Low-temperature quick-drying mask silver paste for intaglio printing and preparation method thereof

A gravure printing and low-temperature technology, which is applied in the field of low-temperature quick-drying mask silver paste for gravure printing and its preparation, can solve the problems of low printing efficiency and achieve clear and complete printing patterns, good electrical conductivity, and enhanced bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

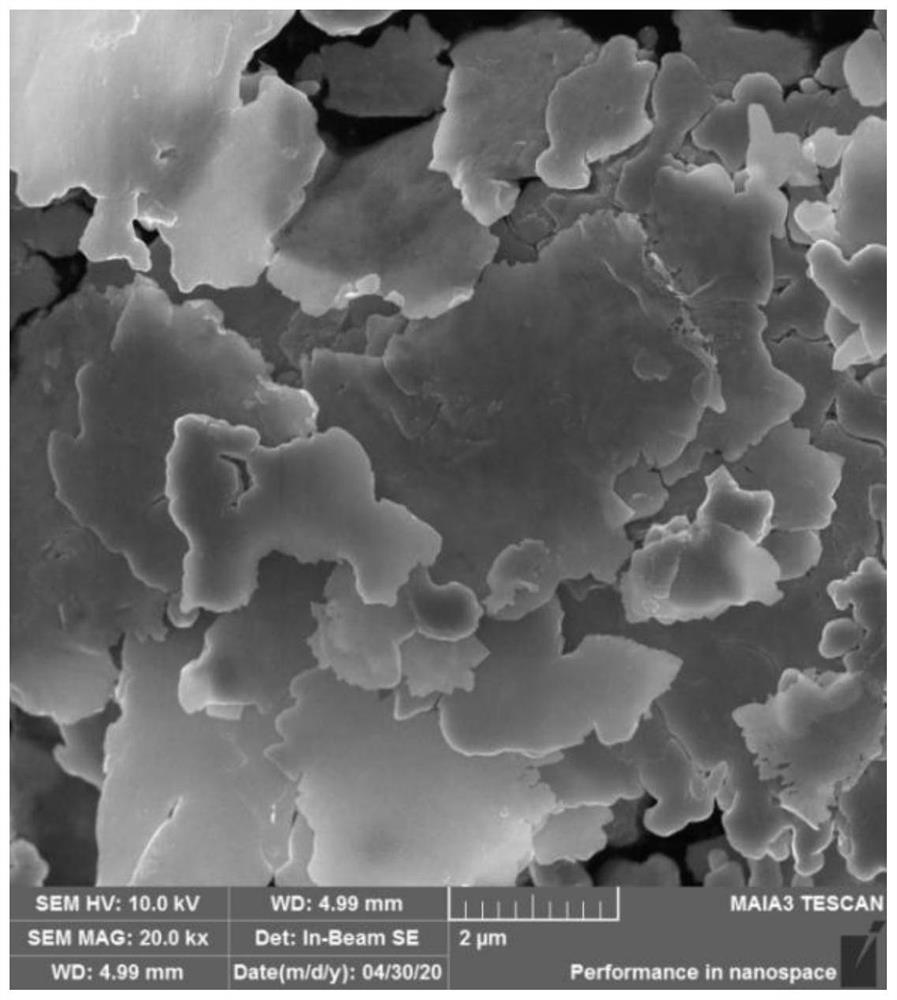

[0052] Preferably, the preparation method of the flake silver powder comprises the following steps:

[0053] S1: to AgNO 3 Add deionized water, stir to dissolve, then add dispersant, stir and mix evenly to obtain reaction bottom liquid;

[0054] S2: Add deionized water to NaOH, stir and dissolve to prepare NaOH solution, and then heat to 70~80℃;

[0055] S3: drop the heated NaOH solution into the reaction bottom liquid, stir and mix to obtain Ag 2 O suspension;

[0056] S4: the Ag 2 The temperature of the O suspension is raised to 60-70°C, and after the temperature is stable, the dissolved reducing agent is added, and stirring is continued to obtain a silver powder suspension;

[0057] S5: putting the silver powder suspension into the powder washing device, suction filtration, then adding deionized water to clean the silver powder, suction filtration;

[0058] S6: Repeat step S5 until the conductivity of the water after washing is less than 30 μS / cm, suction filtration, and...

reference example

[0076] This reference example provides a method for preparing flake silver powder, comprising the following steps:

[0077] 1) Preparation of reaction bottom liquid: add 50kg AgNO to the reaction kettle 3 , then inject 260L of deionized water, stir and dissolve, then add 126-225g of gum arabic and cetyl trimethyl ammonium bromide (CTAB) as dispersants to the reactor, wherein gum arabic and cetyl trimethyl bromide The mass ratio of methyl ammonium bromide (CTAB) is 1:2, stirring and mixing evenly to obtain the reaction bottom liquid, and the temperature of the reaction bottom liquid is controlled to be 40-50 ° C in the whole process;

[0078] 2) Preparation of NaOH solution: add 14kg NaOH to the auxiliary material kettle, then inject 52L of deionized water, stir and dissolve, prepare a NaOH solution, heat, and carry out the next step when the solution temperature in the auxiliary material kettle is 75 ℃ ± 2 ℃;

[0079] 3) Ag 2 Preparation of O suspension: the NaOH solution of...

