Patents

Literature

51results about How to "Volatile stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

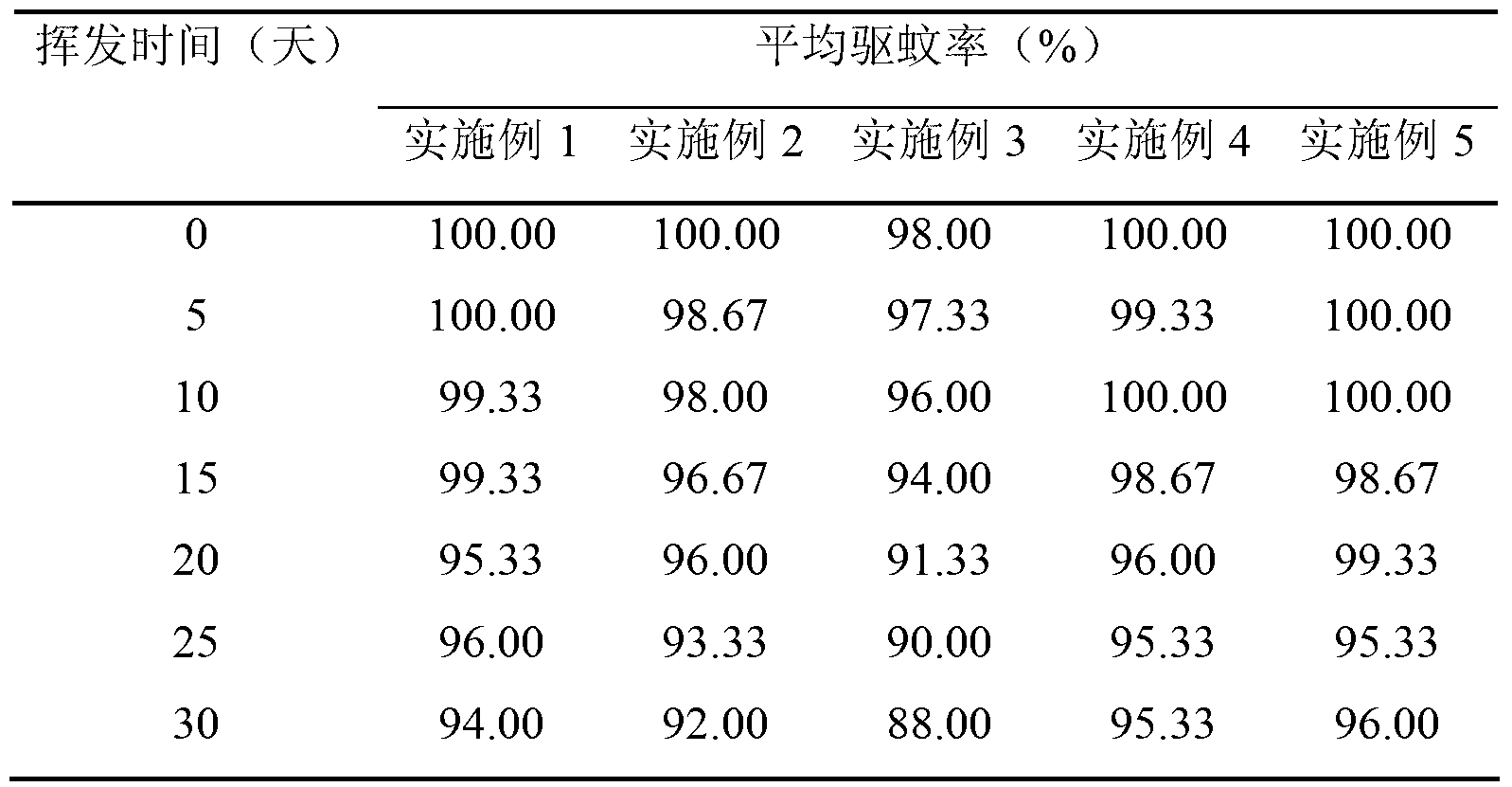

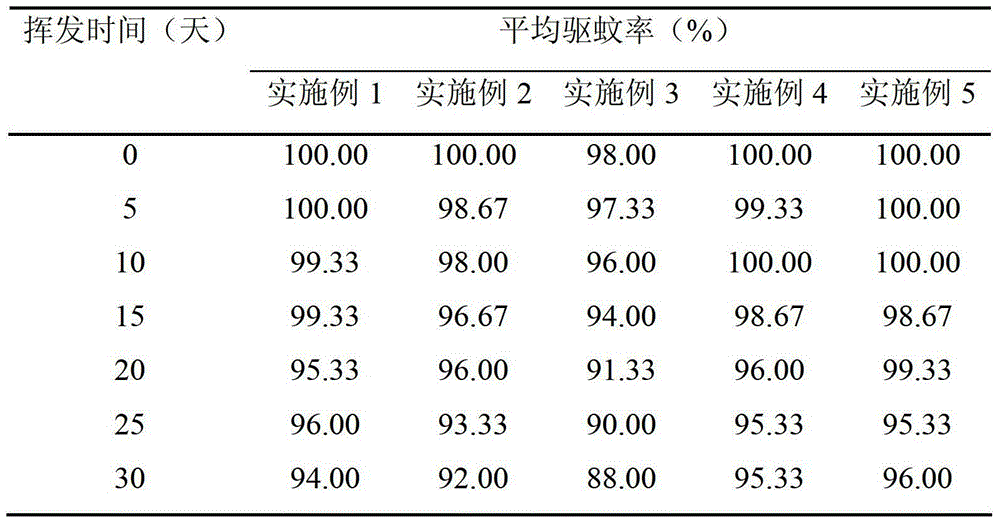

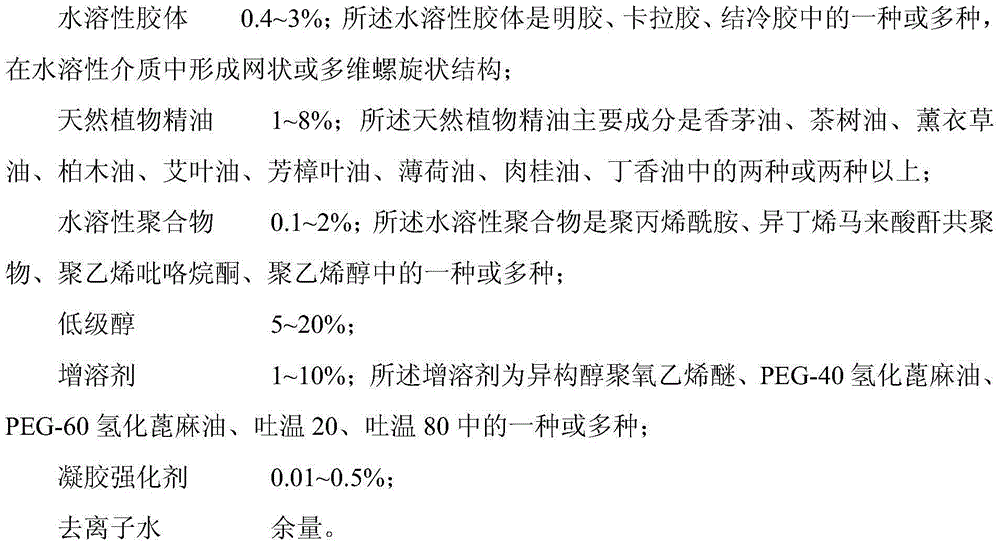

Mosquito repelling gel composition with natural plant essential oil

The invention discloses a mosquito repelling gel composition with natural plant essential oil. The mosquito repelling gel composition comprises the following raw materials in percentage by weight: 0.2-5% of water-soluble colloid, 0.2-10% of natural plant essential oil, 0-5% of water-soluble polymers, 1-20% of low alcohols, 0.5-20% of solubilizing agent, 0-0.5% of gel enhancer and the balance of deionized water. The water-soluble colloid in mosquito repelling gel disclosed by the invention can form a reticular or multi-dimensional spiral structure in a water medium and can be stably dispersed or used for wrapping the natural plant essential oil, so that the essential oil is stably and continuously released, and a better mosquito repelling rate can be kept in the whole release process. A mosquito repelling component adopted in the product is purely-natural plant essential oil which is safe to the environment and human bodies; the product is in a gel form; the essential oil is stably volatilized at normal temperature; and when used, the mosquito repelling gel composition does not need to be in direct contact with the skins of human bodies, is convenient to carry and can be continuously used for repelling mosquitoes indoors and outdoors for a long term.

Owner:安福超威日化有限公司

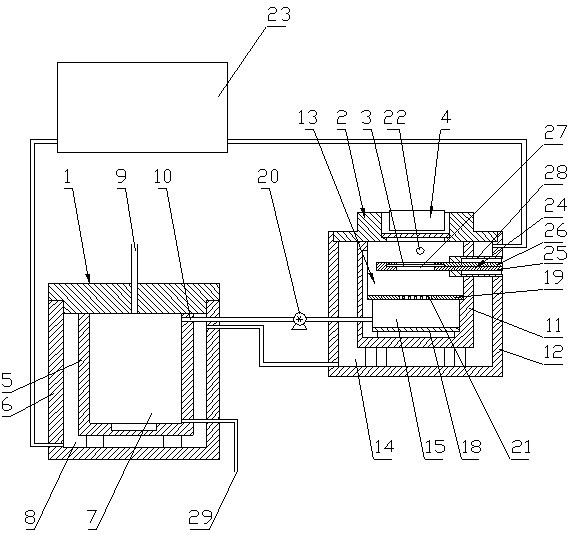

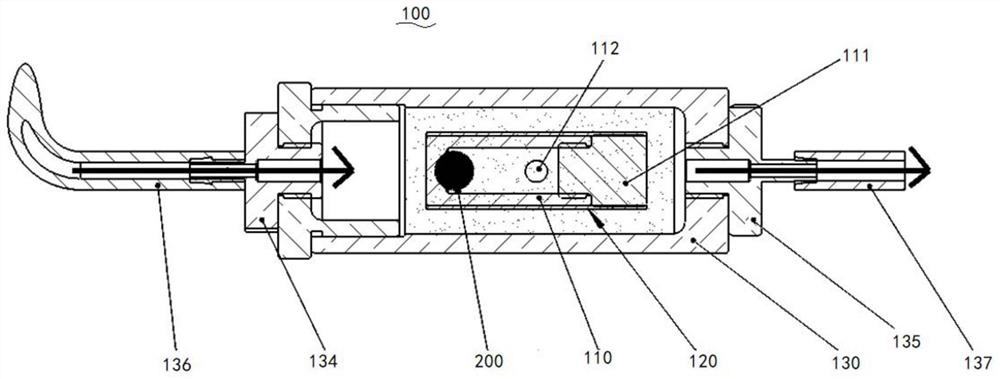

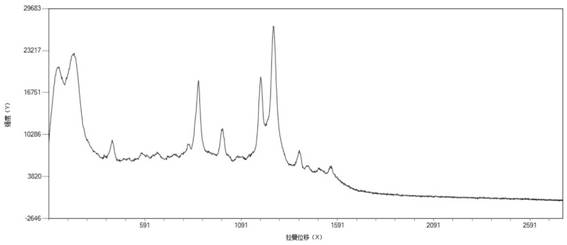

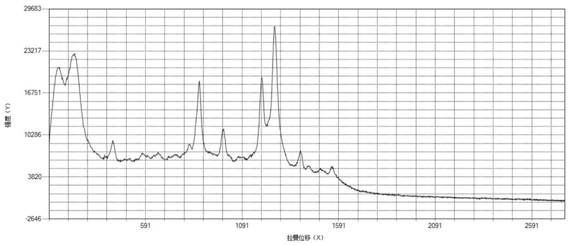

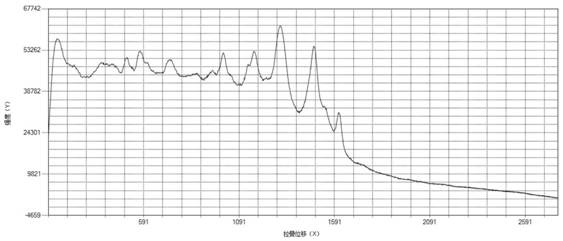

Spirit identifying system based on volatizing control and visualized array sensor

InactiveCN101858854AVolatile stabilityImprove stabilityColor/spectral properties measurementsEngineeringHandling system

The invention relates to a spirit identifying system based on volatizing control and a visualized array sensor. The system comprises a volatizing device, a detecting device, a visualized array sensor and an image collecting instrument, wherein the volatizing device consists of an inner layer I and an outer layer I; the detecting device consists of an inner layer II and an outer layer II; the inner layer I is a spirit storing cavity; a heating cavity I is arranged between the inner layer I and the outer layer I; the inner layer II is a spirit gas detecting cavity; a heating cavity II is arranged between the inner layer II and the outer layer II; the visualized array sensor is arranged in the spirit gas detecting cavity; and the image collecting instrument is arranged at the top of the spirit gas detecting cavity. The spirit is volatized by the volatizing control device under the required condition and comes into contact with the visualized array sensor in the input detecting device, the signal responded by the feature of the sample to be detected is detected by the visualized array sensor, the spectrum change signal collected by the image collecting instrument is input to a signal identifying and processing system, the detecting results are displayed in a spectrogram way and then the visualized detection is realized. The detection is convenient and rapid by adopting the system.

