Patents

Literature

229results about "Temporary coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing compositions and method of forming the same

ActiveUS20060110542A1Increased durabilityImprove conditionsPigmenting treatmentFouling preventionSilica particleAdditive ingredient

A method for processing compositions, compositions obtained by such a process and methods of use are disclosed for forming a detachable and renewable protective coating which is substantially transparent. The inventive process compositions are produced by making a highly concentrated dispersion of hydrophobically modified silica particles in the presence of an optional, yet preferable, disilazane derivative under high shear conditions. These process compositions are intended to be further diluted to final treatment compositions, optionally while adding other functional ingredients.

Owner:EVONIK OPERATIONS GMBH

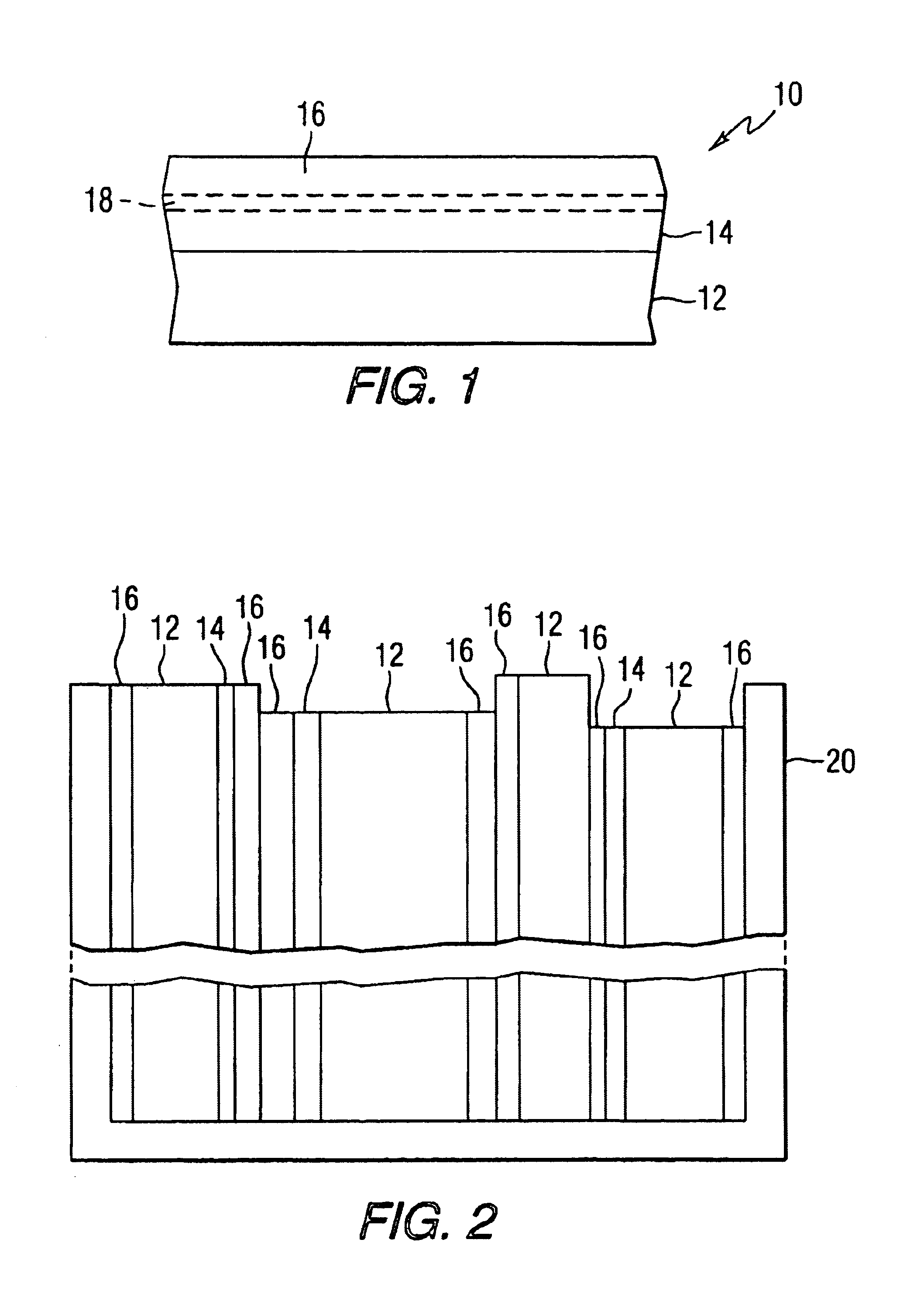

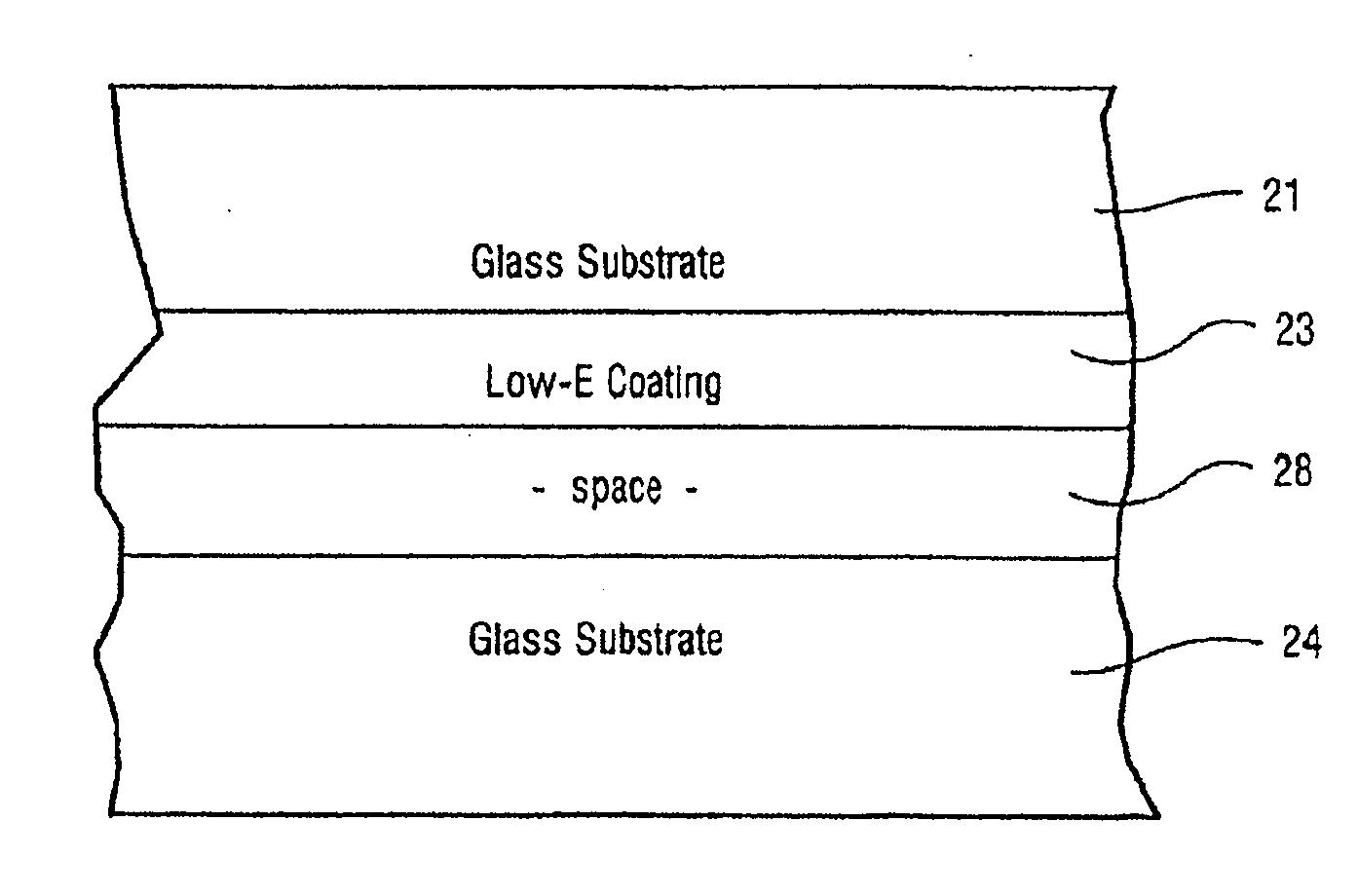

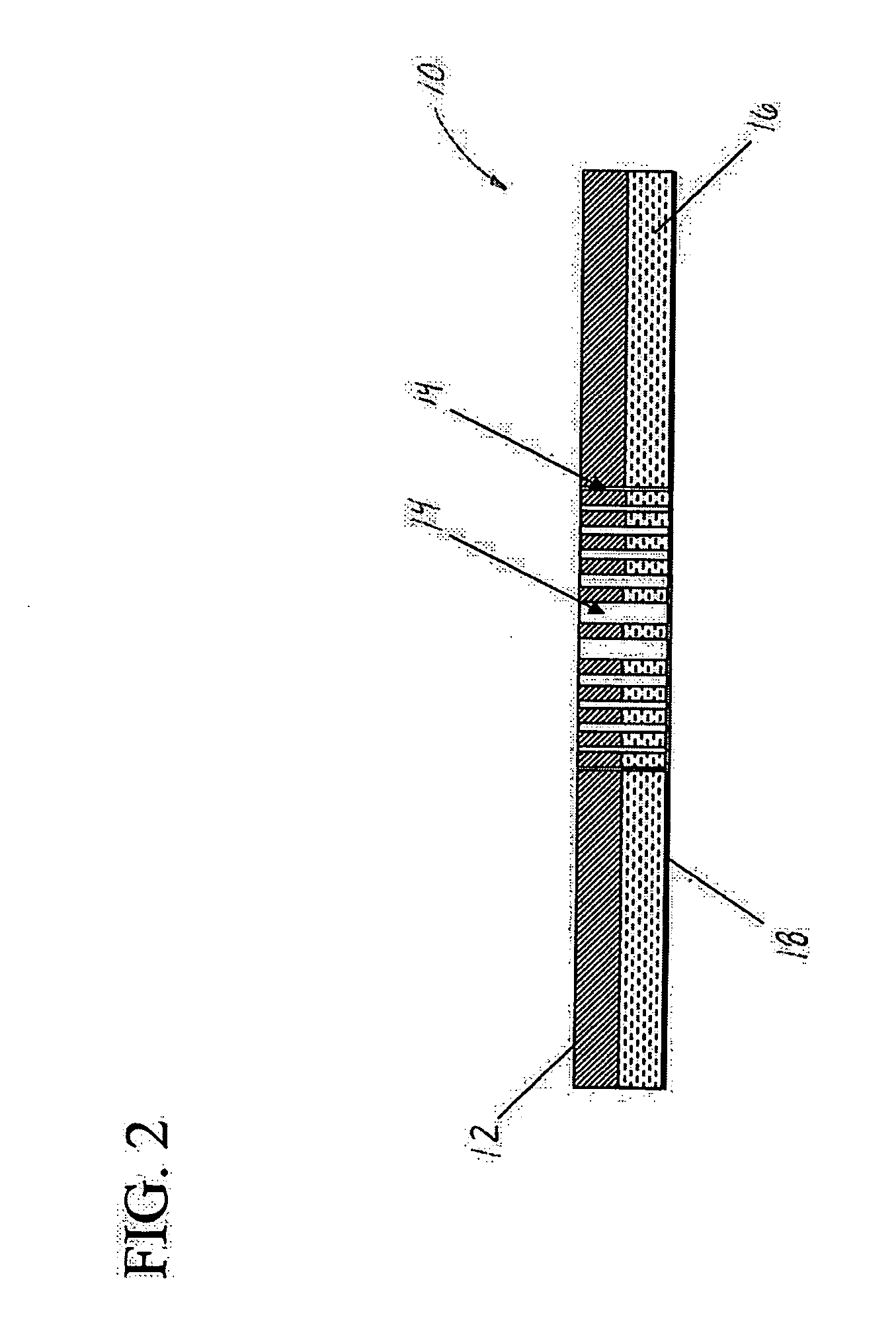

Light-transmitting and/or coated article with removable protective coating and methods of making the same

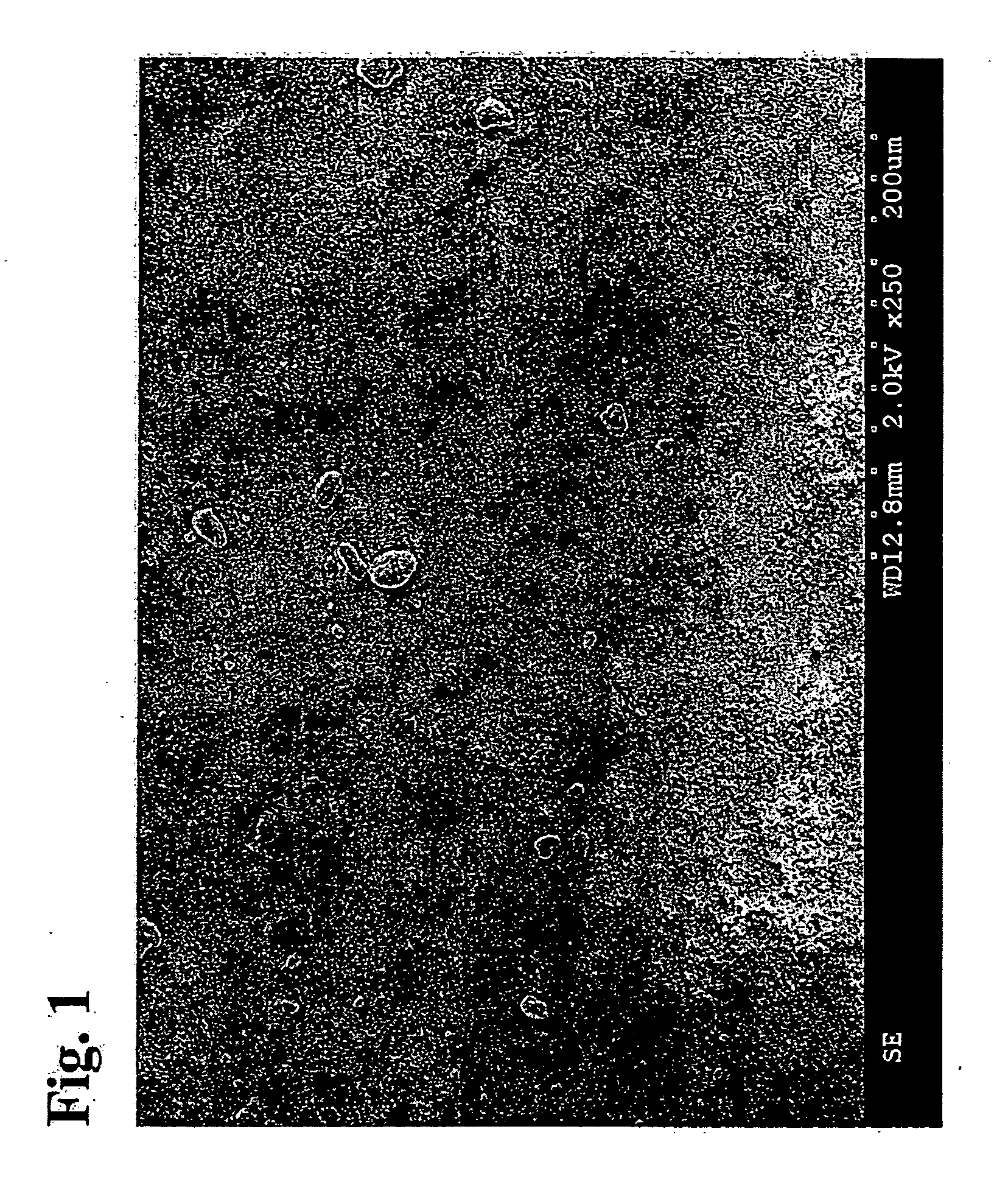

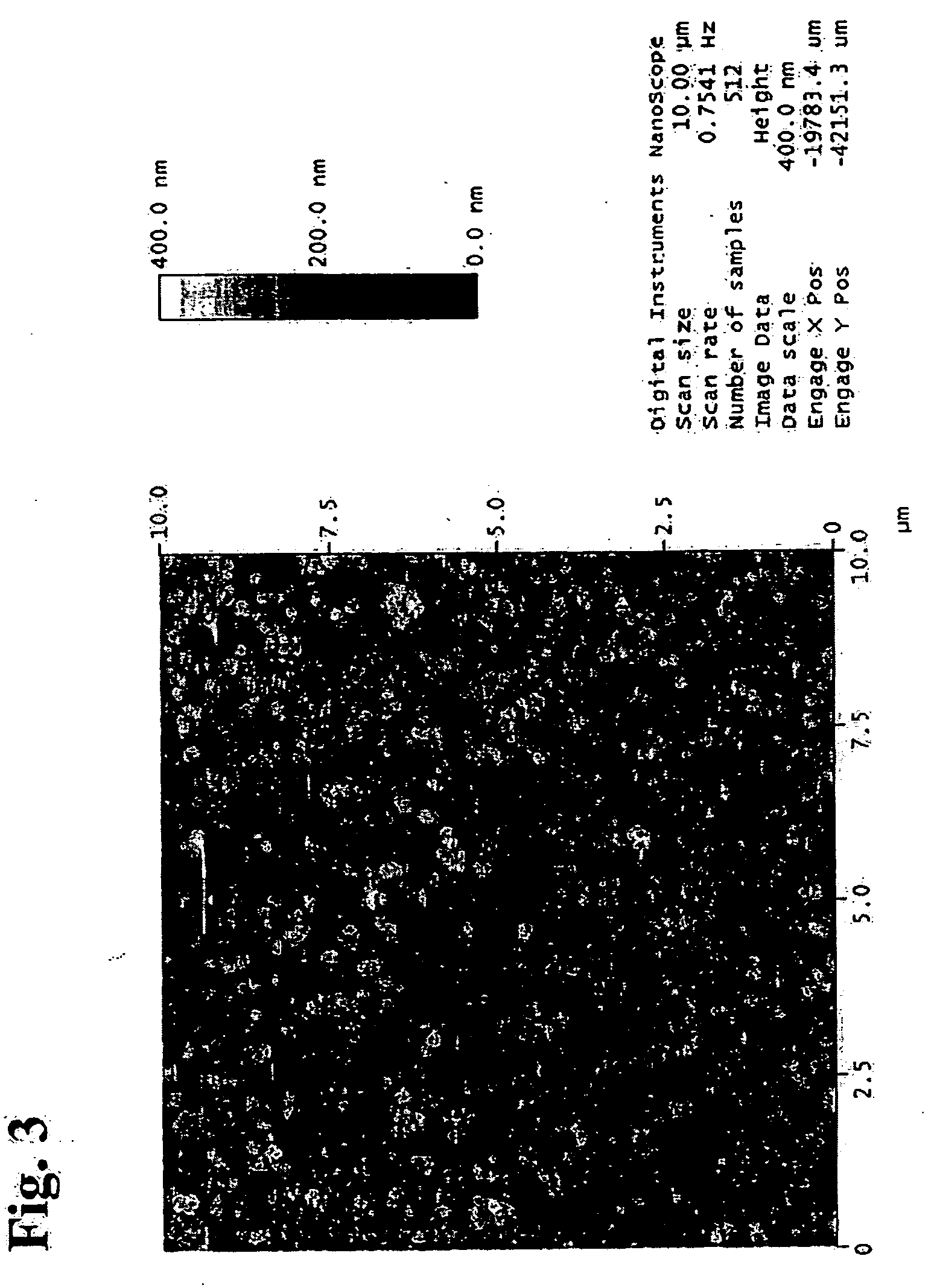

InactiveUS6849328B1Heating evenlyIncrease heat absorptionSynthetic resin layered productsPaints with biocidesCombustionPolyvinyl alcohol

A method and coating are provided for temporarily protecting a substrate or article during shipping, handling or storage by applying a removable protective coating over at least a portion of the substrate. The substrate may be flat or curved and may have zero, one or more functional coatings. A plurality of substrates with the protective coating of the invention may be arranged in a shipping container so that the protective coating reduces the possibility of damage to the substrate or optional functional coating. In one embodiment, the protective coating is the evaporation or reaction product of an aqueous coating composition containing a polyvinyl alcohol polymer which may be subsequently removed by aqueous washing, thermal decomposition or combustion. In another embodiment, the protective coating is formed by sputtering a substantially carbon coating onto the substrate. The carbon coating is subsequently removed by combustion. The protective coating may have identification materials, such as colorants or fragrance materials, such that different types of substrates and / or functional coatings can be distinguished from each other. Additionally, the temporary protective coating can improve the heating of a functionally coated glass substrate.

