Patents

Literature

90 results about "Cobalt carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material Information. Buy Tungsten Carbide/Cobalt on-line. Tungsten Carbide is a hard, brittle ceramic which, when combined with 6% to 10% Cobalt, forms a tough Cermet (Ceramic-Metal). This material was developed for use in cutting tools, having hard ceramic crystals of a few microns in size within a ductile metal matrix.

Fischer-tropsch catalysts containing iron or cobalt selective towards higher hydrocarbons

ActiveUS20120245236A1Highly selective and efficient productionHydrocarbon from carbon oxidesMolecular sieve catalystsCarboxylic acidAlpha hydroxy acid

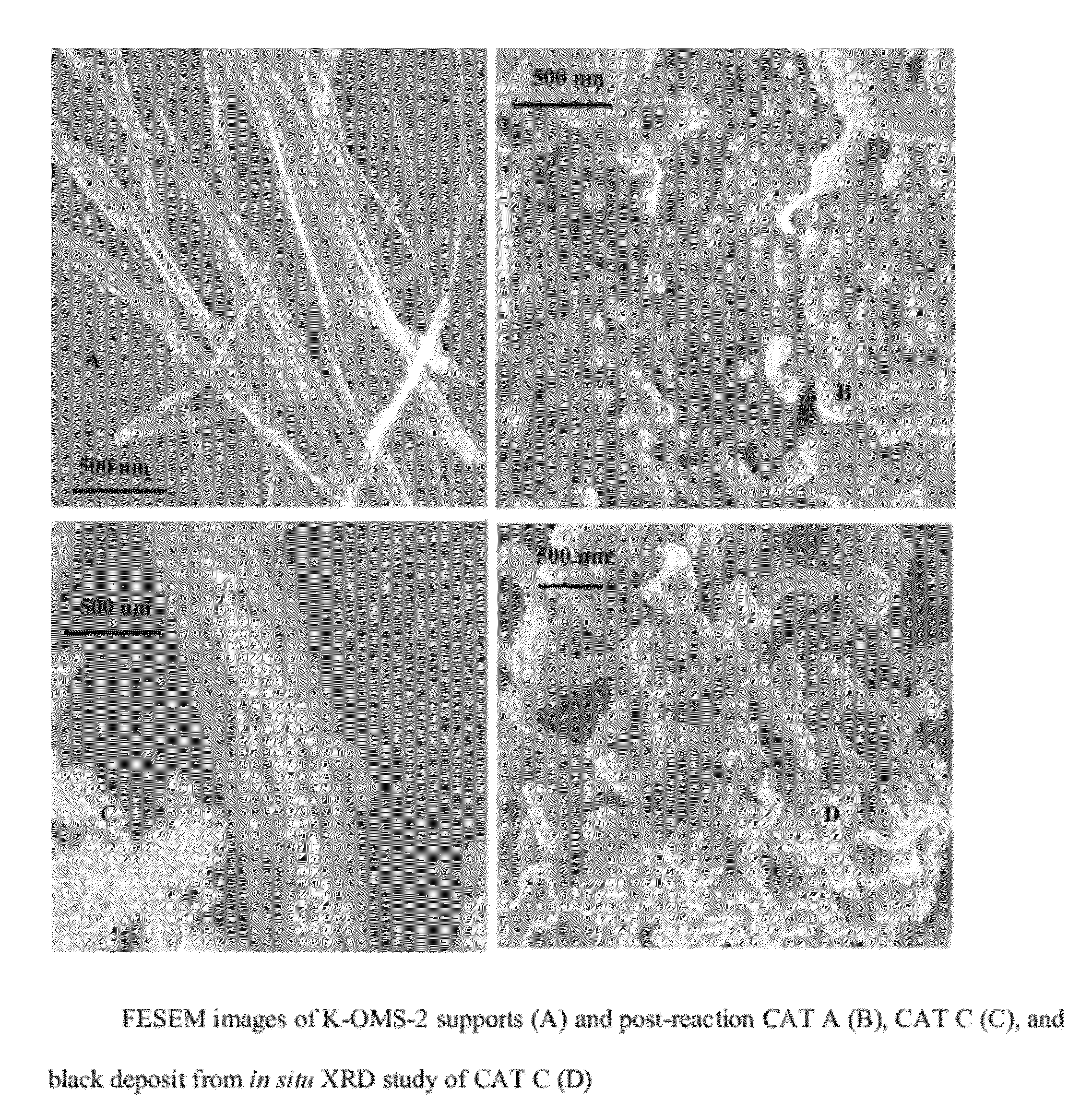

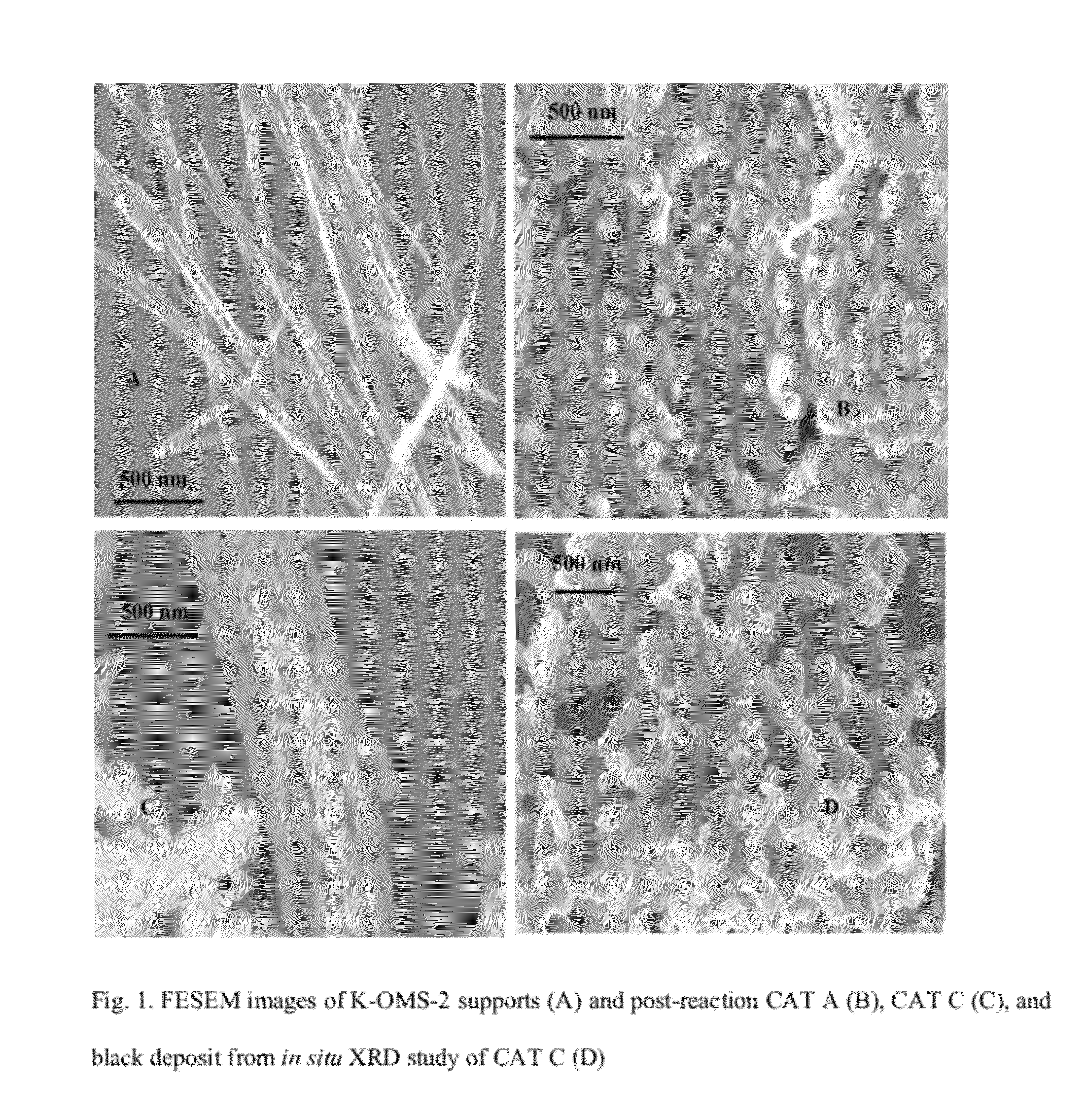

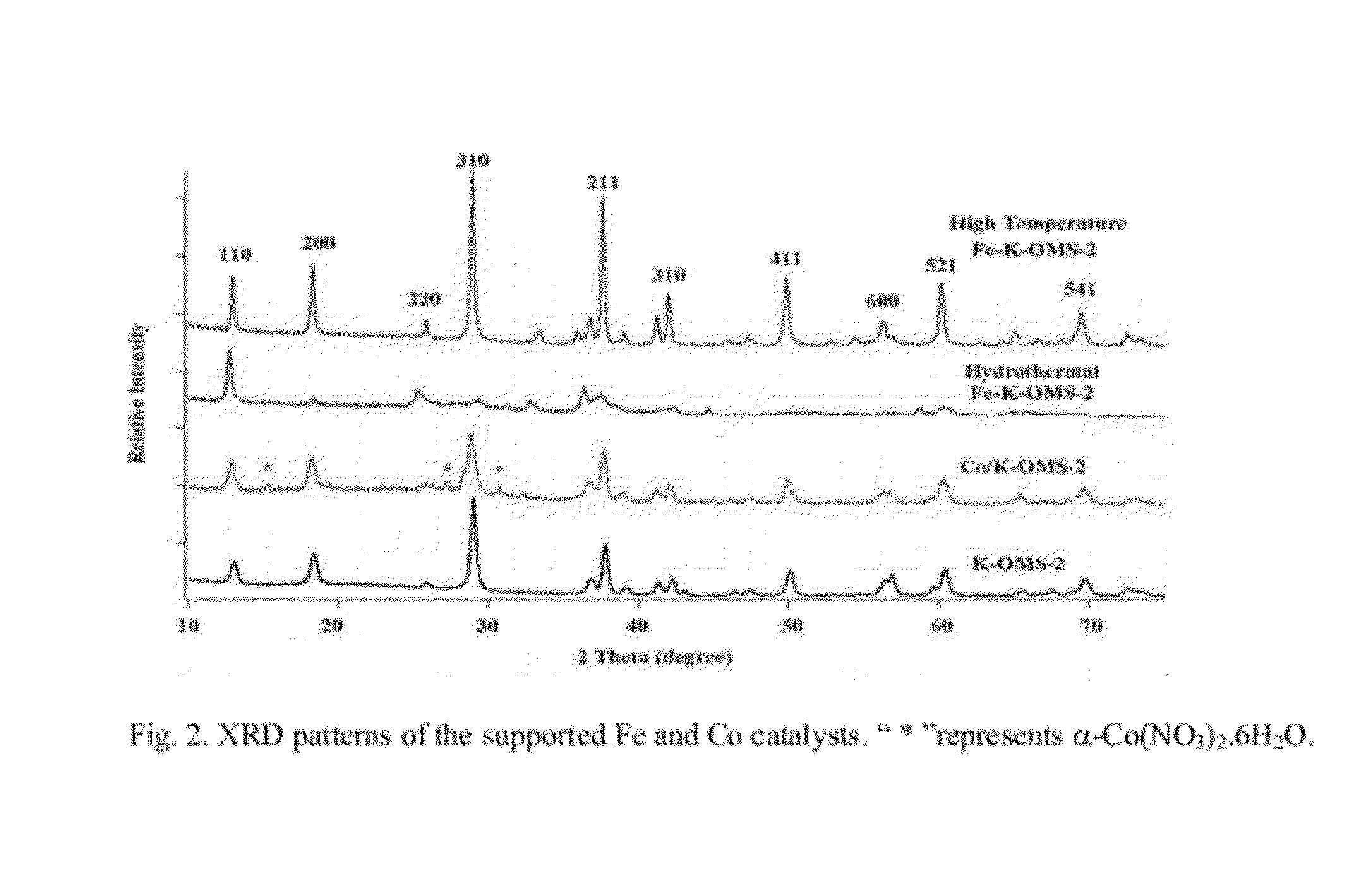

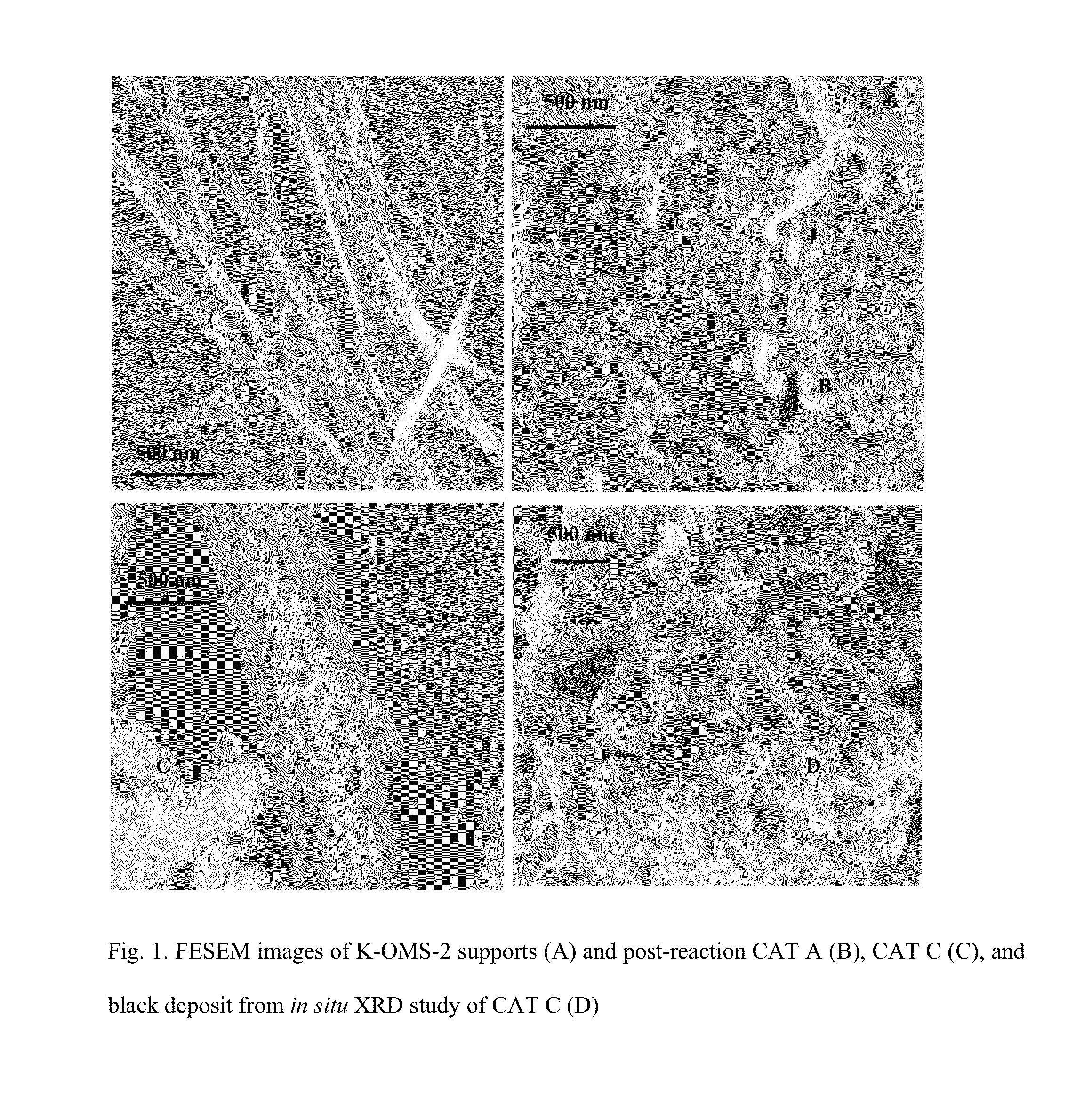

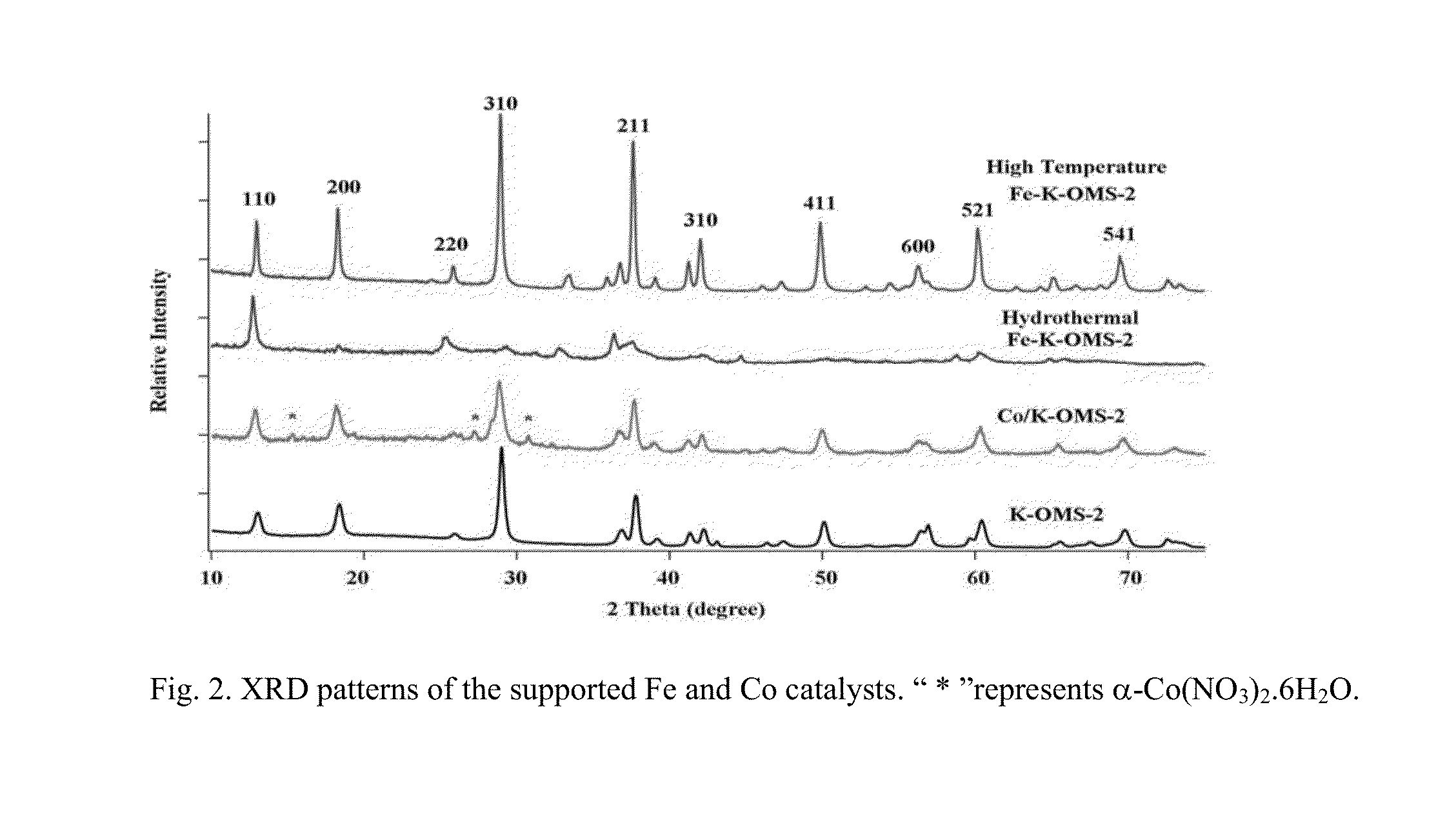

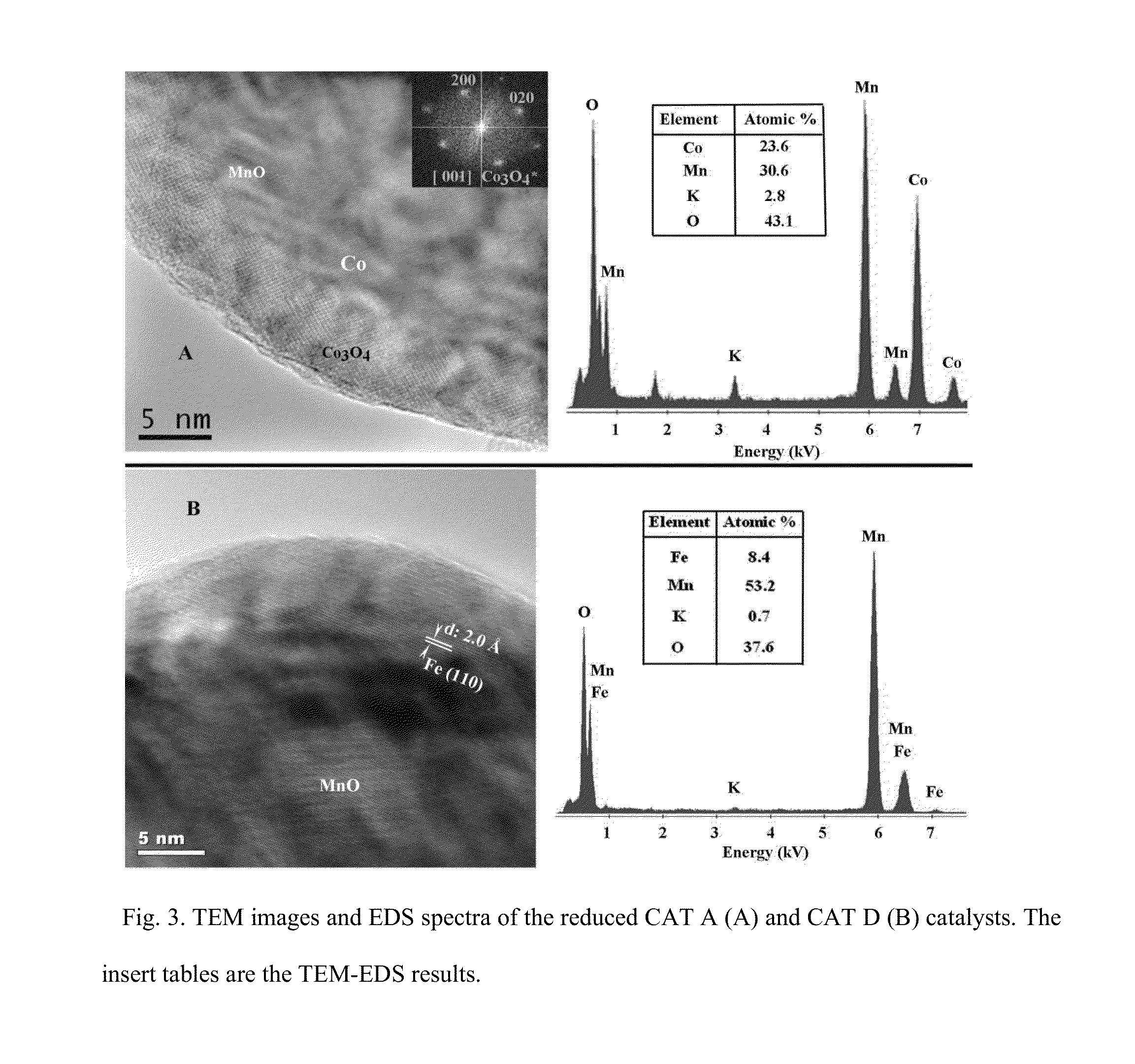

Cryptomelane-type manganese oxide octahedral molecular sieves (OMS-2) supported Fe and Co catalysts are utilized in a method for producing hydrocarbons by a Fischer-Tropsch mechanism. The hydrocarbon producing method includes providing a catalyst of a manganese oxide-based octahedral molecular sieve nanofibers with an active catalyst component of at least one of iron, cobalt, nickel, copper, manganese, vanadium, zinc, and mixtures thereof, and further containing an alkali metal. The formation of iron carbides and cobalt carbides by exposing the catalyst to conditions sufficient to form those carbides is also taught. After the catalyst has been appropriately treated, a carbon source and