging for 12 hours, centrifuge, filter and wash the precipitate with methanol solution 3 times, the white precipitate is at -25 ℃ , freeze-dried for 48h to obtain precursor powder;

[0058] (2) Under the protection of high-purity nitrogen atmosphere, the precursor powder obtained in step (1) is subjected to a heat treatment at 900 ° C for 3 hours to obtain black powder;

[0059] (3) Disperse 100 mg of black powder obtained in step (2) in 10 mL of 0.1 mol / L manganese carbonyl solution, stir at 25 °C for 2 h, and freeze-dry it at -25 °C for 36 h t...

Embodiment 2

[0082] (1) Dissolve 20.0 mg of manganese acetate and 1190 mg of zinc nitrate in 40 mL of methanol solution at room temperature with stirring for 20 min to obtain solution A, and dissolve 1450 mg of dimethylimidazole in 40 mL of methanol solution at room temperature with stirring for 20 min , get solution B, and then mix solution A and solution B at 60 ℃ for 3 hours, then at 60 ℃, let stand for aging for 16 hours, centrifuge, filter and wash the precipitate with methanol solution 3 times, the white precipitate is at -30 At ℃, freeze-drying was carried out for 36h to obtain the precursor powder;

[0083] (2) Under the protection of high-purity argon atmosphere, the precursor powder obtained in step (1) is subjected to a heat treatment at 800 ° C for 2 hours to obtain black powder;

[0084] (3) Disperse 100 mg of black powder obtained in step (2) in 5 mL of 0.2 mol / L manganese acetate solution, stir at 30 °C for 1 h, and freeze-dry it at -30 °C for 48 h to obtain sample powder; ...

Embodiment 3

[0100] (1) Dissolve 30.0 mg of manganese acetylacetonate and 1190 mg of zinc nitrate in 50 mL of deionized water at room temperature for 30 minutes to obtain solution A. Dissolve 1300 mg of dimethylimidazole in 50 mL of deionized water at room temperature for 30 minutes with stirring In water, solution B was obtained, and then solution A and solution B were stirred and mixed at 80 °C for 1 hour, then left to age at 80 °C for 8 hours, centrifuged, and the precipitate was filtered and washed with deionized water for 4 times. Freeze-drying for 24h at -20°C to obtain precursor powder;

[0101] (2) Mix the precursor powder obtained in step (1) in a volume fraction of 5% H 2 / 95%N 2 Under the protection of the mixed gas atmosphere, at 1000 ℃, a heat treatment was carried out for 1 h to obtain black powder;

[0102] (3) Disperse 100 mg of black powder obtained in step (2) in 8 mL of 0.3 mol / L manganese acetylacetonate solution, stir at 20 °C for 1.5 h, and freeze-dry it at -20 °C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com