Lithium ion battery and preparation method thereof

A lithium-ion battery and conductive agent technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of danger in the synthesis process, high production cost, toxic reducing agent, etc., and achieve short process, simple operation, and cycle performance and the effect of rate performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

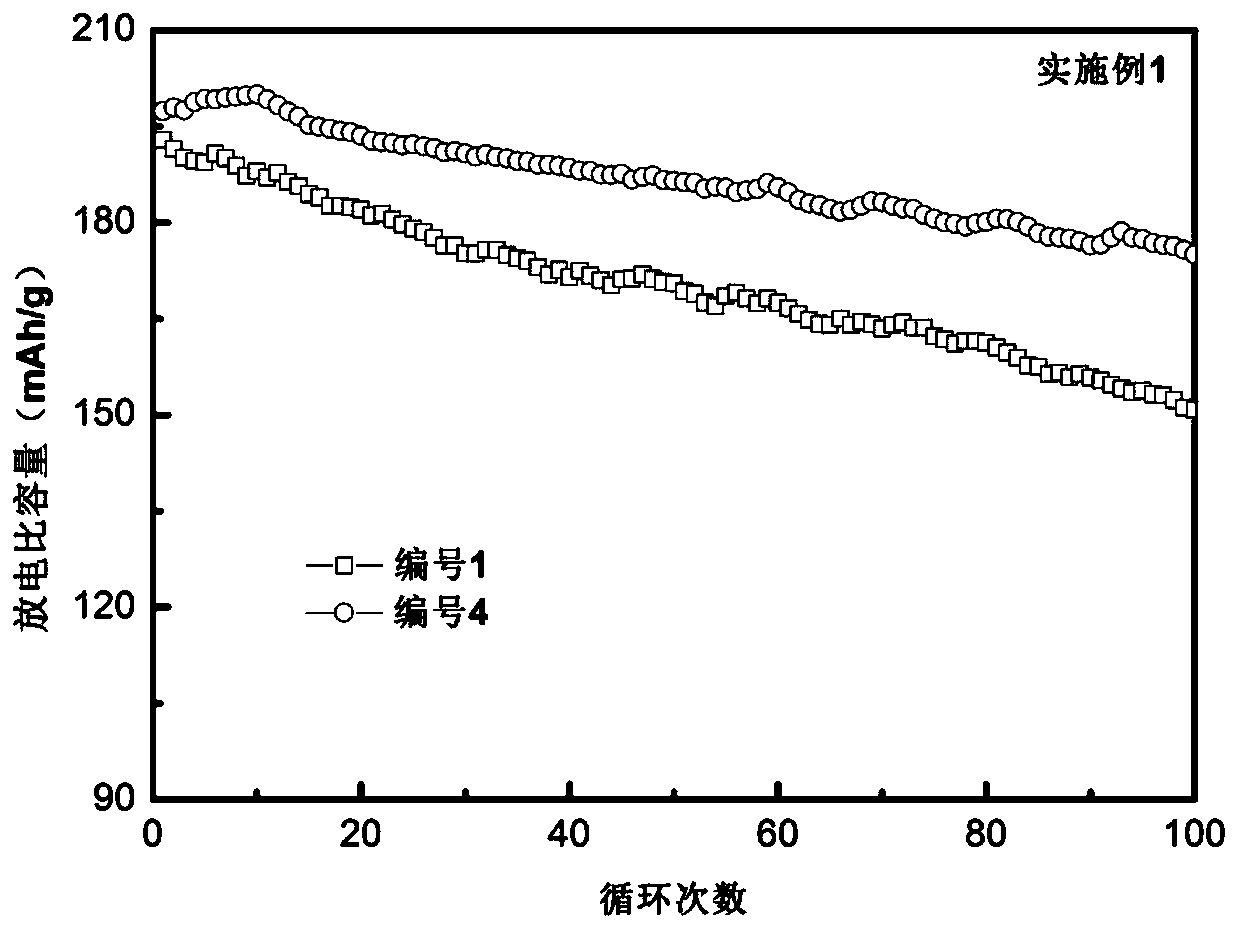

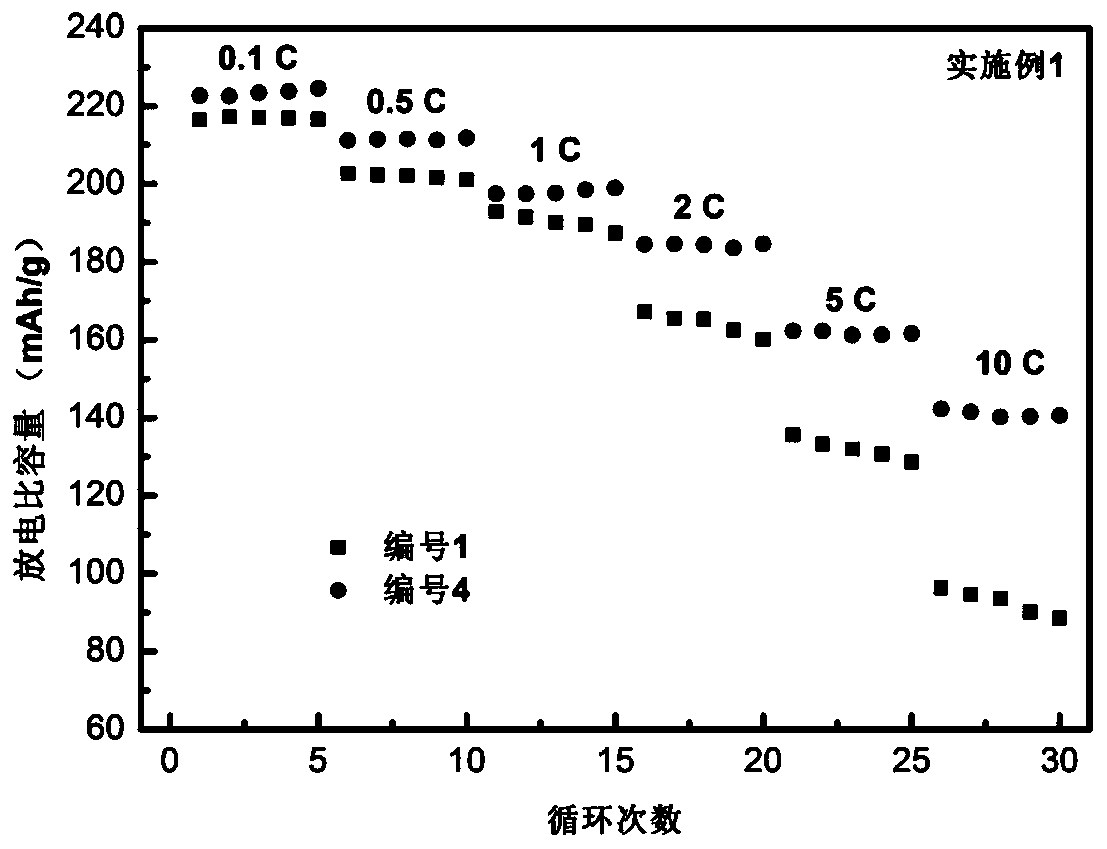

Embodiment 1

[0034] A kind of preparation reduced graphene oxide modified ternary material positive electrode sheet of the present invention, its preparation method comprises the following steps:

[0035] (1) Weigh 0.2g LiNi 0.6 co 0.2 mn 0.2 o 2 , with PVDF and conductive carbon black in a mass ratio of 8:1:1, after being fully ground in a mortar, evenly coated on an aluminum foil, and then placed in a blast drying oven to dry to obtain a positive electrode sheet;

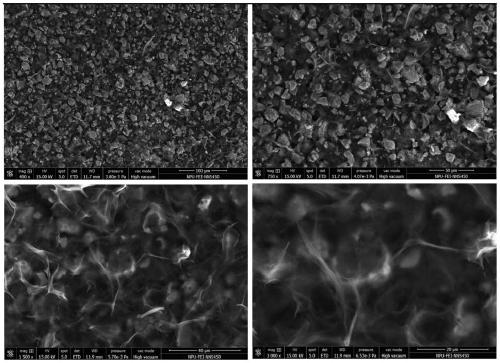

[0036] (2) Take 5 parts of graphene oxide and disperse in NMP solution, ultrasonically disperse for 1 hour, and prepare a concentration of 0 g·mL -1 , 0.001g·mL -1 , 0.002g·mL -1 , 0.01g·mL -1 and 0.02g·mL -1 graphene oxide dispersion. Graphene oxide dispersions with different concentrations are coated on the positive electrode sheet in step (1), and the thickness of the graphene oxide coating is controlled to be 100 μm by a coating machine. Dry in a blast drying oven to obtain the reduced graphene oxide-modified tern...

Embodiment 2

[0048] A kind of preparation reduced graphene oxide modified ternary material positive electrode sheet of the present invention, its preparation method comprises the following steps:

