Pressure sustaining system for lpg bombe

A technology of air pressure and gas tank, which is applied in the direction of charging system, power plant, and the arrangement combined with the fuel supply of internal combustion engine, etc., which can solve the problems such as the decline of engine starting ability, and achieve the effect of smooth injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

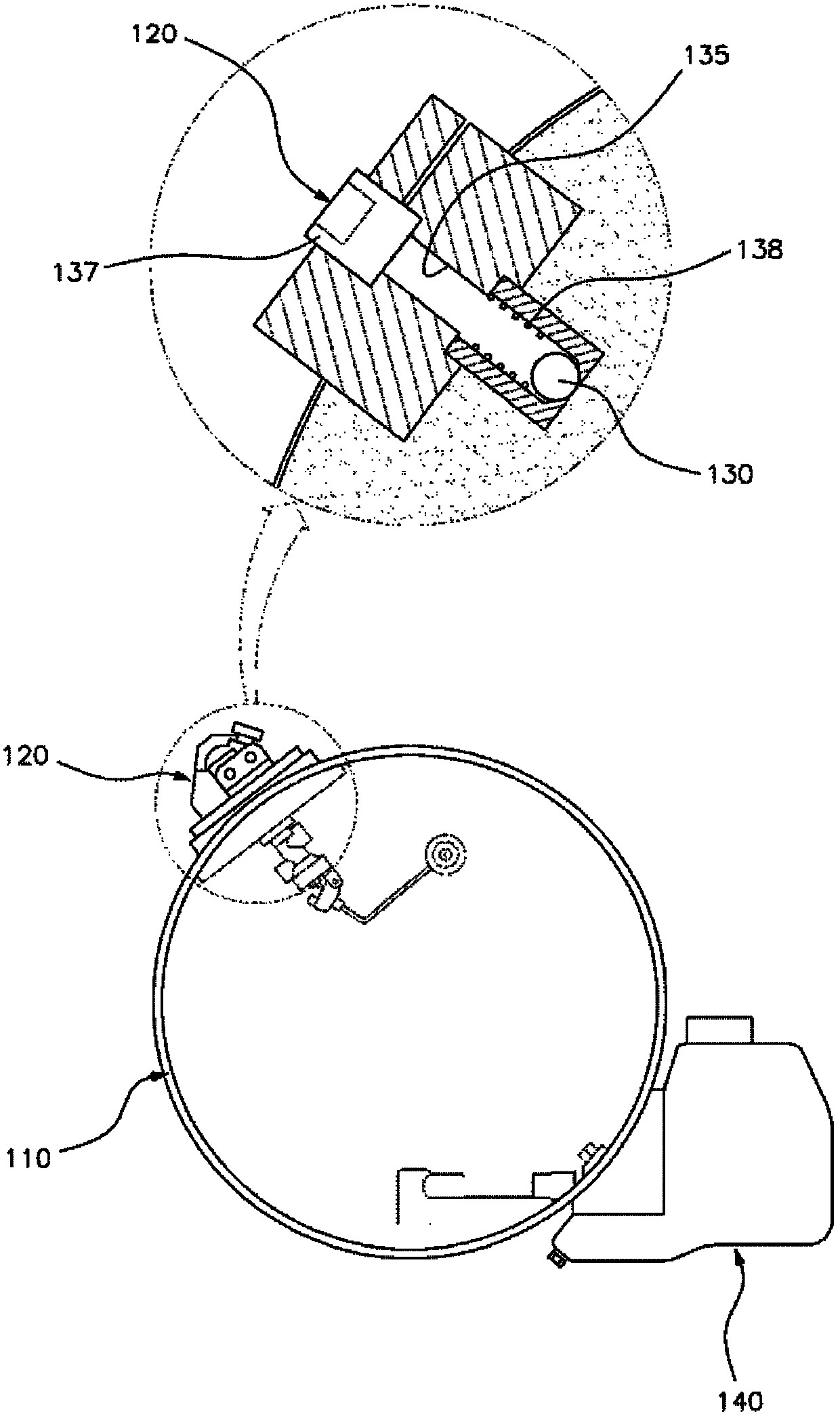

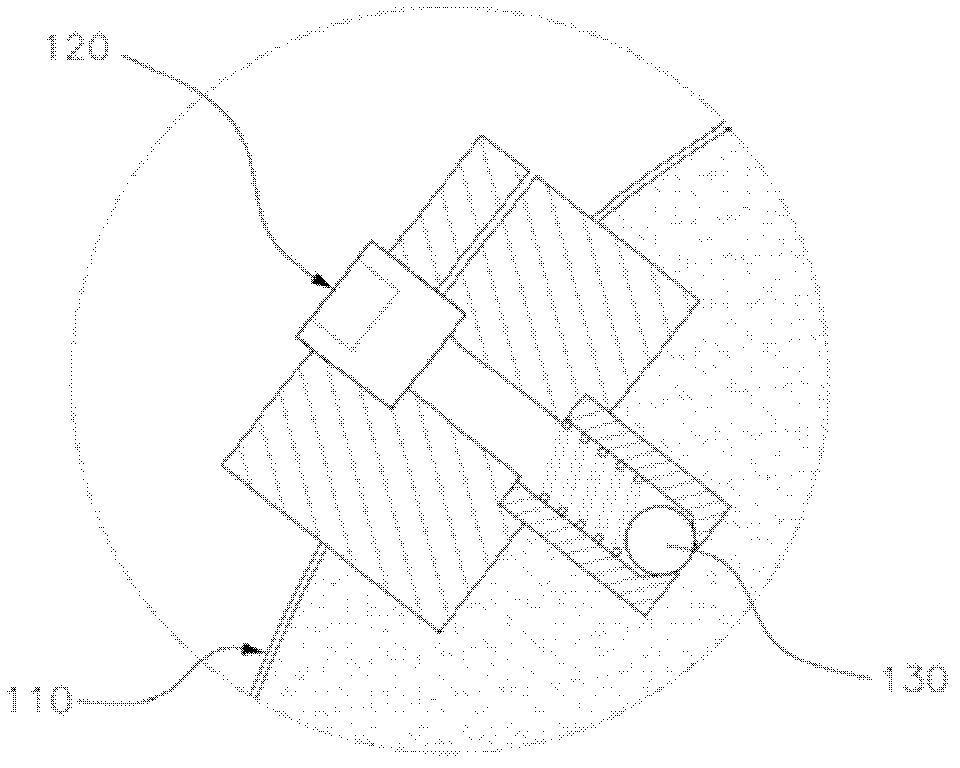

[0044] According to an exemplary embodiment of the present invention, when a small amount of air is left in the LPG gas tank 110, if the air pressure in the gas tank is less than the external atmospheric pressure measured with a pressure gauge, the check valve 130 is shown in Figure 2(a) Closed as shown and the air in the tank will not leak.