Owner:VITRO FLAT GLASS LLC

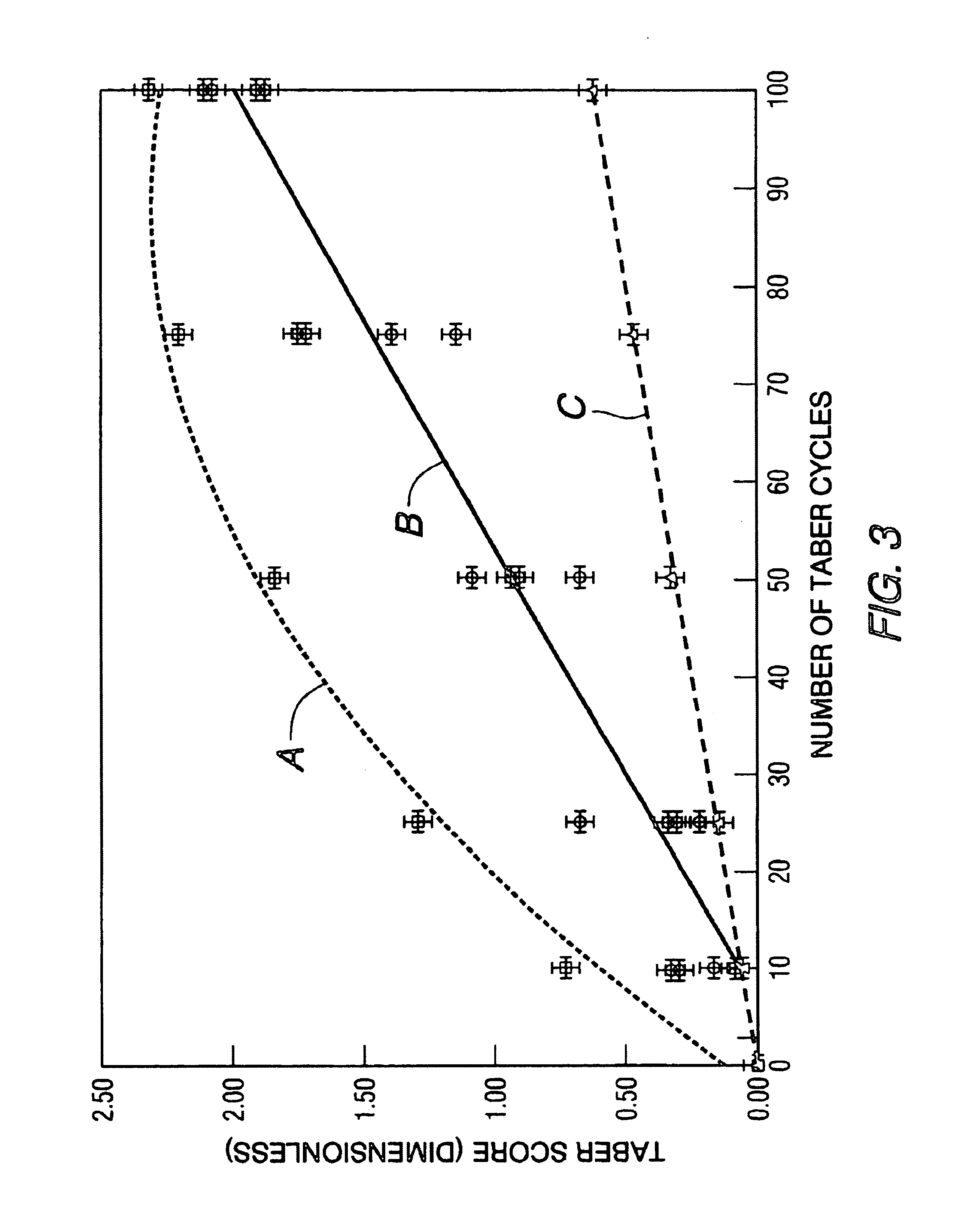

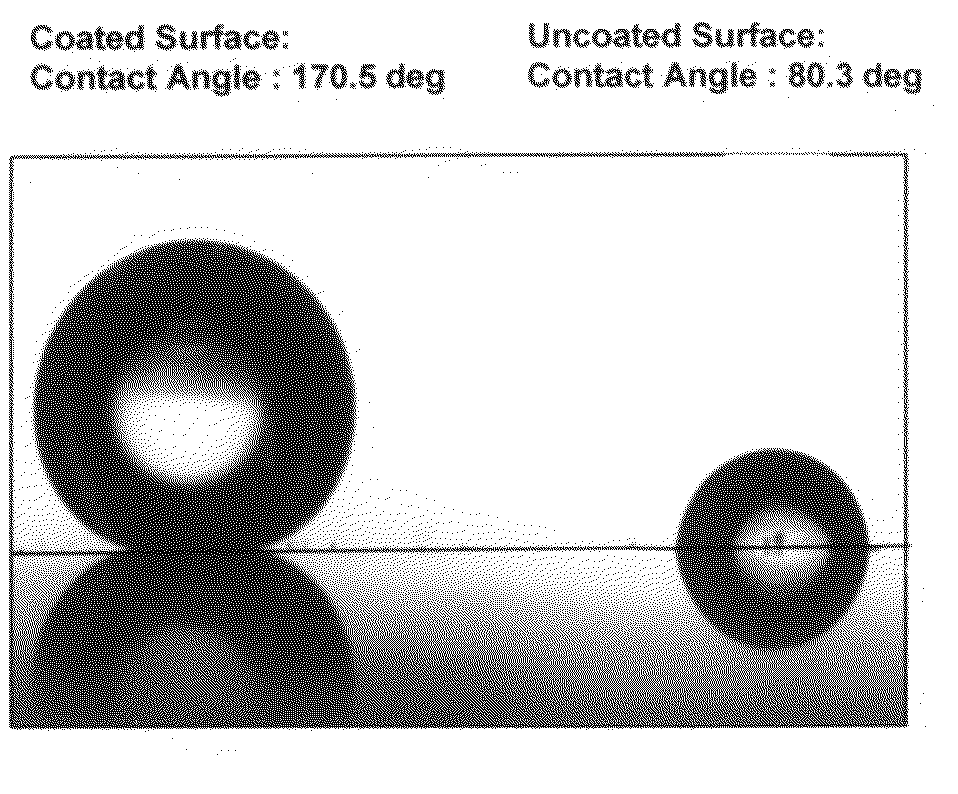

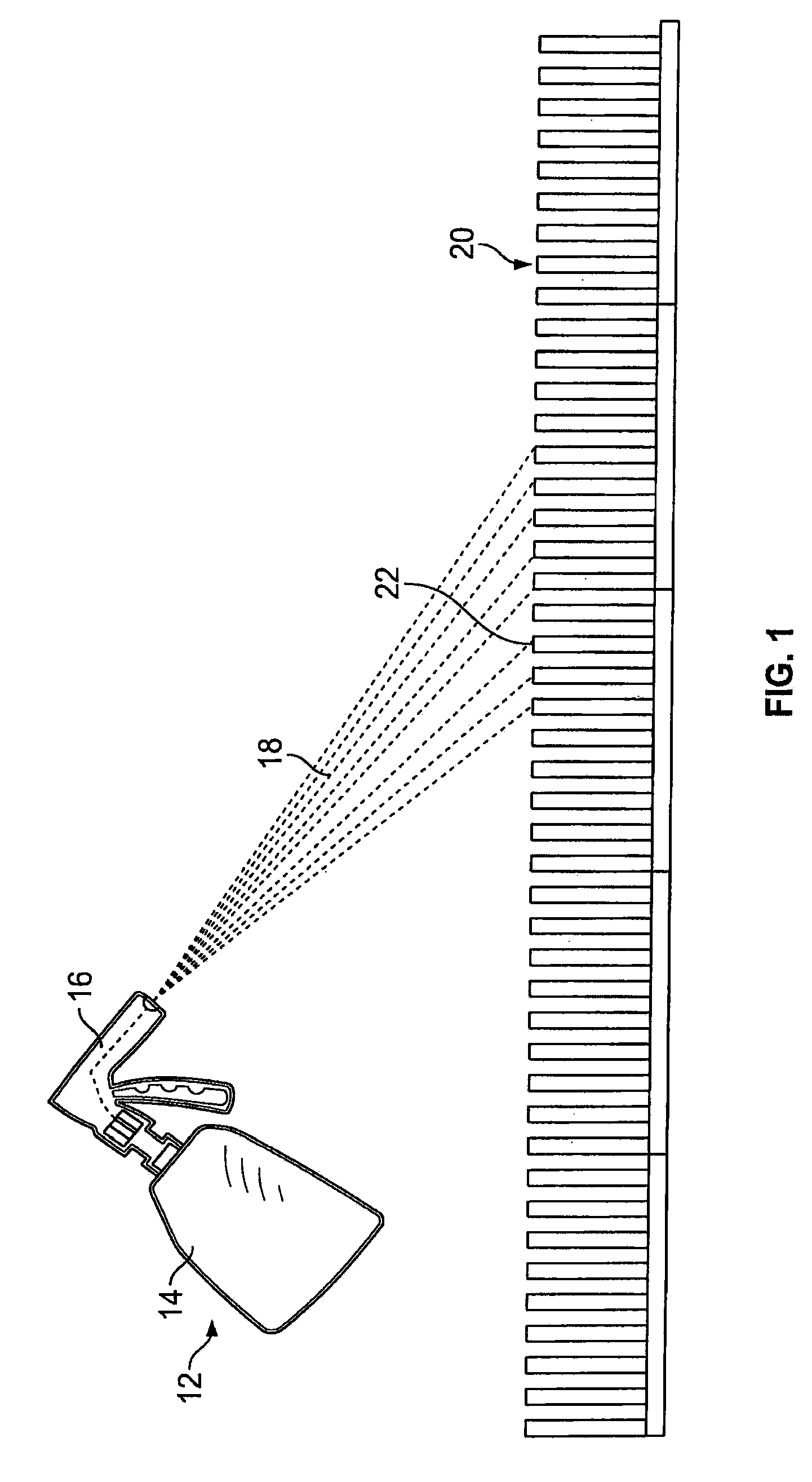

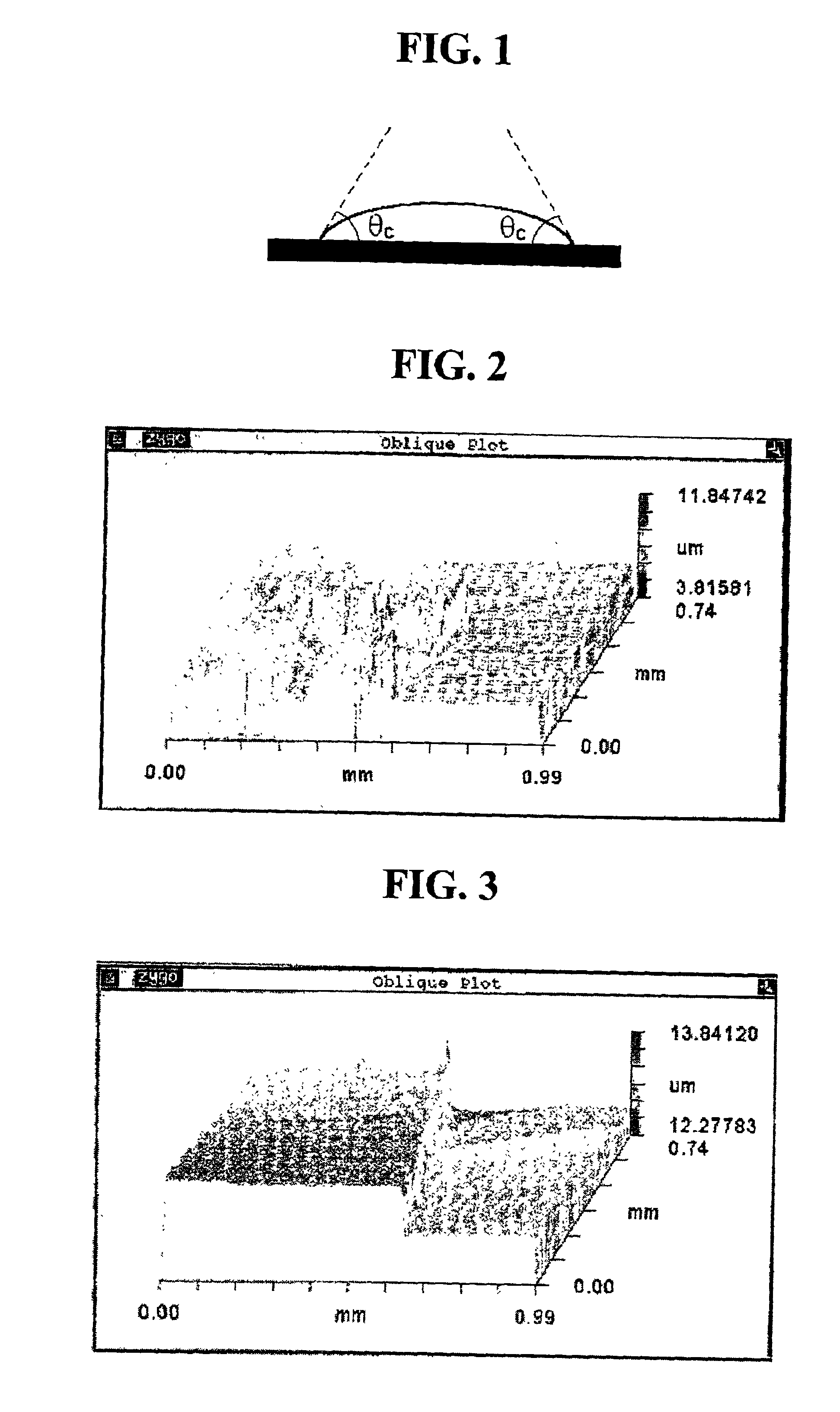

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

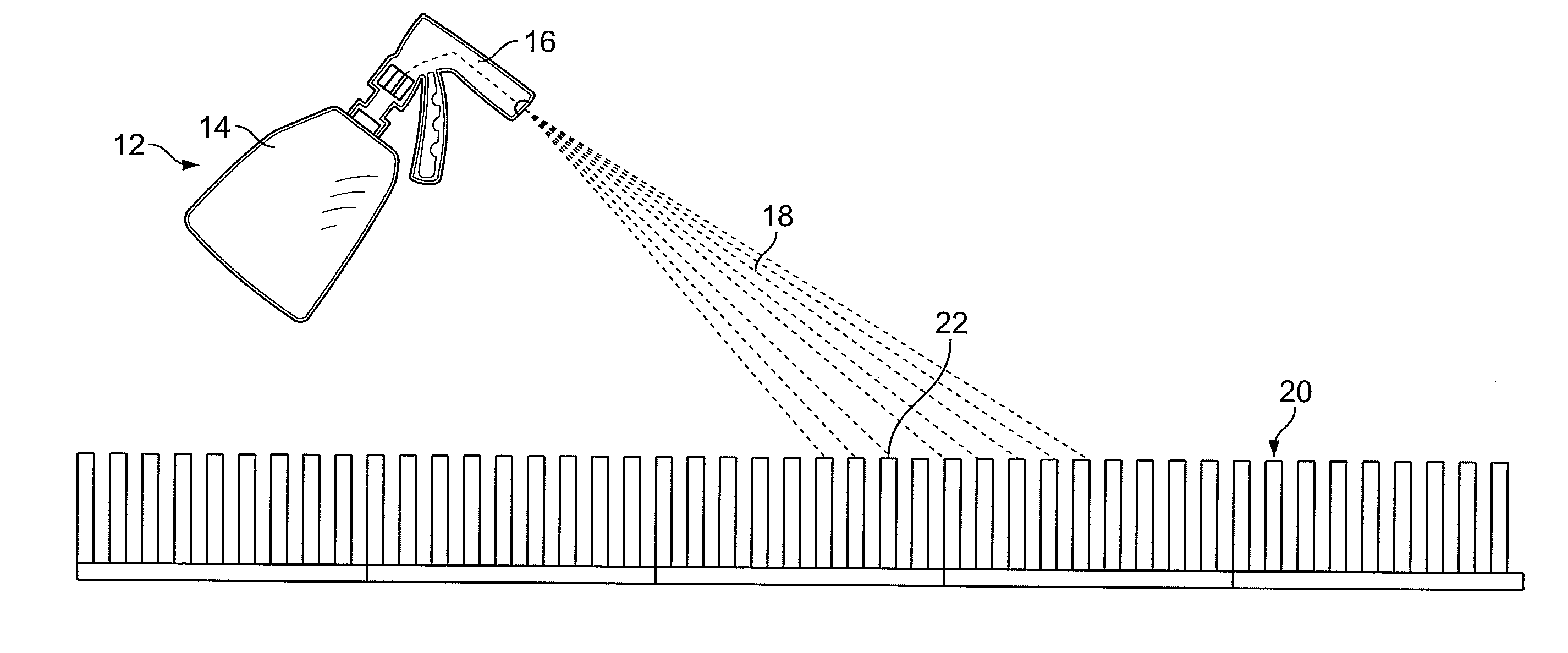

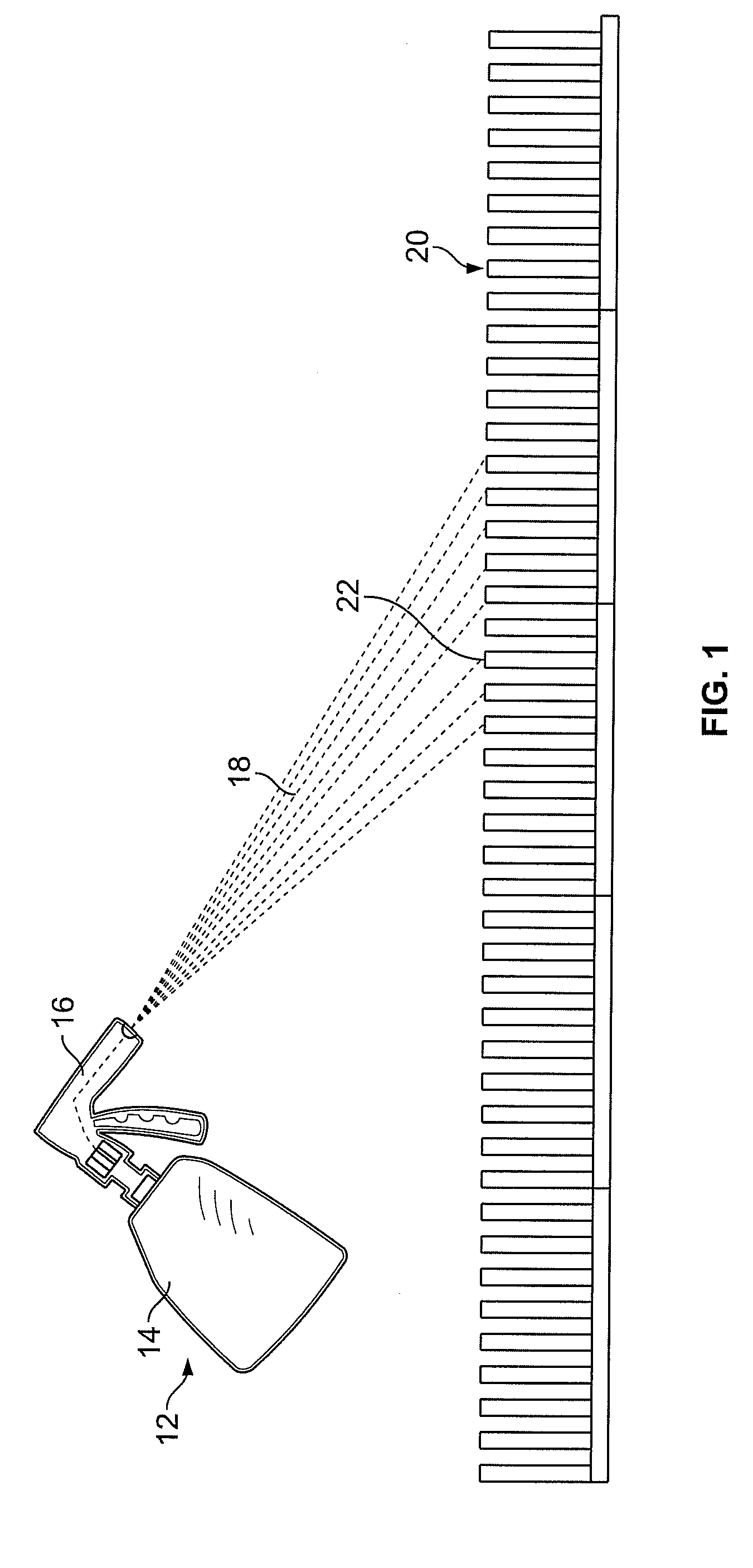

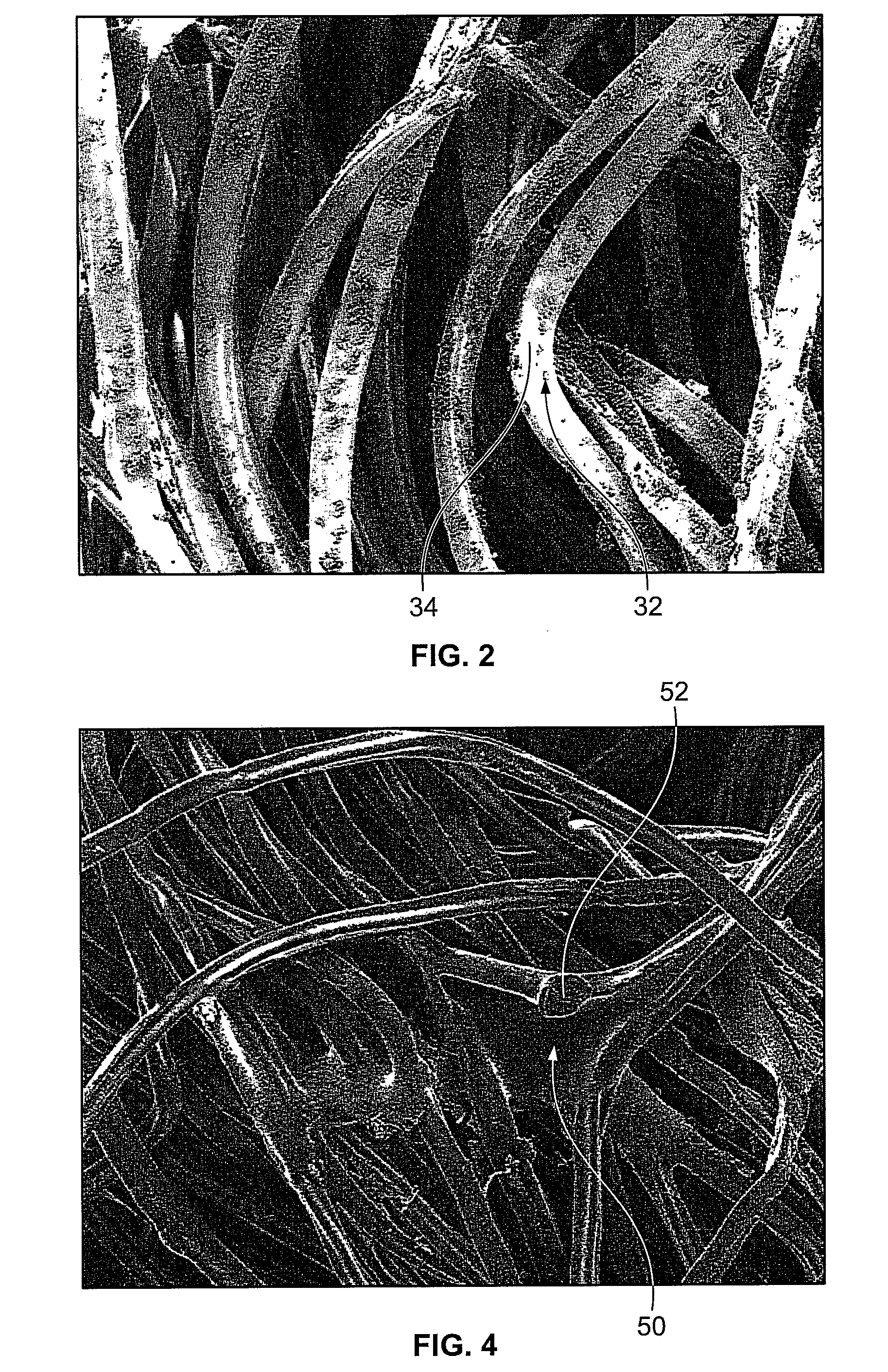

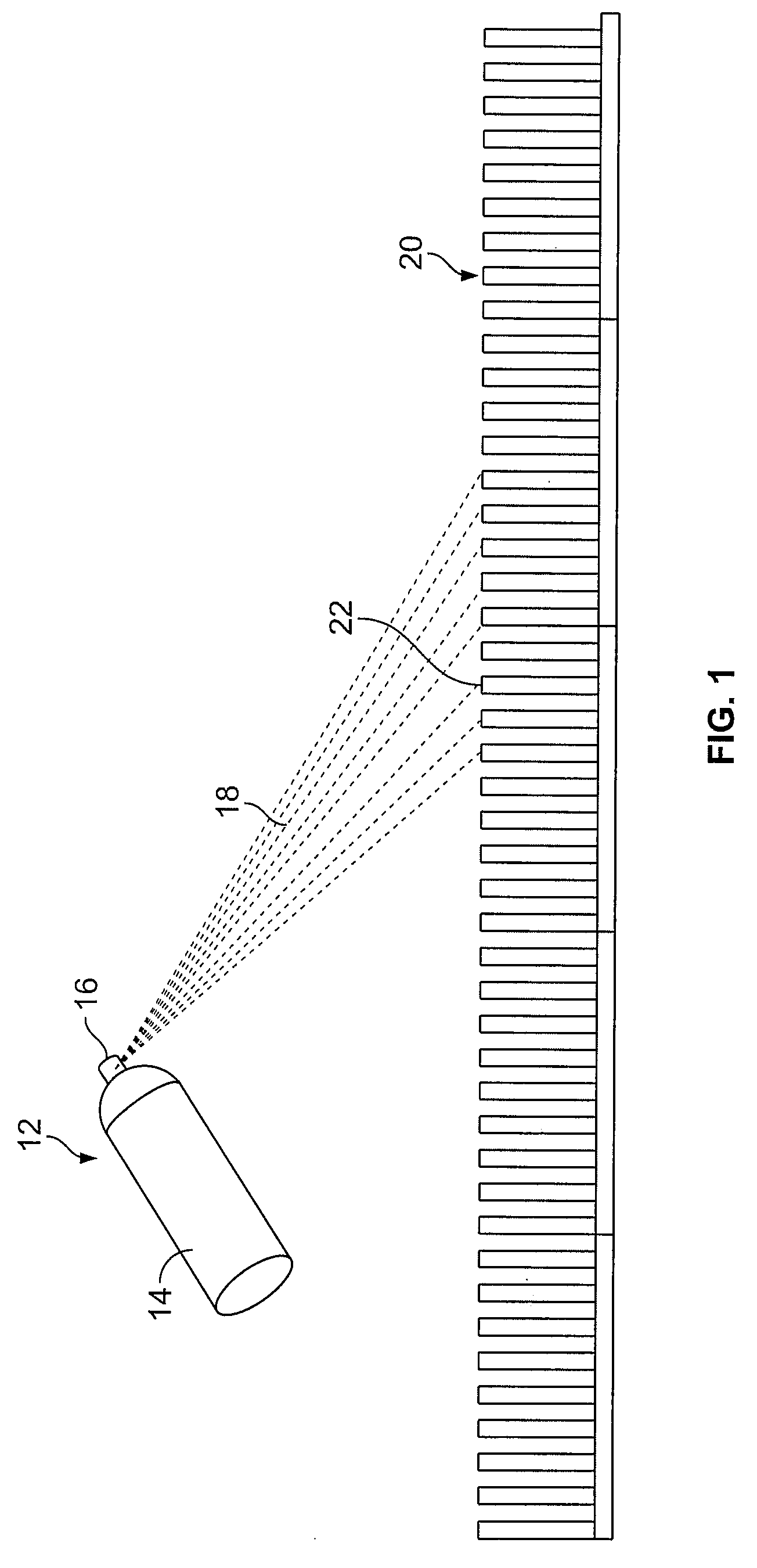

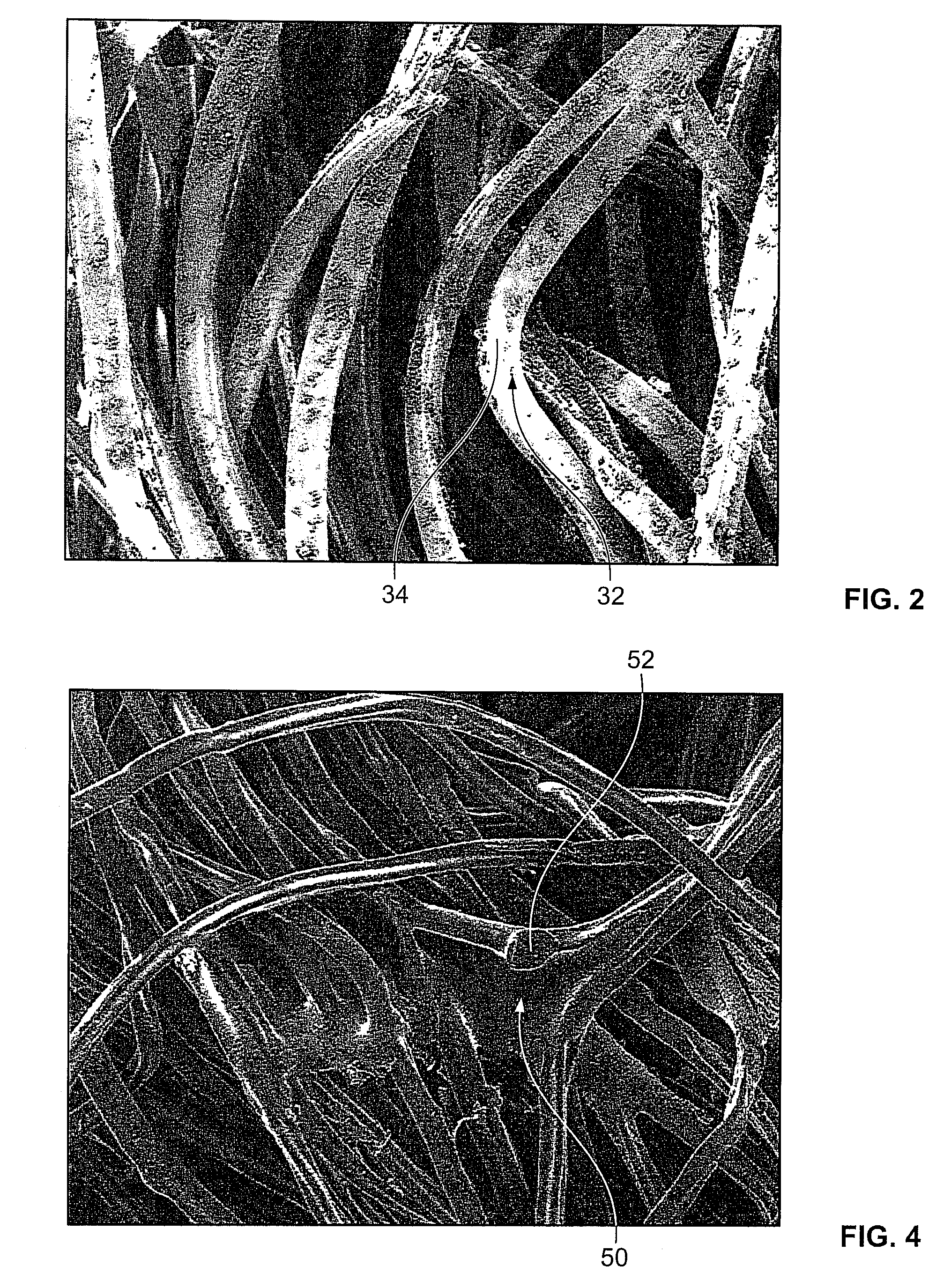

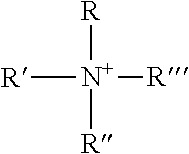

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Hydrophobic self-cleaning coating compositions

InactiveUS20090018249A1Reduce icingInexpensive comparedOther chemical processesSpecial tyresEvaporationSolvent

A hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface forming creating a wet and dry dirt repellent coating on the surface. The coating utilizes hydrophobic nanoparticles of fumed silica and / or titania in a solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. Virtually transparent coating are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. One preferred coating composition utilizing an effective amount of a treated fumed silica in a solvent forms a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The self-cleaning coating composition imparts a degree of hydrophobicity to a surface so that the treated surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher.

Owner:ASHLAND LICENSING & INTPROP LLC

Masking solutions comprising siloxane-based surfactants for using in painting operations

This invention provides a masking material that can be used to protect an underling surface (e.g. an automobile surface) during an overcoating (e.g. painting) operation. The masking material in one embodiment includes a thickener and a pH control agent and water. The masking material can be applied to a surface that is to be protected from paint overspray or other coating processes, allowed to dry, and the surface then coated (e.g. with paint). After drying of the paint, or other coating, the masking material can removed by water washing.

