Separation and purification system and method of n-butyraldehyde and isobutylaldehyde

A purification method and technology of isobutyraldehyde, which is applied in the field of separation and purification system of n-butyraldehyde and isobutyraldehyde, can solve the problems of low purity of isobutyraldehyde products and high content of heavy components in n-butyraldehyde products, so as to improve prices and competition Advantages, increasing competitive advantage, and improving the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

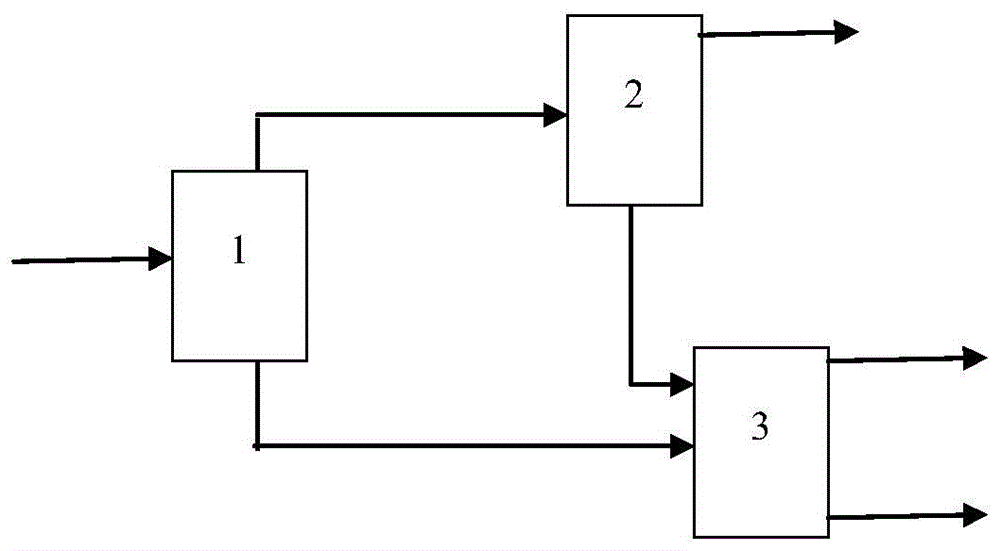

[0025] The top of the butyraldehyde isomerization tower 1 is heated to 80°C, and the raw material with a lower boiling point is discharged from the top of the tower, and enters the first rectification tower 2 from the middle feed port of the first rectification tower 2, and the butyraldehyde isomerization The heat of material evaporation in the stereotype tower 1 is provided by the tower kettle reboiler of the butyraldehyde isomer tower 1, and the mixed butyraldehyde discharged from the top of the butyraldehyde isomer tower 1 is discharged from the first rectification tower 2 Sixty-seven trays are added, the flow rate is 8800Kg / h, and the temperature of the material is 80°C, which is the feed for the bubble point. The material extracted from the top of the first rectification tower 2 is sent to the isobutyraldehyde reflux tank after being condensed by the tower top condenser, and part of the material is returned to the first rectification tower 2, and the reflux is bubble point...

Embodiment 2

[0029] The top of the butyraldehyde isomer tower 1 is heated to 90°C, and the raw material with a lower boiling point is discharged from the top of the tower, and enters the first rectification tower 2 from the middle feed port of the first rectification tower 2, and the butyraldehyde isomerization The heat of material evaporation in the stereotype tower 1 is provided by the tower kettle reboiler of the butyraldehyde isomer tower 1, and the mixed butyraldehyde discharged from the top of the butyraldehyde isomer tower 1 is discharged from the first rectification tower 2 Sixty-seven trays are added, the flow rate is 8000Kg / h, and the temperature of the material is 75°C, which is the feed for the bubble point. The material extracted from the top of the first rectification tower 2 is sent to the isobutyraldehyde reflux tank after being condensed by the tower top condenser, and part of the material is returned to the first rectification tower 2, and the reflux is bubble point reflux...

Embodiment 3

[0033] The top of the butyraldehyde isomerization tower 1 is heated to 70°C, and the raw material with a lower boiling point is discharged through the top of the tower, and enters the first rectification tower 2 from the middle feed port of the first rectification tower 2, and the butyraldehyde isomerization The heat of material evaporation in the stereotype tower 1 is provided by the tower kettle reboiler of the butyraldehyde isomer tower 1, and the mixed butyraldehyde discharged from the top of the butyraldehyde isomer tower 1 is discharged from the first rectification tower 2 Sixty-seven trays are added, the flow rate is 7800Kg / h, the material temperature is 80°C, and it is the bubble point feed. The material extracted from the top of the first rectification tower 2 is sent to the isobutyraldehyde reflux tank after being condensed by the tower top condenser, and part of the material is returned to the first rectification tower 2, and the reflux is bubble point reflux, and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com