A flame-retardant heat-resistant flexible cellulose nanocrystalline color film and its preparation method

A cellulose and color film technology, applied in the coating and other directions, can solve the problems of hard and brittle limited application, and achieve the effect of increased elongation at break, excellent flexibility and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

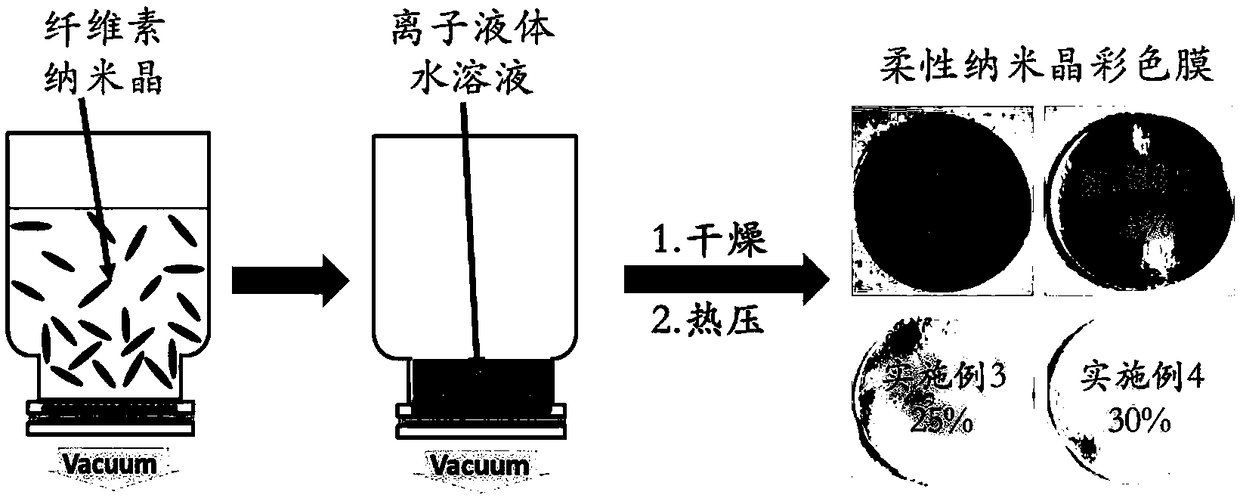

Method used

Image

Examples

Embodiment 1

[0042] Add 175 ml of 64% sulfuric acid to 10 g of pulverized cellulose and mix evenly. After stirring at 45°C for 1 hour, add 1500 ml of deionized water to terminate the reaction. Leave the mixture to stand for 24 hours and then separate into layers. Discard the supernatant , centrifuge the lower layer at a speed of 8000rpm / min for 10min, add water and wash several times until the upper layer becomes turbid after the last centrifugation, dilute the obtained cellulose nanocrystal suspension to 1wt%, take 18ml and place it in an ice-water bath Sonicate until the solution becomes transparent, and remove water with negative pressure suction to obtain a cellulose nanocrystal color membrane supported by a filter membrane, and weigh the quality of the prepared membrane.

[0043] Add 5wt% ionic liquid aqueous solution to the surface of the cellulose nanocrystal color film supported by the above-mentioned filter membrane, suck under negative pressure until there is no residual liquid on...