a hydrogen source are provided and contacted with the catalyst to thereby form a hydrocarbon containing product. The catalyst have high catalytic activity and selectivity (75%) for C2+ hydrocarbons in both CO hydrogenation and CO2 hydrogenation. Highly selective syntheses of high value jet fuel, C2-C6 alkenes, C2-C6 carboxylic acids; α-hydroxylic acids and their derivatives have been realized by tuning the oxidation ability of OMS-2 supports and by doping with Cu2+ ions.

Owner:UNIV OF CONNECTICUT +1

Method for manufacturing nanometer tungsten/cobalt carbide composite powder

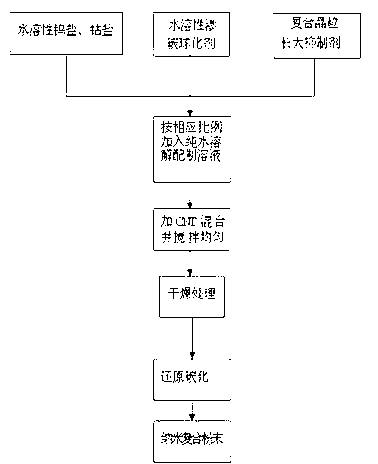

The invention discloses a method for manufacturing nanometer tungsten / cobalt carbide composite powder. The method is characterized by comprising technological steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, adding carbon nano-tubes (CNT) accounting for 1-10% of the total mass of the aqueous solution into the mixed aqueous solution obtained in the first step and enabling the carbon nano-tubes to be uniformly mixed in the mixed aqueous solution; thirdly, performing quick low-temperature spray drying for mixed aqueous solution obtained in the second step to obtain precursor powder of ultrafine tungsten and cobalt composite salt; and fourthly, performing reduction synthesis and carbon conditioning at the temperature ranging from 900 DEG C to 1000 DEG C for the precursor powder obtained in the third step to prepare tungsten / cobalt carbide composite powder materials with nanostructures.

Owner:ADVANCED FOR MATERIALS & EQUIP

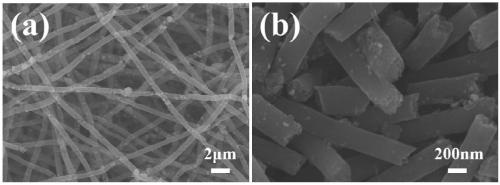

