Method for preparing large-area orderly porous membrane

A porous membrane, large-area technology, applied in the field of preparation of large-area ordered porous membranes, can solve the problems of inability to take into account the preparation of porous membranes with nano-scale pore size and micro-scale pore size, inability to achieve large areas, and increased production costs, etc. Simple structure, improved stability and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

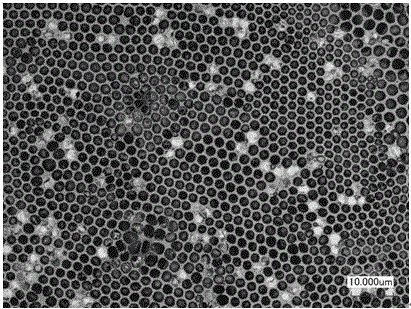

Image

Examples

Embodiment 1

[0035] (1) Dissolve polystyrene, polyvinylpyrrolidone, polyethylene glycol and cocamidopropyl betaine in carbon disulfide to prepare a polymer solution with a polymer concentration of 10mg / ml;

[0036] (2) Drop the prepared polymer solution onto the surface of the single crystal silicon wafer and place it in a closed container;

[0037] (3) Pour steam into the closed container from below the monocrystalline silicon wafer, and adjust the relative humidity in the closed container by controlling the flow rate and temperature of the steam, control the relative humidity at 80%, and keep the monocrystalline silicon wafer in a stable state Let stand for 10 minutes in a humidity atmosphere of 5%; the steam is generated by the gas passing through the liquid environment; the gas is high-purity (90% or 95% purity) nitrogen; the liquid environment contains deionized water, methanol, and isopropanol ,Isobutanol;

[0038] (4) Take out the monocrystalline silicon wafer from the humidity atmosphere...

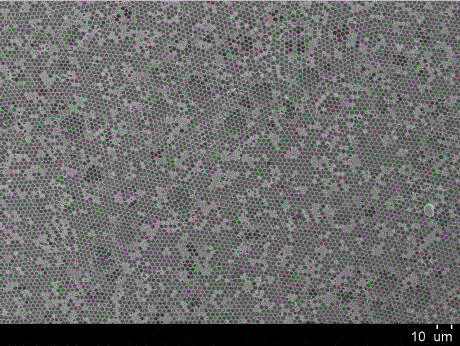

Embodiment 2

[0041] (1) Dissolve polylactic acid-glycolic acid copolymer and betaine citrate in chloroform to prepare a polymer solution with a polymer concentration of 25mg / ml;

[0042] (2) Drop the prepared polymer solution onto the surface of the glass sheet and place it in a closed container;

[0043] (3) Pass steam into the closed container from under the glass sheet, and adjust the relative humidity in the closed container by controlling the flow rate and temperature of the steam, control the relative humidity at 60%, and keep the glass sheet in a stable humidity atmosphere Let stand for 20 minutes; the steam is generated by the gas passing through a liquid environment; the gas is high-purity (100% purity) nitrogen; the liquid environment contains deionized water, ethanol, ethylene glycol, and isobutanol;

[0044] (4) Remove the glass sheet from the humidity atmosphere and dry it to obtain an ordered porous film.

[0045] The pore size of the ordered porous membrane obtained in this example ...

Embodiment 3

[0047] (1) Dissolve polystyrene, polyethylene glycol and decyl diphenyl sulfonate in a mixed solvent of carbon disulfide and tetrahydrofuran to prepare a polymer solution with a polymer concentration of 20 mg / ml;

[0048] (2) Drop the prepared polymer solution onto the surface of the polyester film and place it in a closed container;

[0049] (3) Pass steam into the closed container from below the polyester film, and adjust the relative humidity in the closed container by controlling the flow rate and temperature of the steam. The relative humidity is controlled at 60%, and the humidity of the polyester film in a stable state Let stand in the atmosphere for 30 minutes; the steam is generated by the gas passing through the liquid environment; the gas is compressed air; the liquid environment contains deionized water, isopropanol, ethylene glycol, and isobutanol;

[0050] (4) Take out the polyester film from the humidity atmosphere and dry it to obtain an ordered porous film.

[0051] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com