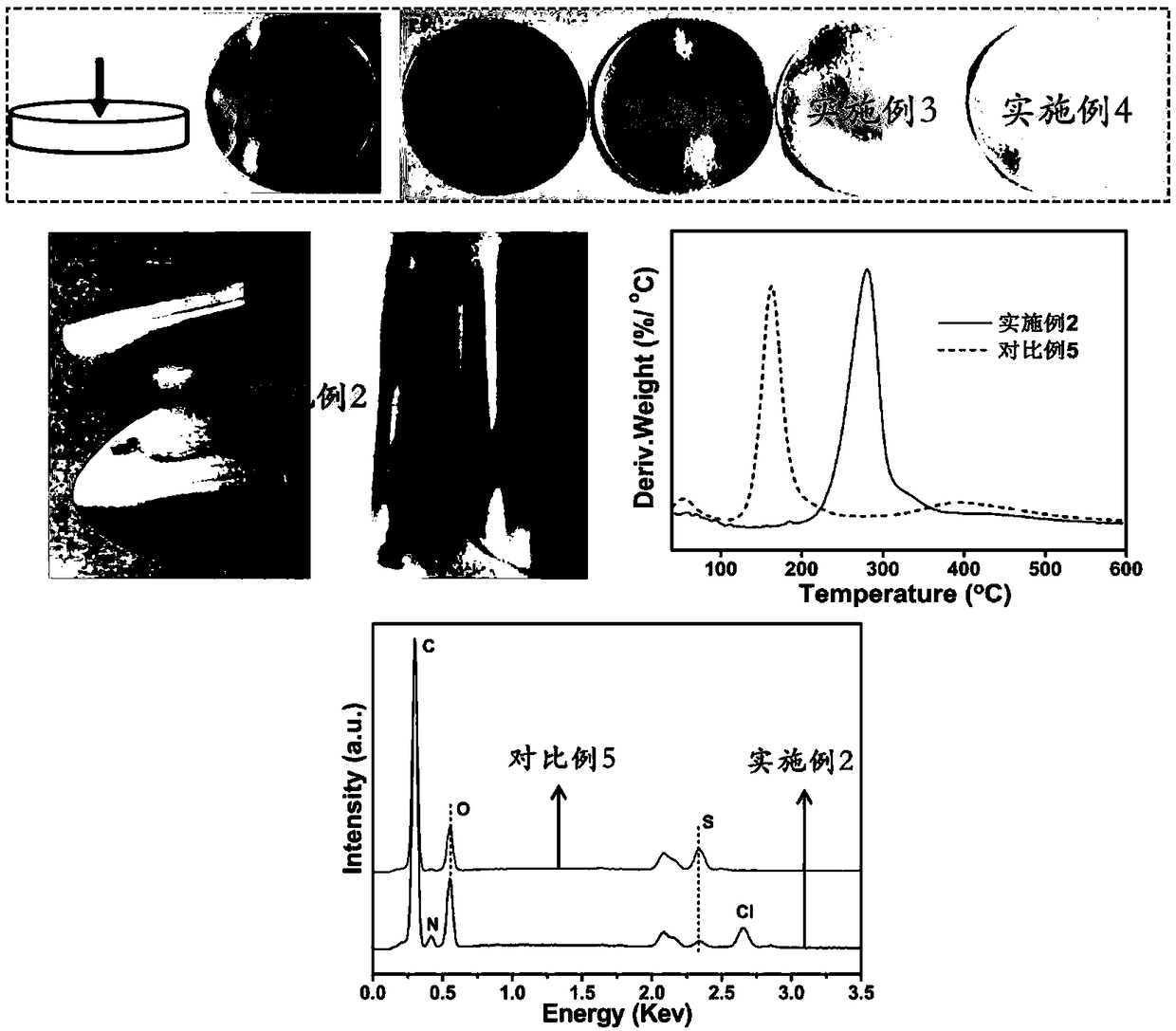

Embodiment 2

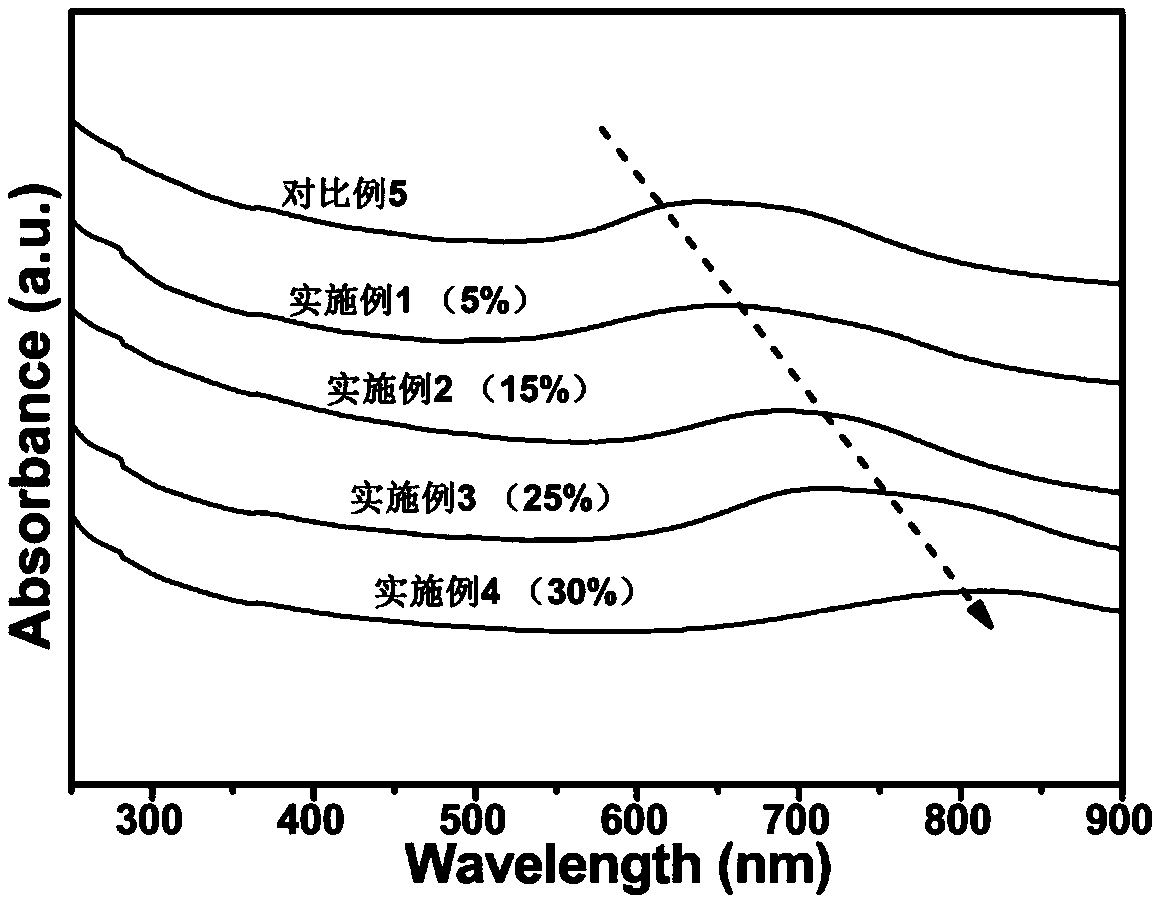

[0047] The type of material used, the amount and the process flow are the same as in Example 1, except that after the cellulose nanocrystal color film is generated, 15 wt% of an ionic liquid aqueous solution is added to the surface of the cellulose nanocrystal color film supported by the filter membrane, and the negative pressure pumping is continued. Suction until there is no residual liquid on the upper surface of the color membrane, remove it together with the filter membrane and dry in an oven at 70°C for 1-2 hours, remove the filter membrane to obtain a self-supporting cellulose nanocrystal color membrane, weigh the mass of the prepared membrane , calculated by differential gravimetric method, the content of ionic liquid in the membrane is about 10wt%. The film is then hot-pressed at 100-150° C. and 5-10 MPa for 5-20 minutes. The photo of the colored film made by the present embodiment is as follows: figure 2 As shown, the membrane appears blue when viewed upright, as ...

Embodiment 3

[0049] The type of material used, the dosage and the process flow are the same as in Example 1, except that after the cellulose nanocrystal color film is formed, 25 wt% of an ionic liquid aqueous solution is added to the surface of the cellulose nanocrystal color film supported by the filter membrane, and the negative pressure suction is continued. When there is no residual liquid on the upper surface of the color film, remove it together with the filter film and place it in an oven at 70°C for 1-2 hours to dry, then remove the filter film to obtain a self-supporting cellulose nanocrystal color film, weigh the quality of the prepared film, The content of ionic liquid in the membrane is about 27wt% calculated by differential gravimetric method. The film is then hot-pressed at 100-150° C. and 5-10 MPa for 5-20 minutes. The photo of the colored film made by the present embodiment is as follows: figure 2 As shown, the membrane surface appears light blue in front view, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com