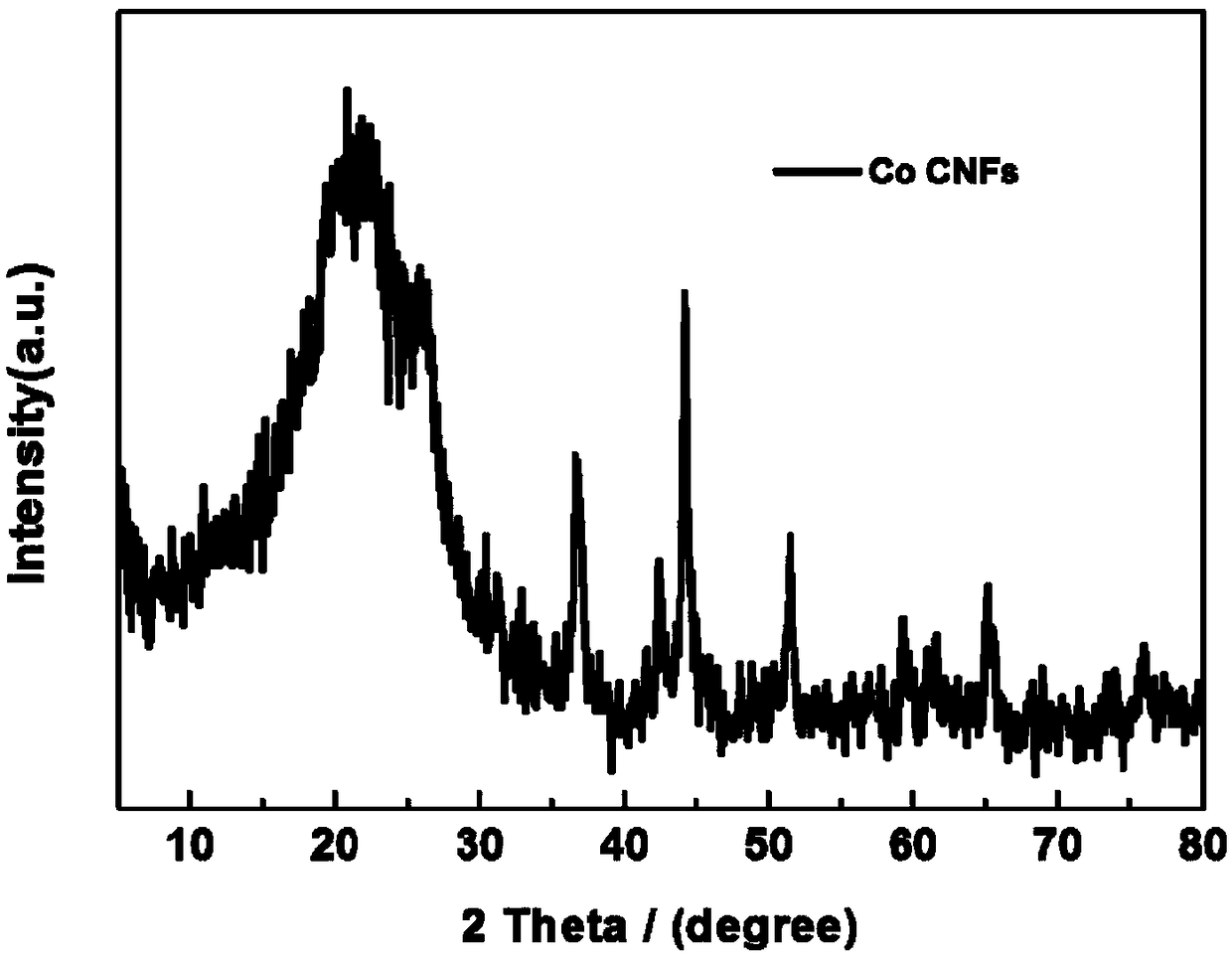

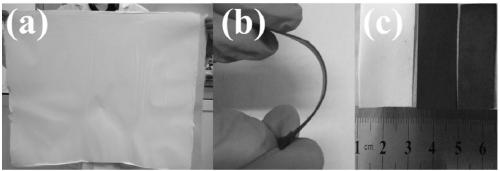

Preparation method and application of flexible catalytic material for water electrolysis

InactiveCN108940285AEasy to prepareRealize large-area continuous productionMetal/metal-oxides/metal-hydroxide catalystsElectrodesCarbon fibersSpinning

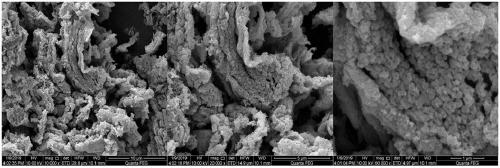

The invention discloses a preparation method and an application of a flexible catalytic material for water electrolysis, and belongs to the technical field of hydrogen production by water electrolysis. The preparation method comprises the following steps: (1) preparing cobalt-based Prussian blue analogue nanoparticles; (2) dispersing the cobalt-based Prussian blue analogue nanoparticles in an organic solvent, then adding polyacrylonitrile to prepare a spinning solution, and electrostatically spinning to prepare a Co-PBA / PAN composite nanofiber membrane; (3) pre-oxidizing the Co-PBA / PAN composite nanofiber membrane, and then carbonizing in an inert atmosphere to prepare the flexible catalytic material for water electrolysis. In the catalytic material for water electrolysis prepared in the invention, cobalt carbide is uniformly dispersed in porous carbon fiber, so that catalytic sites are increased. Meanwhile, the porous carbon fiber provides carriers for the catalytic sites and enhancesthe conductivity, thereby improving the problems of easy falling and loss of conventional powder catalytic materials; and a production method is easy and convenient, environment-friendly and safe, and can achieve large-area continuous production.

