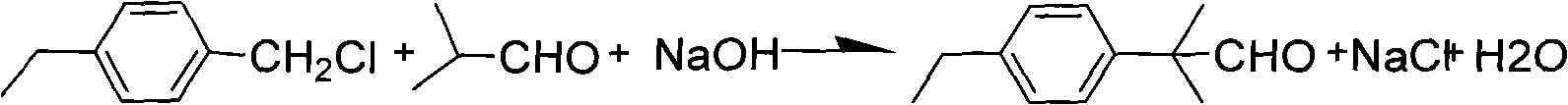

Preparation technology of alpha, alpha-dimethyl-ethide phenylpropyl aldehyde

A technology for the preparation of ethyl phenylpropionaldehyde, which is applied in the field of α, and can solve the problems of low yield, large pollution, and high cost of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 20% sodium hydroxide solution, benzene, triethylamine, and sodium iodide in sequence in the reaction kettle, stir and heat up to 70°C, and add the mixture of ethylbenzyl chloride and isobutyraldehyde dropwise under this temperature condition, 5 Drop within 1 hour, keep warm for 2 hours, cool to room temperature, add water, stir, let stand for liquid separation, take the supernatant liquid and add phosphoric acid, heat to 70 degrees, stir for 1 hour, wash off the enol ether, then wash with water, dehydrate, and distill get the product.

Embodiment 2

[0022] Add 40% sodium hydroxide solution, toluene, triethylamine, and potassium iodide in sequence in the reaction kettle, stir, and raise the temperature to 70°C. Under this temperature condition, add the mixture of ethylbenzyl chloride and isobutyraldehyde dropwise, within 8 hours After dripping, keep warm for 3 hours, cool to room temperature, add water, stir, stand for liquid separation, take the supernatant liquid and add phosphoric acid, heat to 75 degrees, stir for 2 hours, wash off the enol ether, then wash with water, dehydrate, and distill to obtain the product .

Embodiment 3

[0024] Add 40% potassium hydroxide solution, xylene, tetrabutylammonium bromide, and potassium iodide in sequence in the reaction kettle, stir, raise the temperature to 75°C, and add the mixture of ethylbenzyl chloride and isobutyraldehyde dropwise under this temperature condition , drop it within 10 hours, keep warm for 3 hours, cool to room temperature, add water, stir, stand still and separate the liquid, take the upper layer and add p-toluenesulfonic acid, heat to 75 ° C, stir for 3 hours, wash off the enol ether, and then Washed, dehydrated, distilled products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com