Owner:CAL WEST SPECIALTY COATINGS

Temporary, Water-Proof, Clear or Tinted System, Method of Use and Removal

InactiveUS20080241371A1Easily and simply removedImprove solubilityOrganic dyesTemporary coatingsMaterials sciencePolymer

A highly water resistant coating is described for use as a temporary protective or tinting finish for a wide variety of personal items, including one's vehicle and tires. The film forming polymer of the coating is desirable as it can be applied with polar solvents but then upon evaporation of a solubilizing additive becomes water resistant or water proof. Thereafter if a similar solubilizing additive is used in a polar solvent, the coating can be removed without damaging the surface of the substrate.

Owner:THE LUBRIZOL CORP

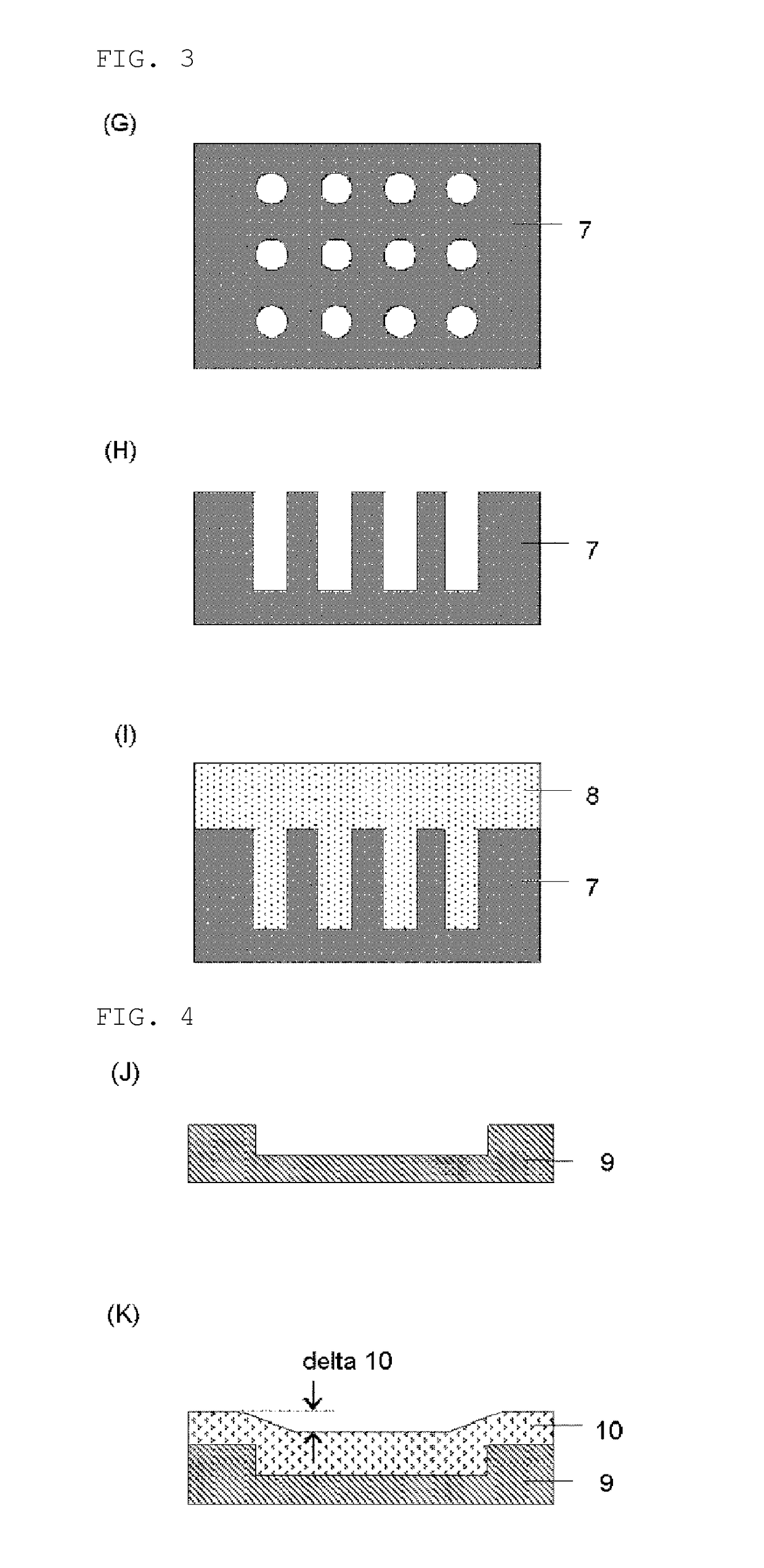

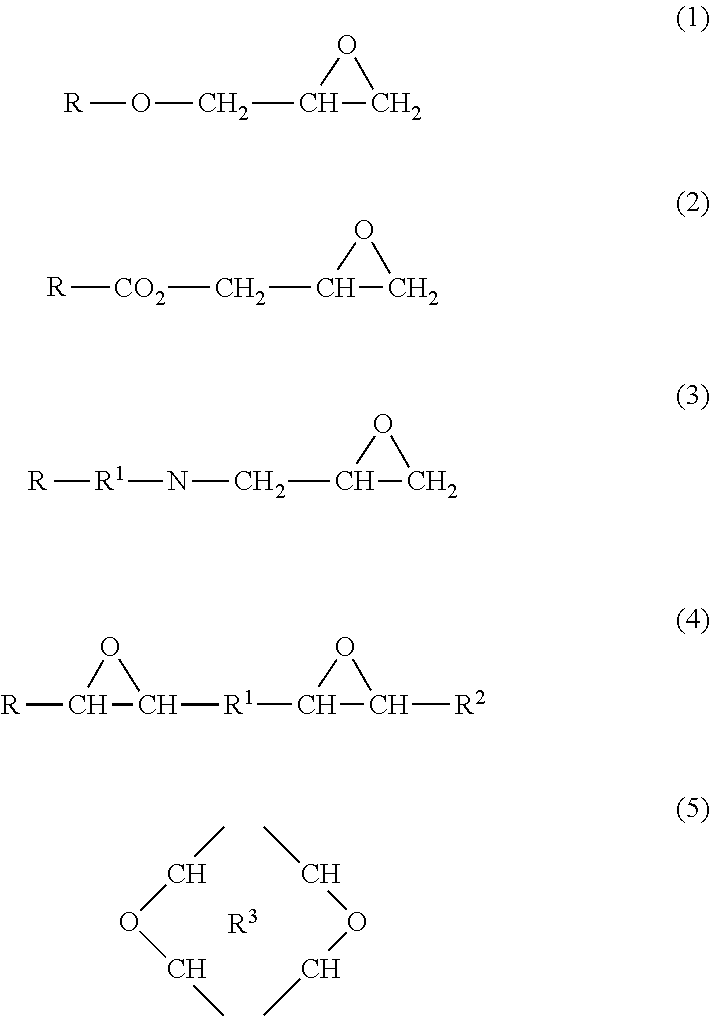

Compound for forming organic film, composition for forming organic film, method for forming organic film, and patterning process

ActiveUS20170184968A1Good dry etching resistanceHigh propertyOrganic chemistryOrganic compound preparationOrganic filmHydrogen atom

A compound for forming an organic film shown by the formula (1A),R—(—X)m1 (1A)wherein R represents a single bond or an organic group having 1 to 50 carbon atoms; X represents a group shown by formula (1B); and ml represents an integer satisfying 2≦m1≦10,wherein X2 represents a divalent organic group having 1 to 10 carbon atoms; n1 represents 0 or 1; n2 represents 1 or 2; X3 represents a group shown by the formula (1C); and n5 represents 0, 1, or 2,wherein R10 represents a hydrogen atom or a saturated or unsaturated hydrocarbon group having 1 to 10 carbon atoms, wherein a hydrogen atom of the benzene ring in formula (1C) may be substituted with a methyl group or methoxy group. This compound for forming an organic film can provide organic film composition having good dry etching resistance, heat resistance to 400° C. or higher, high filling and planarizing properties.