Owner:JIAXING UNIV

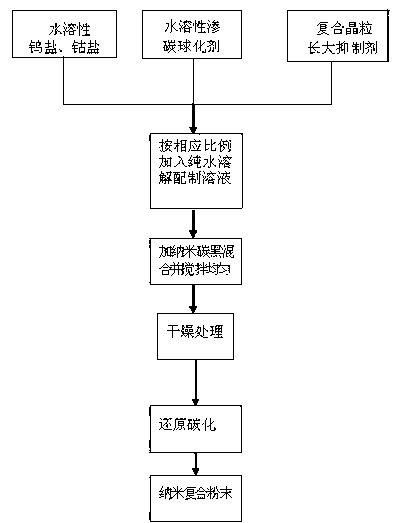

Method for manufacturing nanometer tungsten/cobalt carbide composite powder

The invention discloses a method for manufacturing nanometer tungsten / cobalt carbide composite powder. The method includes steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, adding nanometer carbon black accounting for 1-10% of the total mass of the aqueous solution into the mixed aqueous solution obtained in the first step, stirring the nanometer carbon black in the mixed aqueous solution at the rate of 10-30 revolutions per minute for 30-60 minutes so that the nanometer carbon black can be uniformly mixed in the mixed aqueous solution; thirdly, performing quick low-temperature spray drying for mixed aqueous solution obtained in the second step to obtain precursor powder of ultrafine tungsten and cobalt composite salt; and fourthly, performing reduction synthesis and carbon conditioning at the temperature ranging from 900 DEG C to 1000 DEG C for the precursor powder obtained in the third step to manufacture tungsten / cobalt carbide composite powder materials with nanostructures.

Owner:ANHUI RONGDA COMPOSITE POWDERS TECH

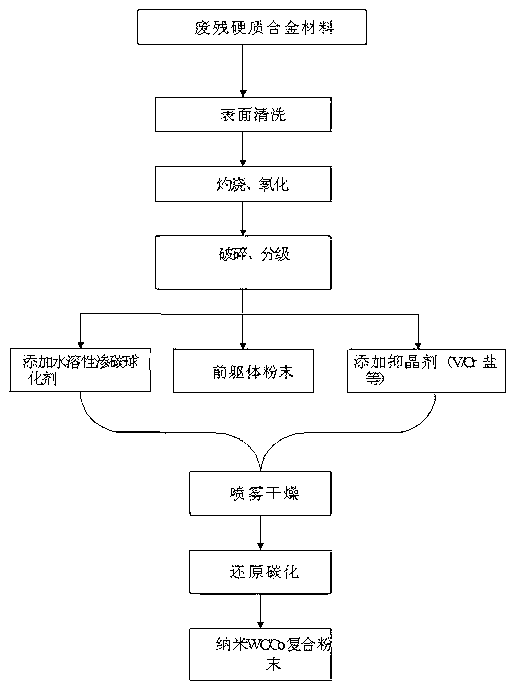

Method for preparing spherical nanostructure tungsten/cobalt carbide compound powder

The invention discloses a method for preparing spherical nanostructure tungsten / cobalt carbide compound powder by waste hard alloy. The method is characterized by including the steps of firstly, oxidizing and crushing waste tungsten / cobalt carbide material to obtain tungsten / cobalt compound oxide powder; secondly, dissolving 93-96% of the tungsten / cobalt compound oxide powder obtained in the step 1, 3-6% of water-soluble carburization spheroidizing agent and 0.1-2% of water-soluble compound grain growth inhibitor in water with 3-5 times of mass to obtain mixed water solution; thirdly, subjecting the mixed water solution obtained in the step 2 to fast spray-drying to obtain intermediate with evenly distributed components; and fourthly, subjecting the intermediate obtained in the step 3 to reduction, synthesis and carbon regulation at 900-1000 DEG C to obtain the nanostructure spherical tungsten / cobalt carbide compound powder.

Owner:ADVANCED FOR MATERIALS & EQUIP

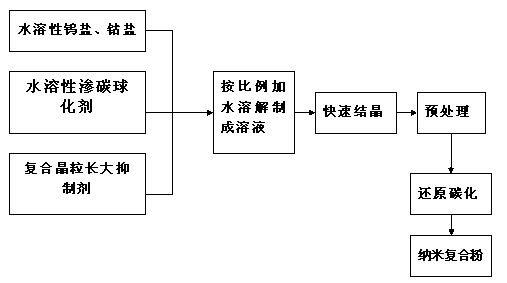

Method for manufacturing tungsten/ cobalt carbide composite powder with nanostructure

The invention discloses a method for manufacturing tungsten / cobalt carbide composite powder with a nanostructure. The method includes steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, quickly crystallizing the mixed aqueous solution obtained in the first step; thirdly, pre-treating crystalline, which is obtained in the second step, at the pretreatment temperature ranging from 500 DEG C to 700 DEG C to obtain nodular powder; and fourthly, performing reduction synthesis and carbon conditioning for powder materials, which are obtained in the third step, at the temperature ranging from 900 DEG C to 1000 DEG C to manufacture tungsten / cobalt carbide composite powder materials with nanostructures. The method has the advantages that a process is simple, and the hard alloy powder materials with the nanostructures can be produced in an industrialized manner.

