Mosquito repelling gel composition with natural plant essential oil

A natural plant essential oil and gel composition technology, applied in the field of daily chemicals, can solve the problems of greasy feeling, lower concentration of volatile essential oil, and short repellent time, and achieve the effect of easy portability and good repellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

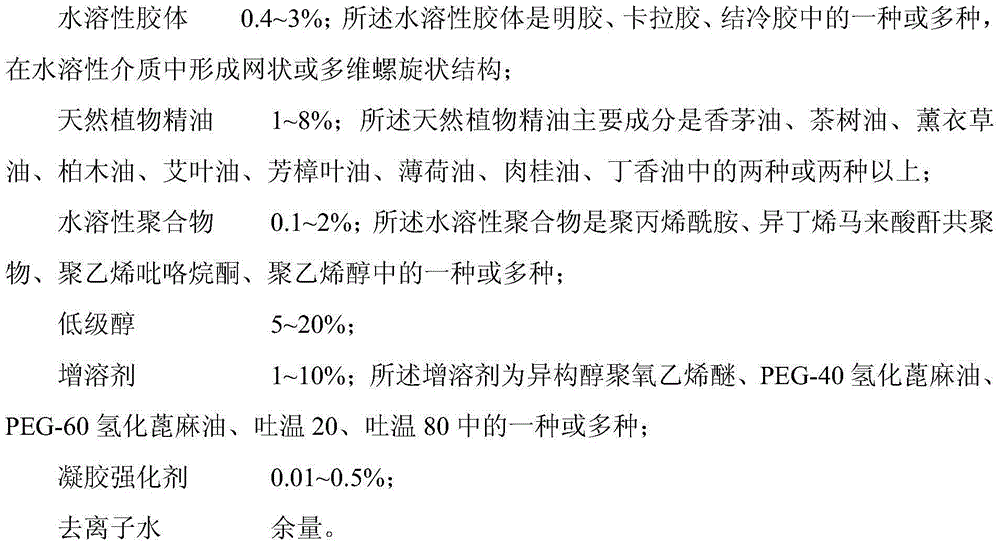

Method used

Image

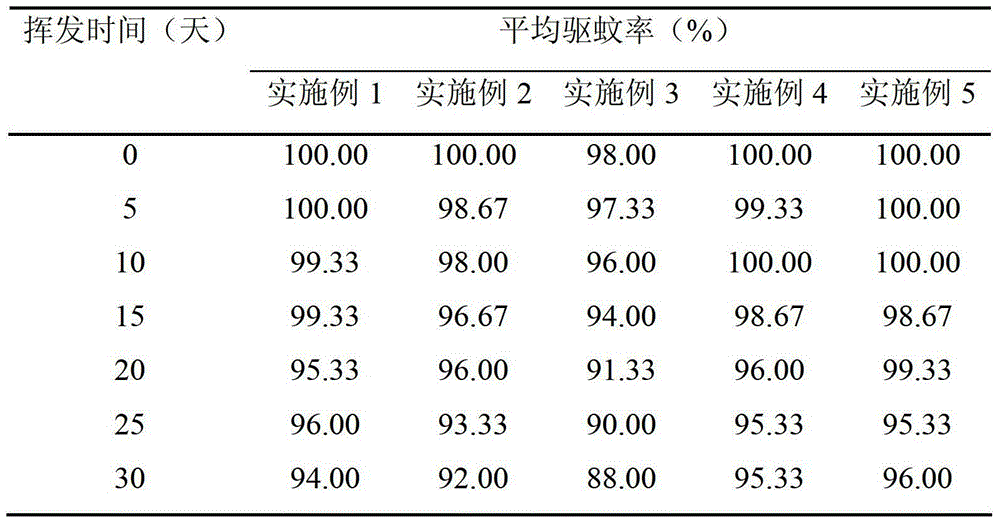

Examples

Embodiment 1

[0040] Gelatin 1%;

[0041] Gellan gum 0.4%;

[0042] Natural plant essential oil 5%;

[0043] Isobutylene maleic anhydride copolymer 0.4%;

[0044] Ethylene glycol 10%;

[0045] PEG-40 hydrogenated castor oil 6%;

[0046] Tween 20 2%;

[0047] Potassium chloride 0.1%;

[0048]Deionized water balance.

[0049] The preparation method of mosquito repellent gel of the present invention is:

[0050] Heat gelatin and gellan gum separately to dissolve, mix at 60°C after complete dissolution, dissolve isobutylene maleic anhydride copolymer in deionized water, slowly add to the colloid solution, and keep the solution at 60°C. Mix natural plant essential oil, ethylene glycol, PEG-40 hydrogenated castor oil, Tween 20, and part of deionized water evenly to obtain a homogeneous solution. Add the homogeneous solution of solubilized essential oil into the colloidal solution, keep stirring, keep the solution temperature between 45-60°C, stir for about 10 minutes, add aqueous potassiu...

Embodiment 2

[0052] Gelatin 3%;

[0053] Isobutylene maleic anhydride copolymer 0.8%;

[0054] Natural plant essential oil 3%

[0055] Ethanol 8%;

[0056] PEG-60 hydrogenated castor oil 6%;

[0057] Deionized water balance.

[0058] Heat the gelatin at 50°C to dissolve, dissolve the isobutylene maleic anhydride copolymer in deionized water, slowly add it into the colloid solution, and keep it warm at 40-45°C. Mix natural plant essential oil, ethanol, PEG-60 hydrogenated castor oil, and partially deionized water evenly to obtain a homogeneous solution. Add the homogeneous solution of solubilized essential oil into the colloidal solution, keep stirring, keep the temperature of the solution between 40-45°C, stir for about 15 minutes, discharge, fill and cool to room temperature, and the shaped gel can be obtained.

Embodiment 3

[0060] Carrageenan 1.5%;

[0061] 1% natural plant essential oil;

[0062] Polyacrylamide 0.2%;

[0063] Polyvinyl alcohol 1.8%;

[0064] Butanediol 5%;

[0065] PEG-40 hydrogenated castor oil 0.5%;

[0066] Isomerized alcohol polyoxyethylene ether 0.5%;

[0067] Potassium chloride 0.5%;

[0068] Deionized water balance.

[0069] Carrageenan and polyvinyl alcohol are heated to dissolve, polyacrylamide is dissolved in deionized water and added to the colloidal solution, and the colloidal solution is kept at 60°C. The natural plant essential oil, butylene glycol, PEG-40 hydrogenated castor oil, isomeric alcohol polyoxyethylene ether, and part of deionized water are evenly mixed to obtain a homogeneous solution. Add the homogeneous solution of solubilized essential oil into the colloidal solution, keep stirring, keep the solution temperature between 45-60°C, add potassium chloride aqueous solution, continue stirring at constant temperature for a period of time, discharge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com