Owner:SHIN ETSU CHEM IND CO LTD

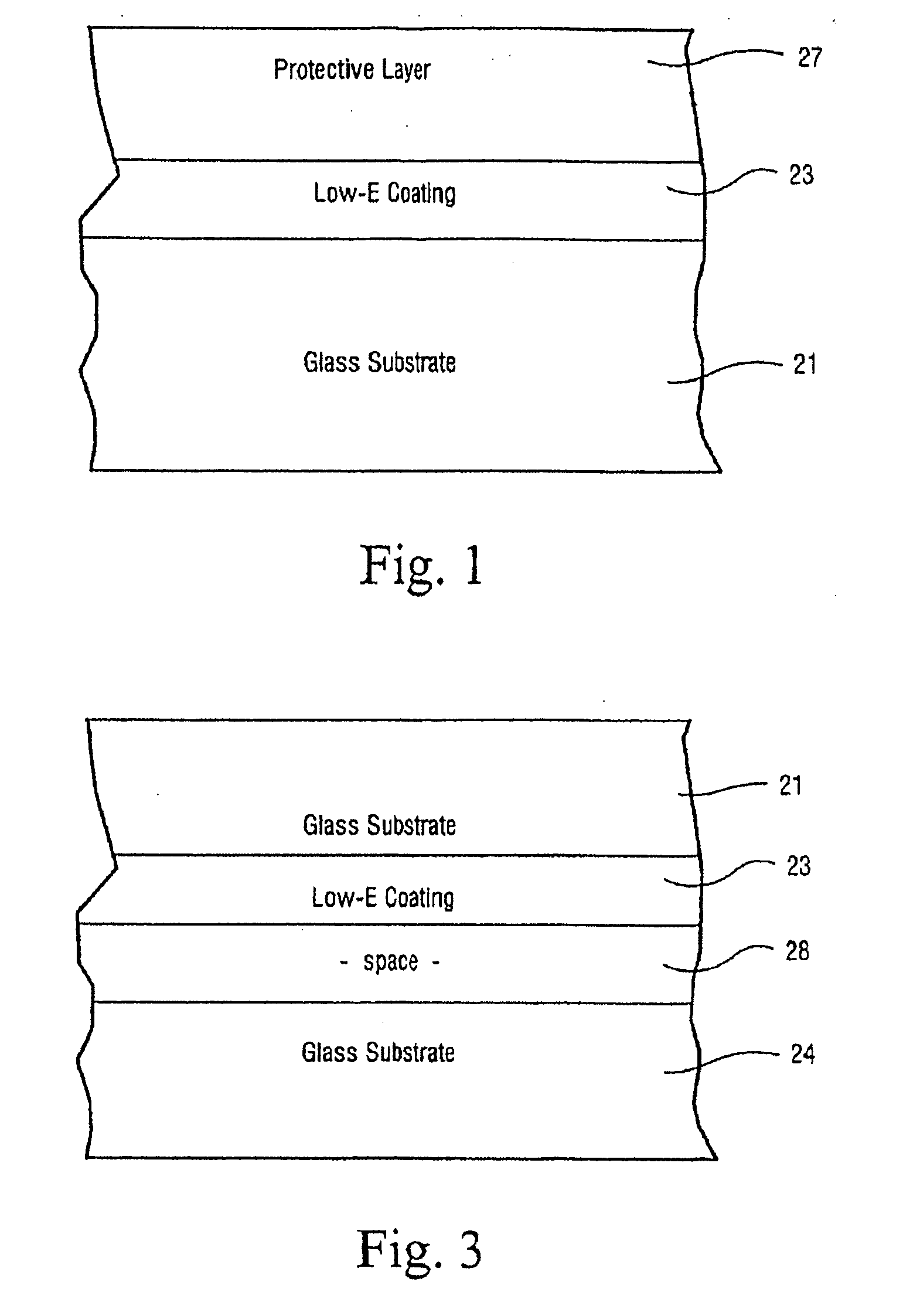

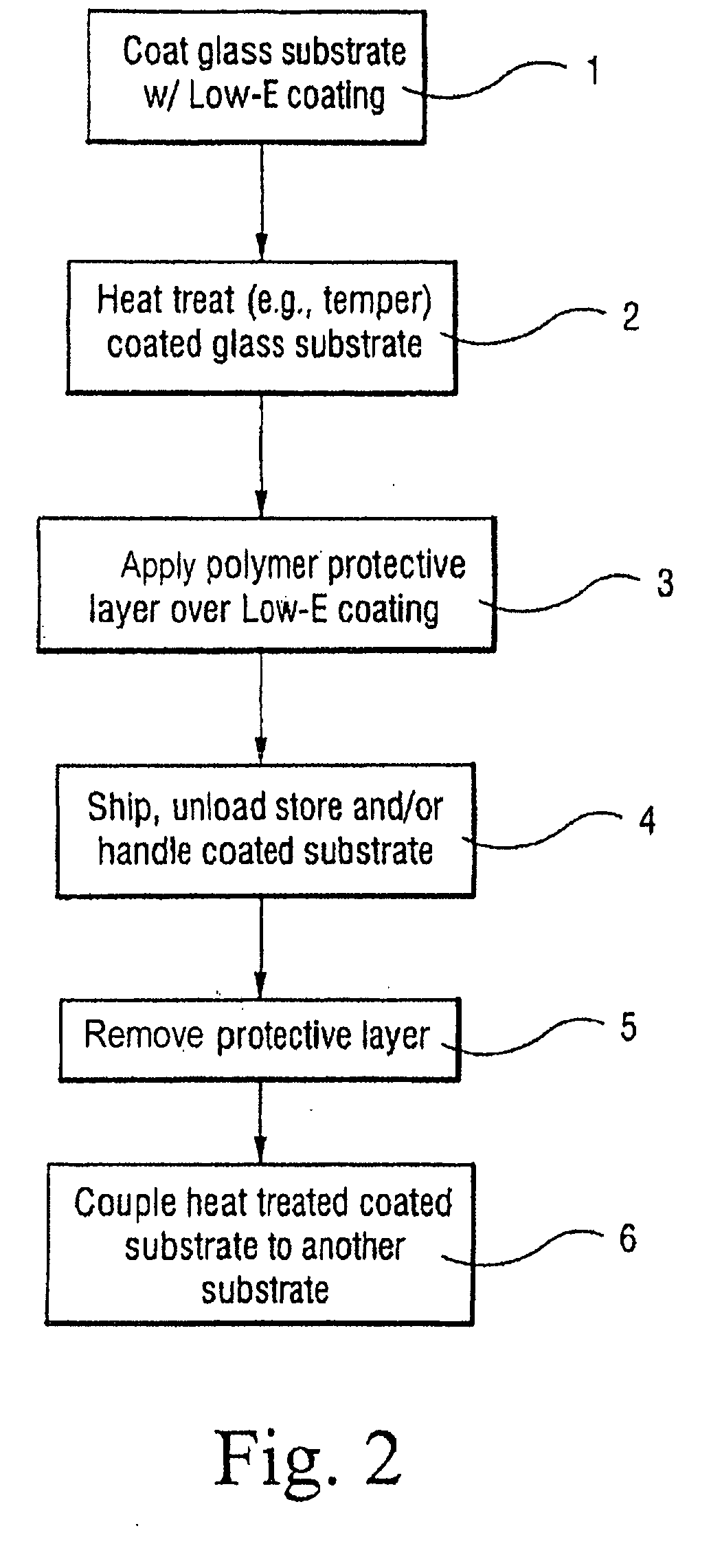

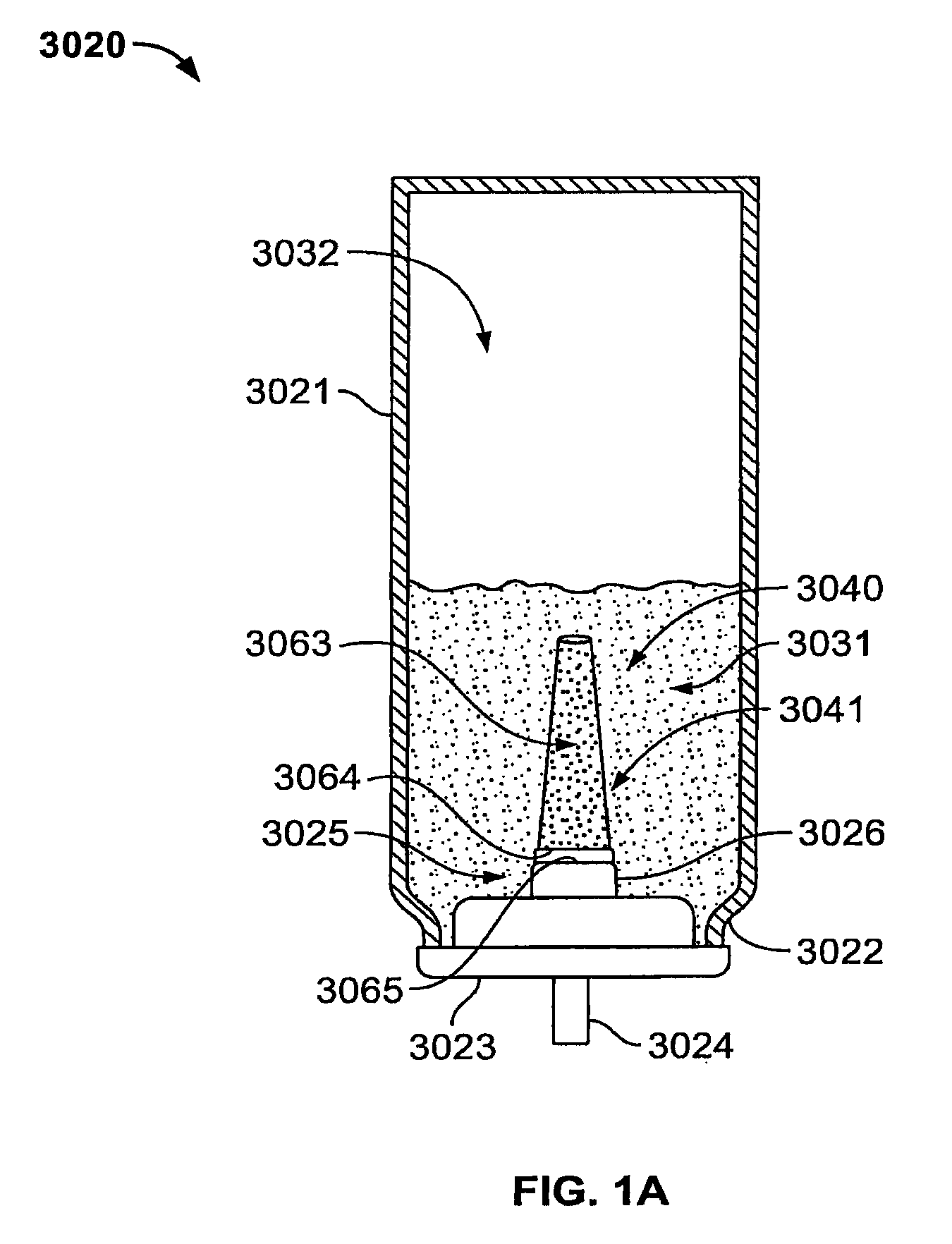

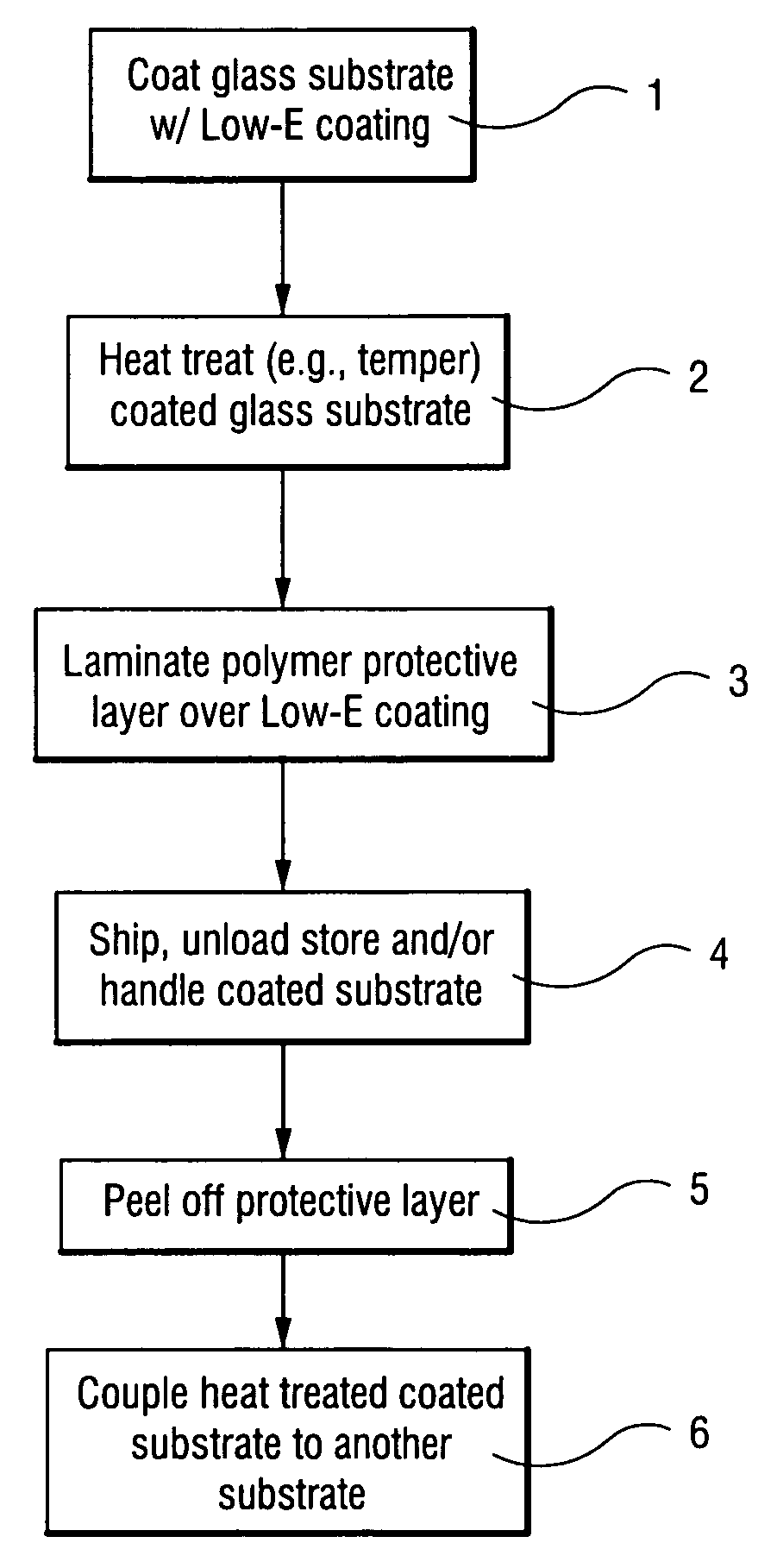

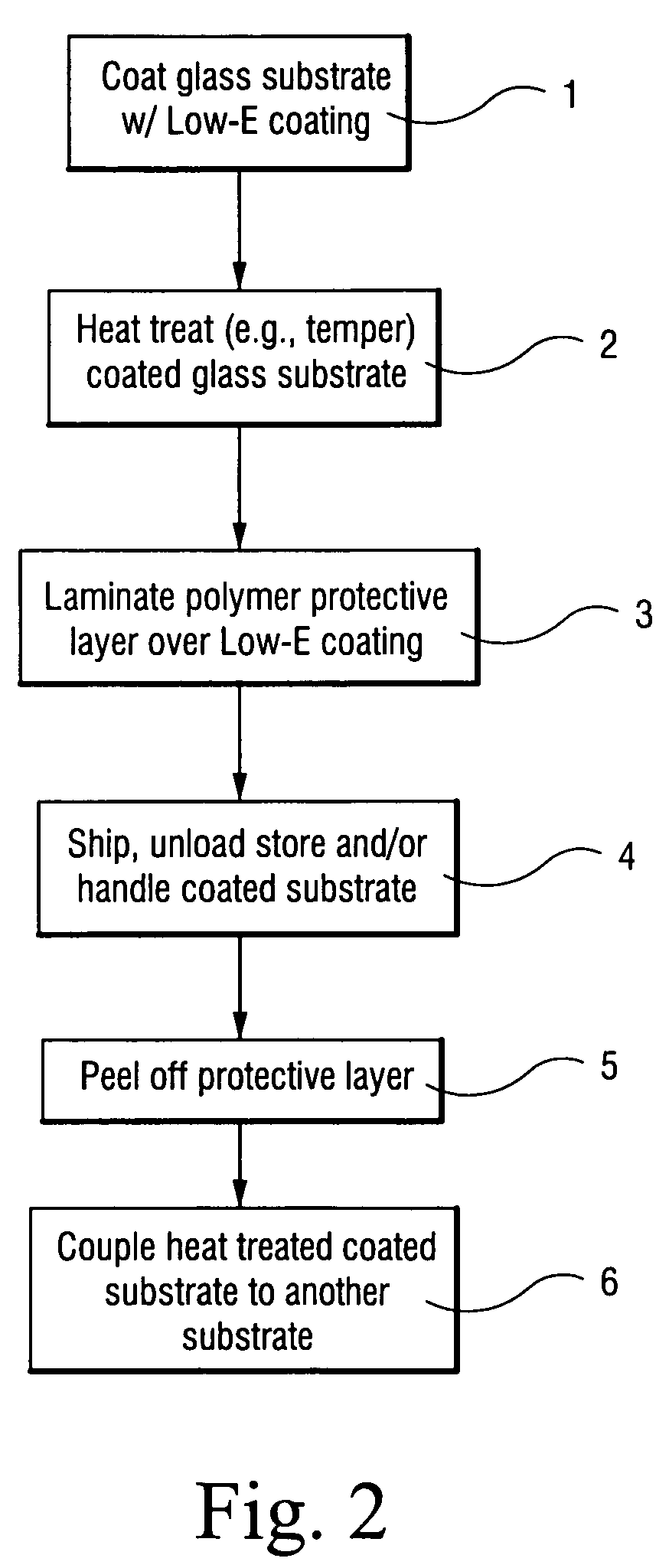

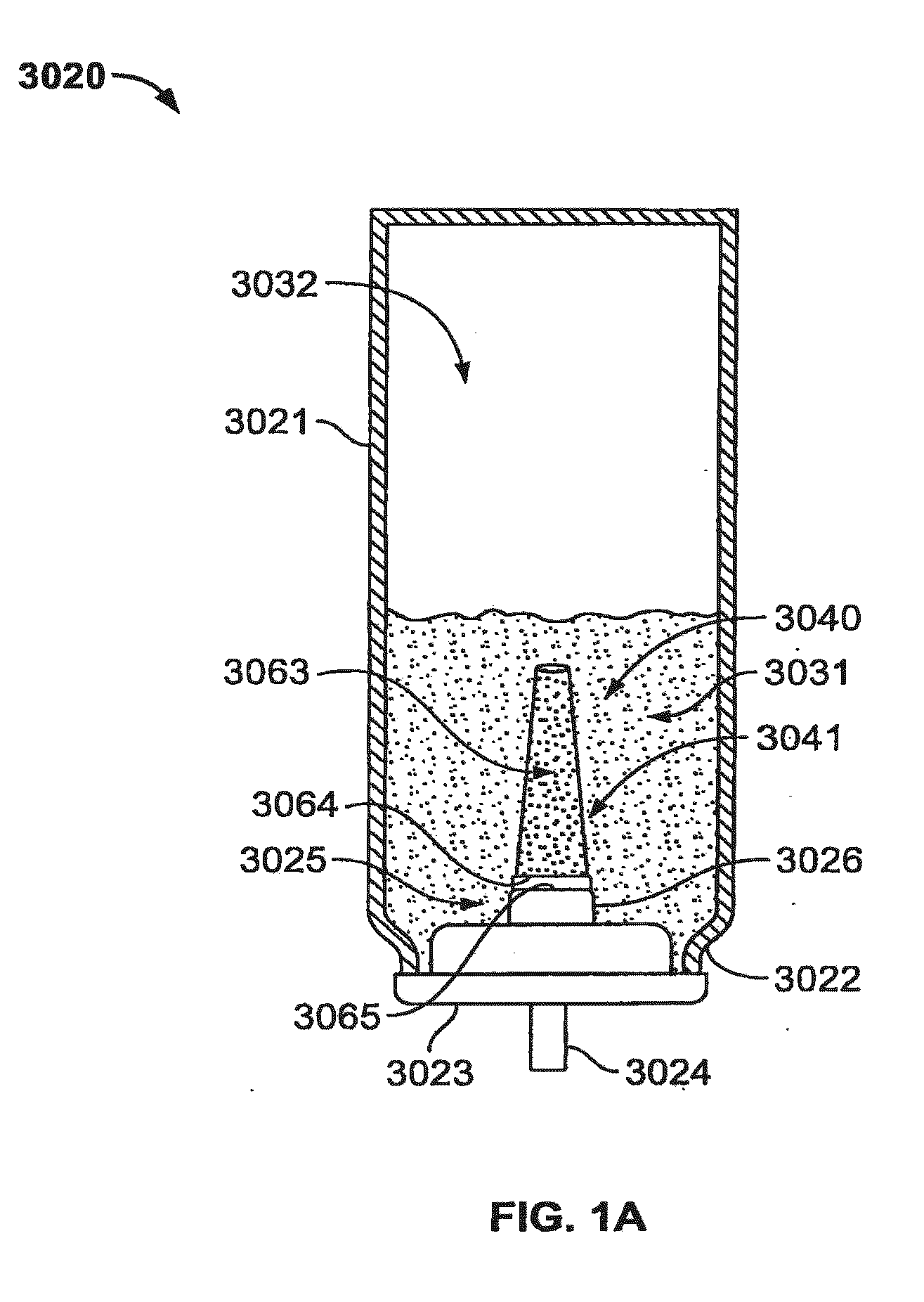

Method of making a heat-treated coated glass article using a polymer dispersion

InactiveUS20090044897A1Easy to disassembleCooled/evaporated relatively quicklyLamination ancillary operationsLaminationHeat treatedSolution processed

A temporary protective coating is provided over a coated glass substrate. The temporary protective coating is preferably applied in an aqueous dispersion then solidified on the substrate. In some instances, the temporary protective coating may be removed by treatment with a basic solution. In certain example embodiments, the temporary protective coating is applied after heat treatment before the coated substrate is coupled to another substrate to form a window unit such as an IG window unit or a laminated vehicle windshield.