Owner:CHONGQING UNIV

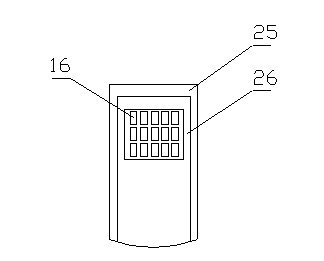

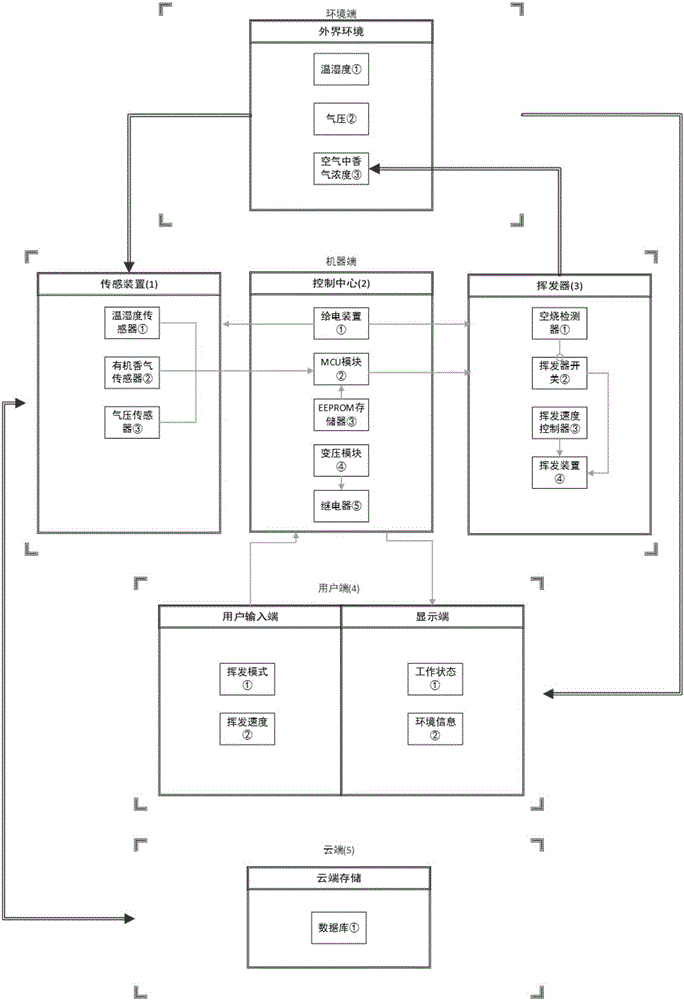

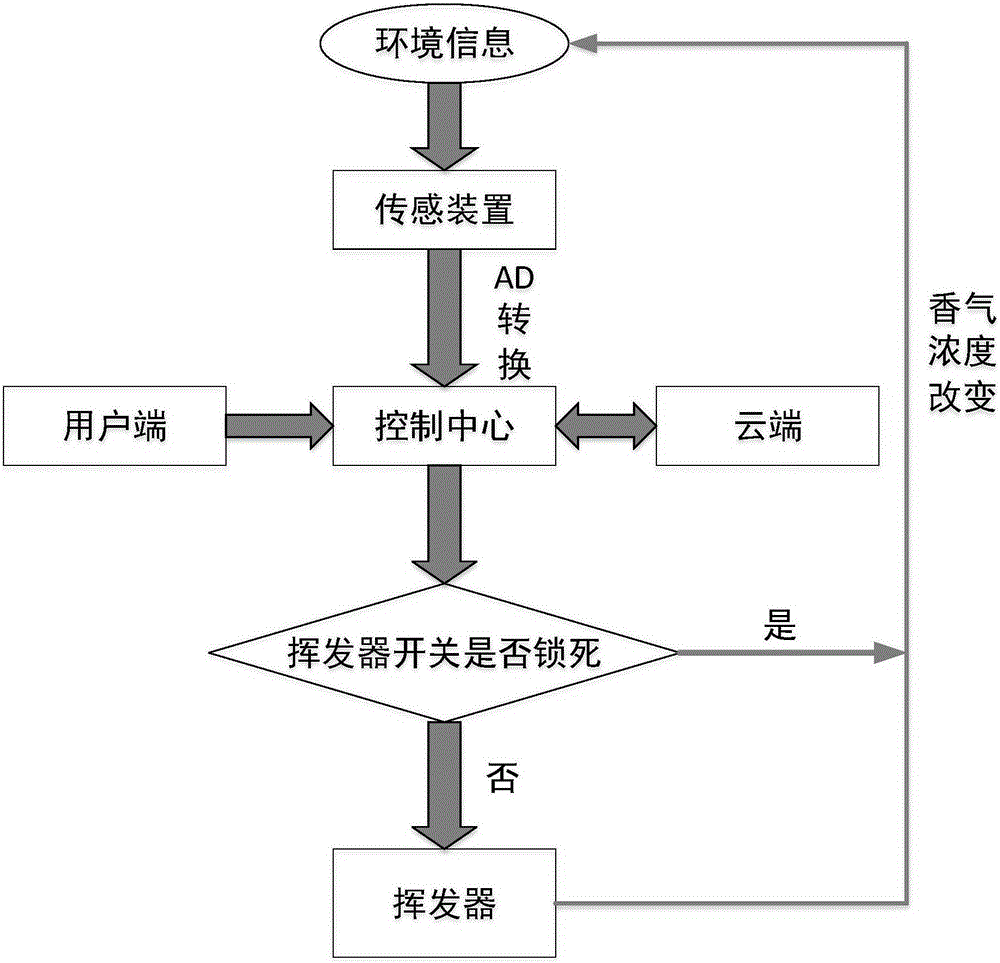

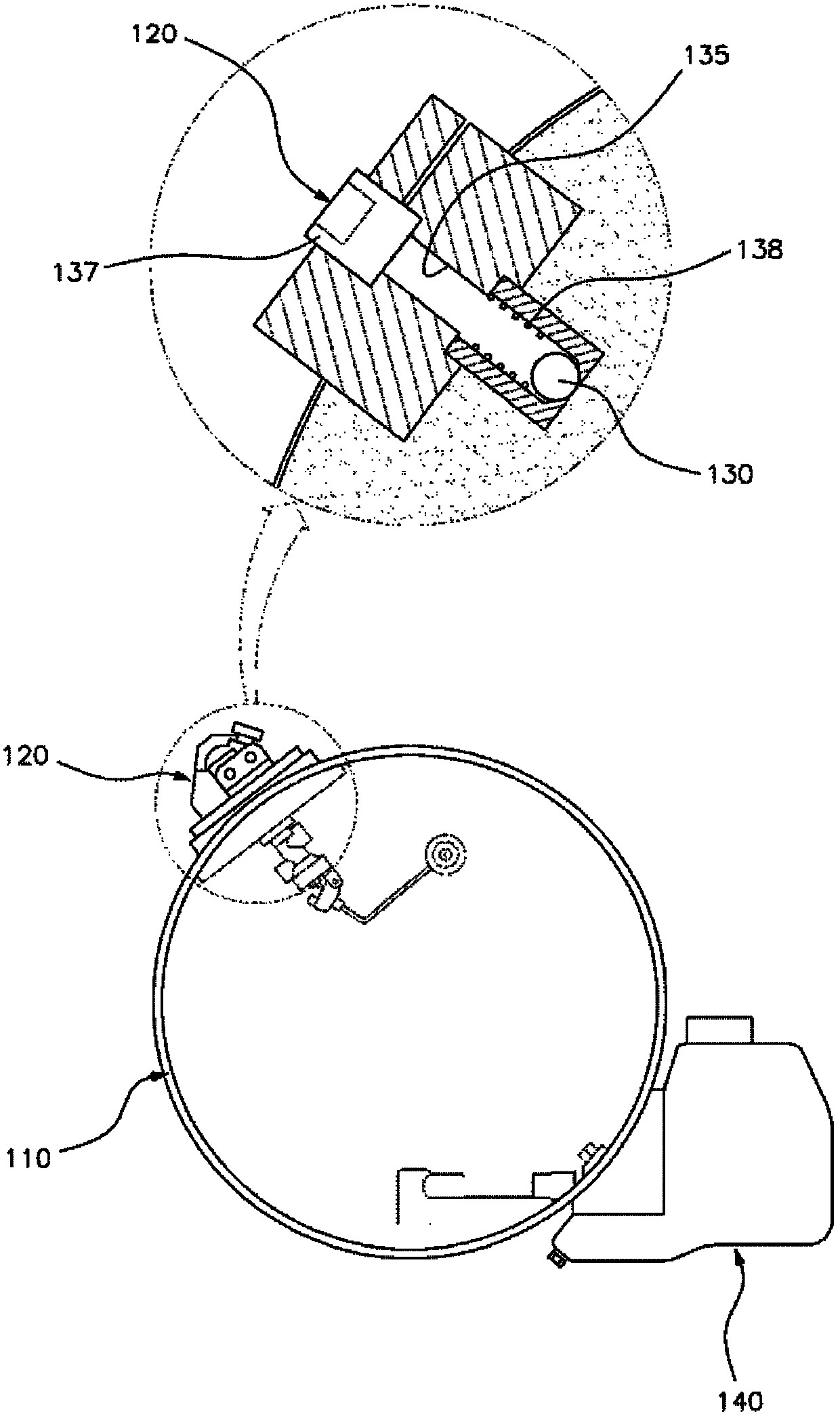

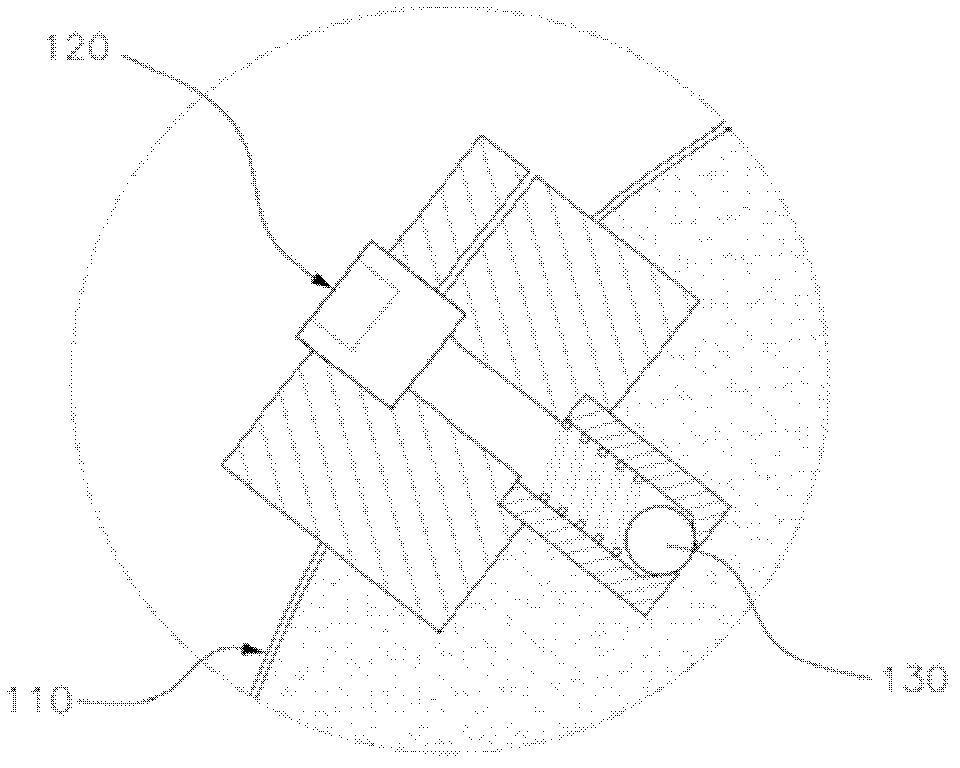

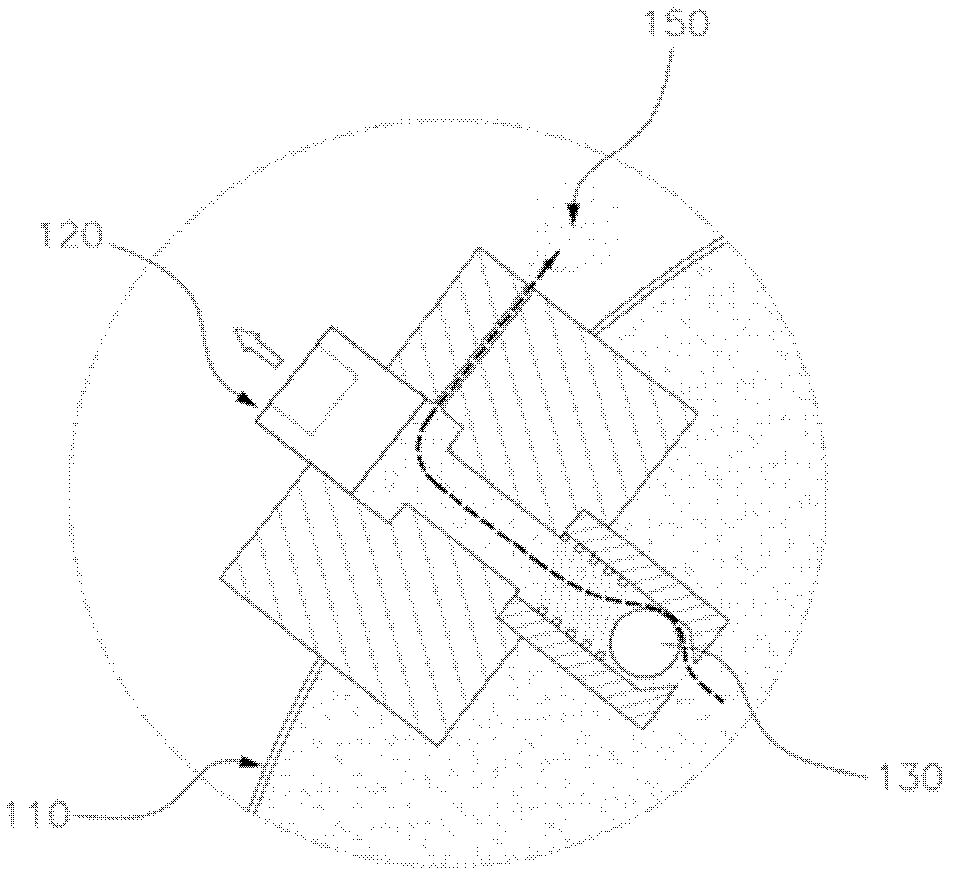

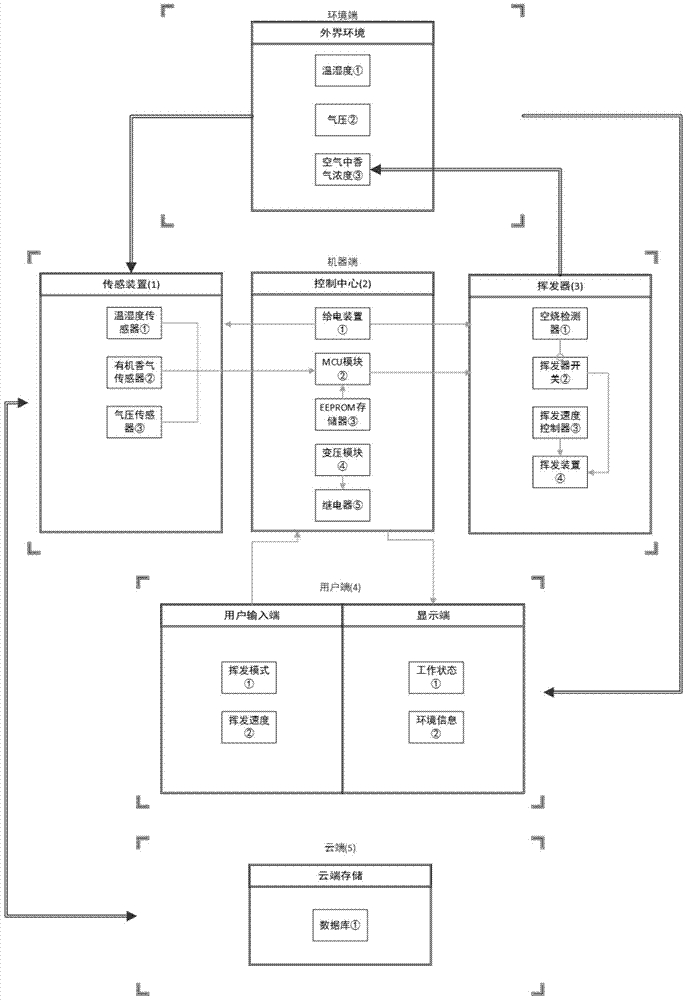

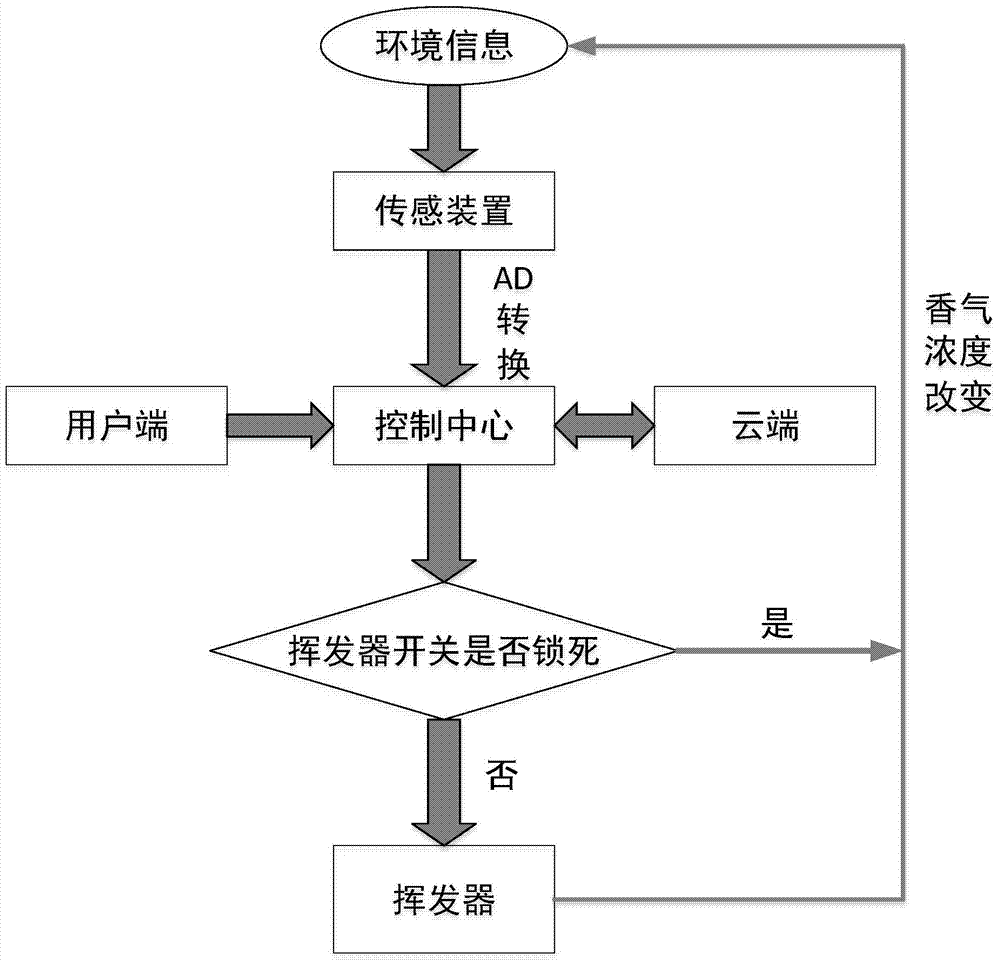

Intelligent aroma volatilizing system

InactiveCN105194709AVolatile stabilityImprove communication accuracyGaseous substancesProgramme control in sequence/logic controllersControl signalAdditive ingredient

The invention discloses an intelligent aroma volatilizing system which comprises a sensing device, a control center, a volatilizer, a client and a cloud, wherein the sensing device is used for collecting and extracting environmental parameter information influencing volatilization and volatilizing state in an external environment, converting the environmental parameter information into an electric signal, and transmitting the electric signal to the control center; the control center is used for controlling the volatilizer by combining historical control information of the cloud and the behavioral habit of the user according to an input instruction of the user at the client and the volatilization environmental information transmitted by the sensing device, and transmitting the operating state of the system to the client; the volatilizer is used for accepting a control signal of the control center, and controlling multidimensional volatilization of aroma. The intelligent aroma volatilizing system disclosed by the invention is controlled by a mobile terminal to finally produce high-end intelligent home equipment which can be used for simulating multiple scenes; the high-end intelligent home equipment has a main function of simulating smell, and realizes sense similarity of environmental atmosphere and ingredient similarity of healthy health-care functions.

Owner:SHANGHAI JIAO TONG UNIV

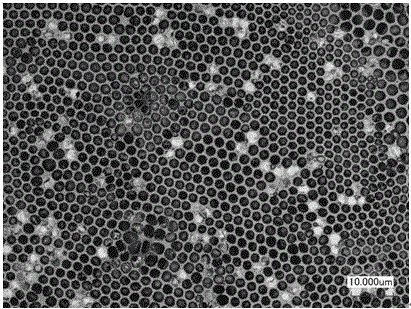

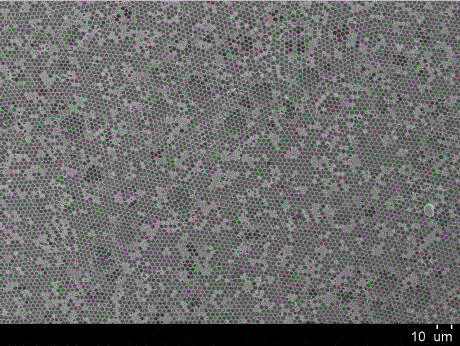

Method for preparing large-area orderly porous membrane