[0049] (1) Weigh 0.2gLiNi 0.6 co 0.2 mn 0.2 o 2 , with PVDF and conductive carbon black in a mass ratio of 8:1:1, after being fully ground in a mortar, evenly coated on an aluminum foil, and then placed in a blast drying oven to dry to obtain a positive electrode sheet;

[0050] (2) Disperse graphene oxide in NMP solution, ultrasonically disperse for 1h, and prepare a concentration of 0.01g mL -1 graphene oxide dispersion. The graphene oxide dispersion is coated on the positive electrode sheet prepared by step (1), and the thickness of the graphene oxide coating is controlled by a coating machine to be 0, 50, 100 and 200 μm respectively. Dry in a blast drying oven to obtain the reduced graphene oxide-modified ternary material positive electrode sheet, and calculate the mass percentage of th...

Embodiment 3

[0058] A kind of preparation reduced graphene oxide modified ternary material positive electrode sheet of the present invention, its preparation method comprises the following steps:

[0059] (1) Weigh 0.2g LiNi 0.6 co 0.2 mn 0.2 o 2 , with PVDF and conductive carbon black in a mass ratio of 8:1:1, after being fully ground in a mortar, evenly coated on an aluminum foil, and then placed in a blast drying oven to dry to obtain a positive electrode sheet;

[0060] (2) Disperse graphene oxide in NMP solution, ultrasonically disperse for 1h, and prepare a concentration of 0.01g mL -1 graphene oxide dispersion. The graphene oxide dispersion is coated on the positive electrode sheet made by step (1), and the thickness of the graphene oxide coating is controlled to be 100 μm by a coating machine. Dry in a blast drying oven to obtain the reduced graphene oxide-modified ternary material positive electrode sheet, and calculate the mass percentage of the coated graphene oxide in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com