Owner:GUARDIAN GLASS LLC

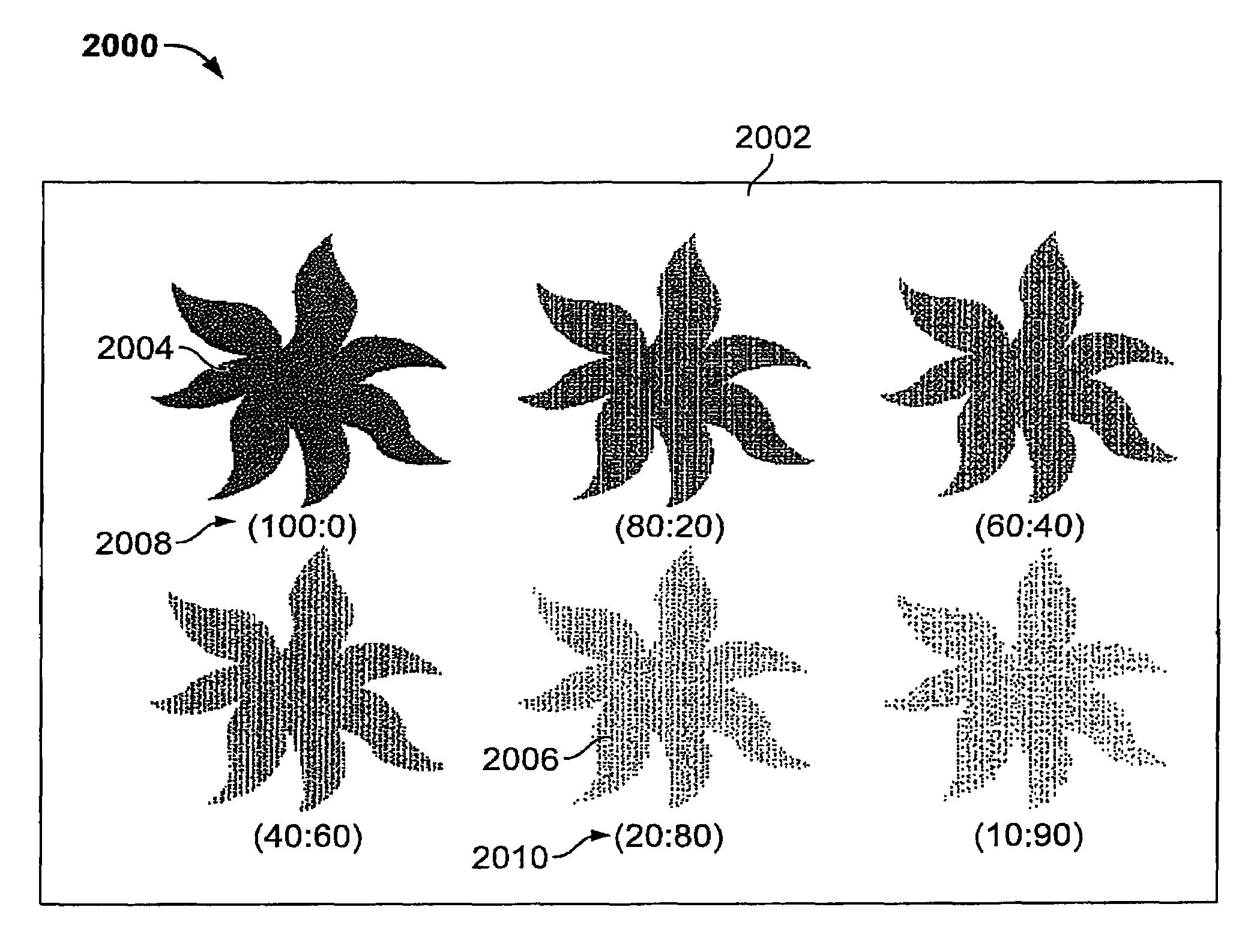

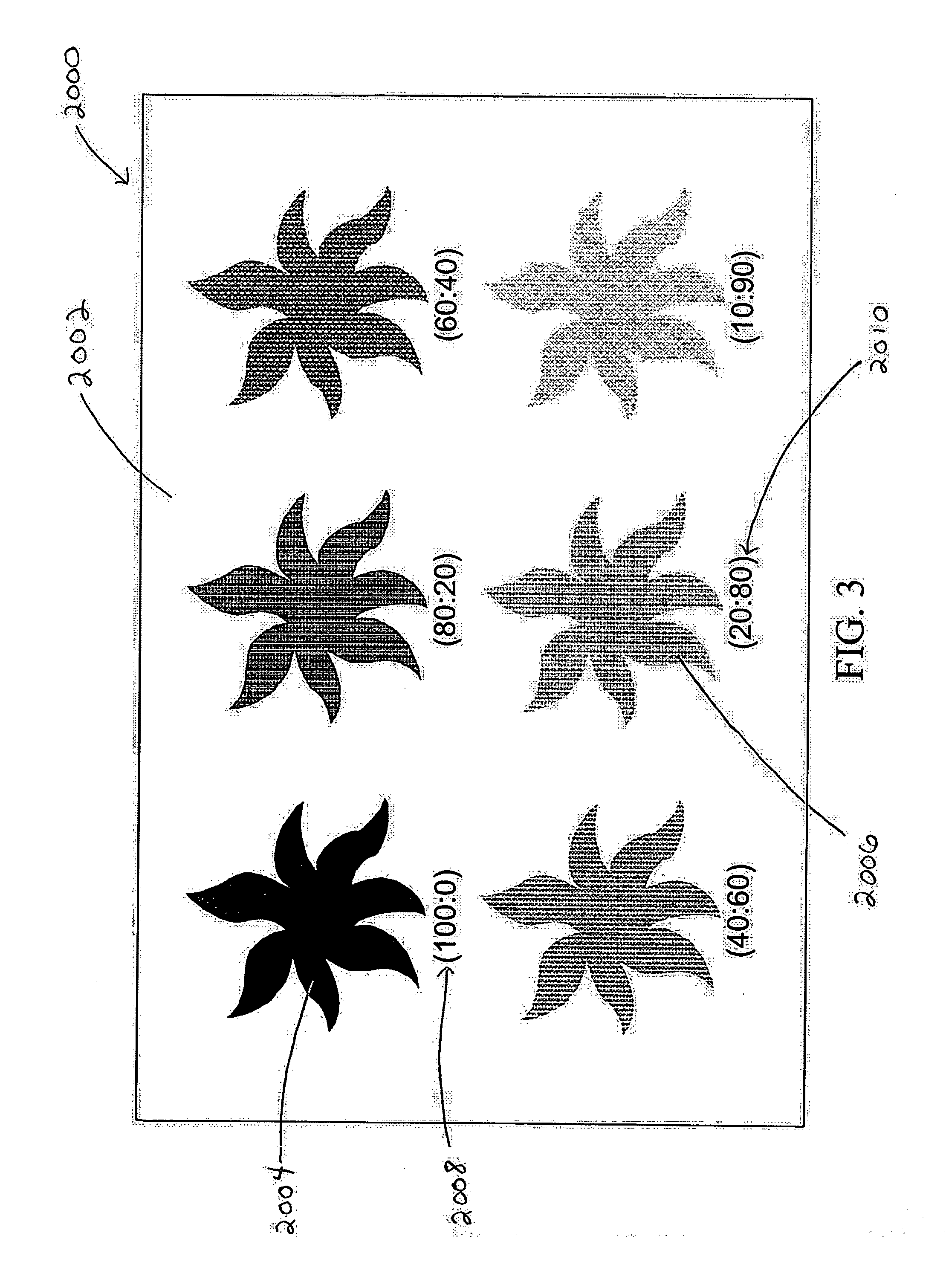

Composition for application to a surface

The present disclosure provides compositions, methods, apparatuses, kits, and combinations thereof for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The décor product is formulated to be applied and affixed to a surface, and may be substantially removed from the surface before being affixed thereto. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, methods such as heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemicals may be used. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Protective coating for painted or glossy surfaces

InactiveUS20070178239A1Improve water repellencyAccurate protectionPretreated surfacesOrganic dyesEmulsionFilm-forming agent

A glossy protective coating for painted or glossy surfaces is formed from a substantially silicone-free aqueous emulsion of film-forming agent, solvent, and a fluoropolymer that reduces soil adhesion and increases water repellency.