The invention discloses a method for preparing a large-area orderly porous membrane. The method comprises the following steps: (1) dissolving a polymer and a surfactant into a solvent so as to prepare a polymer solution; (2) dropwise adding the prepared polymer solution to the surface of a substrate, and putting the substrate into a closed container; (3) introducing steam into the closed container from the downside of the substrate, controlling relative humidity to a stable state, and carrying out standing on the substrate for a certain time in a stable-state humidity atmosphere; (4) taking the substrate out of the humidity atmosphere, and drying the substrate, thereby obtaining the orderly porous membrane. According to the method, the preparation of nanoscale-pore-size and micron-scale-pore-size porous membranes can be taken into account by one process route, and the process route is not required to be changed during the production of the porous membranes of different pore sizes, so that the production cost is reduced; the large-area orderly porous membrane with high stability can be prepared.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Anti-mosquito water-proof non-woven fabric production technology

ActiveCN105177858AVolatile stabilityHas anti-mosquito effectLiquid/gas/vapor removalArtificial filaments from viscoseWoven fabricBed sheets

The invention relates to a non-woven fabric production technology, in particular to an anti-mosquito water-proof non-woven fabric production technology to solve the problem of a single function of the non-woven fabric. Water-proof agent is uniformly sprayed on a non-woven fabric fiber mesh through a spraying method. The non-woven fabric fiber mesh is vibrated vertically to enable the water-proof agent to filter into the non-woven fabric mesh quickly and uniformly. The non-woven fabric fiber mesh after vibration treatment enters into an oven to be dried, the temperature of the oven is 250 to 260 degrees, the non-woven fabric fiber mesh passes through the oven with the speed of 40 to 50 m / min, the vibration amplitude is 12 to 16 mm, the frequency of vibration is 220 times / min to 320 times / min, and the anti-mosquito water-proof non-woven fabric is obtained. The anti-mosquito water-proof non-woven fabric production technology enables the non-woven fabric itself to have the anti-mosquito effect, the non-woven fabric can be used to produce a tent, a bed sheet and a pillow cover, can be especially used by the crowd who are afraid of being bit by mosquitoes and are allergic to the biting of the mosquitoes and can also be used by the crowd working outdoor, and the hidden danger of liquid medicine spraying directly to the skin to the body is avoided.

