Mixed organic solvent for preparing high-temperature sintered conductive paste

A conductive paste and organic solvent technology, applied in the field of oily organic solvents, can solve the problems of slow volatilization, achieve stable volatilization, improve affinity and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Made from the following ingredients:

[0024] Ethylene glycol monophenyl ether acetate 60wt%;

[0025] Butyl carbitol acetate 10wt%;

[0026] 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 5.4wt%;

[0027] Dimethyl adipate 24wt%;

[0028] γ-methacryloxypropyltrimethoxysilane 0.1wt%;

[0029] Silicone oil 1.0wt%;

[0030] Described ethylene glycol monophenyl ether acetate is prepared by following raw material and method:

[0031] The molar ratio of ethylene glycol monophenyl ether and acetic anhydride is 1:1.5, toluene 20wt%, appropriate amount of sulfonic acid molecular sieves;

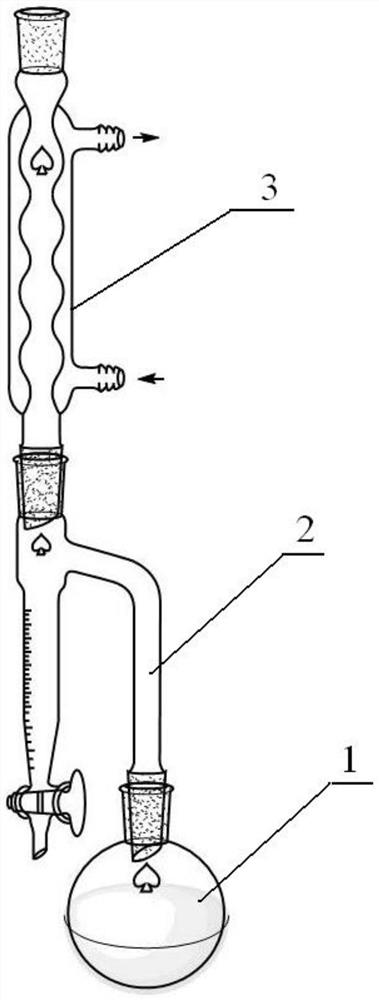

[0032] Install a water separator 2 and a spherical condenser 3 on the round bottom flask 1, heat the oil bath to the reflux of toluene under the condition of magnetic stirring, and keep the toluene to reflux stably for 8 hours; remove the water separator and install a drier; After cooling to room temperature, it was distilled under reduced pressure to collect the main fraction.

Embodiment 2

[0034] Made from the following ingredients:

[0035] Propylene glycol monophenyl ether acetate 10wt%;

[0036] Butyl carbitol acetate 60wt%;

[0037] 2,2,4-trimethyl-1,3-pentanediol diisobutyrate 1wt%;

[0038] Dimethyl adipate 28wt%;

[0039] γ-methacryloxypropyltrimethoxysilane 0.5wt%;

[0040] Silicone oil 0.5wt%.

[0041] Propylene glycol monophenyl ether acetate of the present invention is prepared by following raw material and method:

[0042] The mol ratio of propylene glycol monophenyl ether and acetic anhydride is 1:1.1, toluene 15wt%, appropriate amount of sulfonic acid molecular sieves;

[0043] Install a water separator 2 and a spherical condenser 3 on the round bottom flask 1, heat the oil bath to the reflux of toluene under the condition of magnetic stirring, and keep the toluene stable reflux for 4 hours; remove the water separator and install a drier; After cooling to room temperature, it was distilled under reduced pressure to collect the main fraction. ...

Embodiment 3

[0045] Made from the following ingredients:

[0046] Propylene glycol monophenyl ether butyrate 35wt%;

[0047] Butyl carbitol acetate 35wt%;

[0048] 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 5wt%, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate 5wt%;

[0049] Dimethyl adipate 18.2wt%;

[0050] γ-methacryloxypropyltrimethoxysilane 0.3wt%;

[0051] Silicone oil 1.5wt%.

[0052] Propylene glycol monophenyl ether butyrate of the present invention is prepared by following raw materials and method:

[0053] The mol ratio of propylene glycol monophenyl ether and butyric anhydride is 1:1.3, toluene 10wt%, appropriate amount of sulfonic acid molecular sieves;

[0054] Install a water separator 2 and a spherical condenser 3 on the round bottom flask 1, heat the oil bath to the reflux of toluene under the condition of magnetic stirring, and keep the toluene to reflux stably for 2 hours; remove the water separator and install a drier; After cooling to room temperature, it was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com