Owner:ZEP IP HLDG LLC

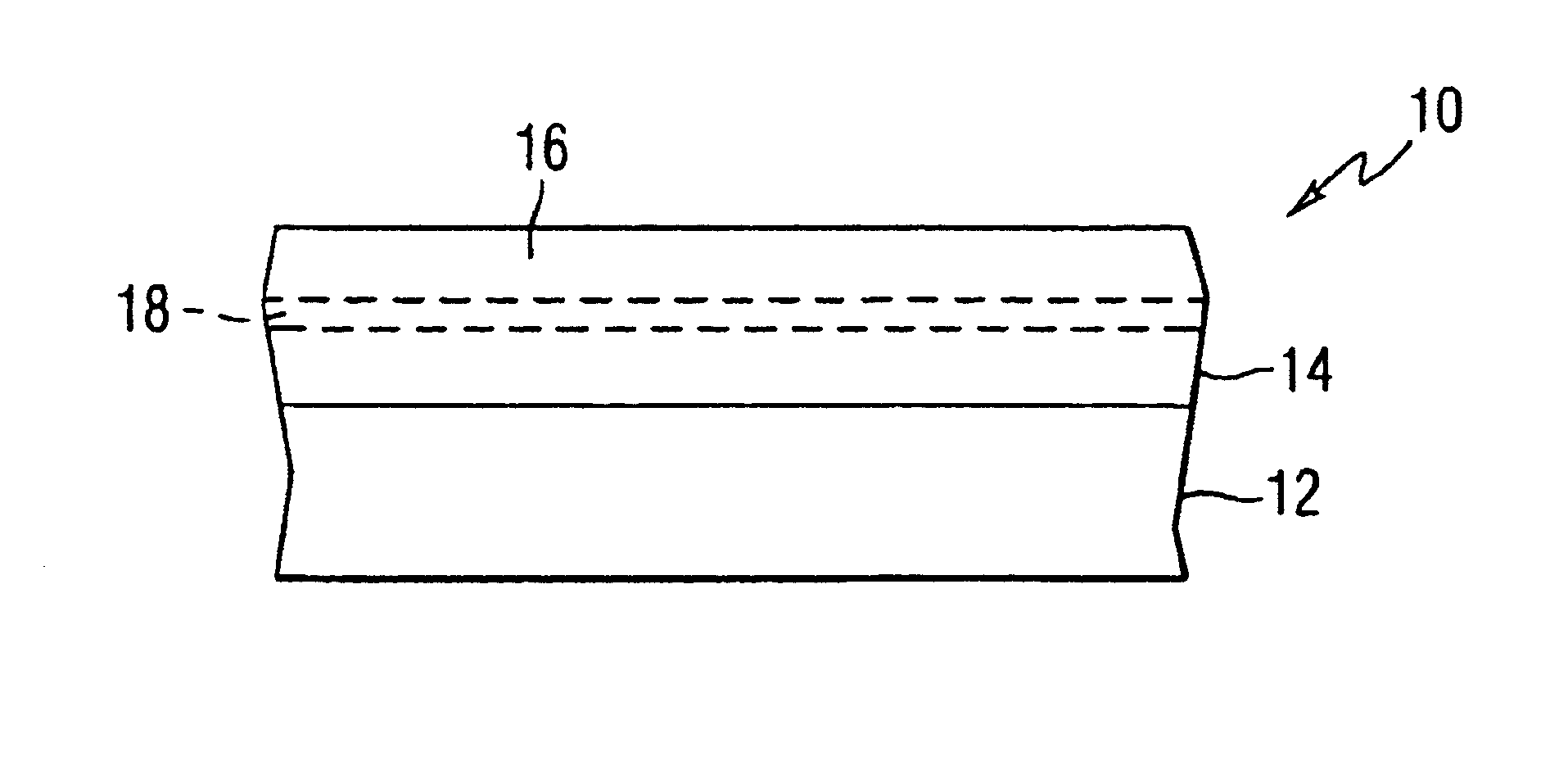

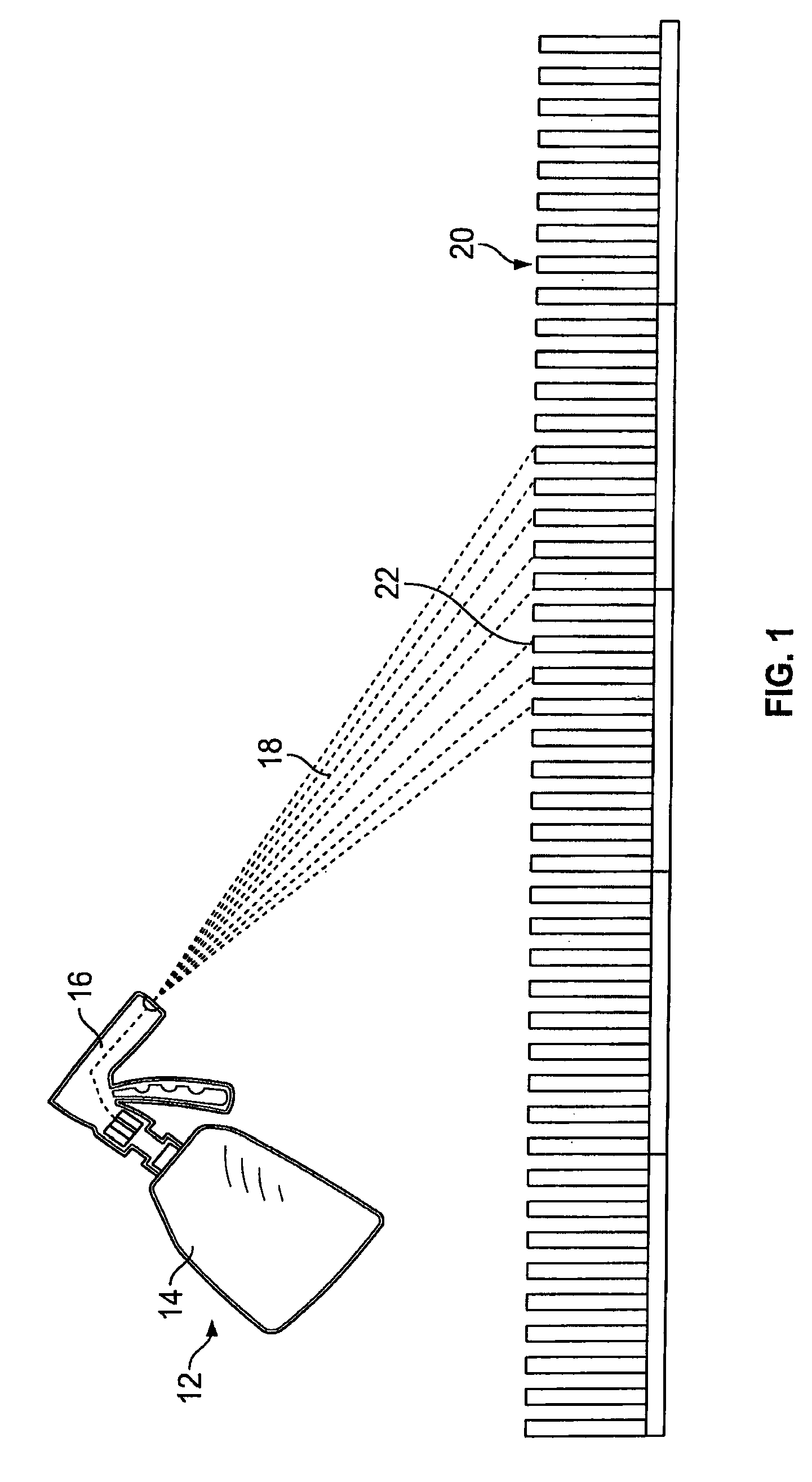

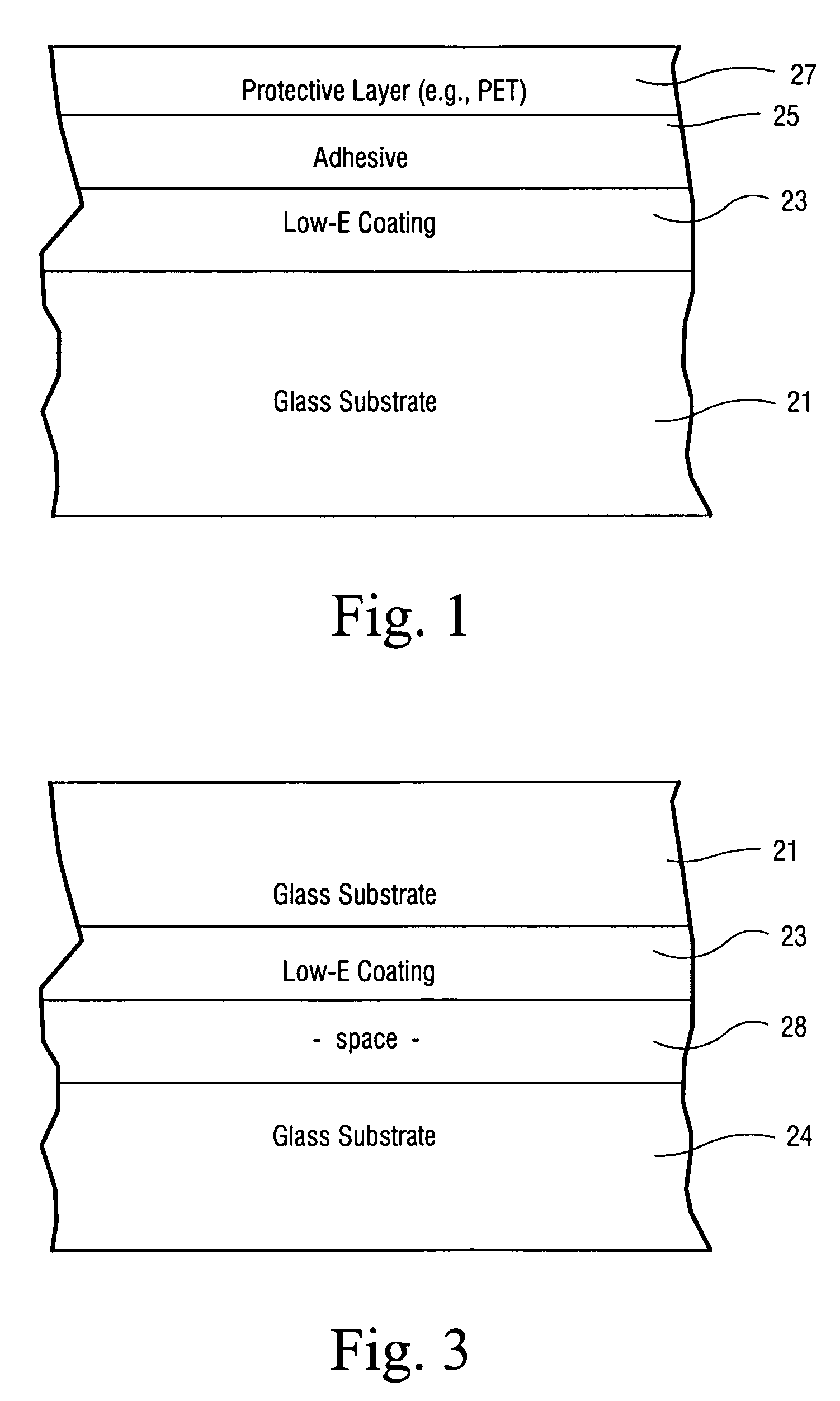

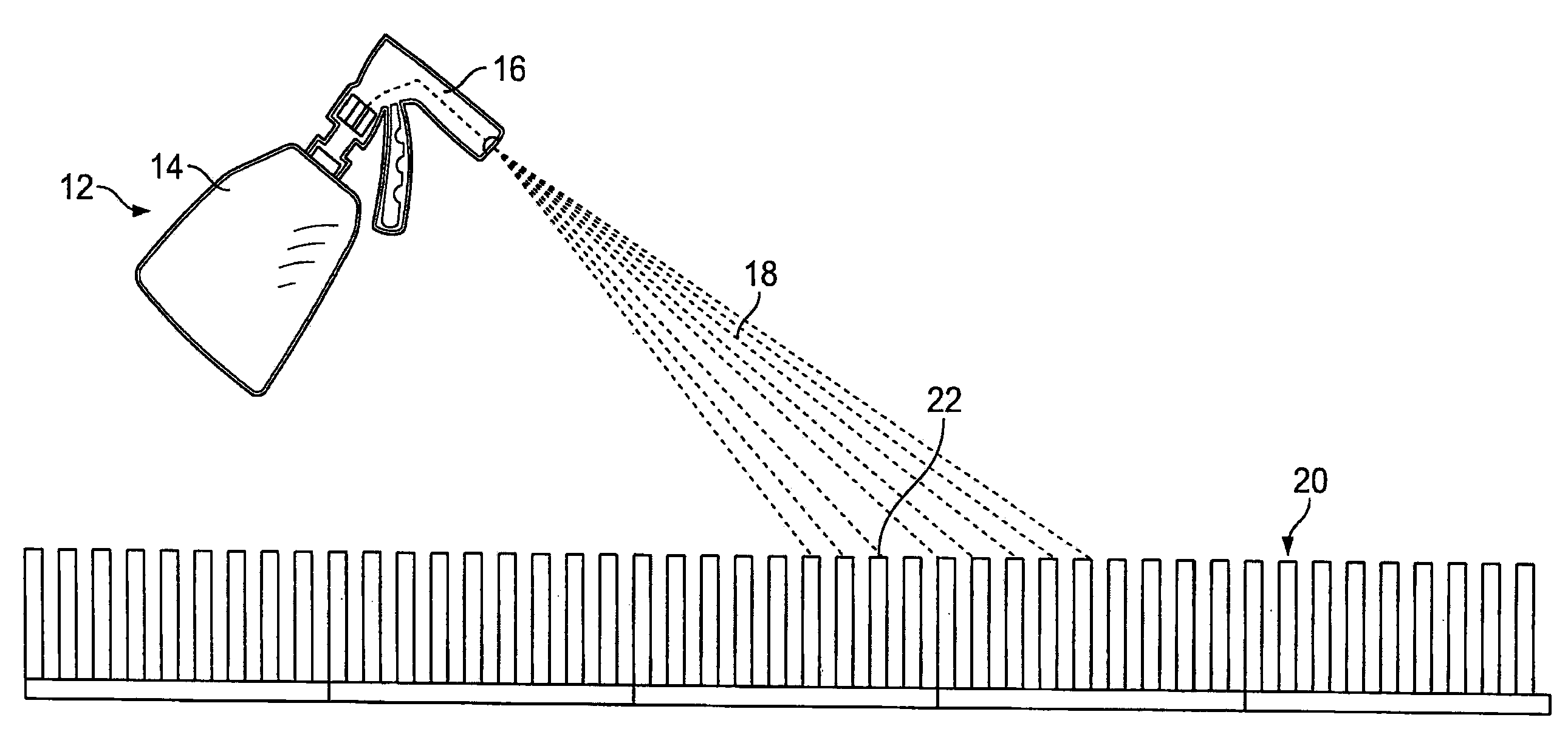

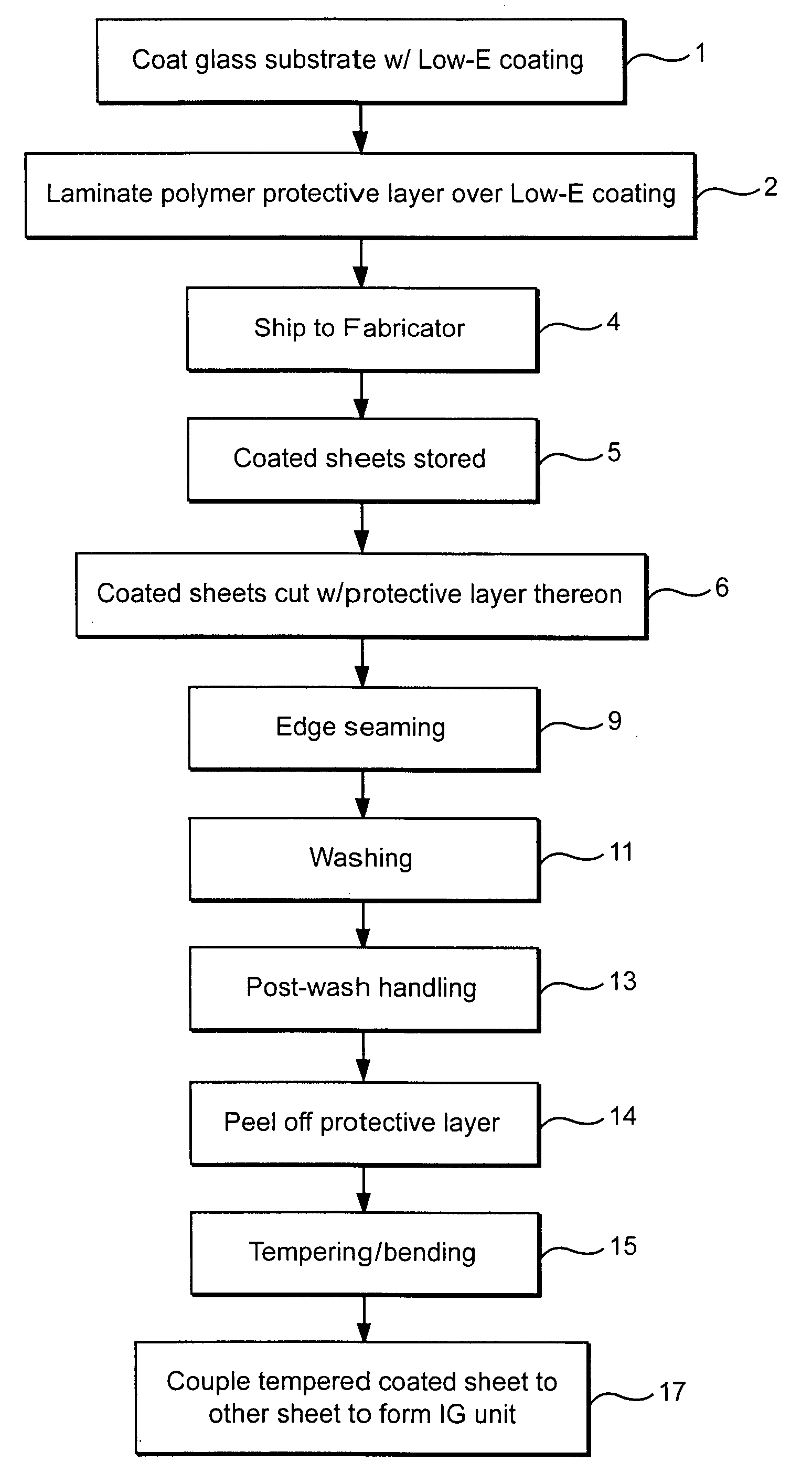

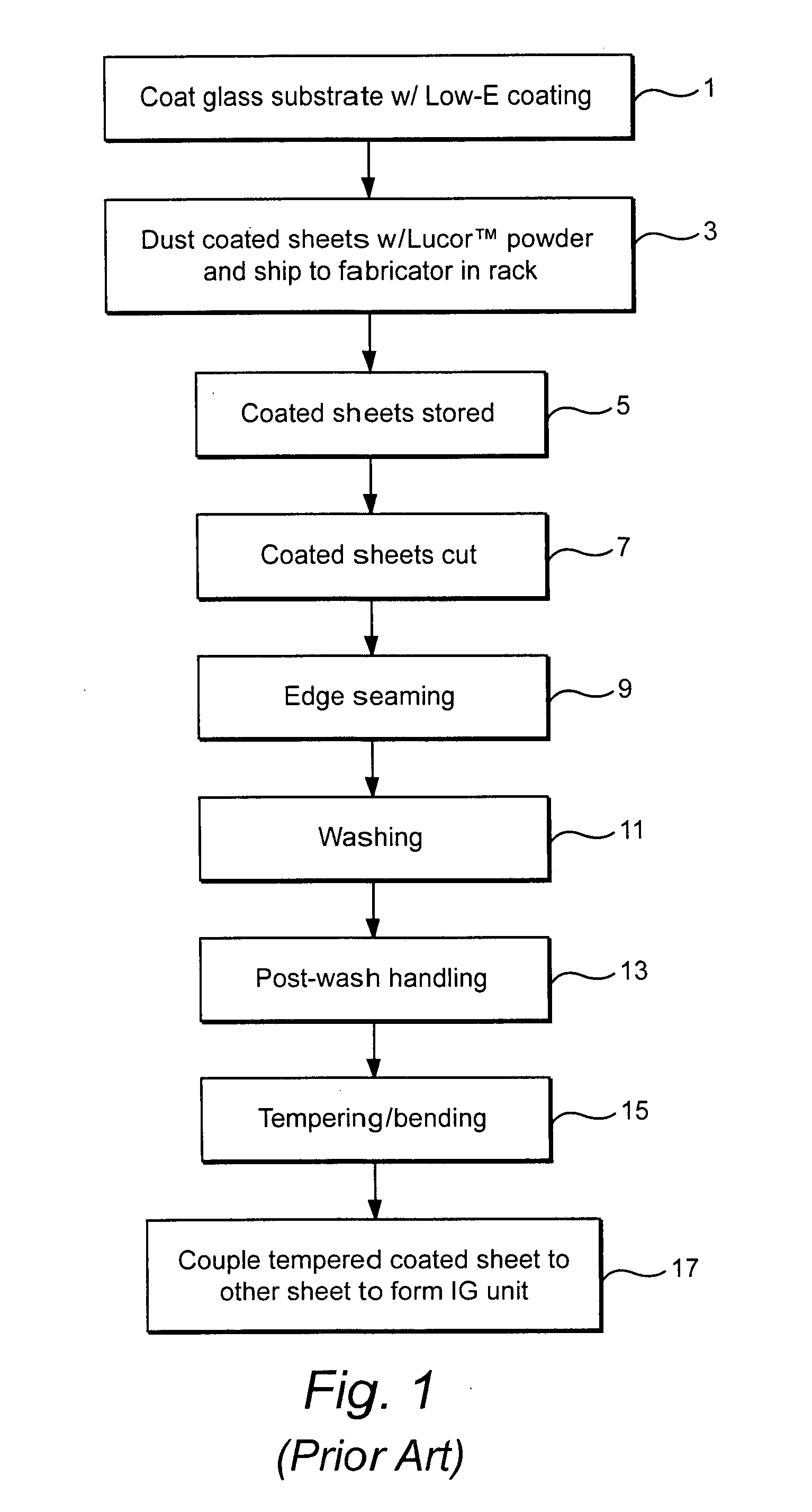

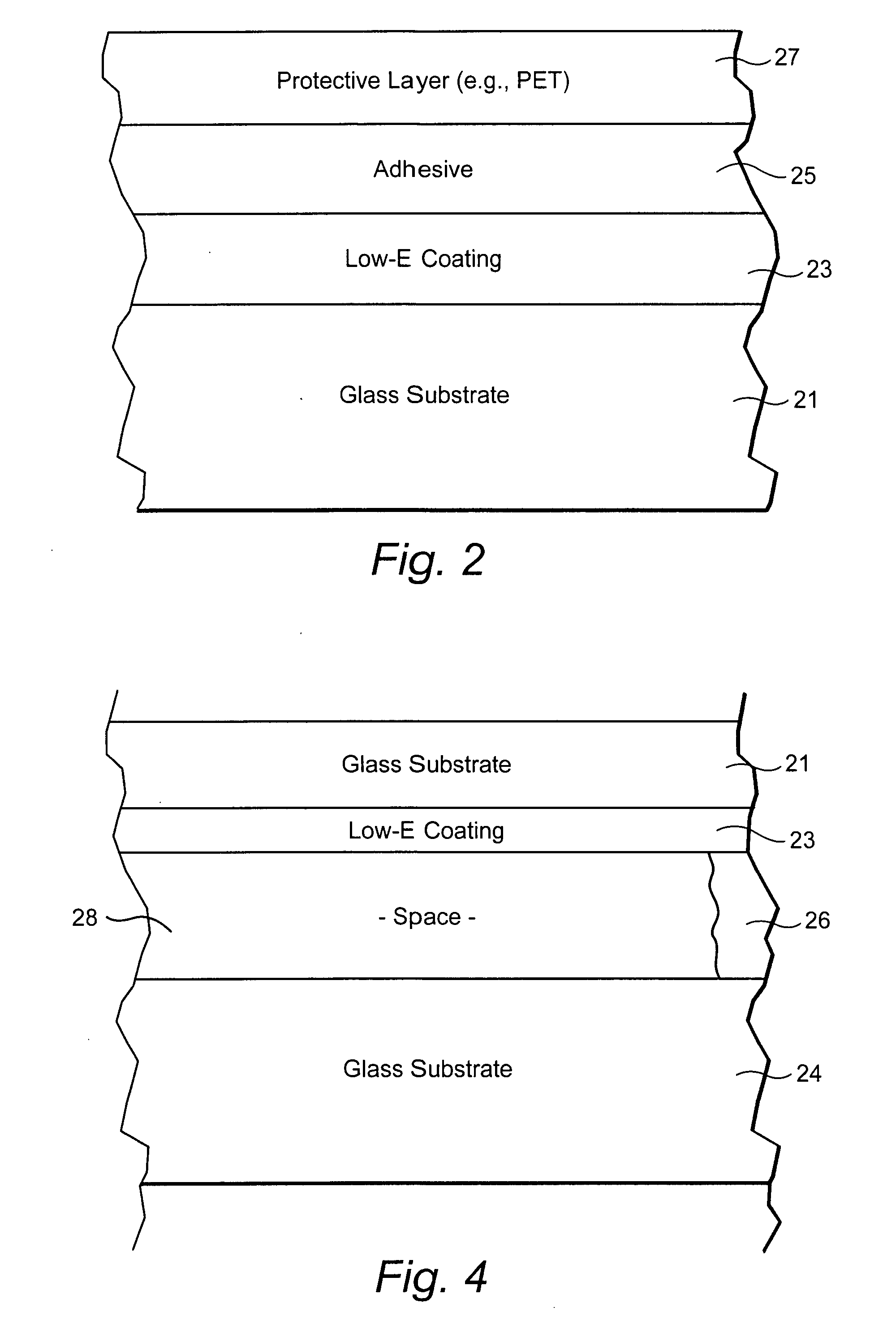

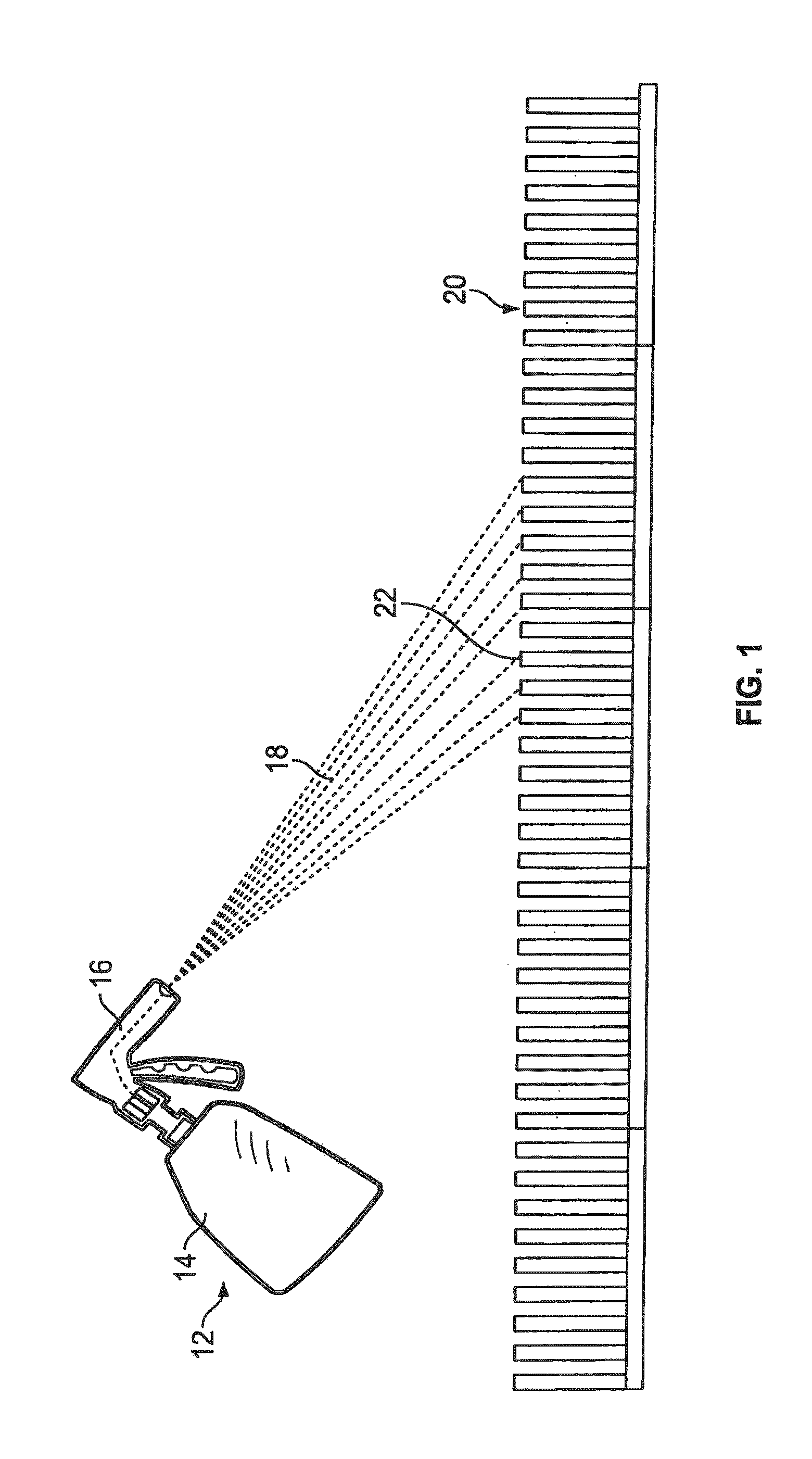

Method of making heat treated coated glass article, and intermediate product used in same

InactiveUS20060065350A1Easy to disassembleSynthetic resin layered productsTemporary coatingsHeat treatedIntermediate product

A temporary protective coating is provided over a coated glass substrate. The temporary protective coating is preferably applied in solid form (i.e., as opposed to liquid form) so that no significant curing is needed. Moreover, the temporary protective coating can be easily removed by simply peeling it off. In certain example embodiments, the temporary protective coating is applied after heat treatment and is removed by peeling it off before the coated substrate is coupled to another substrate to form a window unit such as an IG window unit or a laminated vehicle windshield.

Owner:GUARDIAN GLASS LLC

Aqueous durable hydrophilic washing and coating compositions

The present invention relates to an aqueous hydrophilic coating composition and method for treating various hard surfaces including, but not limited to, rubber metal, glass, plastic, vinyl, ceramic, stone, or various other painted surfaces to create a hydrophilic surface without visible residue or water spots. The coating composition comprises a hydroxyl functional compound, a silane compound and water. The aqueous hydrophilic coating composition can be used both as a dilute washing solution to clean surfaces and a coating composition to provide a durable protection from future stains and residues. The coating composition can be applied directly or indirectly to a solid surface using various application devices including, but not limited to, spray, aerosol, wipes, towels, sponges and pads.

Owner:THE CLOROX CO

Composition For Application To A Surface

The present disclosure provides compositions, methods, apparatuses, kits, and combinations thereof for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The décor product is formulated to be applied and affixed to a surface, and may be substantially removed from the surface before being affixed thereto. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, methods such as heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemicals may be used. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Two-layer protective coating system for LCD glass

InactiveUS6896928B2Same and smoothnessImprove scratch resistancePretreated surfacesRecord information storageSolubilityGlass chip

Two-layer protective coating system for glass surfaces is disclosed. The base coating comprises at least one polysaccharide, and the top coating has a lower solubility in water than the base coating. The coating system provides good protection against contaminants and glass chips, good removability in mild cleaning condition, and extra water resistance during process steps where water is used as a cooling agent.

Owner:CORNING INC

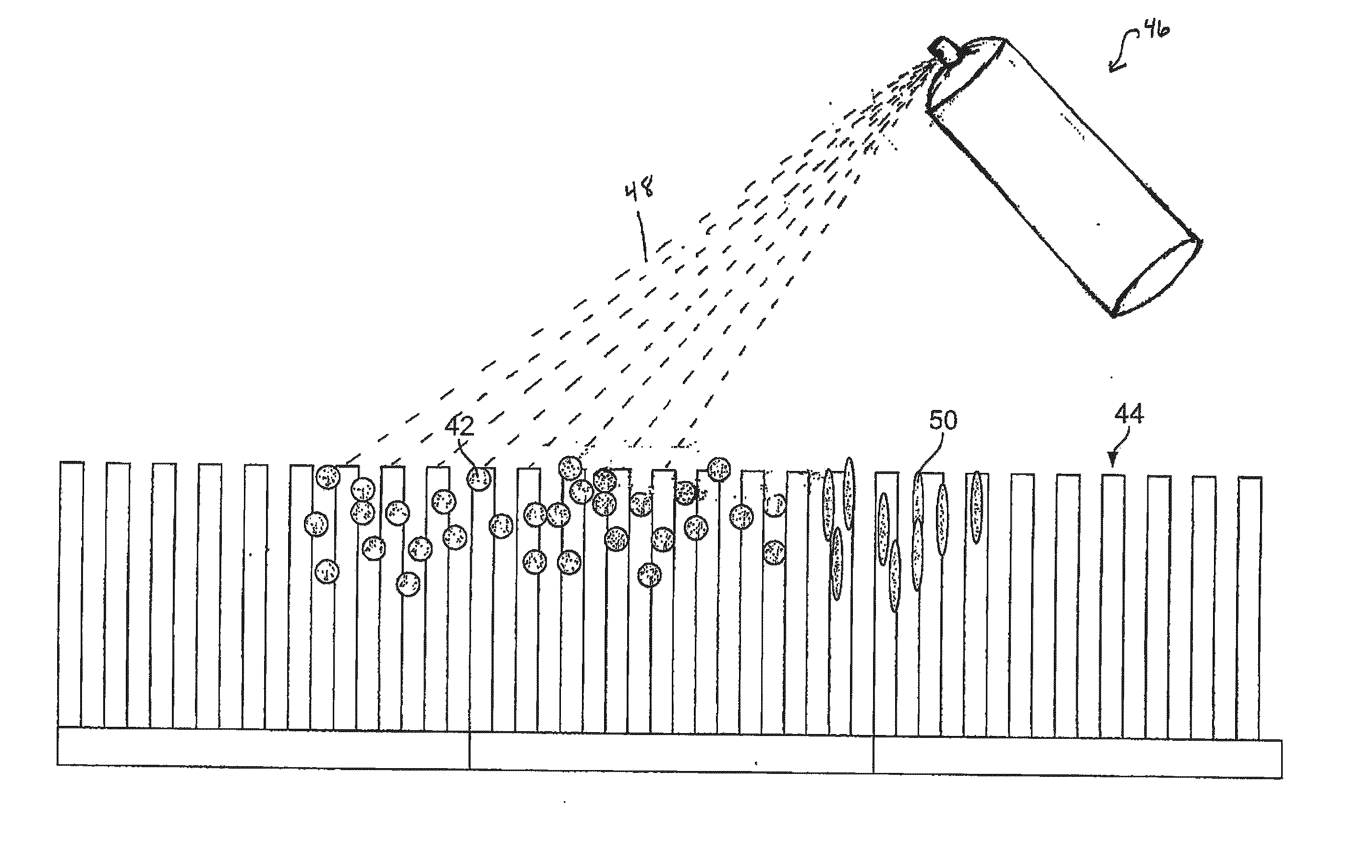

Method of making coated glass article, and intermediate product used in same

InactiveUS20080302462A1Increased abrasionEasily damagedDoor/window applicationsTemporary coatingsEngineeringHeat treated

In certain example embodiments of this invention, there is provided a method of making a window, the method including: forming a multi-layered low-E and / or solar control coating on a glass substrate; providing at least two flexible protective sheets in non-liquid form to the glass substrate over at least part of the low-E and / or solar control coating; applying at least one protective coating in liquid form, before and / or after the flexible protective sheets are provided, so as to reduce one or more gaps formed between the low-E and / or solar control coating and the flexible protective sheet(s) and / or between the flexible protective sheets; and performing one or more of cutting, edge seaming, and / or washing the coated article with the protective coating and protective sheets thereon and peeling the protective sheets and at least part of the protective coating off of the top surface of the low-E and / or solar control coating. Heat treatment (e.g., thermal tempering) may then be performed, and the heat treated coated article may be used in a window unit or the like.