Owner:丹阳市华荣无纺布有限公司

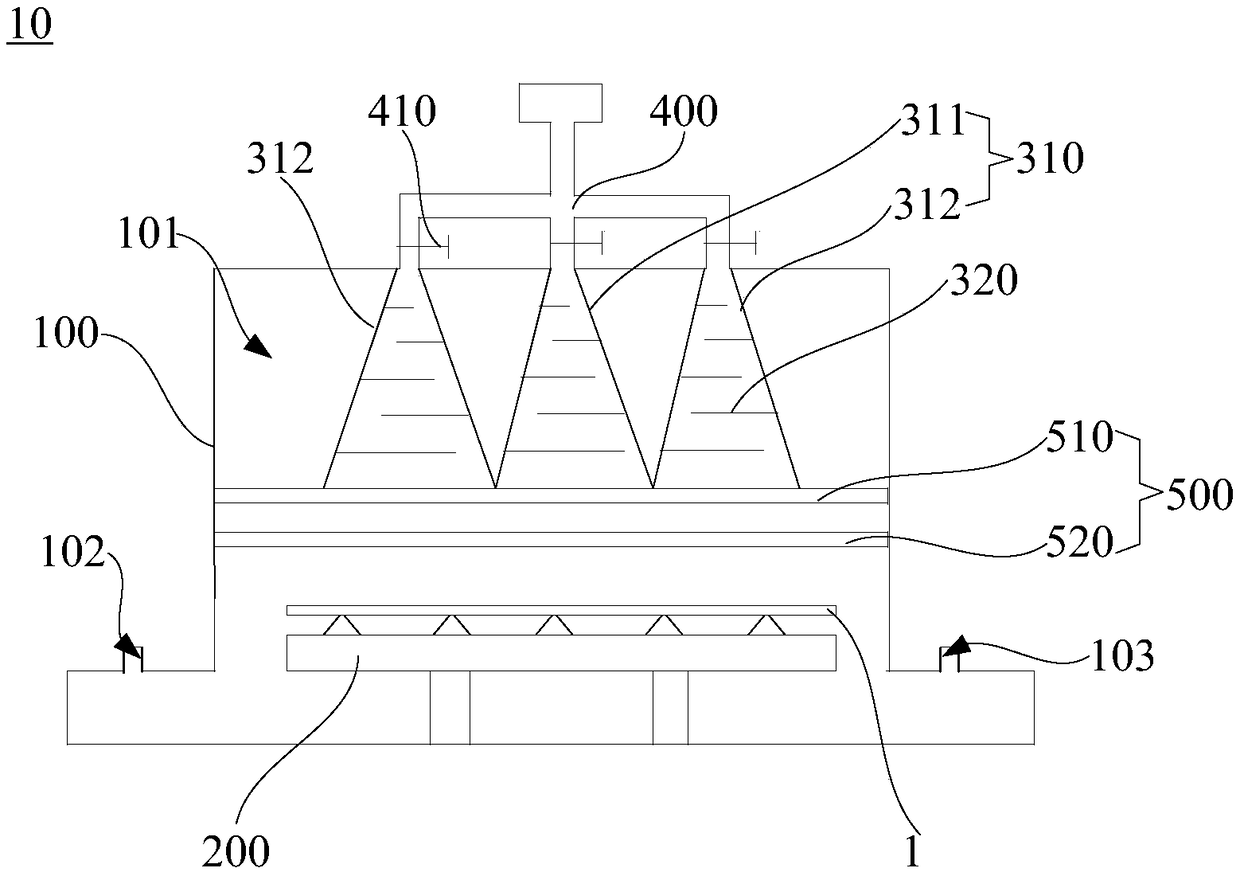

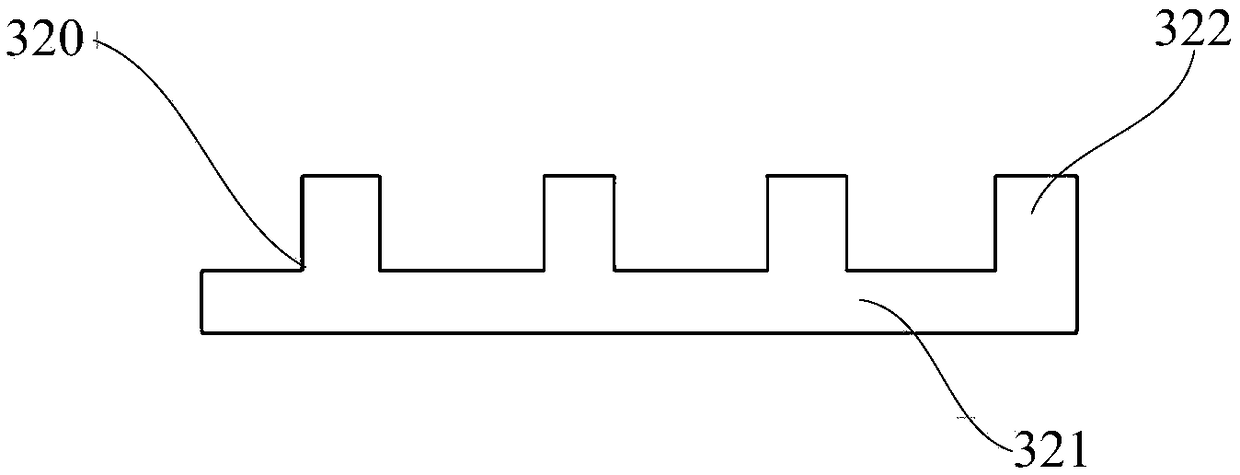

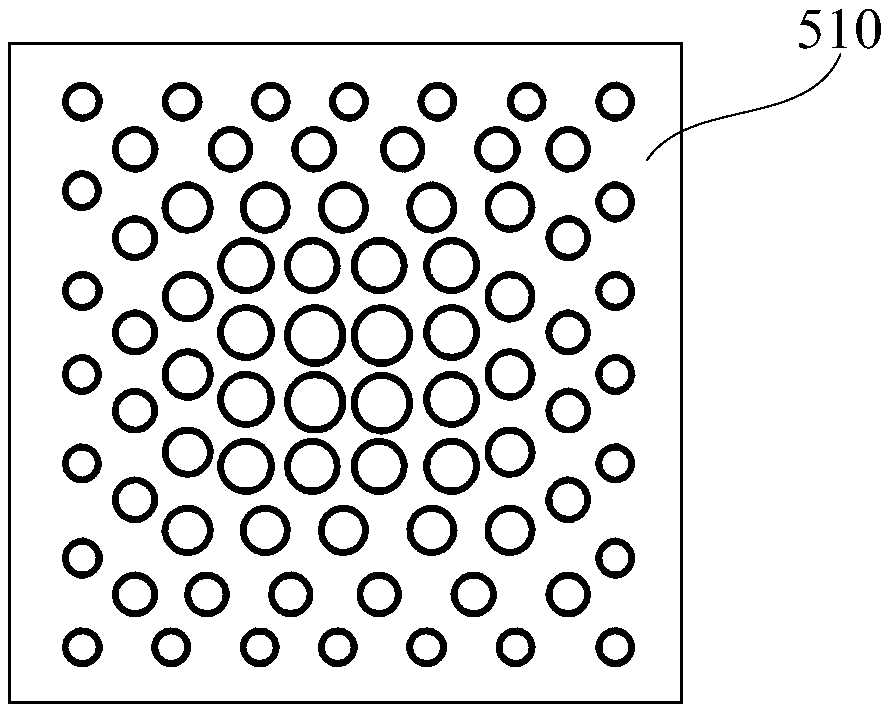

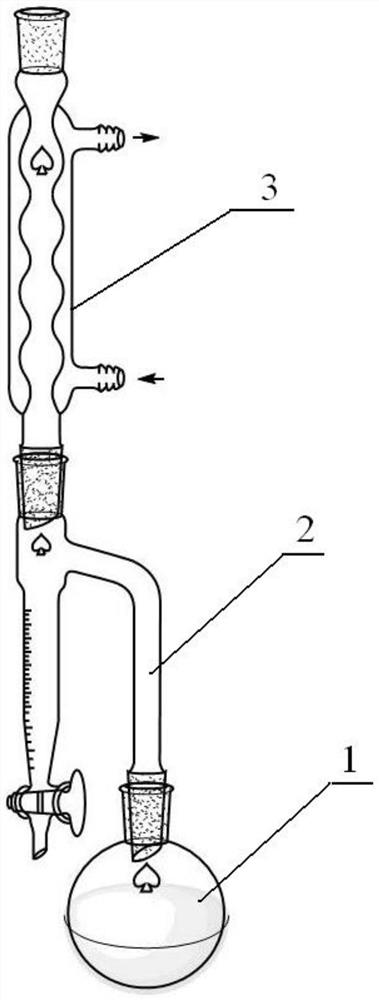

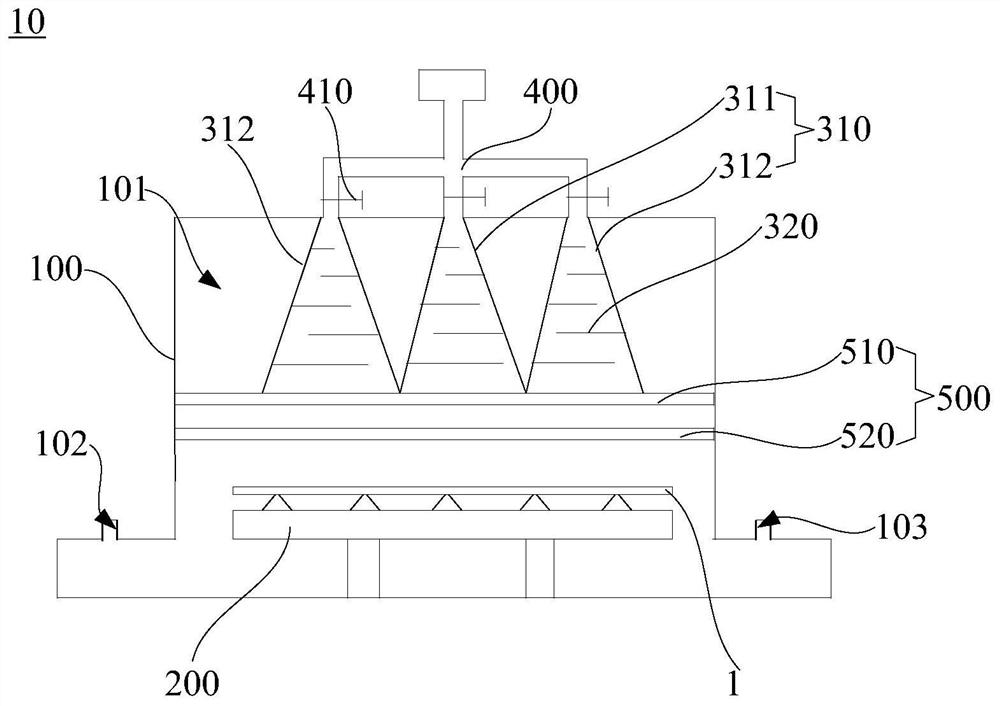

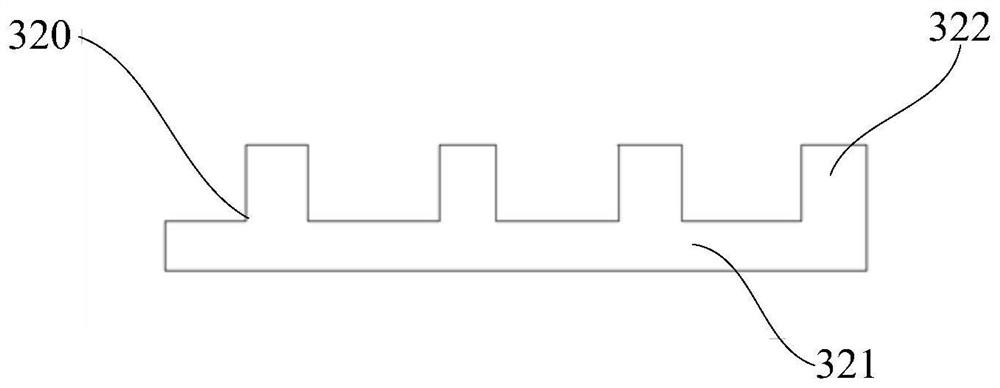

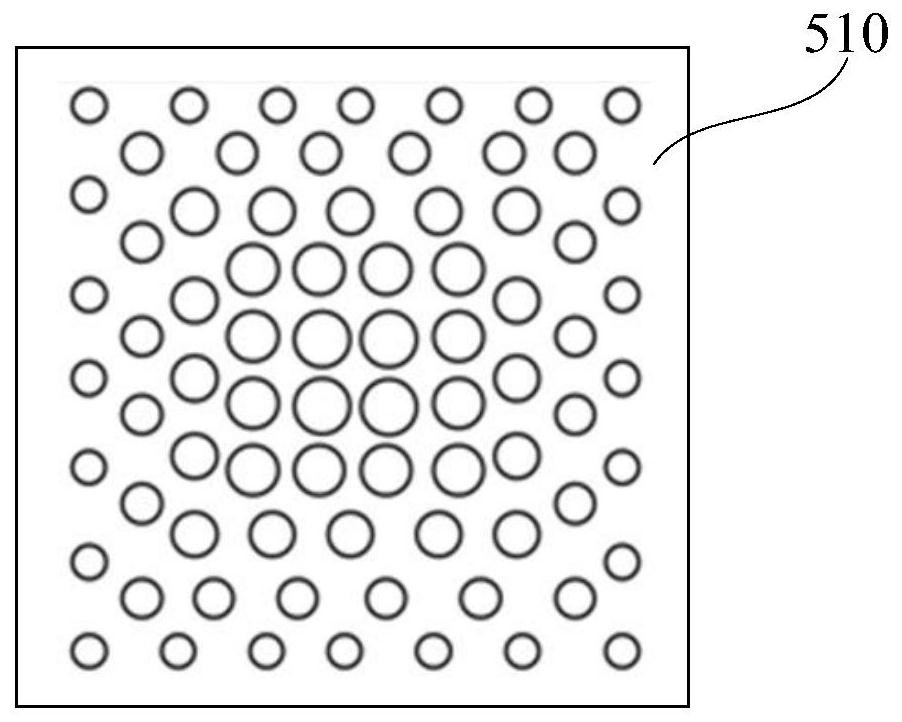

Vacuum drying device

ActiveCN108344254AExtend the distribution pathStable and uniform changeDrying solid materials without heatDrying gas arrangementsEngineeringVacuum drying

The invention relates to a vacuum drying device. The vacuum drying device comprises a drying chamber, a sample table and a flow stabilizing channel, wherein the drying chamber is provided with a vacuum cavity, the sample table is arranged in the vacuum cavity, the flow stabilizing channel is arranged in the vacuum cavity, one end of the flow stabilizing channel is used for communicating with an air extracting device, and the other end of the flow stabilizing channel is arranged towards the sample table and is provided with an airflow inlet. Compared with a conventional vacuum drier, a stable layer flow is formed on the surface of a sample by adopting the vacuum drying device, so that the situation of turbulence formed in a membrane layer or the situation that intermediate drying speed is small while the peripheral drying speed is high in the membrane layer can be avoided, water in ink and other materials to be volatilized can be uniformly volatilized as much as possible, the uniformityof membrane forming is effectively improved, and the performance of the device is further improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

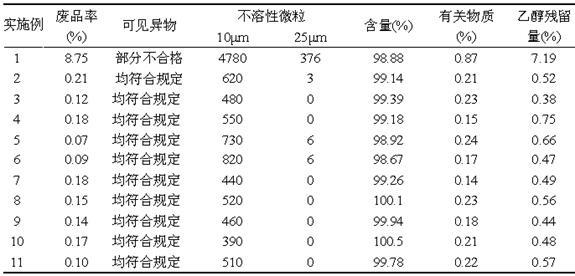

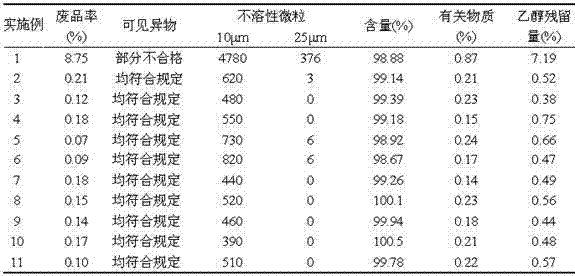

Docetaxel combination for injection and preparation method thereof

ActiveCN101862319AAvoid sharp drops in temperatureElimination of visible foreign matter and insoluble particulate failuresOrganic active ingredientsLyophilised deliverySolventSpecific gravity

