Synthesis method of reproceesable thermosetting polymer

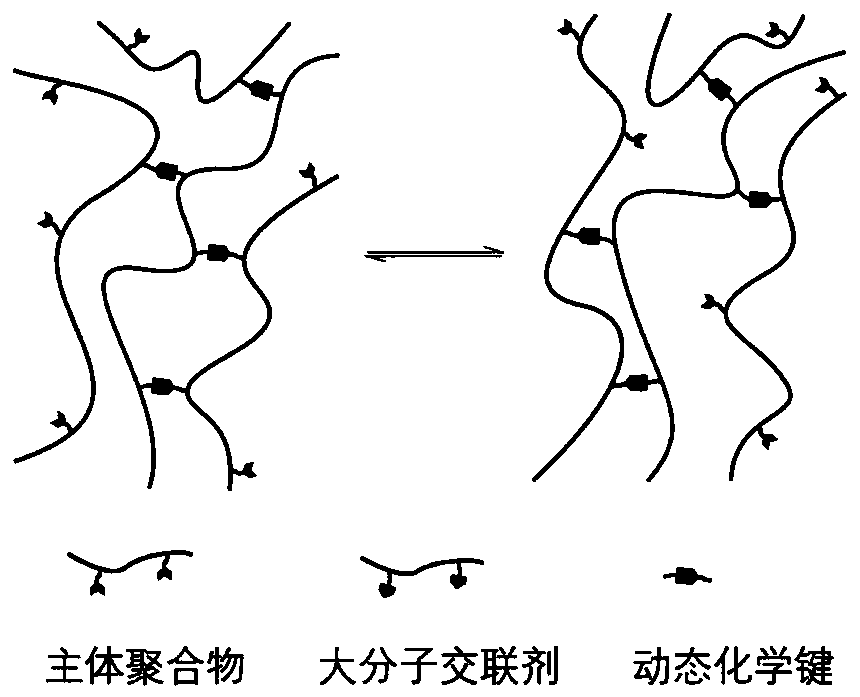

A technology of repeated processing and synthesis method, which is applied in the field of synthesis of thermosetting polymers, can solve problems such as pollution, poor resistance to organic solvents, corrosion of organic solvents, etc., and achieve the effects of simple synthesis process, improved mechanical properties, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

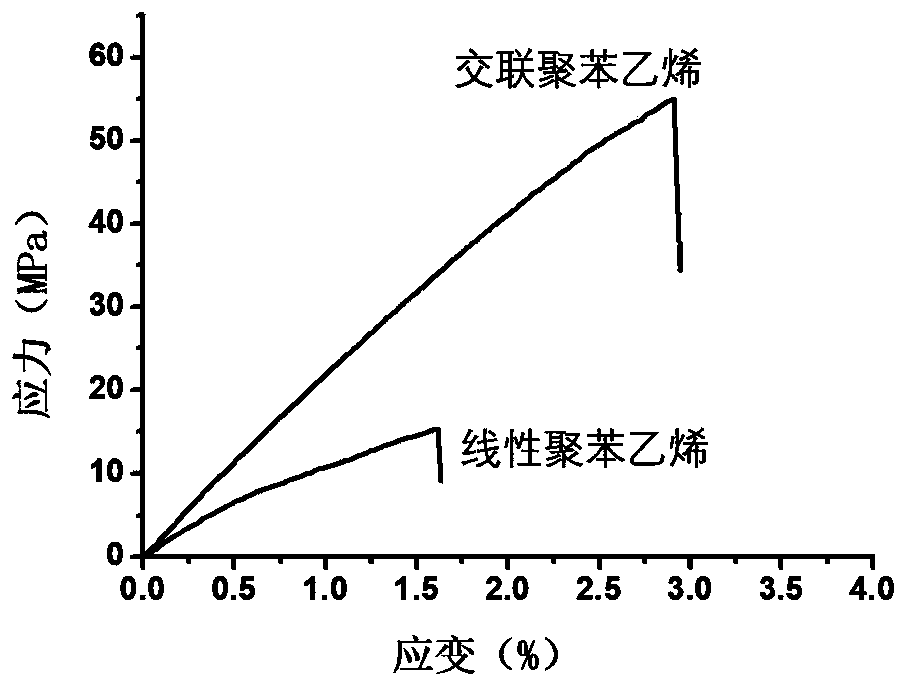

[0037] Example 1. Synthesis of reproducible cross-linked styrene (representing the method for synthesizing thermosetting polymers from styrene and its derivative monomers).

[0038] Add 100 mmol of styrene, monomer A (glyceryl methacrylate-phenylboronate), 0.1 mmol of initiator, and 0.02 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 10 mL of dimethyl sulfoxide as a solvent, then stir the reaction bottle in an oil bath at 110°C for 24 hours, then cool the reaction to room temperature, pour the reaction liquid into methanol to precipitate a polymer precipitate, and vacuum dry to constant weight , to obtain polymer 1. Its synthetic route is:

[0039]

[0040] Add 10 mmol of styrene, monomer B (propylene glycol vinyl phenyl borate), 0.01 mmol of RAFT initiator, and 0.002 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 2mL of dimethyl sulfoxide as a solvent, then stir the reaction flask in an oil bath at 110°C for 24 hours, then cool t...

Embodiment 2

[0045] Example 2. Synthesis of reproducible cross-linked polymethyl methacrylate (representing a method for synthesizing thermosetting polymers from methacrylate monomers).

[0046] Add 100 mmol of methyl methacrylate, monomer A (glyceryl methacrylate-phenylboronate), 0.1 mmol of initiator, and 0.02 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 10 mL of dimethyl sulfoxide as a solvent, then stir the reaction bottle in an oil bath at 65°C for 16 hours, then cool the reaction to room temperature, pour the reaction solution into methanol to precipitate a polymer, and dry it in vacuum to constant weight , to obtain polymer 4. Its synthetic route is:

[0047]

[0048] Add 10 mmol of methyl methacrylate, monomer B (propylene glycol vinyl phenyl borate), 0.01 mmol of RAFT initiator, and 0.002 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 2 mL of dimethyl sulfoxide as a solvent, then stir the reaction bottle in an oil bath at 65°C for 1...

Embodiment 3

[0053] Example 3. Synthesis of reproducible cross-linked n-butyl acrylate (representing a method for synthesizing thermosetting polymers from acrylate monomers).

[0054] Add 100 mmol of n-butyl acrylate, monomer A (glyceryl methacrylate-phenylboronate), 0.1 mmol of initiator, and 0.02 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 10mL of dimethyl sulfoxide as a solvent, then stir the reaction bottle in an oil bath at 65°C for 8 hours, then cool the reaction to room temperature and add 10mL of tetrahydrofuran, mix well and pour into petroleum ether to precipitate a polymer precipitate, Drying in vacuo to constant weight afforded polymer 7. Its synthetic route is:

[0055]

[0056] Add 10 mmol of n-butyl acrylate, monomer B (propylene glycol vinyl phenyl borate), 0.01 mmol of RAFT initiator, and 0.002 mmol of azobisisobutyronitrile into the Schlenk reaction flask. Add 2mL of dimethyl sulfoxide as a solvent, then stir the reaction bottle in an oil bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com