Owner:GUARDIAN EURO S A R L +1

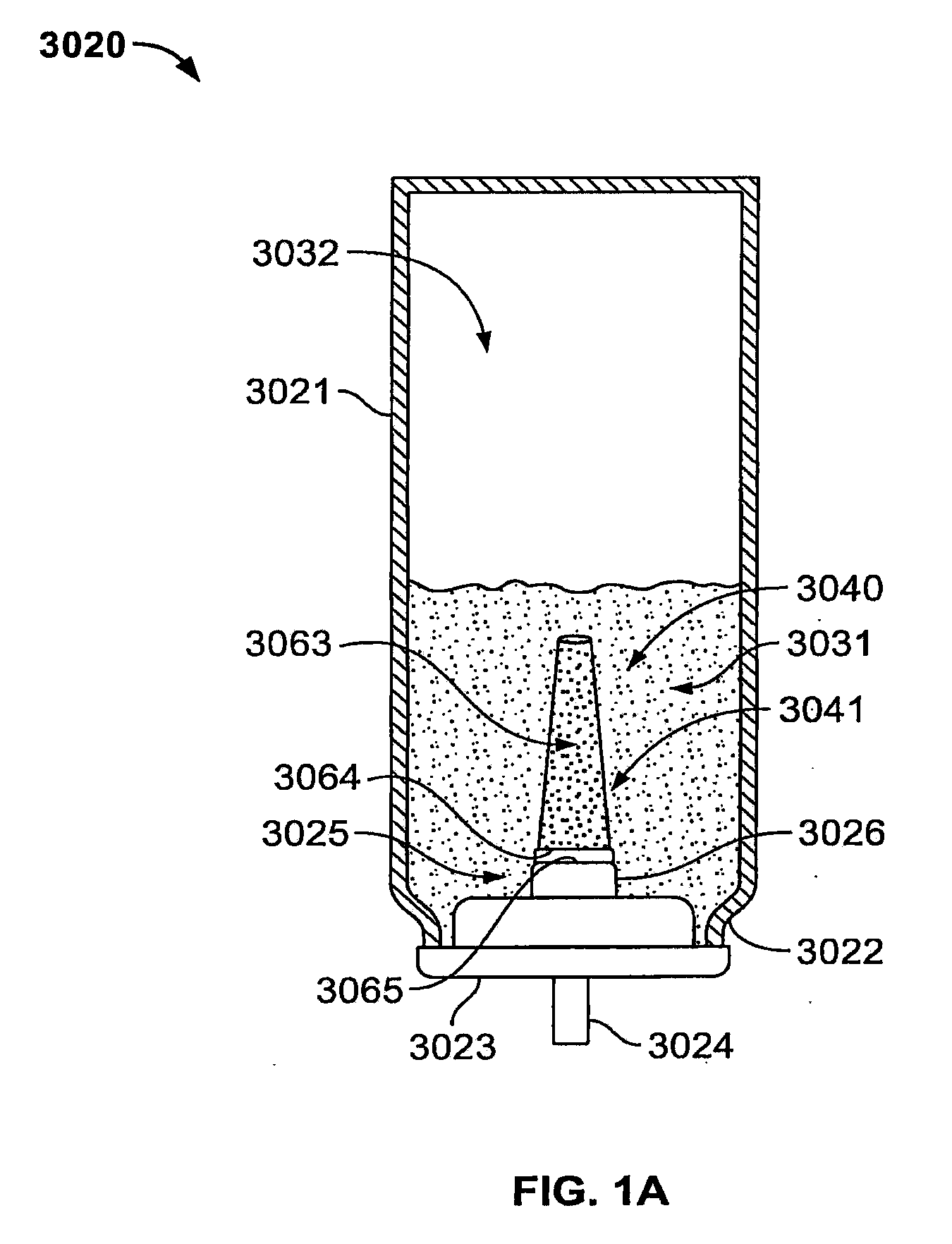

Methods for Improving Coatings on Downhole Tools

The present invention relates to the use of degradable coatings suitable for use on downhole tools. In particular, the present invention relates to pliable coatings for use on downhole tools that have been designed to be able to resist flaking or breaking off of the tool in response to a physical shock. Some embodiments of the present invention provide methods of reacting lactic acid, glycolic acid, or a combination thereof in a polymerization reaction to form a degradable polymer; combining the degradable polymer and a plasticizer to form a coating composition; applying the coating composition to a downhole tool; placing the coated downhole tool into a portion of a subterranean formation; and, hydrolyzing the degradable polymer of the coating composition to release an acid and degrade the coating.

Owner:HALLIBURTON ENERGY SERVICES INC

Removable antimicrobial coating compositions containing acid-activated rheology agent and methods of use

A method is provided for controlling microorganisms comprising coating a surface with a removable, antimicrobial film-forming composition. More specifically, the removable, antimicrobial film-forming composition comprises at least one antimicrobial agent and at least one acid-activated rheology agent.

Owner:EI DU PONT DE NEMOURS & CO

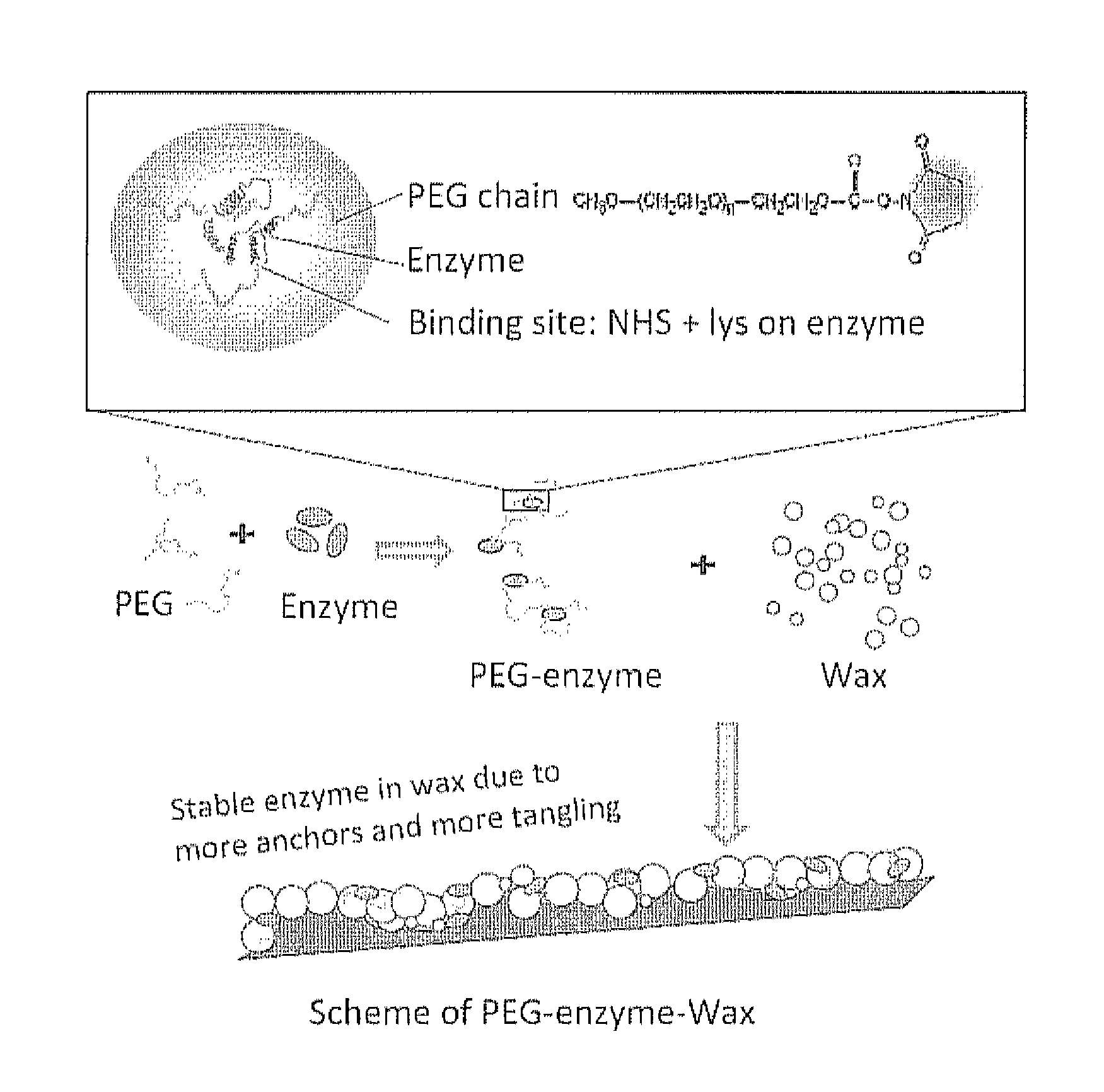

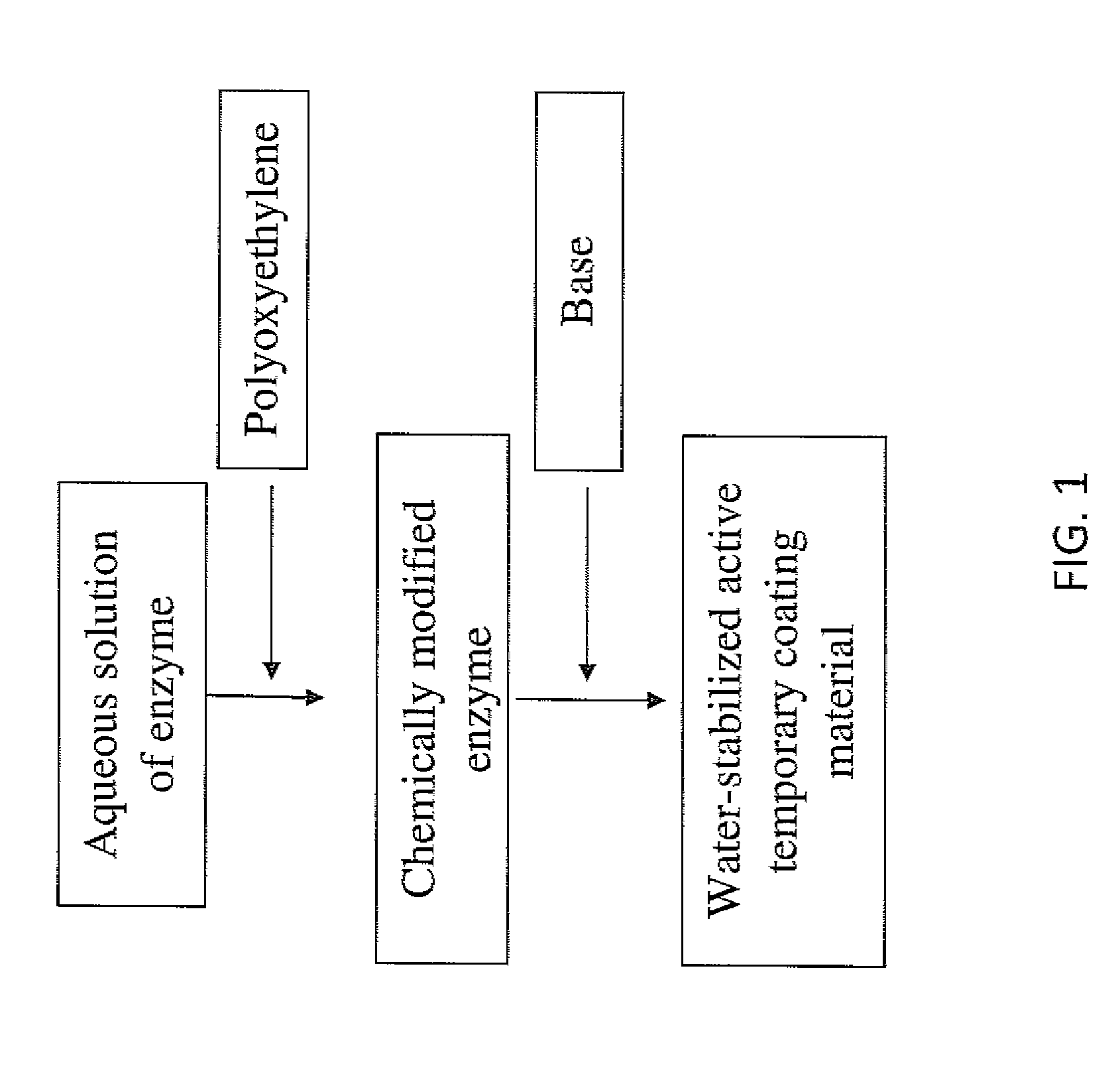

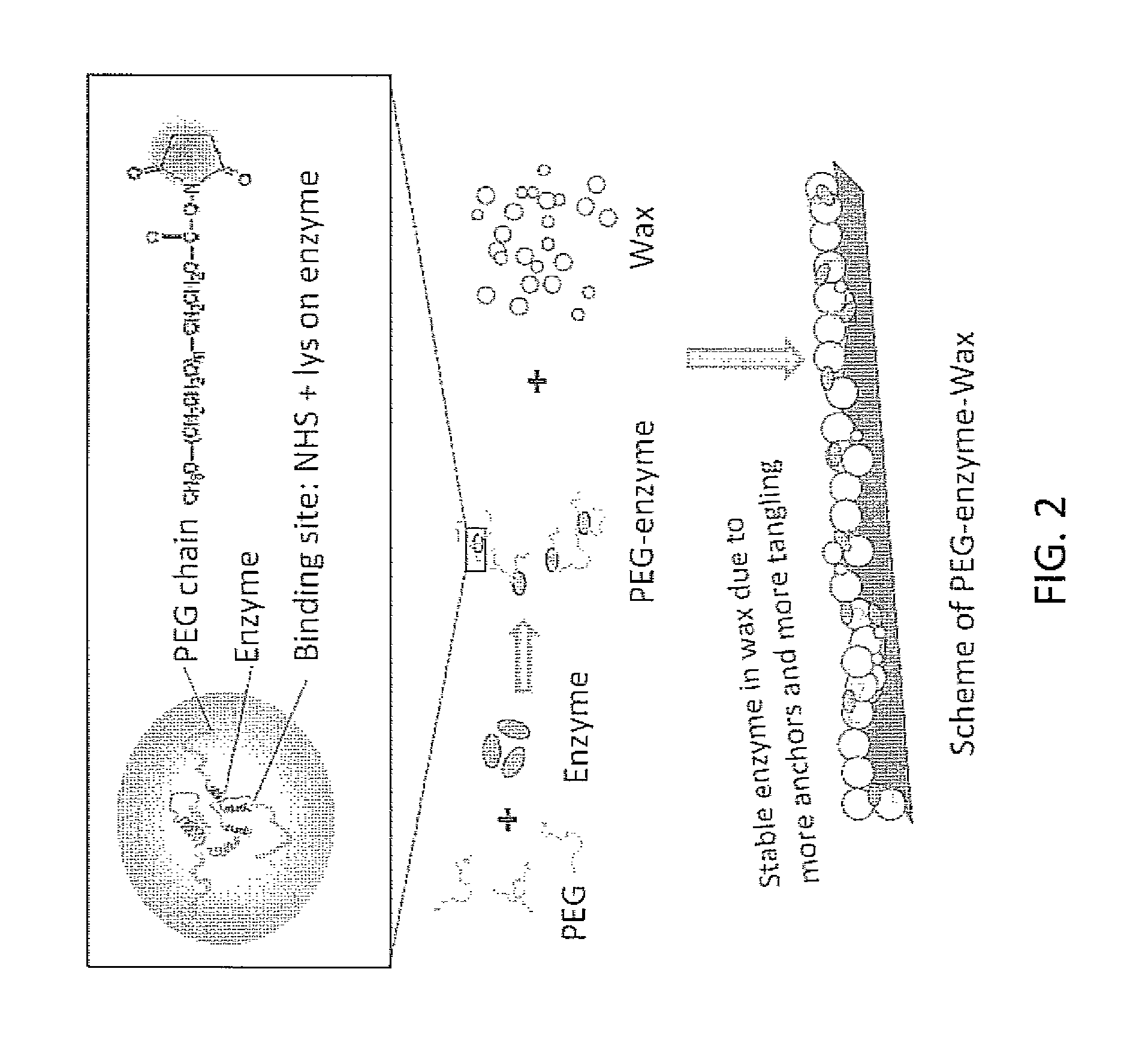

Coatings Containing Polymer Modified Enzyme For Stable Self-Cleaning Of Organic Stains

ActiveUS20120276617A1Easy to disassembleBiochemical fibre treatmentDetergent mixture composition preparationPolymer modifiedOrganic matter

Temporary active coatings that are stabilized against inactivation by weathering are provided including a base associated with a chemically modified enzyme, and, optionally a first polyoxyethylene present in the base and independent of the enzyme. The coatings are optionally overlayered onto a substrate to form an active coating facilitating the removal of organic stains or organic material from food, insects, or the environment.

Owner:TOYOTA MOTOR CO LTD

Carpet décor and setting solution compositions

InactiveUS20110236587A1Liquid surface applicatorsOther chemical processesMedicineSolution composition

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product may be removed by, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be part of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to a surface.

Owner:SC JOHNSON & SON INC

Top coating for indoor and outdoor temporary removable graphics and system and method for making, applying and removing such graphics

InactiveUS20080264559A1Lamination ancillary operationsChemical paints/ink removersGraphicsEngineering

A composition for a removable top coating for protecting the exposed face of a temporary removable graphic is provided. A remover for the transferred graphic image is provided that completely dissolves the temporary removable graphic, but does not affect the commonly encountered substrates such as concrete, brick, wooden floors, asphalt surfaces, terrazzo and motor vehicle body surfaces, marine and aeronautical craft surfaces. A method for making, applying and removing the temporary removable graphic is provided.

Owner:OCONEE COATING TECH LLC

Dry film lubricant

InactiveUS20060003901A1Good anti-blockingImprove anti-corrosion performanceDrilling rodsMoulding toolsWaxParticulates

The present invention relates to compositions and methods employing a first copolymer that is an acrylic copolymer or styrene / acrylic copolymer having a weight average molecular weight (Mw) of about 8,000 to about 14,000; a second copolymer that is an acrylic copolymer having a Mw of about 90,000 to about 130,000; a wax emulsion or dispersion, and a particulate additive. Optionally, the composition further comprises at least one of a rheological additive, ammonium hydroxide or a defoaming compound.