The invention relates to a Docetaxel combination for injection, which comprises the following components by mass ratio: 1 part of Docetaxel and 26.75 parts of polysorbate 80, wherein absolute alcohol is used as solvent in the preparation. The preparation method thereof comprises the following steps: 1) preparing mother liquid: adding polysorbate 80 to a liquid preparation tank and slowly adding absolute alcohol while stirring until the density of the mother liquid reaches 0.886g / ml to 0.896g / ml according to a hydrometer; 2) dissolving Docetaxel in the mother liquid; 3) carrying out sterile filtration, split-charging and partially stoppering; and 4) vacuum-drying, removing alcohol, stoppering, decrating and tying by aluminum-plastic composite covers stage by stage, and packaging upon qualification to obtain the Docetaxel combination for injection.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Preparation method for improving quality factor of microwave dielectric ceramic

The invention discloses a preparation method for improving a quality factor of a microwave dielectric ceramic. The preparation method comprises the following steps: putting a powder material and zirconia balls into a ball mill tank according to a 1:3 mass ratio of the powder material to the balls, and performing ball-milling on the mixture using a revolution way, drying the ball milled mixture, and performing pre-firing on the raw material mixture powder to obtain a sample clinker; grinding the sample clinker, performing ball milling for 2h using a revolution way, and then adding a small amount of dispersant, performing ball milling for 1h using an autorotation way, and drying after the ball milling to obtain a sample powder; and putting the dried sample powder into a ball mill tank containing a deionized water and ethanol mixture, then putting the ball mill tank into an ultrasonic cleaning machine, and performing ultrasonic vibration and thermal insulation at temperatures of 40 DEG Cand 95 DEG C successively, drying to obtain a sample powder, performing granulation, sieving and compression molding on the sample powder, and finally sintering the sample powder into the microwave dielectric ceramic. The microwave dielectric ceramic prepared by the method has a higher quality factor, has a lower sintering temperature, has fine powder particles without agglomeration, has low production costs, and is suitable for industrial production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Docetaxel combination for injection and preparation method thereof

ActiveCN101862319BLow content of related substancesStable and uniform qualityOrganic active ingredientsLyophilised deliveryHydrometerDocetaxel

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

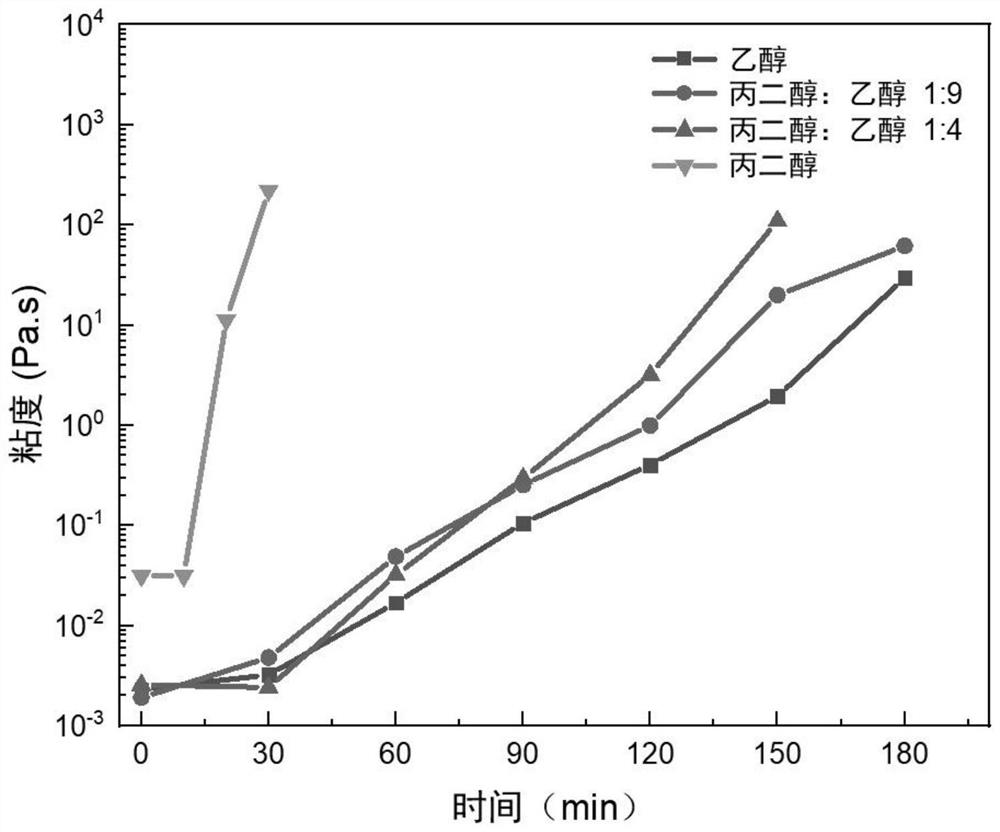

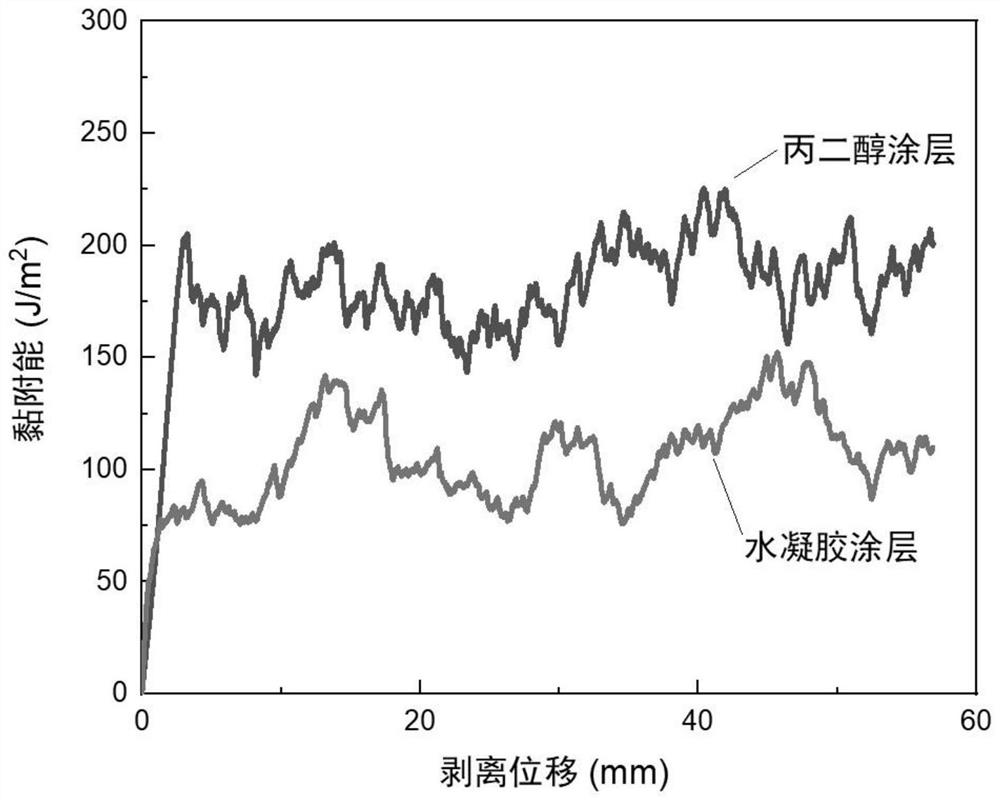

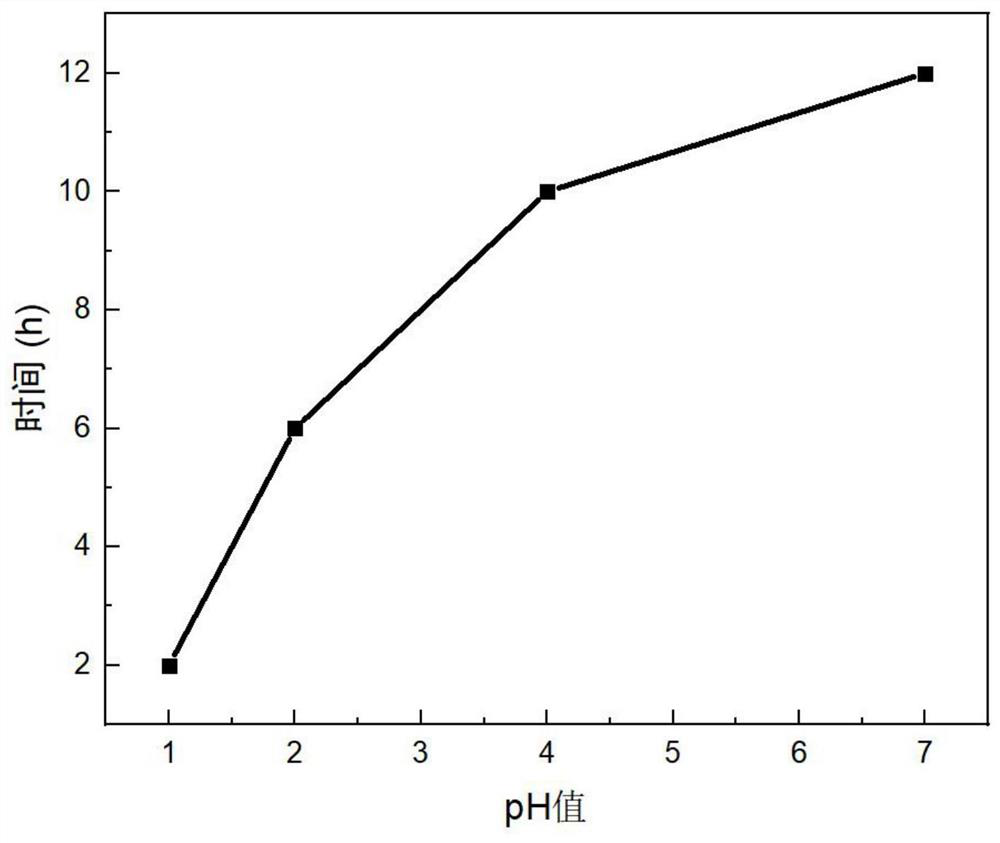

Sprayable hydrogel coating and preparation method of coating thereof

The invention discloses a sprayable hydrogel coating and a preparation method of the coating. The preparation method is characterized by comprising the following steps: S1, performing synthesis of an ultraviolet polymerization viscous solution: mixing a solvent, a monomer, a cross-linking agent and an initiator in a reaction container to form a mixed reaction solution, stirring and carrying out free radical polymerization reaction under the condition of ultraviolet illumination to obtain the ultraviolet polymerization viscous solution; s2, performing solution dilution: diluting the ultraviolet polymerization viscous solution by adding ethanol to obtain a dilute solution which can be directly used for spraying; s3, adjusting the pH value of the dilute solution which can be directly used for spraying to obtain a solution C; and S4, spraying and curing. The hydrogel coating prepared from the coating obtained by the method has the advantages of mild preparation conditions, no environmental pollution, capability of generating chemical bonding on various solid surfaces and the like; and the method for spraying the hydrogel coating is feasible, the preservation time is long, and the hydrogel coating can be sprayed on the surfaces of various substrate materials and can be stably bonded with a substrate.

Owner:HENAN UNIVERSITY

Method for enriching and stabilizing mercury in coal-fired flue gas by using blast furnace slag modified desulfurizer

ActiveCN108159870APromote enrichmentLess catchGas treatmentDispersed particle separationAtmospheric airSlag

The invention discloses a method for enriching and stabilizing mercury in coal-fired flue gas by using a blast furnace slag modified desulfurizer. The method comprises the following steps: using an FGD desulfurizer slurry, using blast furnace slag as a modifier, and mixing the blast furnace slag and the desulfurizer slurry according to a mass ratio of the blast furnace slag to a dry desulfurizer of 1 to 2-3 to form iron manganese oxide-desulfurizer mixture system so as to prepare a desulfurizing-mercury capturing composite slurry; then using the desulfurizing-mercury capturing composite slurryfor desulfurizing the coal-fired flue gas and enriching and absorbing the mercury in the coal-fired flue gas. According to the method, the blast furnace slag and the desulfurizer are mixed to preparethe desulfurizer slurry for desulfurizing flue gas in a coal-fired power plant; toxicity leaching and volatilization testing are performed on the mercury in an obtained desulfurization material, themercury in the obtained desulfurization material is more stable than ordinary desulfurization gypsum, the concentration of the leached mercury is lowered, the volatile release rate is greatly reduced,and the inhibitory effect on an environmental mercury pollution source is strong. Therefore, the method is of a great significance in atmospheric environmental protection.

Owner:SHANGHAI UNIV

Mixed organic solvent for preparing high-temperature sintered conductive paste

ActiveCN112133469AHigh affinityImprove solubilityNon-conductive material with dispersed conductive materialPhotovoltaic industryPhenyl Ethers

The invention relates to a mixed organic solvent for preparing high-temperature sintered conductive paste, and belongs to the technical field of oily organic solvents. The mixed organic solvent comprises 10-60 wt% of fatty acid ester containing a phenyl ether structure, 10-60 wt% of butyl carbitol acetate, 0.1-10 wt% of at least one of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, 10-30 wt% of dimethyl adipate, 0.1-0.5 wt% of gamma-methacryloxypropyltrimethoxysilane and 0.5-1.5 wt% of silicone oil. The mixed organic solvent has the advantages that the solvent has the characteristics of good resin solubility, good wettability to metal particles, no volatilization at room temperature, stable volatilization at high temperature and the like, various types of resin commonly used by photovoltaic front silver paste can be well dissolved, and experiments prove that compared with a traditional single solvent system, the solvent is more suitablefor the requirements of silver paste printing and sintering; and the solvent is simple in reaction condition and high high product yield, and has favorable application prospects in the photovoltaic industry and electronic conductive paste related fields.

