Preparation method of solid acid catalyst applied to producing of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate

A technology of pentanediol diisobutyrate and solid acid catalyst, which is applied in the field of preparation of solid acid catalyst, can solve the problems of high catalyst preparation cost, complicated preparation process, and difficult handling, and achieves overcoming serious equipment corrosion, low activity and low High selectivity and good prospects for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

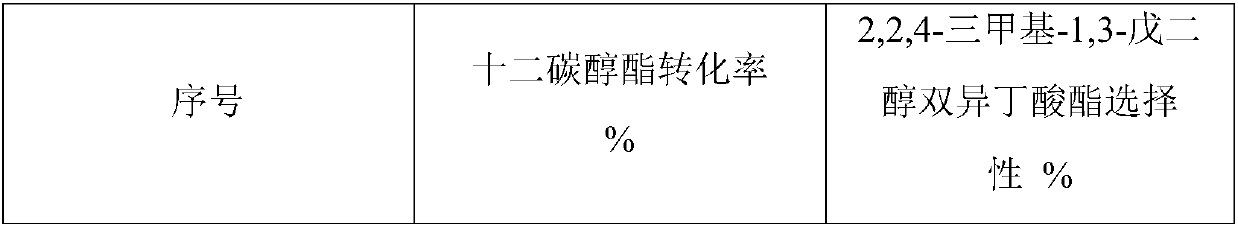

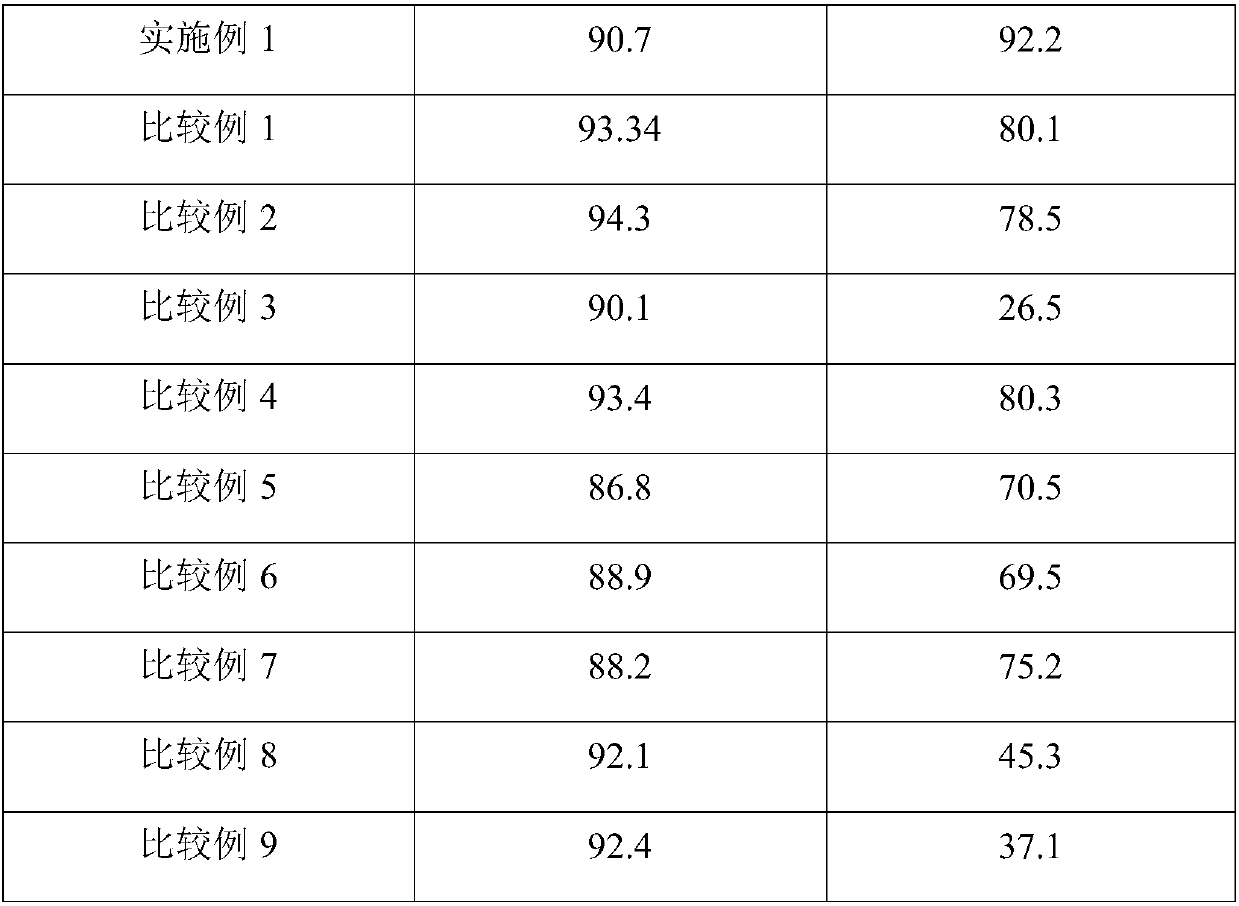

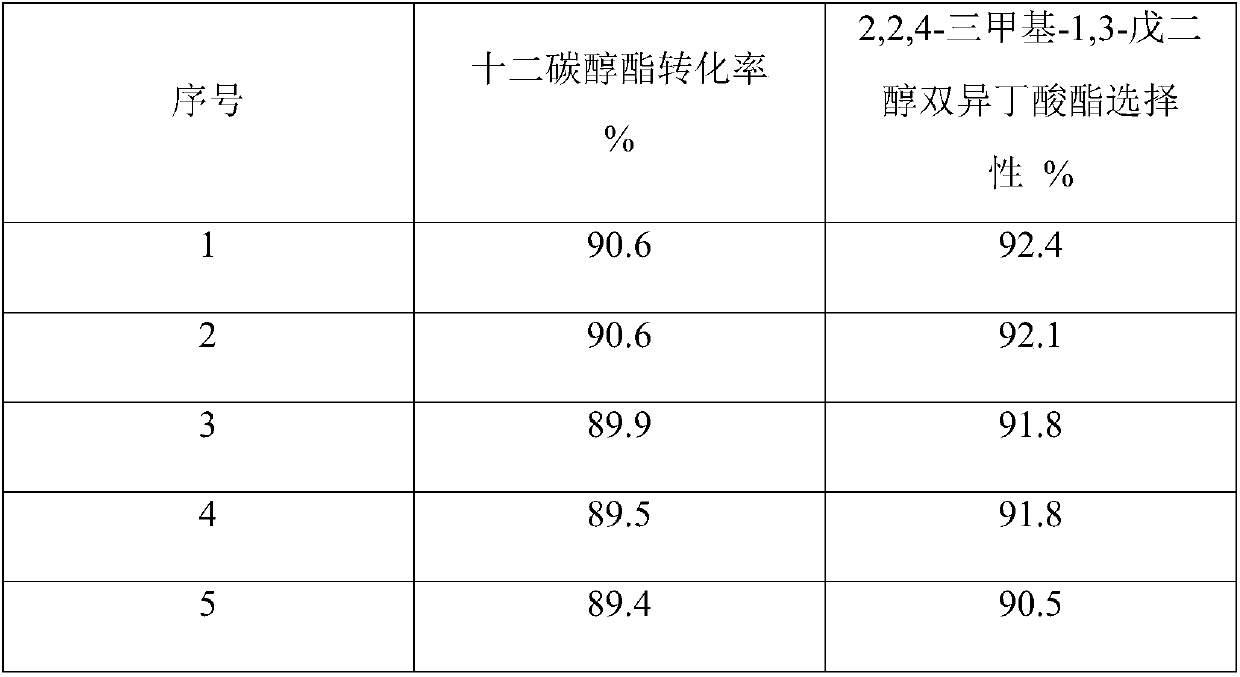

Examples

Embodiment 1

[0023] Weigh 32.2g ZrOCl 2 ·8H 2 Dissolve O in a beaker containing an appropriate amount of deionized water, and then add 57g TiCl 4 Dissolved in 100mL of ethanol, TiCl will be dissolved 4 The ethanol solution is added to the ZrOCl 2 ·8H 2 O in the beaker; add concentrated ammonia and deionized water drop by drop to adjust the pH value to 8-11, continue to stir for 1 to 2h, and then stand for 24h; wash with a high-speed centrifuge until there is no Cl - , Placed in a 70℃ vacuum drying oven for 12h; after grinding, calcined in a muffle furnace at 450~550℃ for 4h to obtain TiO 2 -ZrO 2 Composite carrier.

[0024] ZrOCl 2 ·8H 2 O and TiCl 4 The molar ratio of adding is 1:3.

[0025] Weigh 20g composite carrier Zr0 2 -TiO 2 Add to 300ml 0.5mol / L H 2 SO 4 In the solution, stir at room temperature for 1 to 3 hours, filter while hot, filter out the solid, dry in a vacuum drying oven at 80°C, grind to powder, and calcinate in a muffle furnace at 450 to 550°C for 4 hours to obtain SO 4 2- / Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com