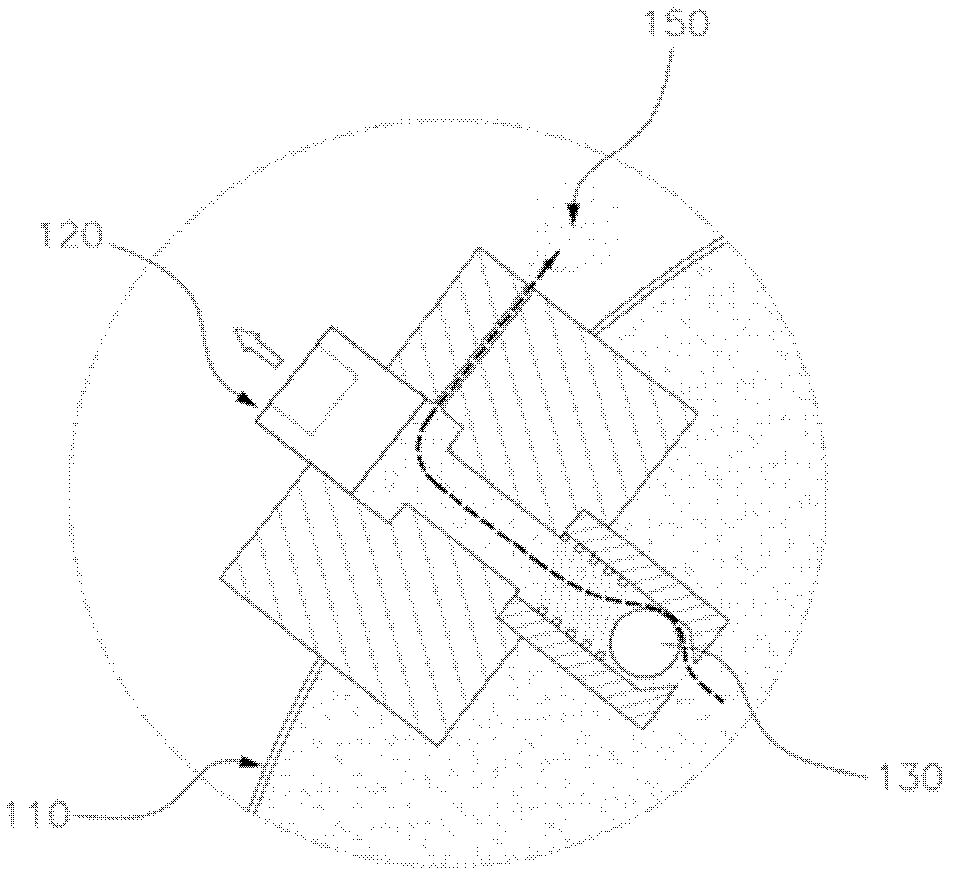

[0045] On the other hand, if the air pressure inside the LPG tank 110 is greater than the external atmospheric pressure measured with a pressure gauge, the check valve 130 is opened as shown in FIG. 2(b) and the air 150 inside the tank is injected.

[0046] As explained above, in an exemplary embodiment of the present invention, whether the check valve 130 is opened or closed is determined by comparing the air pressure inside the air tank with the atmospheric pressure outside the air tank. Therefore, this properly controls the evaporation pressure of the LPG fuel in the gas tank, and thus provides a fuel tank with LPG fuel. Therefore, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com