Owner:CHANGCHUN GOLD RES INST

Peppermint essential oil mosquito liquid and preparation method thereof

ActiveCN105475372AFresh and fragrantStrong repellent effectBiocideDead animal preservationPeppermintsSODIUM CUMENESULFONATE

The invention discloses peppermint essential oil mosquito liquid and a preparation method thereof. The peppermint essential oil mosquito liquid is prepared from, by weight, 0.5-2.5 parts of transfluthrin, 0.1-0.5 part of peppermint essential oil, 50-60 parts of diethylene glycol butyl ether, 0.05-0.15 part of 4-sodium cumenesulfonate, 0.1-0.5 part of synergist, 0.1-0.5 part of antioxidant and 35-45 parts of water. The peppermint essential oil mosquito liquid is fresh and fragrant in smell, has a strong dispelling and killing effect on mosquitoes, is environmentally friendly, strong in effect, safe, inflammable and stable in volatilization, can lower the indoor organic volatile content, and is an ideal choice for healthy home life.

Owner:许银亚

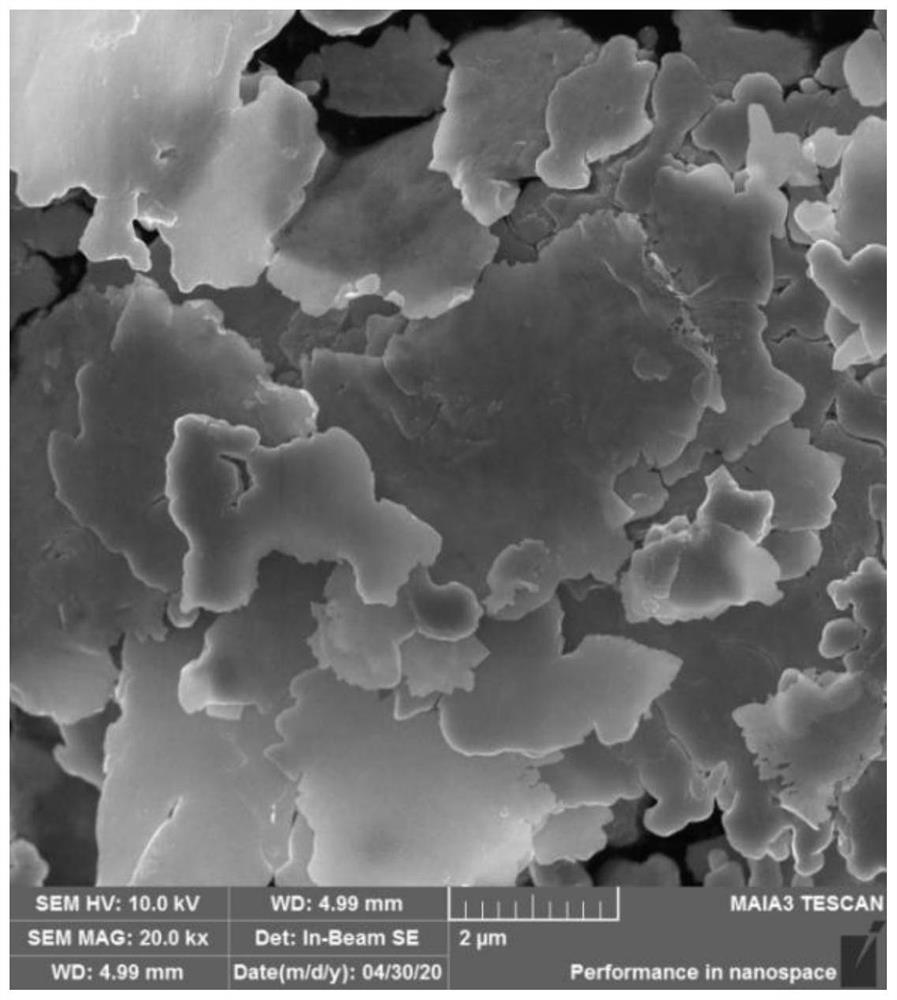

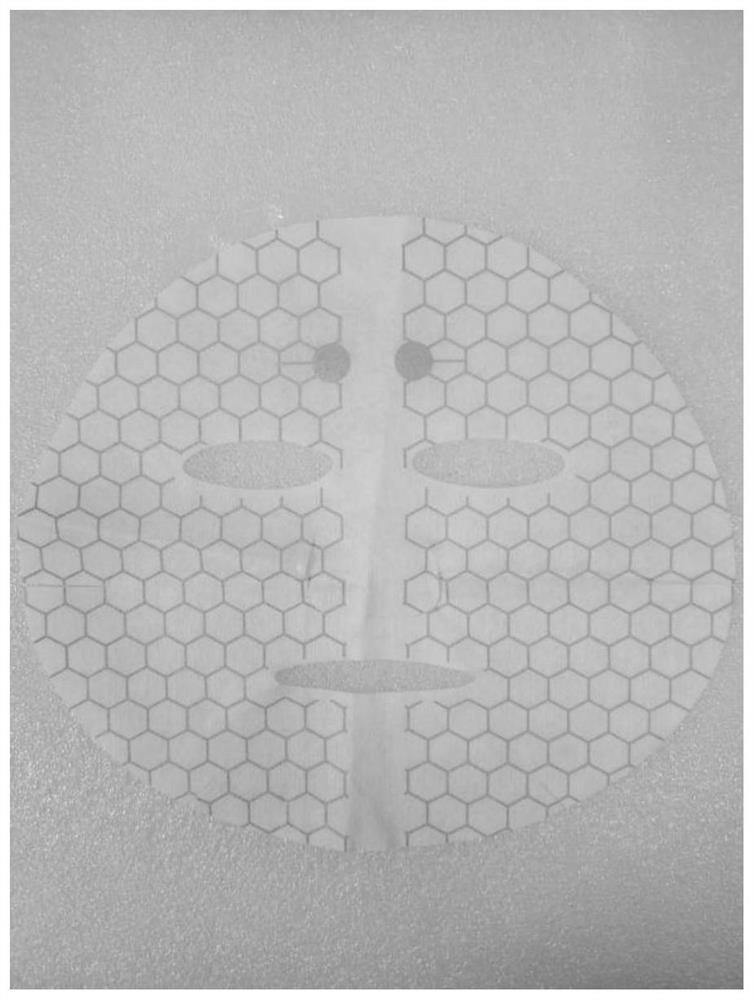

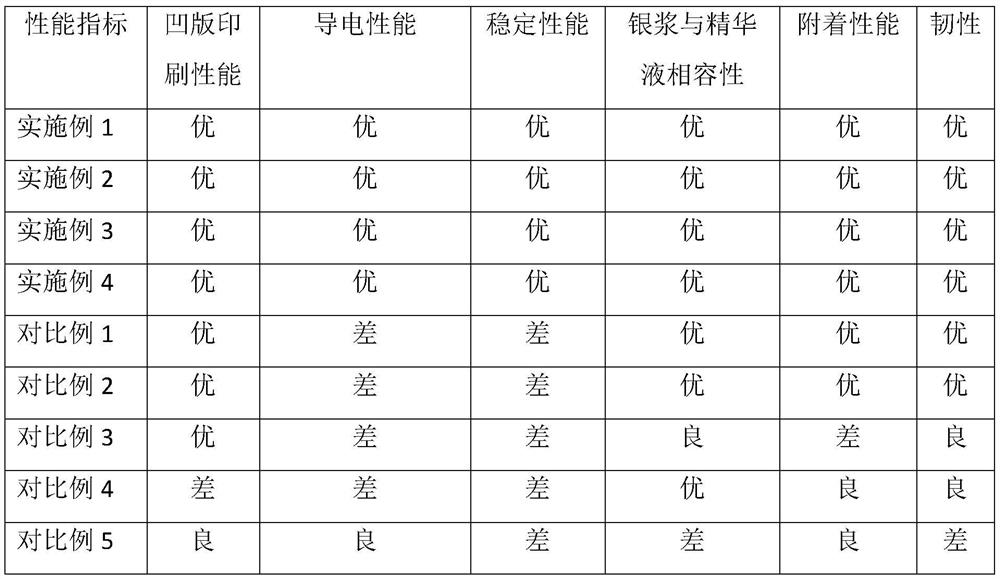

Low-temperature quick-drying mask silver paste for intaglio printing and preparation method thereof

PendingCN114864132AImprove adhesion strengthNot easy to fall offElectrotherapyNon-conductive material with dispersed conductive materialSilver pastePolymer resin

The invention discloses low-temperature quick-drying mask silver paste for intaglio printing and a preparation method of the low-temperature quick-drying mask silver paste. The mask silver paste is prepared from 30-50 wt% of flaky silver powder, 40-60 wt% of organic solvent, 5-10 wt% of polymer resin and 1-5 wt% of functional additive. Firstly, flake silver powder with large particle size, high tap density and few surface flatness defects is selected as the silver powder, so that the silver paste still has a good conductive effect under the condition of low silver content. And then, specifically selected macromolecular resin and functional auxiliaries are adopted to provide proper gravure printing process viscosity and excellent fluidity for the mask silver paste, so that a printed pattern is clear and complete, the flaky silver powder is uniformly dispersed in the printed pattern, meanwhile, excellent adhesion strength is provided for the mask silver paste, the mask silver paste is ensured to be adhered to mask cloth, and the mask cloth is prevented from being damaged. Falling is not prone to occurring; in addition, the polymer resin and the functional additive also play roles in protecting the mask silver paste from being interfered by soaking of the essence and ensuring the stable conductivity of the mask silver paste.

Owner:湖南省国银新材料有限公司

Manufacture method for nanocrystallization of natural phytoncide molecule without agglomeration

InactiveCN107201273AImprove the bactericidal effectIncrease specific surface reaction areaBiocideFatty-oils/fats refiningAlcoholAqueous solution

The invention discloses a manufacture method for nanocrystallization of natural phytoncide molecule without agglomeration, and relates to a manufacture method of plant essential oil. Compound phytoncide essential oil is conducted according to the following step sequence: firstly, pouring 1000ml of pure phytoncide essential oil into a supermolecular film filter, so as to filter impurities; secondly, mixing and pouring 800ml of pure phytoncide essential oil and 200ml of tea tree essential oil into a blender, stirring at 500 revolutions per minute, continuously heating the pure phytoncide essential oil and the tea tree essential oil to 65 to 70 DEG C, and ensuring that the stirring time is 5 to 8 minutes, so as to obtain 1000ml of compound phytoncide essential oil; thirdly, pouring the 1000ml of compound phytoncide essential oil into the blender, then pouring 3000ml of alcohol and 6000ml of deionized water into the blending, and stirring for 8 to 10 minutes at 500 revolutions per minute. A manufacture method for preventing agglomeration of phytoncide molecule comprises the following steps: pouring 1000ml of compound phytoncide aqueous solution into the blender, then adding 0.5 to 1 percent of an inorganic dispersant, stirring for 3 to 5 minutes, and then pouring the compound phytoncide aqueous solution and the inorganic dispersant into a supersonic oscillator to perform oscillation for 2 to 4 minutes at the frequency of 20KHz.