Owner:HENKEL KGAA

Aqueous detergent soluble coating and adhesive and methods of temporary bonding for manufacturing

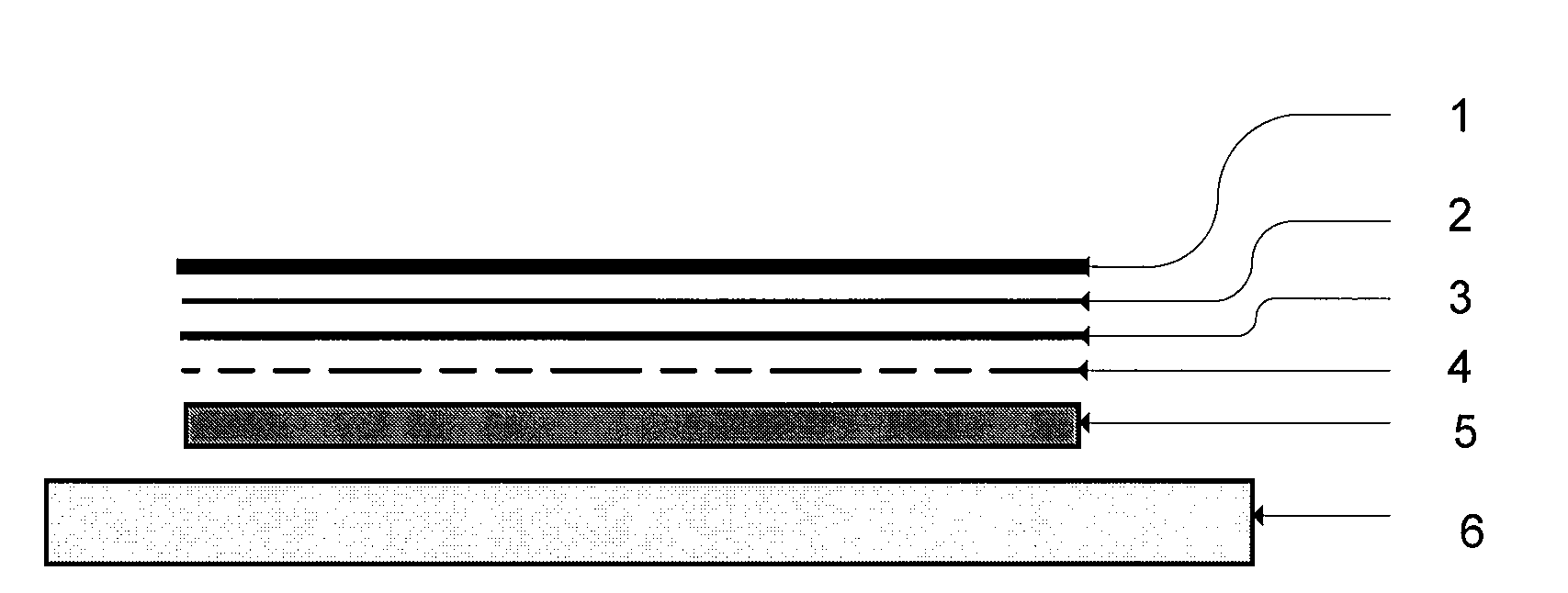

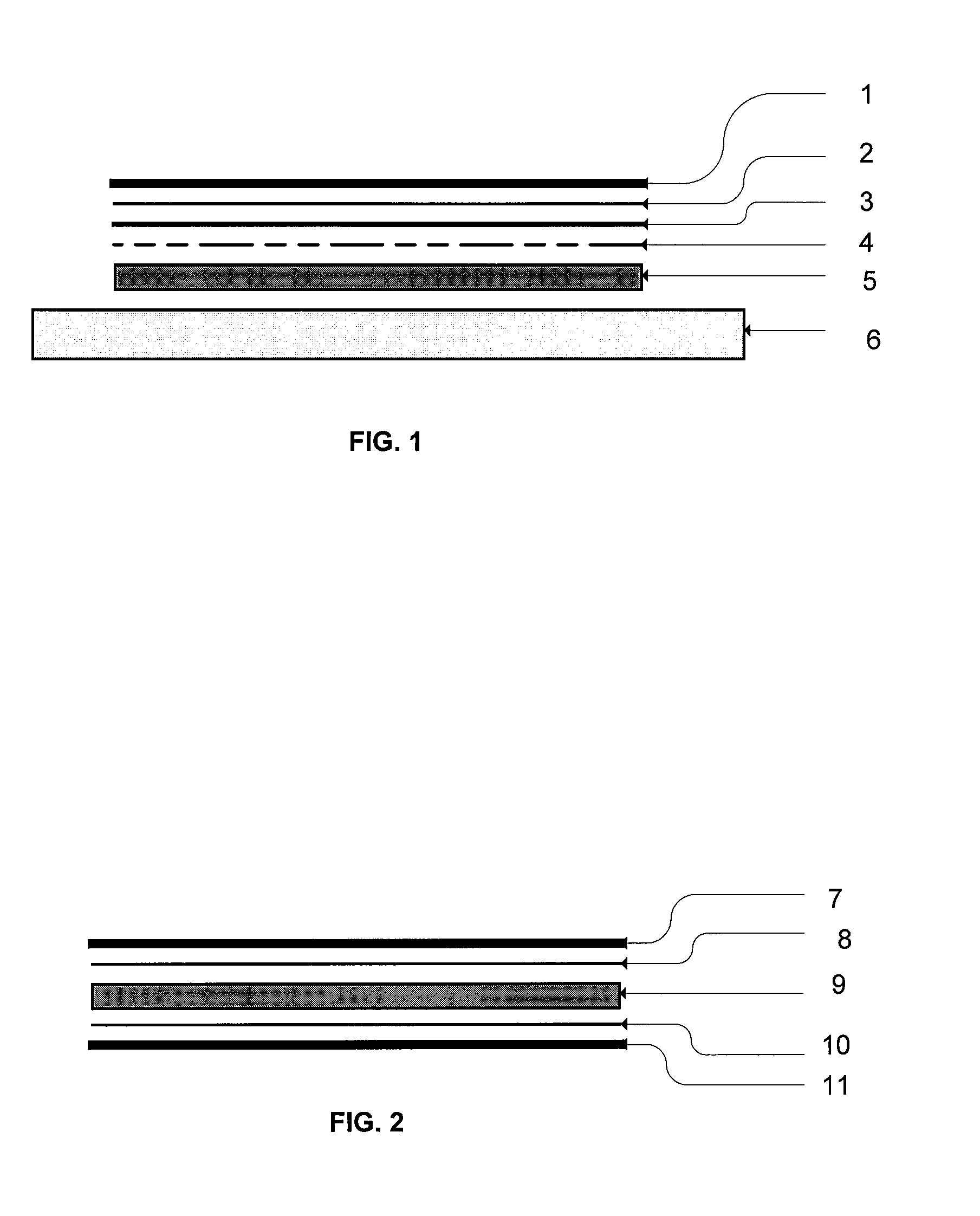

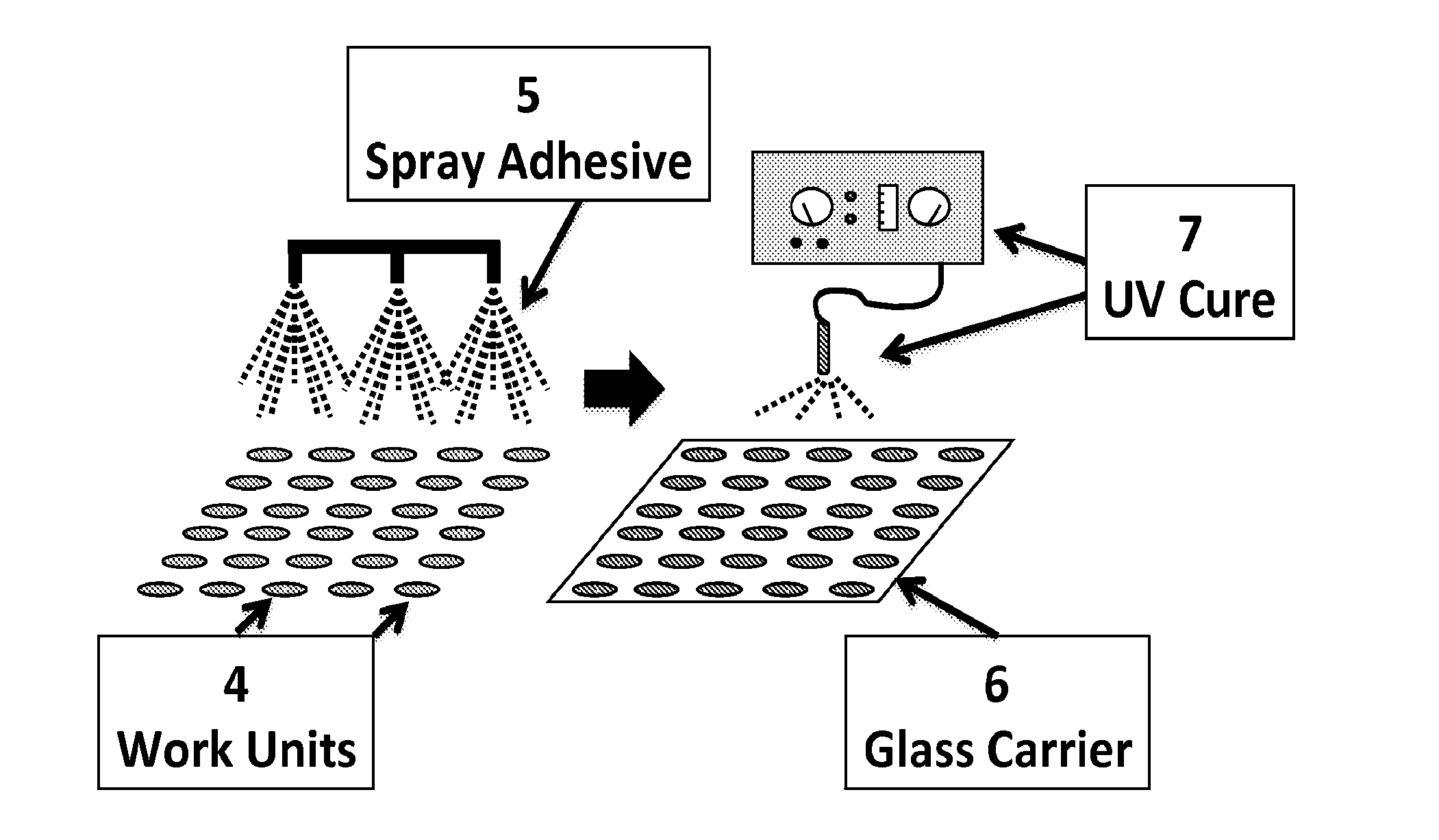

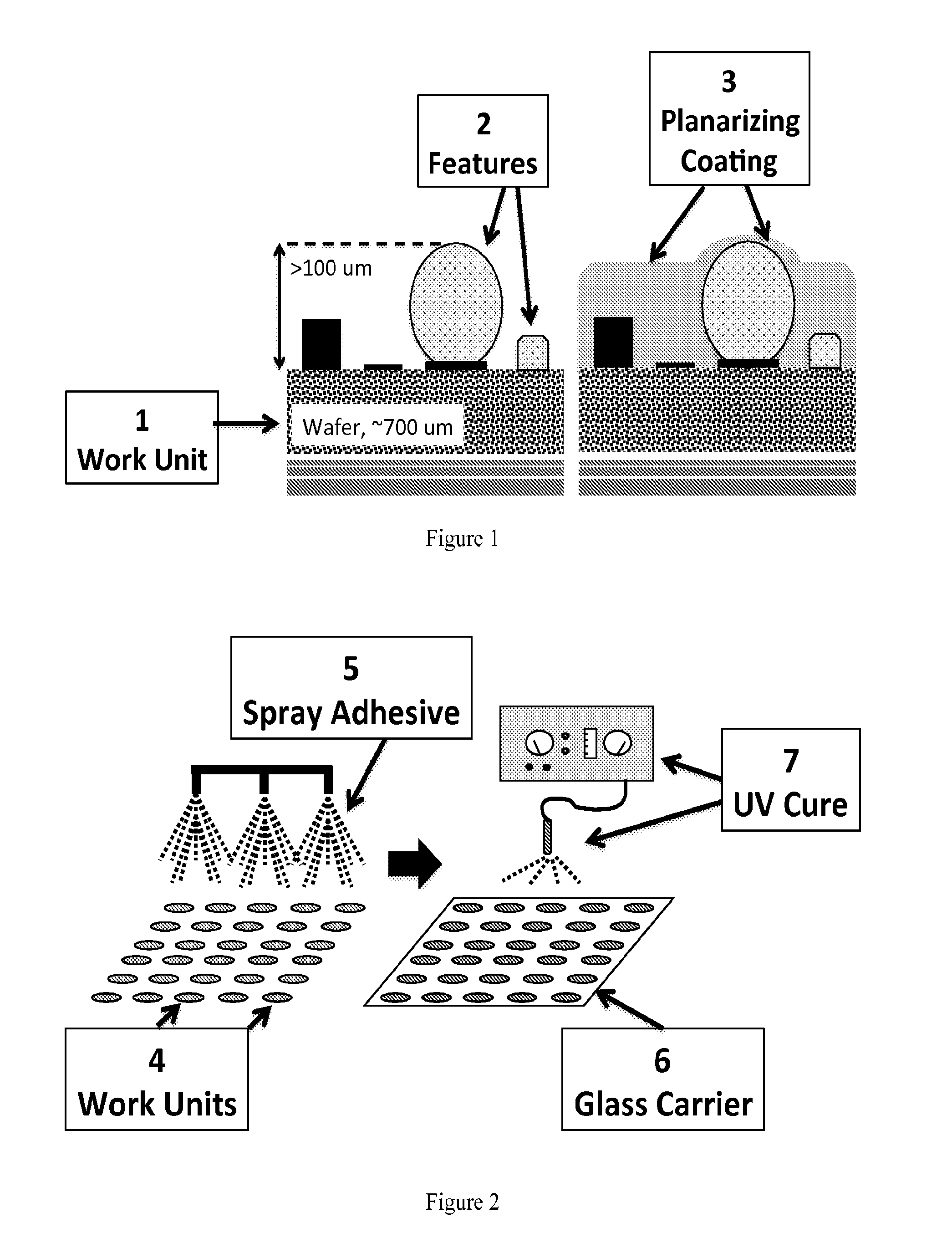

ActiveUS20160009958A1Reduce waste generationReduce complexityNon-macromolecular adhesive additivesSynthetic resin layered productsAdhesiveWork unit

Compositions and methods are described for a temporary coating and adhesive with adjustable acidity for use in coating work units as a planarization coating over high topography and also for affixing thin units onto a carrier whereby such compositions provide sufficient properties to support a manufacturing process, and upon completion, the compositions are removed by an aqueous detergent that dissolves and releases the work unit within a rapid time frame without harm to its integrity. The temporary adhesive provides a tunable acidity based upon Lewis acid represented as its acid dissociative constant, Ka, where it is preferred to have Ka≧1×10−6 (pKa≦6), more preferred Ka≧1×10−5 (pKa≦5), and most preferred Ka≧1×10−4 (pKa≦4). The temporary coating and adhesive may be applied and cured in a variety of ways that meet the needs of the work unit and objectives of the manufacturing process. The invention provides benefits of flexibility and reduced cost when establishing practices to handle difficult work units in the manufacture of semiconductors and flat panel displays.

Owner:MOORE JOHN

Composition for application to a surface

InactiveUS20060288499A1Organic detergent compounding agentsLiquid surface applicatorsEngineeringMaterials science

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Method of neutralizing a stain on a surface

ActiveUS20060276367A1Organic detergent compounding agentsDecorative surface effectsCompound (substance)Dentistry

Compositions, methods, apparatuses, kits, and combinations are described for neutralizing a stain on a surface. The compositions useful in the present disclosure include a composition that is formulated to be applied and affixed to a surface. If desired, the composition may be substantially removed from the surface to remove a portion or substantially all of the stain before being affixed to the surface. If a user desires to remove the composition from the surface, the composition is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the composition to the surface in a permanent or semi-permanent manner, the composition may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The compositions may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the composition to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Method of affixing a design to a surface

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, by a sealant composition such as, for example, a solvent. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Stable, non-chrome, thin-film organic passivates

Storage-stable organic passivate formulations that are essentially chromium-free are provided comprising non-ionic or non-ionically stabilized organic film forming resin; at least one complex fluoride and optionally, dissolved phosphate anions, at least one component comprising vanadium, at least one inorganic oxide in dispersed form; and at least one wax in dispersed form.

Owner:HENKEL KGAA

Heat releasable composite coatings and related methods

Disclosed are heat releasable multi-component composite coatings. These coatings include an under coating and an over coating deposited over at least a portion of the under coating. The under coating is deposited from a coating composition that includes a film-forming resin and thermally expandable capsules having an average diameter of 5 to 25 μm. The over coating layer has a 60 degree gloss of no more than 60 gloss units.

Owner:PPG IND OHIO INC

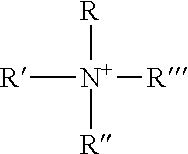

Removable antimicrobial coating compositions containing cationic rheology agent and methods of use

InactiveUS20110177146A1Reducing and preventing growth of microorganismInhibition formationBiocideBiochemical fibre treatmentMicroorganismChemistry

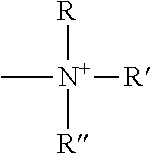

A method is provided for controlling microorganisms comprising coating a surface with a removable, antimicrobial film-forming composition. More specifically, the method relates to a removable antimicrobial coating composition comprising a cationic rheology agent.

Owner:LANXESS CORP

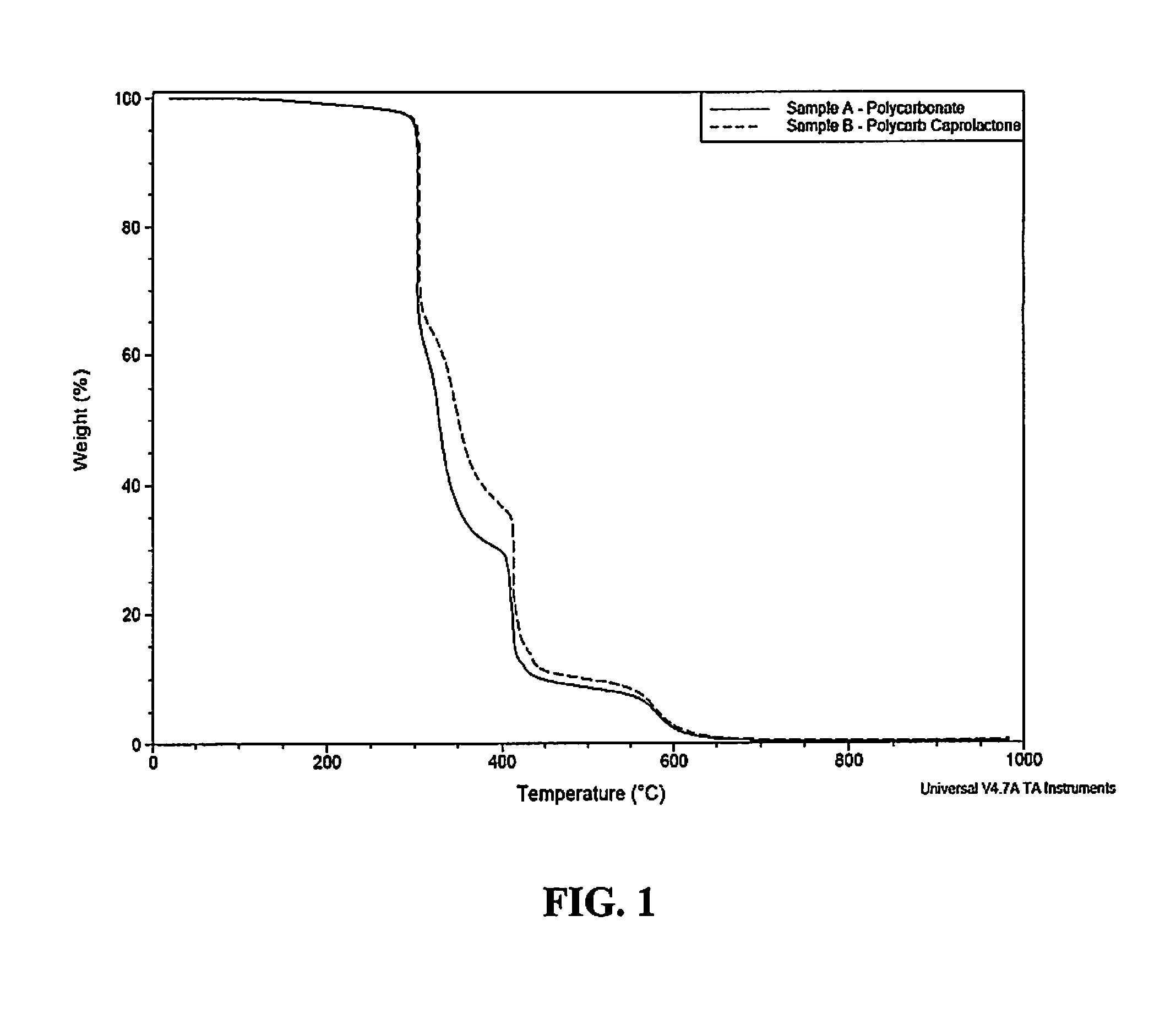

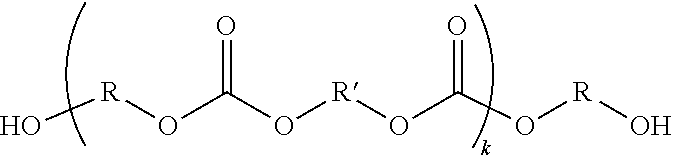

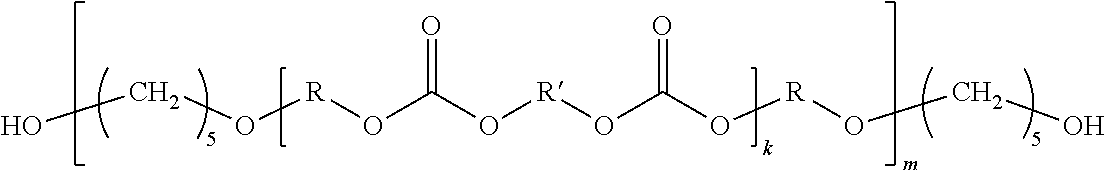

High temperature resistance, radiation curable maskant for metal substrates

A method for shielding a metal substrate surface during the application of heat to the surroundings of the substrate which comprises. A liquid maskant composition is formed which comprises: a) at least one of a polycarbonate urethane diacrylate oligomer, a polycarbonate urethane dimethacrylate oligomer, a polycarbonate caprolactone urethane diacrylate oligomer, or a polycarbonate caprolactone urethane dimethacrylate oligomer; b) a reactive diluent capable of free radical polymerization; and c) a photoinitiator capable of generating free radicals when exposed to actinic radiation. The maskant composition is applied onto a surface of the substrate. The maskant composition is then exposed to sufficient actinic radiation to polymerize or crosslink the composition into a dried maskant. In use the dried maskant is heated on the substrate to a temperature of from about 400° F. to about 600° F. for from about 20 minutes to about 30 minutes, and then the maskant is removed.

Owner:DYMAX

Anti-graffiti coating

ActiveUS20090111910A1Good chemical resistanceEasy to disassembleGroup 4/14 element organic compoundsAntifouling/underwater paintsColloidal silicaPotassium

A non-sacrificial, penetrating, anti-graffiti coating consisting essentially of the combination of alkali metal silicate, such as for example potassium, lithium or sodium silicate, deionized water, ethylene-glycol colloidal silica, aminopropyl oxysilane, fluorinated polyurethane, and alkali metal methyl siliconate, such as for example potassium, lithium or sodium siliconate.

Owner:XUREX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com