Carbon assembled zinc sulfide hollow nanopolyhedral honeycomb material and its preparation and application

A technology of hollow nano and honeycomb materials, which is applied in the field of lithium-ion batteries, can solve the problems of inability to effectively inhibit the volume change of zinc sulfide, unfavorable electrochemical reactions, and unfavorable electrolyte infiltration into its interior, so as to improve structural strength and cycle stability. Improved formability and structural integrity, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 1.13g Zn(NO 3 ) 2·6H 2 O and 1.85g dimethylimidazole were dissolved in 80mL methanol respectively, Zn(NO 3 ) 2 Pour the methanol solution of dimethylimidazole into the methanol solution of dimethylimidazole, continue to stir at 20°C for 24 hours, centrifuge the product, wash it with methanol three times, and dry it at 60°C to obtain ZIF-8.

[0035] (2) Disperse 0.1g ZIF-8 prepared in step (1) in 20mL ethanol; dissolve 0.12g PVP in 6mL ethanol, then pour into the ethanol solution of ZIF-8, stir well; dry the solution in an oven at 70°C ;Put the product at the downstream of the gas in the quartz tube furnace, place 0.12g of sublimed sulfur at the upstream of the gas in the quartz tube furnace, feed argon, and heat at 2°C min -1 The rate of heating to 700 ℃ and holding for 1.5h, to obtain carbon-assembled zinc sulfide hollow nano-polyhedral honeycomb material.

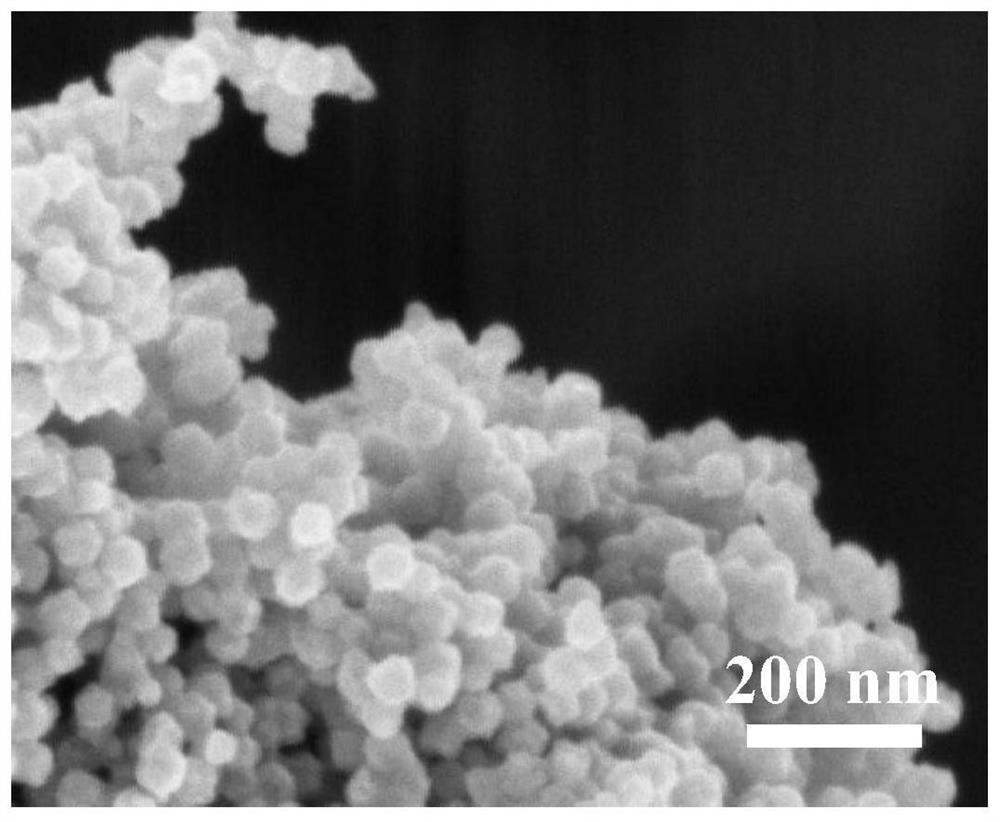

[0036] figure 1 It is the SEM photo of ZIF-8 prepared. ZIF-8 is a crystal with dodecahedral structure,...

Embodiment 2

[0042] (1) 1.13g Zn(NO 3 ) 2 ·6H 2 O and 1.85g dimethylimidazole were dissolved in 80mL methanol respectively, Zn(NO 3 ) 2 Pour the methanol solution of dimethylimidazole into the methanol solution of dimethylimidazole, continue to stir at 20°C for 24 hours, centrifuge the product, wash it with methanol three times, and dry it at 60°C to obtain ZIF-8.

[0043] (2) Disperse 0.1g ZIF-8 prepared in step (1) in 20mL ethanol; dissolve 0.16g PVP in 6mL ethanol, then pour into the ethanol solution of ZIF-8, stir well; dry the solution in an oven at 70°C ;Put the product at the downstream of the gas in the quartz tube furnace, place 0.12g of sublimed sulfur at the upstream of the gas in the quartz tube furnace, feed argon, and heat at 2°C min -1 The rate of heating to 700 ℃ and holding for 1.5h, to obtain carbon-assembled zinc sulfide hollow nano-polyhedral honeycomb material.