Owner:野艳玲

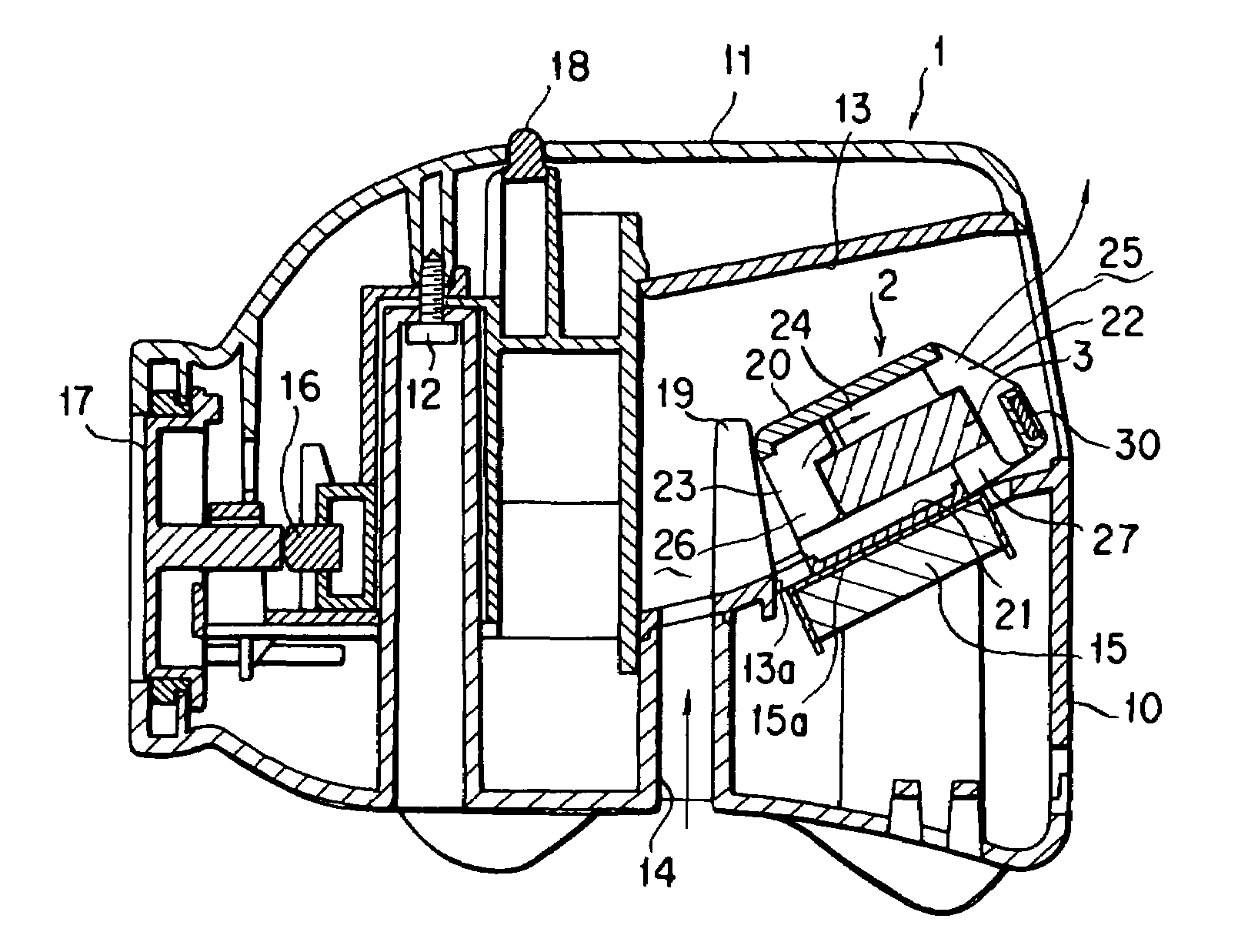

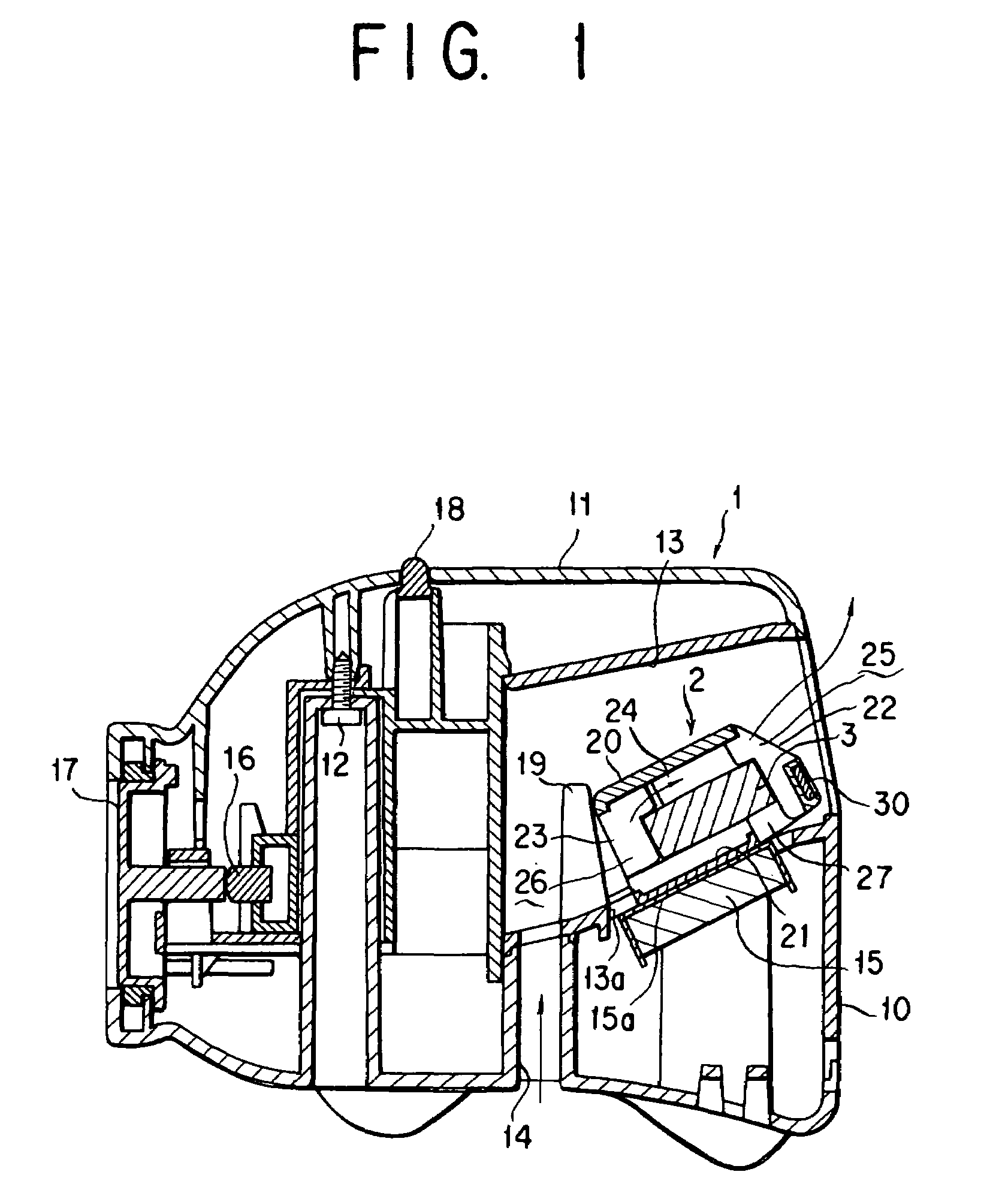

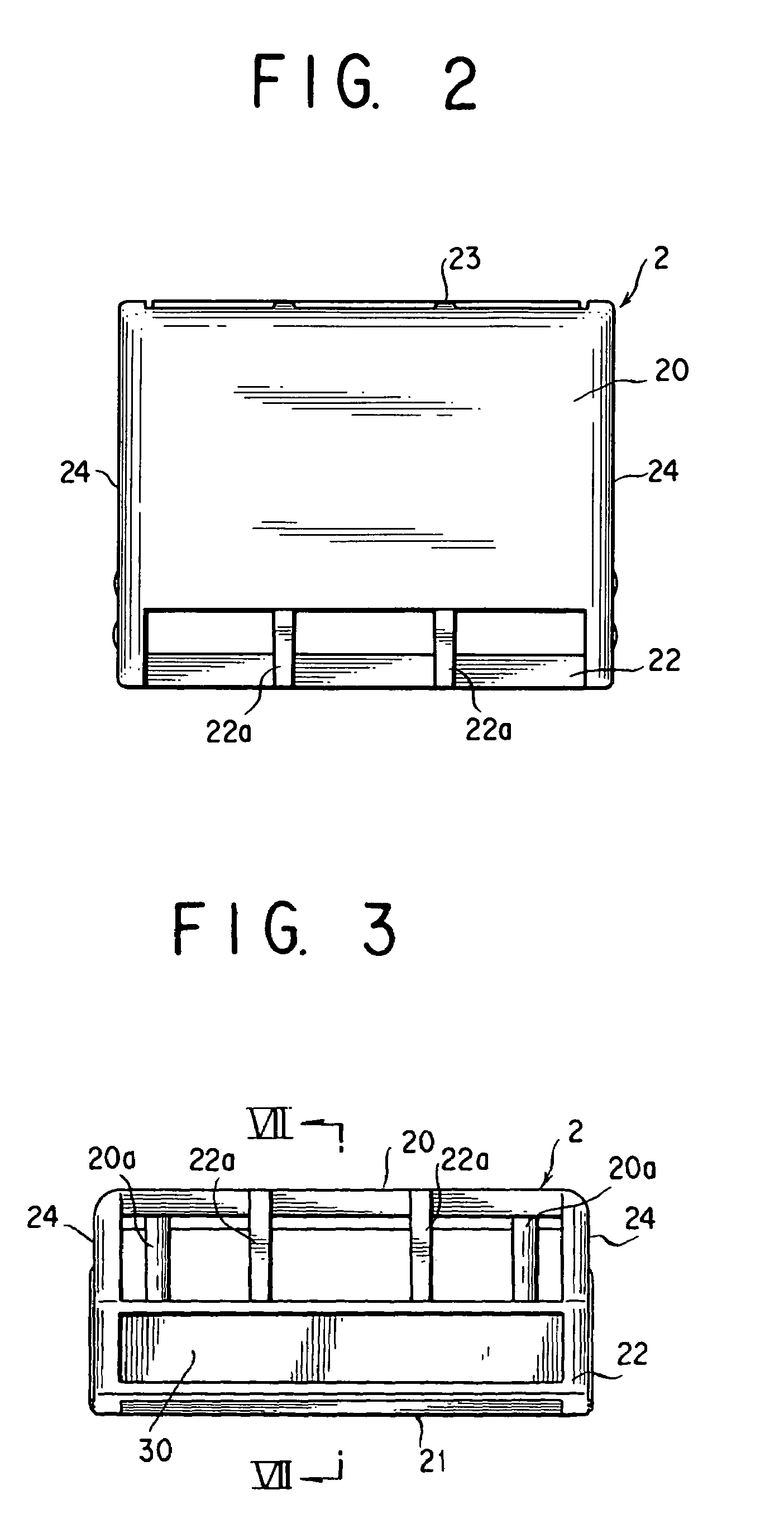

Chemical-containing formed material of type of heating of whole the material, container for holding chemical-containing formed material, device for heating and transpiring chemical and indicator for chemical to be heated and vaporized

ActiveUS7449154B2High in mask powerVolatile stabilityBiocideMeasurement devicesChemical substanceHeating time

Owner:FUMAKILLA

Mosquito repelling gel composition with natural plant essential oil

The invention discloses a mosquito repelling gel composition with natural plant essential oil. The mosquito repelling gel composition comprises the following raw materials in percentage by weight: 0.2-5% of water-soluble colloid, 0.2-10% of natural plant essential oil, 0-5% of water-soluble polymers, 1-20% of low alcohols, 0.5-20% of solubilizing agent, 0-0.5% of gel enhancer and the balance of deionized water. The water-soluble colloid in mosquito repelling gel disclosed by the invention can form a reticular or multi-dimensional spiral structure in a water medium and can be stably dispersed or used for wrapping the natural plant essential oil, so that the essential oil is stably and continuously released, and a better mosquito repelling rate can be kept in the whole release process. A mosquito repelling component adopted in the product is purely-natural plant essential oil which is safe to the environment and human bodies; the product is in a gel form; the essential oil is stably volatilized at normal temperature; and when used, the mosquito repelling gel composition does not need to be in direct contact with the skins of human bodies, is convenient to carry and can be continuously used for repelling mosquitoes indoors and outdoors for a long term.

Owner:安福超威日化有限公司

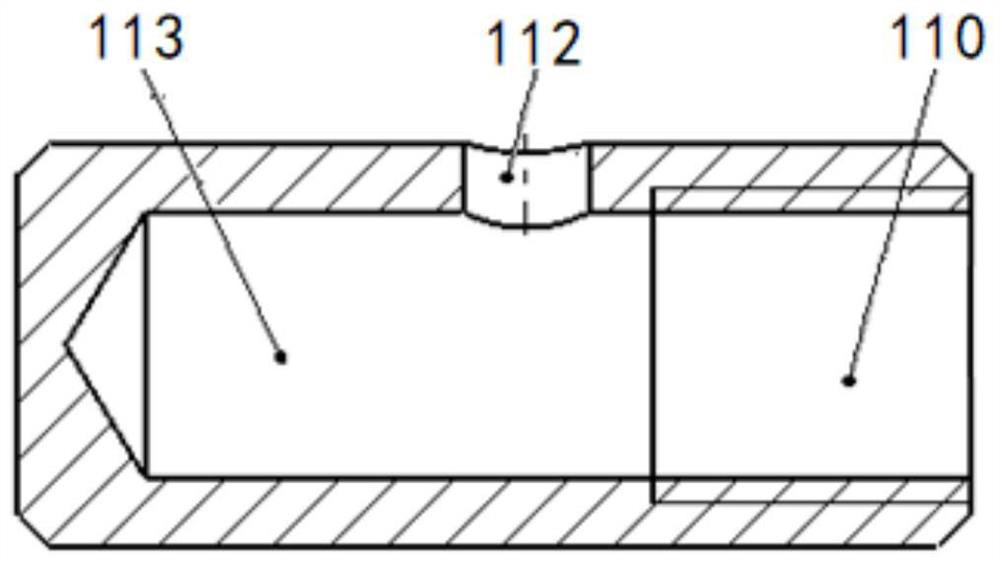

Ion mobility spectrometry trace permeation device

ActiveCN111678967AVolatile stabilitySimple structureUltrafiltrationMaterial analysis by electric/magnetic meansTemperature controlPhysical chemistry

The invention discloses an ion mobility spectrometry trace permeation device which comprises a release tube, a permeable membrane and a heating and heat preservation device, a calibration reagent placement cavity is formed in the release tube, and volatilization holes are formed in the tube wall of the release tube and communicated with the calibration reagent placement cavity; the permeable membrane covers the volatilization hole of the release tube; a heating and heat preservation cavity is formed in the heating and heat preservation device, a release pipe provided with a permeable membranecan be contained in the heating and heat preservation cavity, the heating and heat preservation cavity is communicated with the air inlet channel and the air outlet channel, and air flow can be formedin the heating and heat preservation cavity. The ion mobility spectrometry trace permeation permeation device provided by the invention has a temperature control function and a flow control function,so that stable volatilization of a calibration reagent can be ensured; and meanwhile, the permeation amount of the calibration reagent can be subjected to air control, so that the problems in the prior art can be effectively solved.