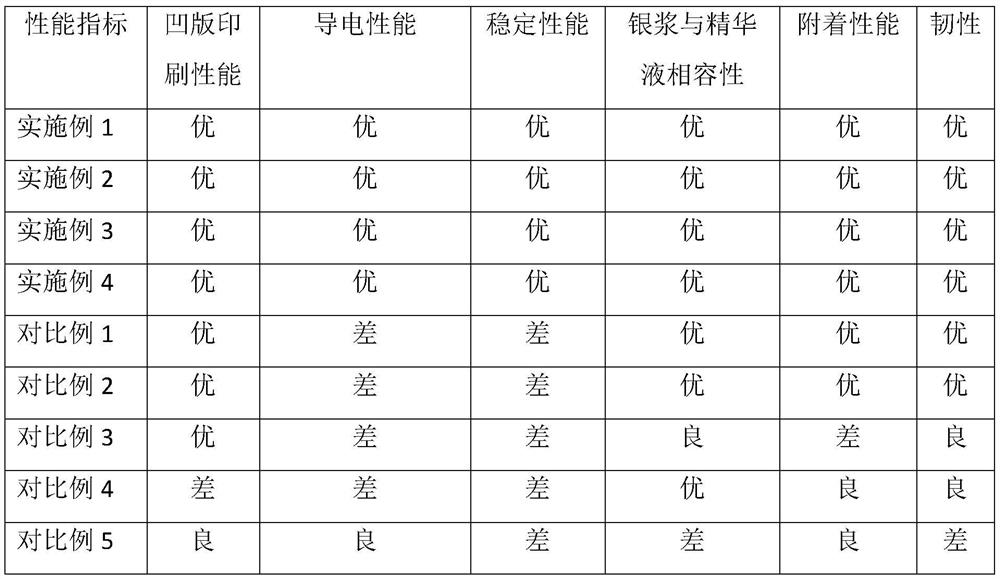

Embodiment 1

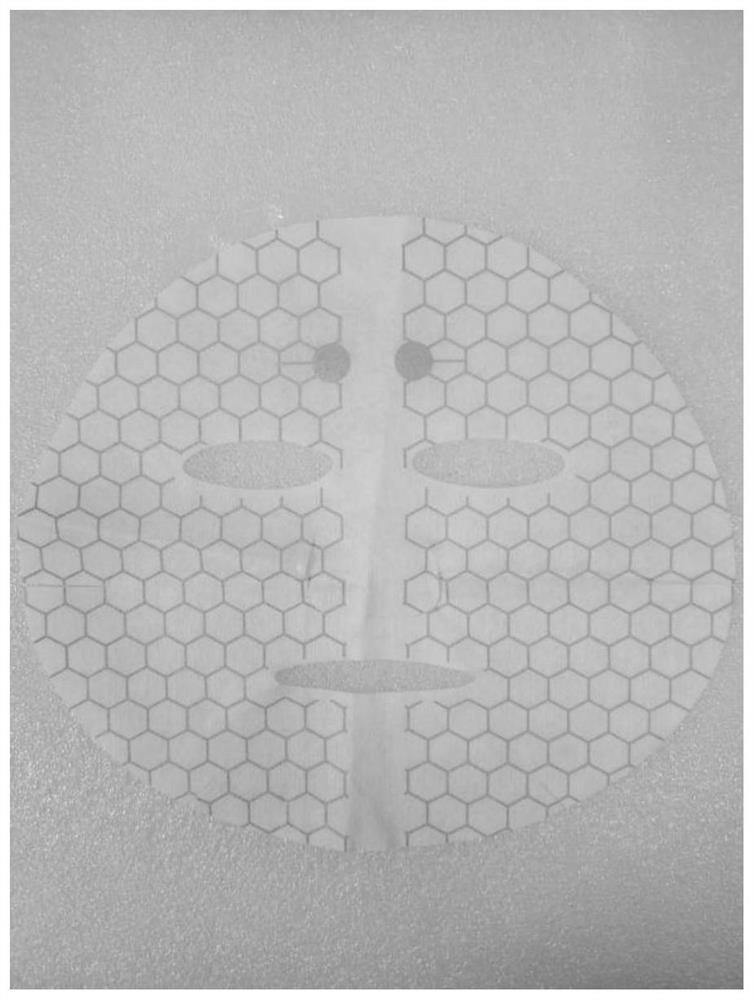

[0087] The present embodiment provides a low-temperature quick-drying mask silver paste for gravure printing, which is made of the following components in mass ratio:

[0088] Flake silver powder (prepared by reference example) 30%, polymer resin 7.8% (CP450 chloroacetate 3.7%, SV-16 polyvinyl butyral 0.8%, SGR-3002W acrylic acid 0.8% and PKHH phenoxy 2.5%),

[0089] Organic solvent 60.2% (diethylene glycol ethyl ether acetate 5%, N-ethylpyrrolidone 4%, propylene glycol butyl ether 26.5%, acetone acetal 8.2% and DBE 16.5%),

[0090] 2% of functional additives (dispersant polyurea 1.0%, plasticizer polyol benzoate 0.3%, defoamer polyether 0.2%, antioxidant phenyl hydroquinone polymer 0.5%) ;

[0091] The particle size D50 of the flake silver powder is 5.627 μm, and the tap density is 5.01 g / cm 3 , burning loss≤0.6%, specific surface area 0.847m 2 / g;

[0092] The preparation method of the above-mentioned low-temperature quick-drying mask silver paste for gravure printing, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com