Owner:ADVANCED FOR MATERIALS & EQUIP

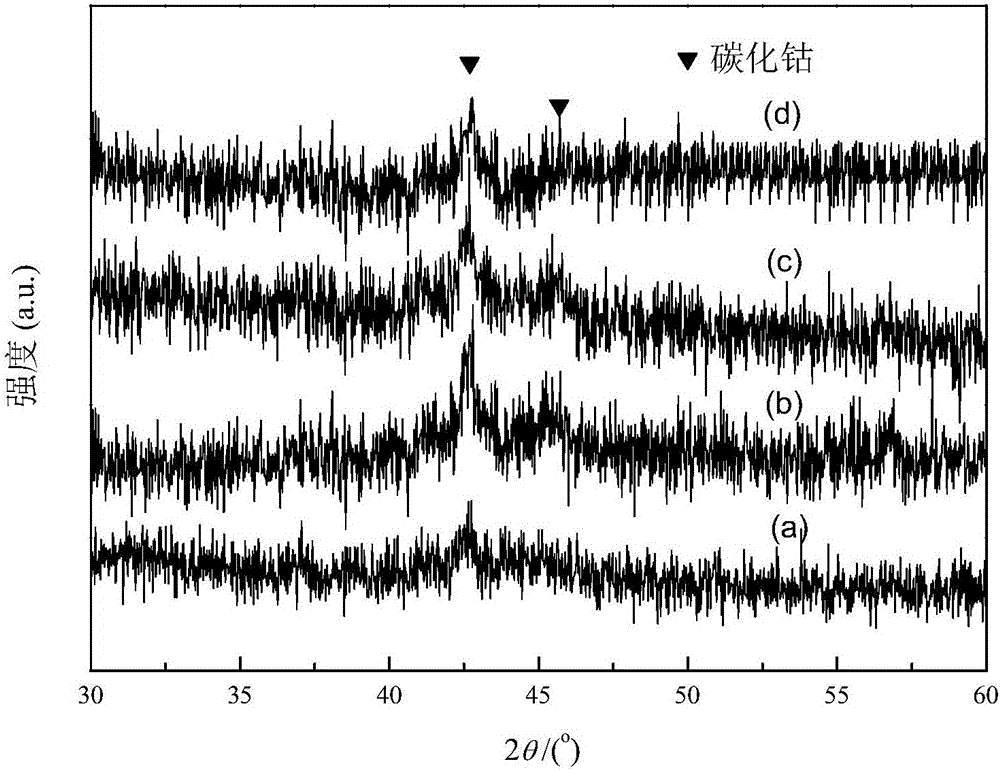

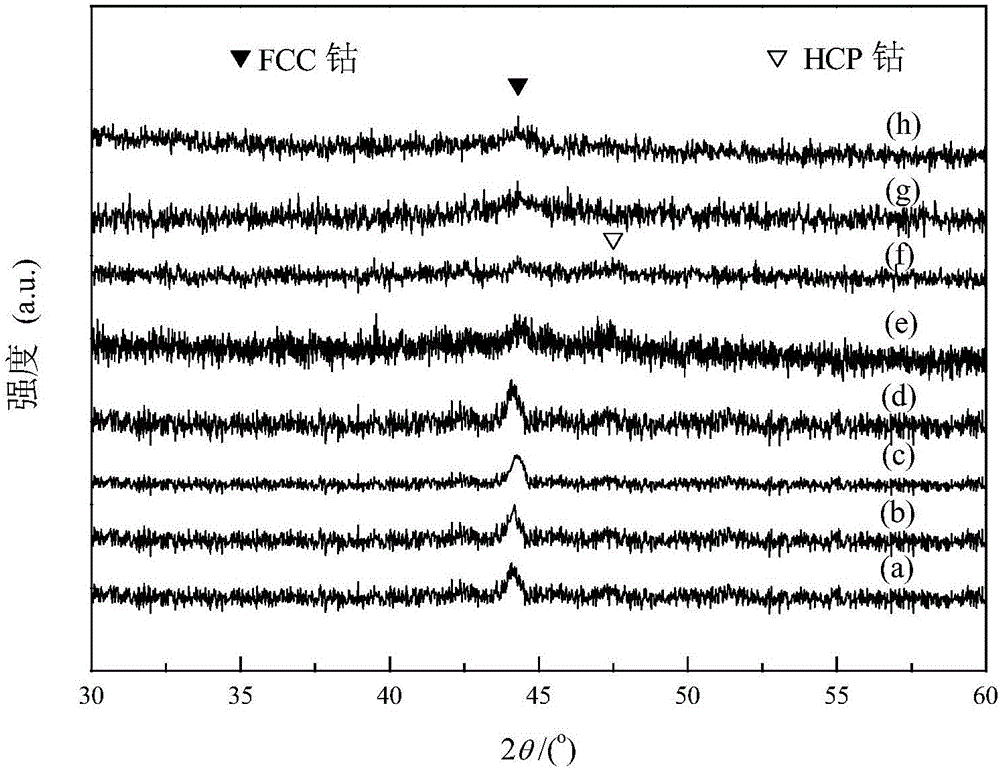

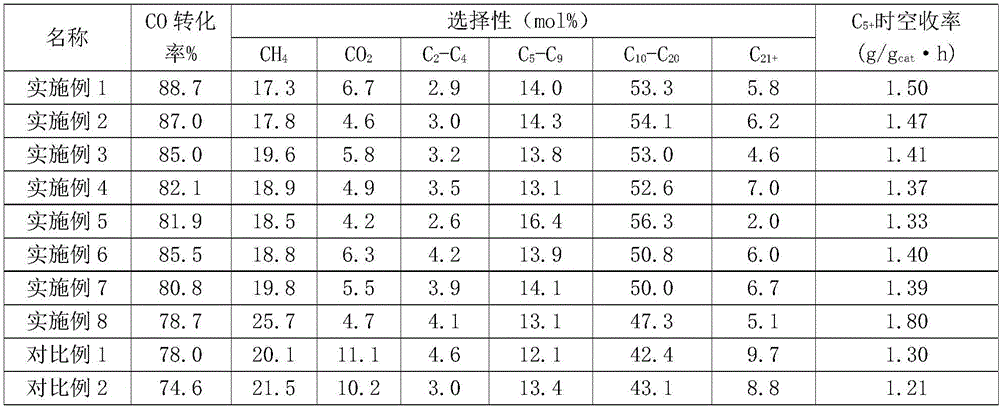

Porous carbon loaded double-crystalline phase cobalt-based fischer-tropsch symthesis catalyst and preparation method and application thereof

ActiveCN106140165AEasy to storeEasy to transportLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsPorous carbonCarbonization

The invention discloses a porous carbon loaded double-crystalline phase cobalt-based fischer-tropsch symthesis catalyst and preparation method and application thereof. The catalyst takes cobalt as an active component, porous carbon as a carrier and FCC and HCP crystalline phase cobalt as active phases, the mass content of the cobalt is 29.0%-30.8%, and the mass ratio of the HCP crystalline phase to FCC crystalline phase of the cobalt is 0.42-0.97:1. During preparation, a cobalt-contained metal organic skeleton is taken as a sacrificial template which is pyrolyzed under inert atmosphere, porous carbon loaded cobalt carbide intermediates by adopting carbonization of carbon monoxide, and a catalyst precursor is obtained by gas passivation treatment; the catalyst is obtained after the precursor is subjected to hydrogenation activation treatment. The cobalt metal active phases include the FCC and HCP crystalline phases which is high in activity and good in C5+selectivity when used in fischer-tropsch synthesis reaction, high C5+space time yield is specifically achieved, and C5+products are mainly composed of gasoline and diesel compositions.

Owner:SOUTH CHINA UNIV OF TECH

A new bionic composite roll manufacturing method with high wear resistance and long service life suitable for repair

InactiveCN102259114AAchieve the perfect combinationSolve segregationRollsMetal rolling arrangementsHigh resistanceWork roll

The present invention provides a new bionic composite roll manufacturing method with high wear resistance and long service life suitable for repair, which is obtained by designing the composite gradient of the roll material from the inside to the outside, and is characterized in that the high wear resistance, long life and high performance composite roll From the inside to the outside, it includes a roll core, a transition layer and a working layer. The roll core is made of conventional nodular iron, carbon steel or low alloy steel, and the working layer is made of tungsten-cobalt cemented carbide, tungsten-titanium Cobalt-based cemented carbide or high-chromium iron and other materials with high hardness and high wear resistance, the physical properties of the transition layer material are between the core material and the working layer material. The invention enhances the wear resistance of the roll and improves its service life. Moreover, the utilization rate of materials is greatly improved, and the production cost is reduced.

Owner:周明 +1

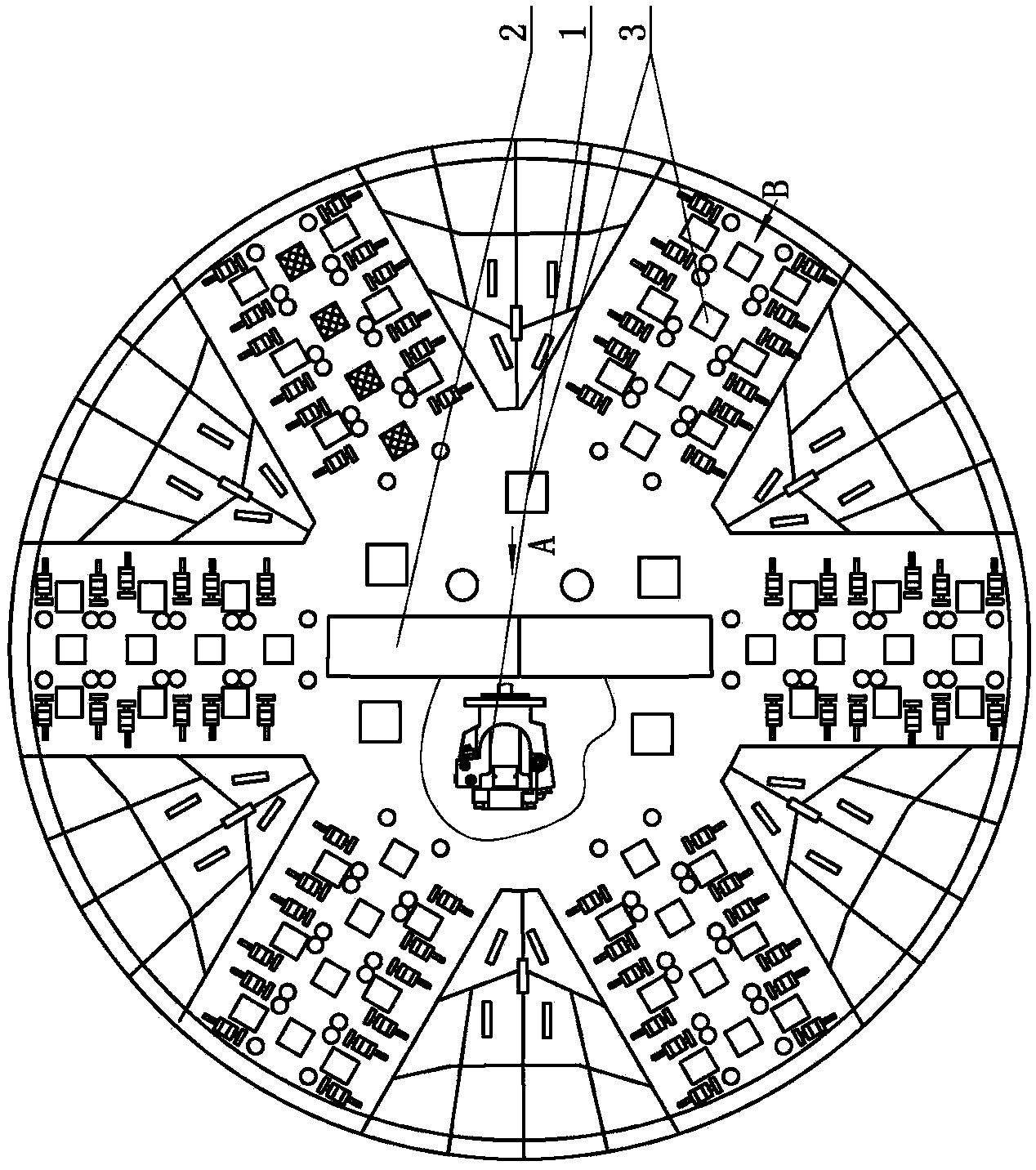

Slurry shield cutter head washing system

ActiveCN103867211AEasy to useAvoid blockingWelding/cutting media/materialsTunnelsManganeseEngineering

The invention relates to a slurry shield cutter head washing system. The slurry shield cutter head washing system comprises a water pump and spray nozzles, wherein the spray nozzles are distributed and installed on a slurry shield cutter head, the spray nozzles consist of middle spray nozzles and peripheral spray nozzles, the middle spray nozzles are installed at the side part of a fishtail cutter frame, the peripheral spray nozzles are distributed on the outer surface of a cutter arm of the slurry shield cutter head, the nozzle orifices of the peripheral spray nozzles face to the outer side of the slurry shield cutter head, U-shaped sheaths are arranged at the upper parts of the peripheral spray nozzles, the sheaths are welded on the slurry shield cutter head and the sheaths are welded with the slurry shield cutter head through high-wear-resistance electrodes, wherein the coating of the high-wear-resistance electrode is made of the following raw materials by weight percentage: 2-5 percent of vanadium iron nitride, 2-5 percent of chromium iron nitride, 2-5 percent of ferromanganese iron nitride, 5-10 percent of ferrotitanium, 5-10 percent of tungsten carbide, 5-10 percent of titanium carbide, 1-5 percent of cobalt carbide, 5-10 percent of ferrotungsten, 10-25 percent of metal manganese, 5-10 percent of ferroboron, 1-5 percent of monazite powder, 2-5 percent of nitrocellulose and balance of metal iron.