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

Pressure sustaining system for lpg bombe

ActiveCN103122809AJet stabilityVolatile stableInternal combustion piston enginesFuel supply apparatusCheck valveEngineering

A pressure sustaining system for an LPG bombe may include the LPG bombe, in which an LPG fuel may be injected and which may be equipped with a ventilation tunnel for emitting the air inside the LPG bombe, and a check valve unit, installed at an opening of the ventilation tunnel, with a fixed conversion pressure so as to keep an air pressure inside the LPG bombe above a predetermined value.

Owner:HYUNDAI MOTOR CO LTD +1

Lavender essential oil liquid mosquito-repellent incense and preparation method thereof

ActiveCN105724444BFresh and fragrantStrong medicineBiocidePest repellentsDiethylene glycol monobutyl etherSulfonate

The invention discloses lavender essential oil mosquito-repellent incense liquid and a preparation method thereof. The lavender essential oil mosquito-repellent incense liquid is prepared from the following raw materials in parts by weight: 0.5-2.5 parts of allethrin, 0.1-0.5 part of lavender essential oil, 50-60 parts of diethylene glycol monobutyl ether, 0.05-0.15 part of sodium xylene sulfonate, 0.1-0.5 part of a synergist, 0.1-0.5 part of an antioxidant and 35-45 parts of water. The lavender essential oil mosquito-repellent incense liquid disclosed by the invention has fresh and fragrant aroma and has a relatively strong repelling effect on mosquitoes; as environment-friendly mosquito-repellent incense liquid, the mosquito-repellent incense liquid has a relatively strong pesticide effect, is safe and non-combustible, can be volatilized stably, can also be used for reducing the content of indoor organic volatile matter and is an ideal option of healthy home livings.

Owner:FOSHAN NANHAI AODI FINE CHEM

Geranium essential oil liquid mosquito-repellent incense and its preparation method

The invention discloses pelargonium essential oil mosquito-repellent incense liquid and a preparation method thereof. The pelargonium essential oil mosquito-repellent incense liquid is prepared from the following raw materials: 0.5-2.5 parts of metofluthrin, 0.1-0.5 part of pelargonium essential oil, 50-60 parts of triethylene glycol monobuthyl ether, 0.05-0.15 part of sodium xylene sulfonate, 0.1-0.5 part of a synergist, 0.1-0.5 part of an antioxidant and 35-45 parts of water. The pelargonium essential oil mosquito-repellent incense liquid disclosed by the invention has fresh and fragrant aroma and has a relatively strong repelling effect on mosquitoes; as environment-friendly mosquito-repellent incense liquid, the pelargonium mosquito-repellent incense liquid has a relatively strong pesticide effect, is safe and non-combustible, can be volatilized stably, can also be used for reducing the content of indoor organic volatile matter and is an ideal option of healthy home livings.

Owner:徐州雅居乐环保科技有限公司

Intelligent aroma volatilization system

InactiveCN105194709BVolatile stabilityImprove Communication AccuracyGaseous substancesProgramme control in sequence/logic controllersElectricityVolatiles

An intelligent aroma volatilization system includes: a sensing device, a control center, a volatilizer, a user terminal, and a cloud; the sensing device is used to collect and extract environmental parameter information that affects volatilization and volatilization state in the external environment, and convert it into electrical The signal is transmitted to the control center; the control center controls the volatilization according to the user's input command at the user end and the volatilization environment information transmitted by the sensor device in combination with the historical control information in the cloud and user behavior habits. device, and transmit the operating status of the system to the client; the volatilizer, receiving the control signal from the control center, controls the multi-dimensional volatilization of aroma. The present invention is controlled by the mobile terminal, and the ultimate goal is to produce a high-end smart home device that can simulate various scenes. The main function is to simulate the smell, so as to achieve the sensory similarity of the environmental atmosphere and the similarity of the components of the health care function.

Owner:SHANGHAI JIAOTONG UNIV

Neroli essential oil liquid mosquito-repellent incense and preparation method thereof

The invention discloses orange flower essential oil liquid mosquito-repellent incense and a preparation method thereof. The orange flower essential oil liquid mosquito-repellent incense is prepared from, by weight, 0.5-2.5 parts of meperfluthrin, 0.1-0.5 part of orange flower essential oil, 50-60 parts of triethylene glycol momobutyl ether, 0.05-0.15 part of 4-sodium isopropylbenzenesulfonate, 0.1-0.5 part of synergist, 0.1-0.5 part of antioxidant and 35-45 parts of water. The orange flower essential oil liquid mosquito-repellent incense is fresh and fragrant in smell, has a strong killing effect on mosquitoes, is environmentally friendly, has the advantages of being powerful in effect, safe, incombustible and stable in volatilization, can reduce the content of indoor organic volatile matter and is an ideal choice for healthy home life.

Owner:LONGYAN TENGHUI MACHINERY CO LTD

Method for Enrichment and Stabilization of Mercury in Coal-fired Flue Gas Using Improved Desulfurizer with Blast Furnace Slag

ActiveCN108159870BPromote enrichmentLess catchGas treatmentDispersed particle separationSlagFlue gas

The invention discloses a method for enriching and stabilizing mercury in coal-fired flue gas by using a desulfurizer improved by blast furnace slag. The mass ratio of the desulfurizer is 1: (2-3), the blast furnace slag and the desulfurizer slurry are mixed to form an iron-manganese oxide-desulfurizer mixture system, and the desulfurization-mercury capture composite slurry is prepared; then the desulfurization-mercury capture The composite slurry is used for desulfurization of coal-fired flue gas, and for the enrichment and absorption of mercury in coal-fired flue gas. The present invention mixes blast furnace slag and desulfurizer to prepare desulfurization slurry, which is used for flue gas desulfurization of coal-fired power plants. The leaching toxicity and volatilization tests of mercury in the obtained desulfurization material show that the mercury in the desulfurization material is more stable than ordinary desulfurization gypsum. The concentration of leached mercury is reduced, the volatilization release rate is greatly reduced, and the inhibition effect on environmental mercury pollution sources is strong, which is of great significance to the protection of the atmospheric environment.

Owner:SHANGHAI UNIV

A device for heating chromatographic plates with low-temperature hot water

ActiveCN112113202BVolatile stabilityGuaranteed heating qualitySteam generation heating methodsBoiler water tubesThermodynamicsWater flow

The invention provides a device for heating a chromatographic plate with low-temperature hot water, which includes a water heater, the water heater includes a hot water outlet, and the hot water outlet is connected to one or more heat utilization devices through pipelines, and the water is heated in the heat utilization device After exchanging heat, it circulates back to the water heater, the at least one heat utilization device includes a flat tube, the upper part of the flat tube is arranged with a device to be heated, and the temperature of the hot water at the hot water outlet is 30-40 degrees Celsius. The present invention is heated by setting hot water, because the hot water can realize low-temperature heating, and the temperature and the flow rate of the hot water can also be controlled during the heating process, thereby ensuring the heating quality and maintaining and controlling the volatilization stability of the chromatographic plate adhesive.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL +1

Electrothermal fly mat and preparation method thereof

ActiveCN101940205AVolatile stabilityTo achieve the effect of killing fliesBiocidePest repellentsOrganic solventEnvironmental hygiene

The invention relates to an electrothermal fly mat and a preparation method thereof. The electrothermal fly mat is prepared by attaching pesticide liquid to a paper-based carrier. The pesticide liquid comprises the following components in percentage by weight: 25-73 percent of pyrethroid, 25-73 percent of organic solvent and 0.5-2.5 percent of essence. The pesticide liquid has the dosage of attaching 10-45g of medical liquid to 100g of the paper-based carrier. The preparation method comprises the following steps of: mixing the pyrethroid, the organic solvent and the essence into the pesticide liquid in proportion; attaching the pesticide liquid on the paper-based carrier; and drying and cutting the paper-based carrier which is attached with the pesticide liquid. The electrothermal fly mat has long pesticide-effect duration, good fly expelling and killing effect, no smoke, no stimulation and safe and convenient use and can be widely used for personal and environmental hygiene protection of families, hotels and schools.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

Vacuum drying device

ActiveCN108344254BExtend the distribution pathImprove uniformityDrying solid materials without heatDrying gas arrangementsEngineeringMechanical engineering

The invention relates to a vacuum drying device. The vacuum drying device comprises a drying chamber, a sample table and a flow stabilizing channel, wherein the drying chamber is provided with a vacuum cavity, the sample table is arranged in the vacuum cavity, the flow stabilizing channel is arranged in the vacuum cavity, one end of the flow stabilizing channel is used for communicating with an air extracting device, and the other end of the flow stabilizing channel is arranged towards the sample table and is provided with an airflow inlet. Compared with a conventional vacuum drier, a stable layer flow is formed on the surface of a sample by adopting the vacuum drying device, so that the situation of turbulence formed in a membrane layer or the situation that intermediate drying speed is small while the peripheral drying speed is high in the membrane layer can be avoided, water in ink and other materials to be volatilized can be uniformly volatilized as much as possible, the uniformityof membrane forming is effectively improved, and the performance of the device is further improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

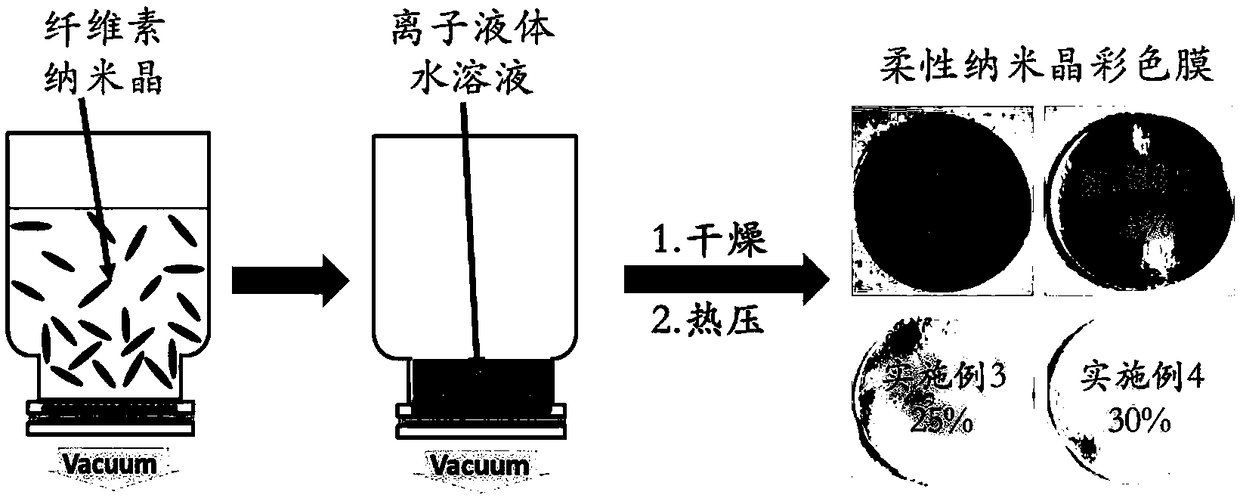

A flame-retardant heat-resistant flexible cellulose nanocrystalline color film and its preparation method

Owner:QINGDAO UNIV OF SCI & TECH

Liquid mosquito-repellent incense with peppermint essential oil and preparation method thereof

ActiveCN105475372BFresh and fragrantStrong medicineBiocideDead animal preservationDiethylene glycol monoethyl etherAntioxidant

The invention discloses peppermint essential oil mosquito liquid and a preparation method thereof. The peppermint essential oil mosquito liquid is prepared from, by weight, 0.5-2.5 parts of transfluthrin, 0.1-0.5 part of peppermint essential oil, 50-60 parts of diethylene glycol butyl ether, 0.05-0.15 part of 4-sodium cumenesulfonate, 0.1-0.5 part of synergist, 0.1-0.5 part of antioxidant and 35-45 parts of water. The peppermint essential oil mosquito liquid is fresh and fragrant in smell, has a strong dispelling and killing effect on mosquitoes, is environmentally friendly, strong in effect, safe, inflammable and stable in volatilization, can lower the indoor organic volatile content, and is an ideal choice for healthy home life.

Owner:ANHUI GREAT NATION ESSENTIAL OILS CO LTD

Jojoba oil liquid mosquito-repellent incense and its preparation method

ActiveCN105875655BFresh and fragrantStrong medicineBiocidePest repellentsSodium-p-toluenesulfinateJojoba oil

The invention discloses a jojoba oil liquid mosquito-repellent incense and a preparing method thereof. The jojoba oil liquid mosquito-repellent incense is prepared from, by weight, 0.5-2.5 parts of prallethrin, 0.1-0.5 part of jojoba oil, 50-60 parts of triethylene glycol momobutyl ether, 0.05-0.15 part of sodium p-toluenesulfonate, 0.1-0.5 part of a synergist, 0.1-0.5 part of an antioxidant and 35-45 parts of water. The jojoba oil liquid mosquito-repellent incense is fresh and aromatic in smell, has a high repelling and killing effect on mosquitoes, is environmentally friendly, strong in pesticide effect, safe, inflammable, stable in volatilization and capable of reducing the content of indoor organic volatile matter, and is an ideal option for healthy home life.

Owner:徐州徐工精密工业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com