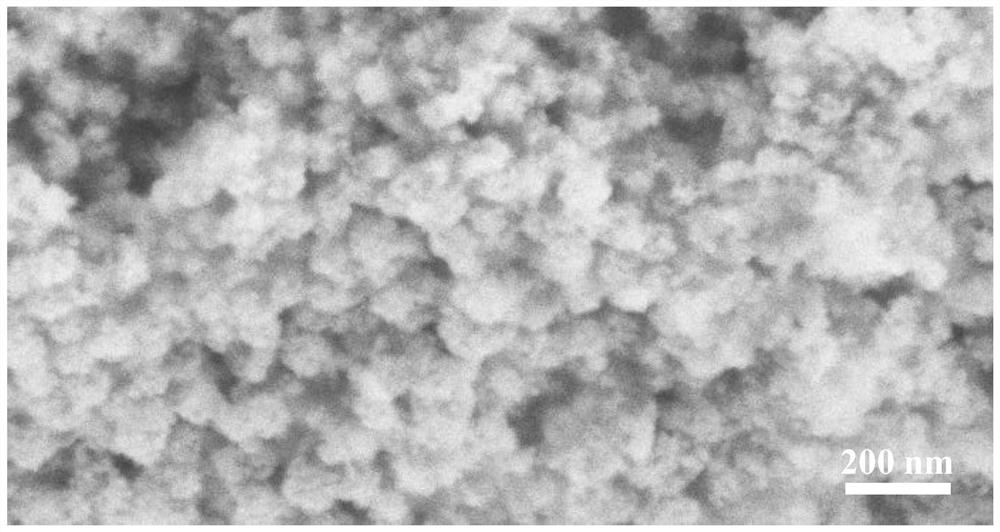

[0044] The structure of the product carbon-assembled zinc sulfide hollow nanopolyhedral honeycomb mate...

Embodiment 3

[0047] (1) 1.13g Zn(NO 3 ) 2 ·6H 2 O and 1.85g dimethylimidazole were dissolved in 80mL methanol respectively, Zn(NO 3 ) 2 Pour the methanol solution of dimethylimidazole into the methanol solution of dimethylimidazole, continue to stir at 35°C for 24 hours, centrifuge the product, wash it with methanol three times, and dry it at 60°C to obtain ZIF-8.

[0048] Subsequent process is identical with embodiment 1.

[0049] The structure of the product carbon-assembled zinc sulfide hollow nanopolyhedron honeycomb material is similar to that of Example 1, the main difference is that the zinc sulfide hollow nanopolyhedron becomes larger, with a particle size of about 100 nm and a wall thickness of about 13 nm.

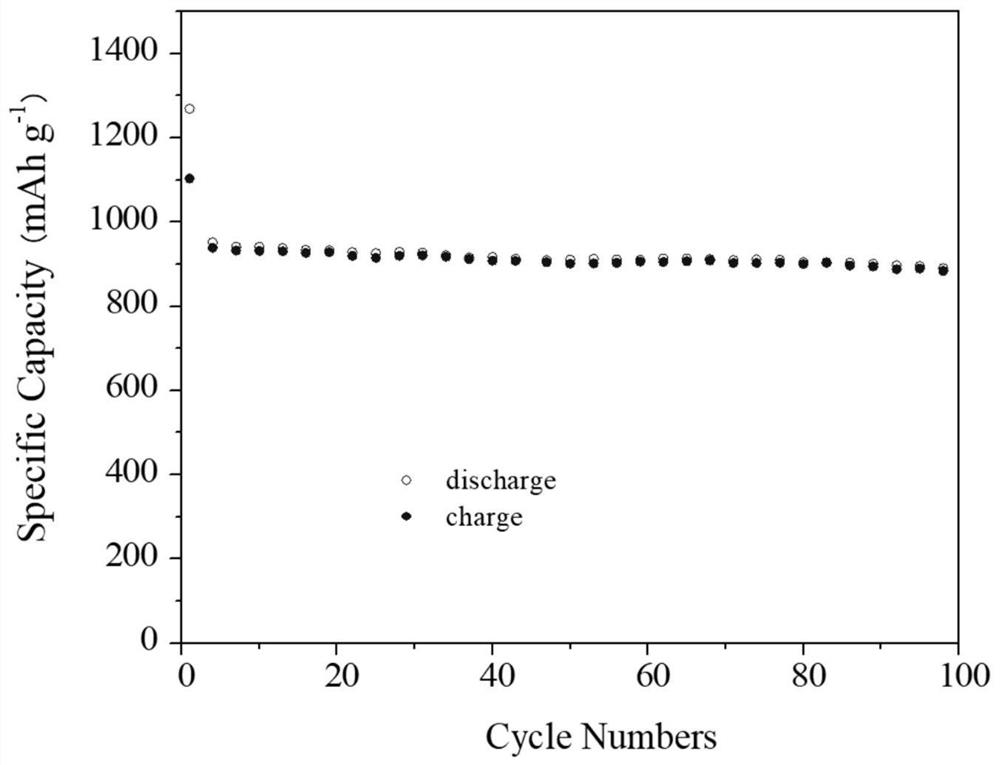

[0050] Adopt the same technology as embodiment 1 to make lithium ion battery negative electrode, assemble into lithium ion battery, with current density 500mA g -1 , 0.01 ~ 3.0V voltage range for cycle charge and discharge test. The discharge specific capacity of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com