Owner:中铁十四局集团装备有限公司

Abrasion-resistant gear and preparation method

The invention discloses an abrasion-resistant gear and a preparation method. A gear material comprises, by mass, 65%-85% of ferrum, 0.3%-1.2% of manganese dioxide, 0.5%-1.6% of molybdenum disulfide, 0.1%-0.9% of nickel oxide, 0.3%-1.2% of cobalt carbide, 1%-3% of silicon carbide, 1%-3% of silicon dioxide, 0.2%-0.8% of chromium, 1.5%-3.5% of tin, 3%-15% of copper, 0.1%-0.3% of phosphorus, 0.1%-0.5% of zirconium, 0.3%-2% of graphite, 0.5%-2% of lanthanum-cerium alloy, 0.2%-0.8% of auxiliaries and the balance inevitable microelements and impurities. The preparation method mainly comprises the steps of weighing of raw materials, pretreatment, component mixing, preforming, high-temperature sintering and aftertreatment. The produced gear material has high strength and hardness and also has good abrasion resistance and impact resistance.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

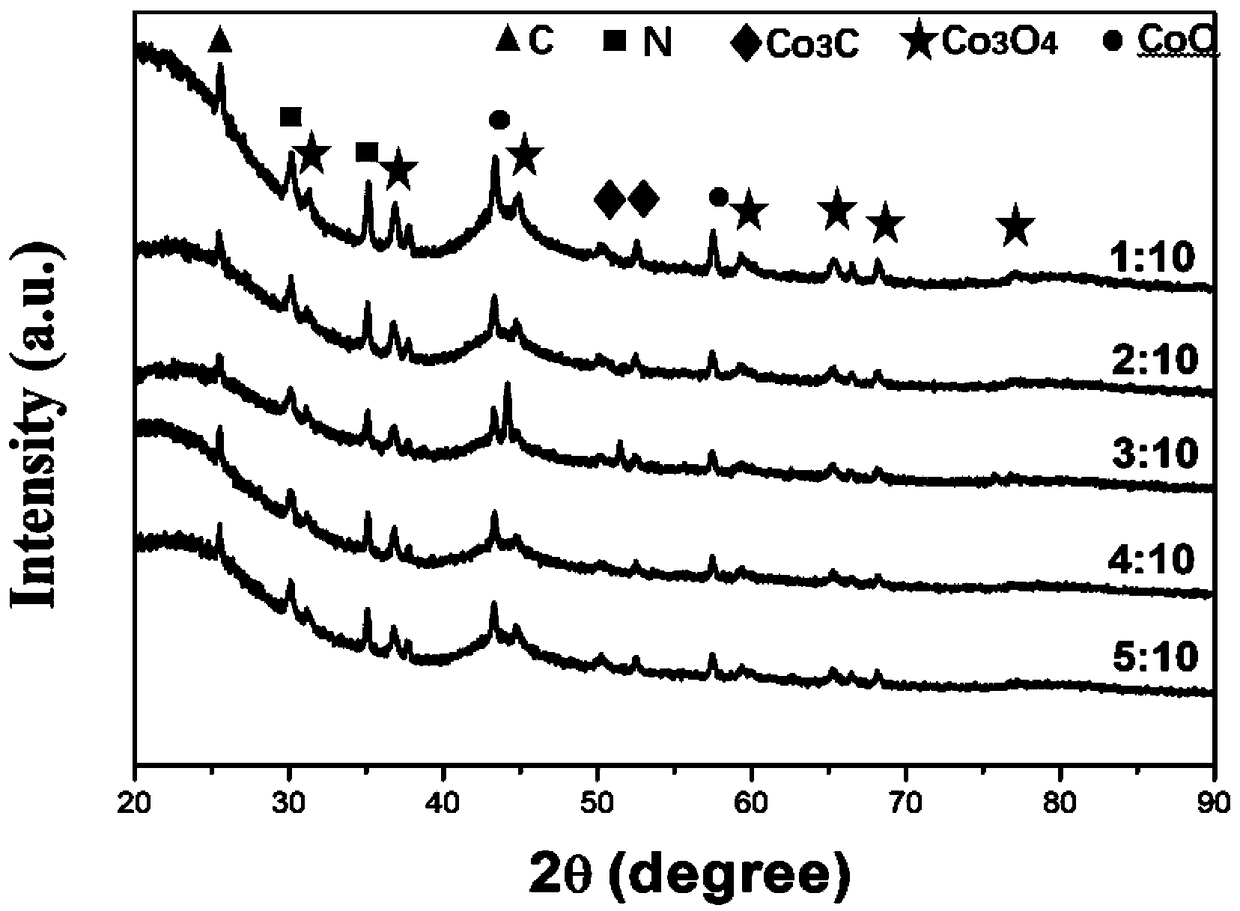

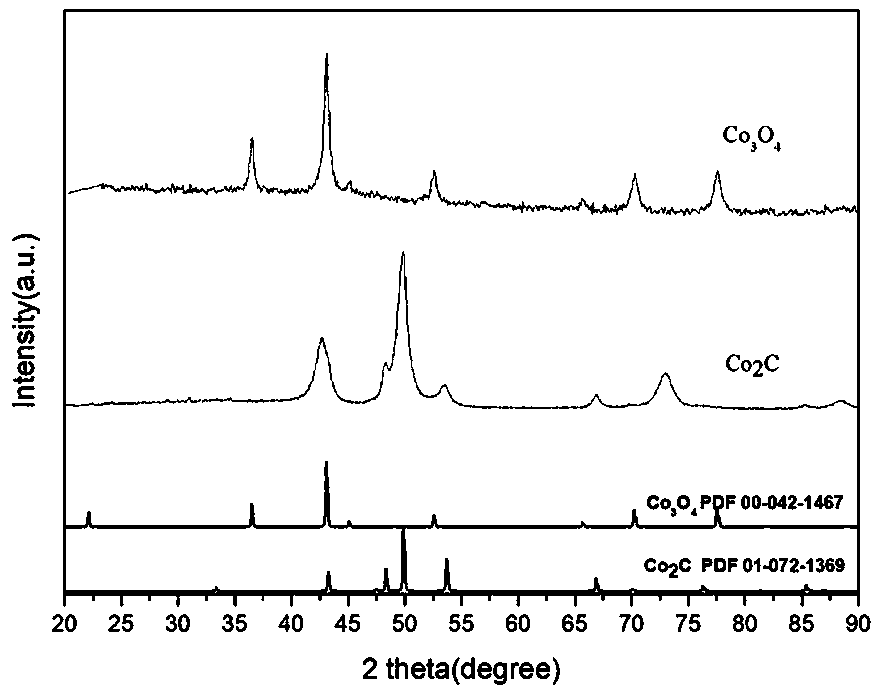

Catalyst for preparing low-carbon mixed alcohol through carbon oxide hydrogenation and preparation method of catalyst

InactiveCN106975486AGood dispersionDense particlesOrganic-compounds/hydrides/coordination-complexes catalystsOxygen compounds preparation by reductionAlcoholCobalt carbide

The invention relates to a catalyst for preparing low-carbon mixed alcohol and liquid hydrocarbon through catalytic conversion of a synthesis gas and a preparation method of the catalyst. The catalyst is prepared from a carrier, an active component and an assistant, wherein the carrier is carbon; the active component is nanocomposite particles of metal Co and cobalt carbide Co2C; the assistant is SiO2; and the mass content of Co is 0.4-2.1wt%, the mass content of the Co2C is 37.7-42.0%, the mass content of the SiO2 is 0-14.3% and the balance is carbon. The preparation method of the catalyst comprises the following steps of (1) preparing a Co-MOF-71 organic metal skeleton material; (2) adopting Co-MOF-71 as a sacrificial template and tetraethylortho silicate as a silicon source and preparing a catalyst precursor containing a Si element in situ; and (3) activating the catalyst precursor to obtain a carbon-supported Co&Co2C catalyst containing the SiO2 assistant. The preparation method is simple, the nanocomposite particles are formed through the Co and the Co2C, distribution of alcohol is narrow and the space-time yield of the alcohol is good. The SiO2 assistant is distributed on the surfaces of the active component particles of the catalyst in an embedded form and plays a relatively good synergistic effect on the catalytic activity.

Owner:NINGXIA UNIVERSITY

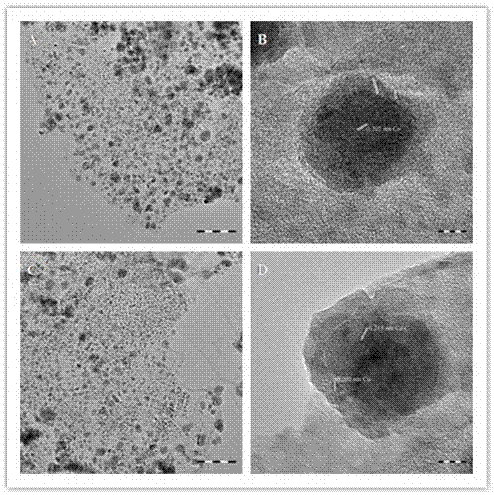

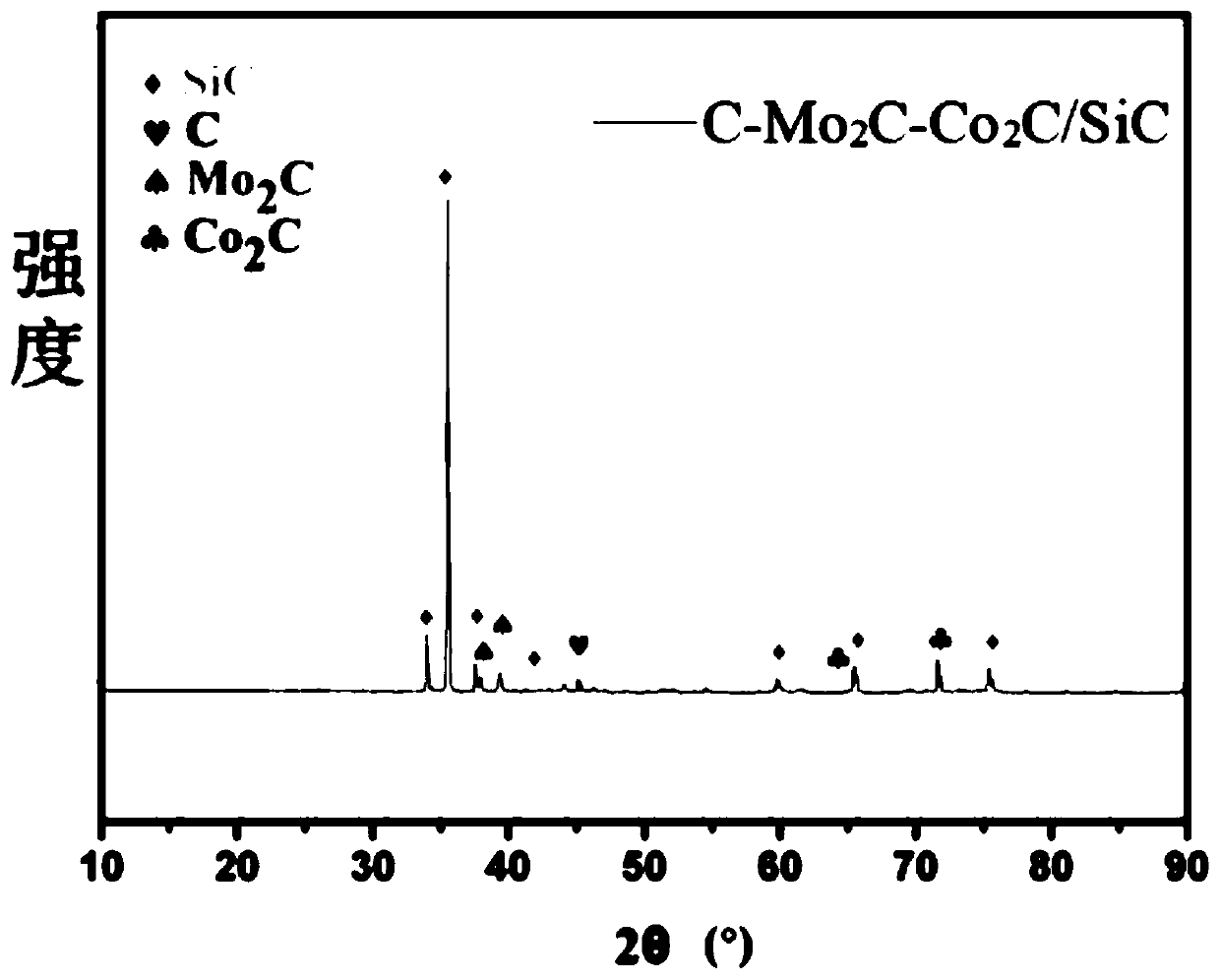

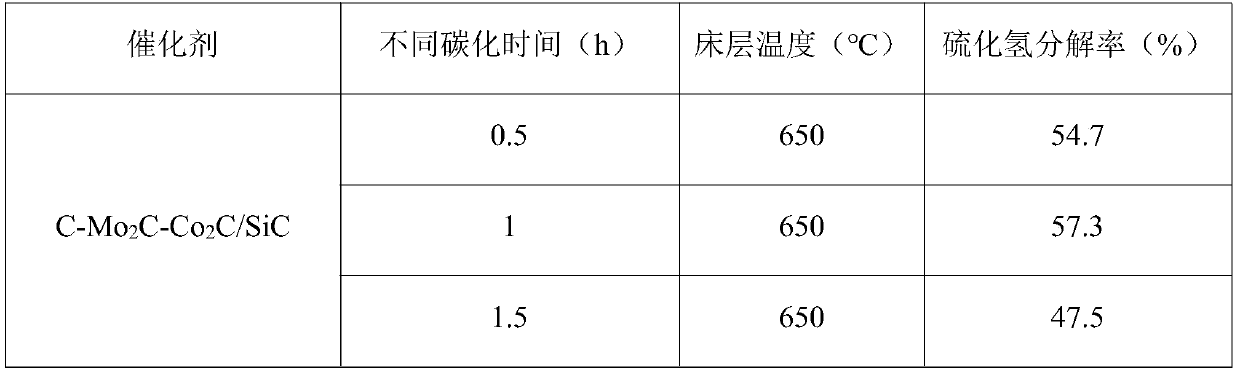

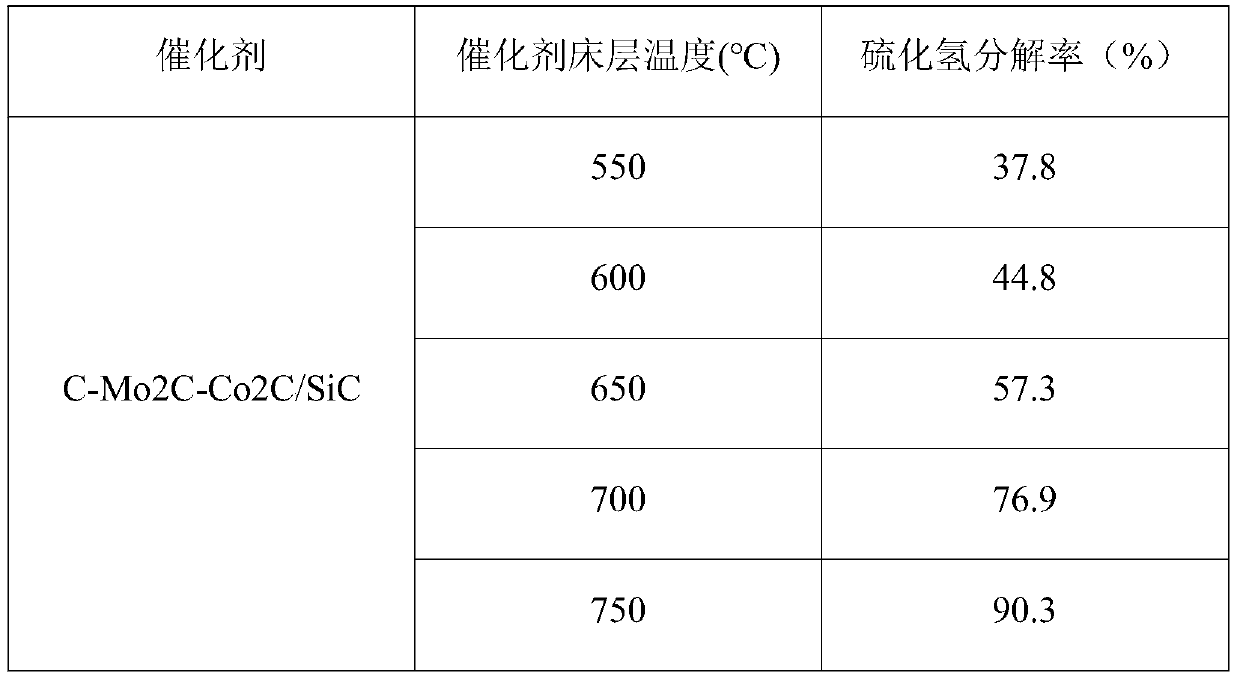

Method for catalytic decomposition of hydrogen sulfide by composite type catalyst

ActiveCN109759106AImprove decomposition efficiencyMild reaction conditionsPhysical/chemical process catalystsSulfur preparation/purificationCatalytic decompositionMolybdenum carbide

The invention provides a method for catalytic decomposition of hydrogen sulfide by a composite type catalyst. The method comprises the following steps of directly catalyzing the hydrogen sulfide to decompose by the composite type catalyst under a microwave field to produce hydrogen gas and sulphur, wherein the composite type catalyst comprises carbon compounded transition metal carbide being at least one of molybdenum carbide, cobalt carbide, iron carbide, tungsten carbide and carrier silicon carbide subjected to alkali treatment. The method comprises the following concrete steps of filling the composite type catalyst into a quartz tube of a microwave reactor to form a microwave catalyst bed layer; then, introducing mixed gas containing hydrogen sulfide so that the gas-solid phase microwave catalyst reaction is performed; the direct decomposition of hydrogen sulfide is realized. The method has various advantages that the reaction conditions are mild; the parameters are controllable; the operation is convenient; the composite type catalyst and the microwave achieve the cooperated effects, so that the decomposition efficiency of the hydrogen sulfide is higher, and the like.

Owner:XIANGTAN UNIV

Co-nitrogen co-doped carbon aerogel catalyst for fuel cell and preparation method thereof

ActiveCN109103462AReduce manufacturing costLarge specific surface areaCell electrodesShielding gasCarbonization

The invention discloses a co-nitrogen co-doped carbon aerogel catalyst for a fuel cell and a preparation method thereof. The core-shell structure and material composition are Co-phen at CA; the carrier is carbon aerogel after high temperature carbonization, and the active components are cobalt, cobalt oxide and cobalt carbides uniformly distributed on the surface of carbon aerogel. Cobalt nitratehexahydrate and organic ligand o-phenanthroline and pyridine 2, 6-dicarboxylic acid react in hydrothermal environment to form a new kind of metal-organic skeleton complexes with sheet structure, and anew kind of composite material is formed by carbon aerogel coating. The calcination process uses N2 as protective gas, thereby obviously reducing the preparation cost, which will promote the furtherdevelopment of non-noble metal catalysts.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

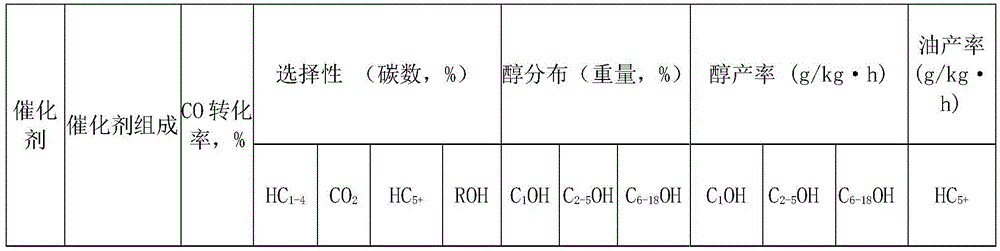

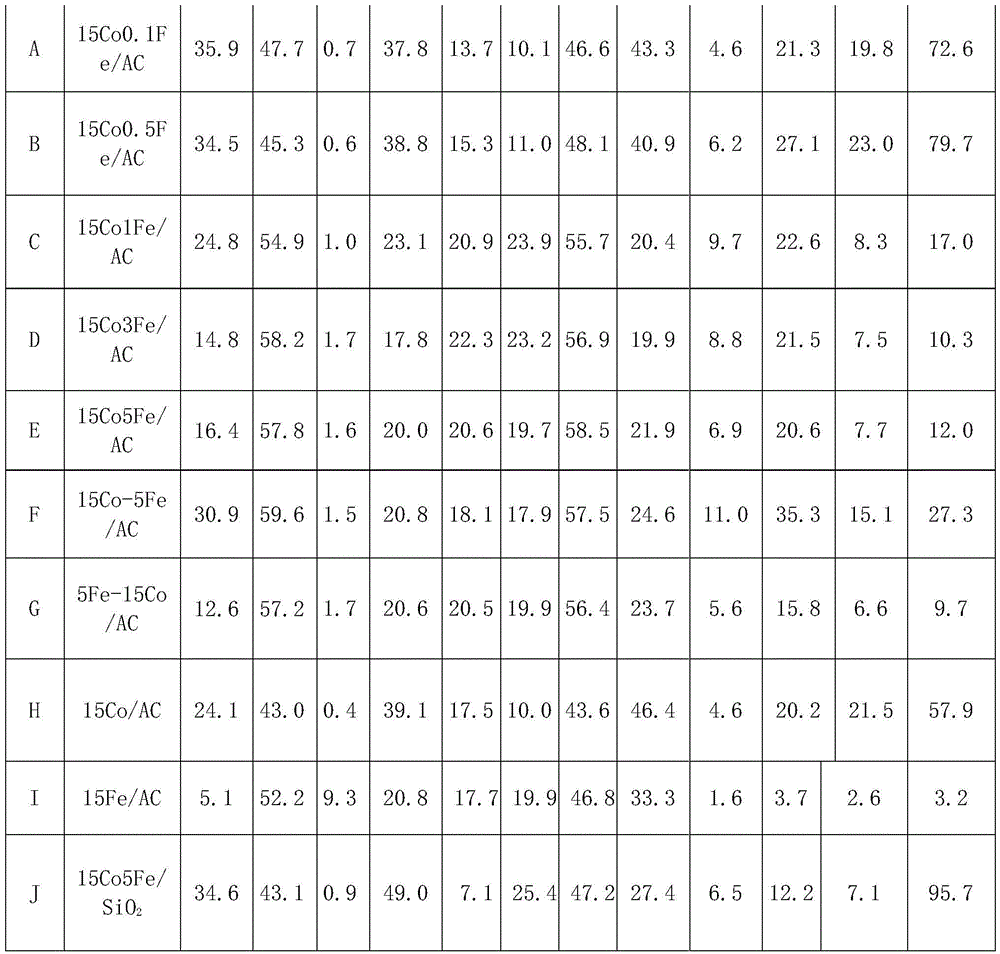

Catalyst for preparing mixed alcohol from synthetic gas as well as preparation method and application of catalyst

ActiveCN106807421AHigh selectivityHigh yieldPhysical/chemical process catalystsOrganic compound preparationAlcoholActive component

The invention discloses a catalyst for preparing a mixed alcohol from synthetic gas as well as a preparation method and application of the catalyst. The invention discloses a catalyst for synthesizing the mixed alcohol through CO hydrogenation; the catalyst comprises a first active component, a second active component and a carrier, wherein the first active component comprises metal cobalt and iron; the second active component comprises cobalt carbide and a cobalt-iron alloy; the carrier is active carbon. The catalyst is prepared from the following components in percentage by mass: 1 percent to 30 percent of the cobalt and 0.1 percent to 10 percent of the iron. The catalyst is prepared by adopting an immersion method; the preparation method is simple and needed catalytic reaction conditions are moderate; the catalyst has the advantages of high catalytic activity and relatively high selectivity of C2 to C18 high-grade alcohols in a product; when the catalyst provided by the invention is used, the alcohol yield of a mixed primary alcohol prepared by the synthetic gas can be improved and the catalyst has good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

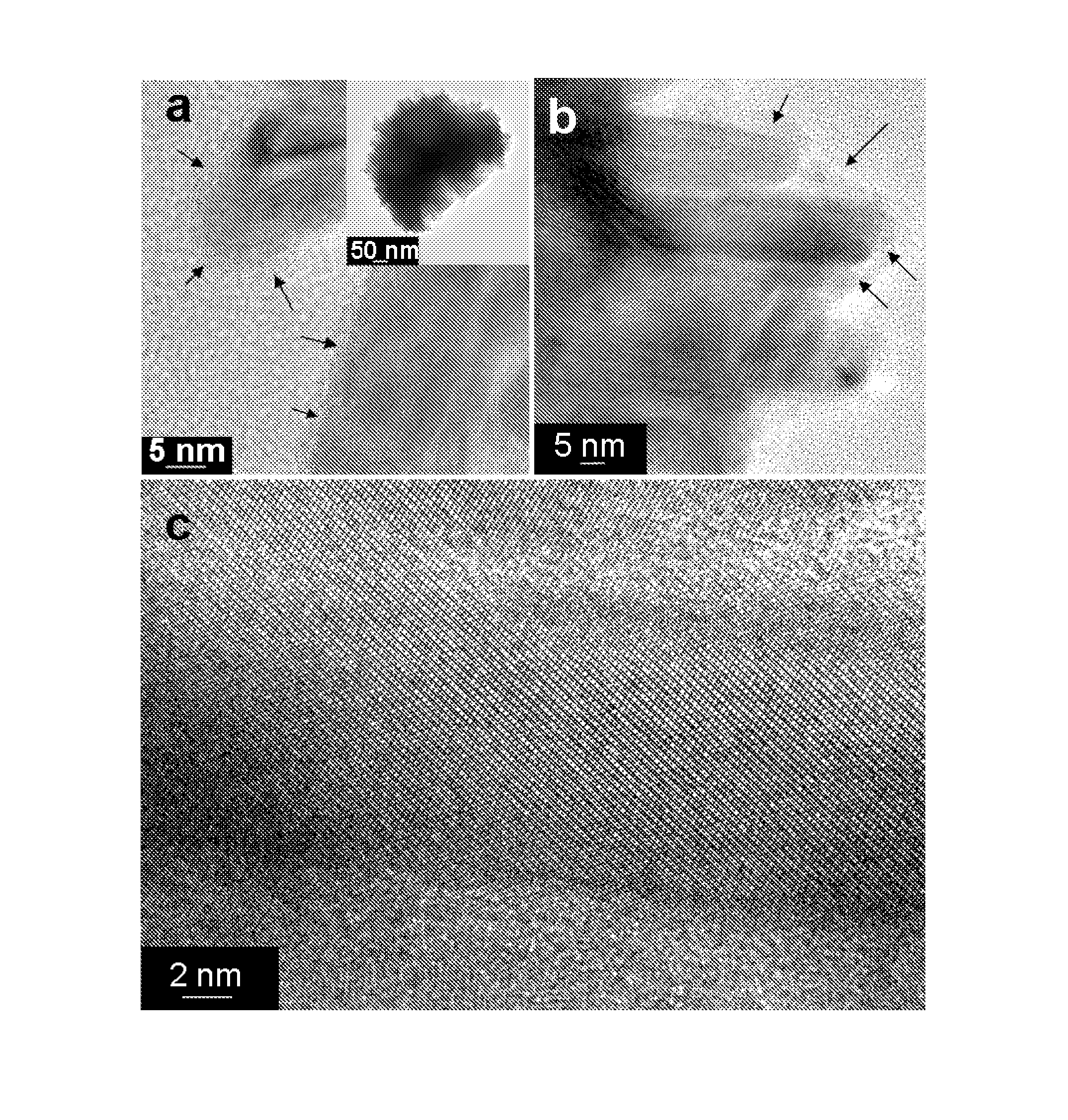

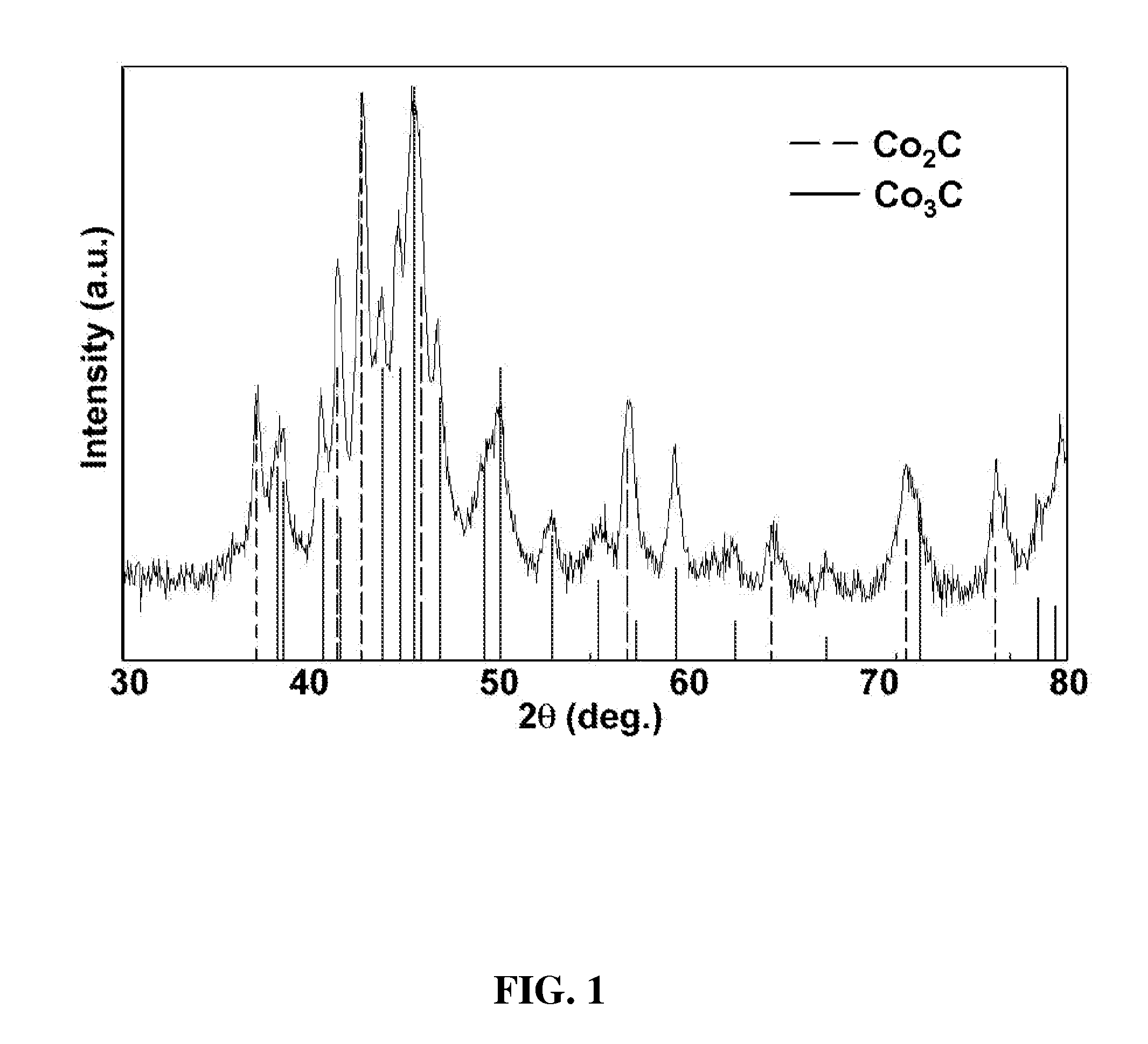

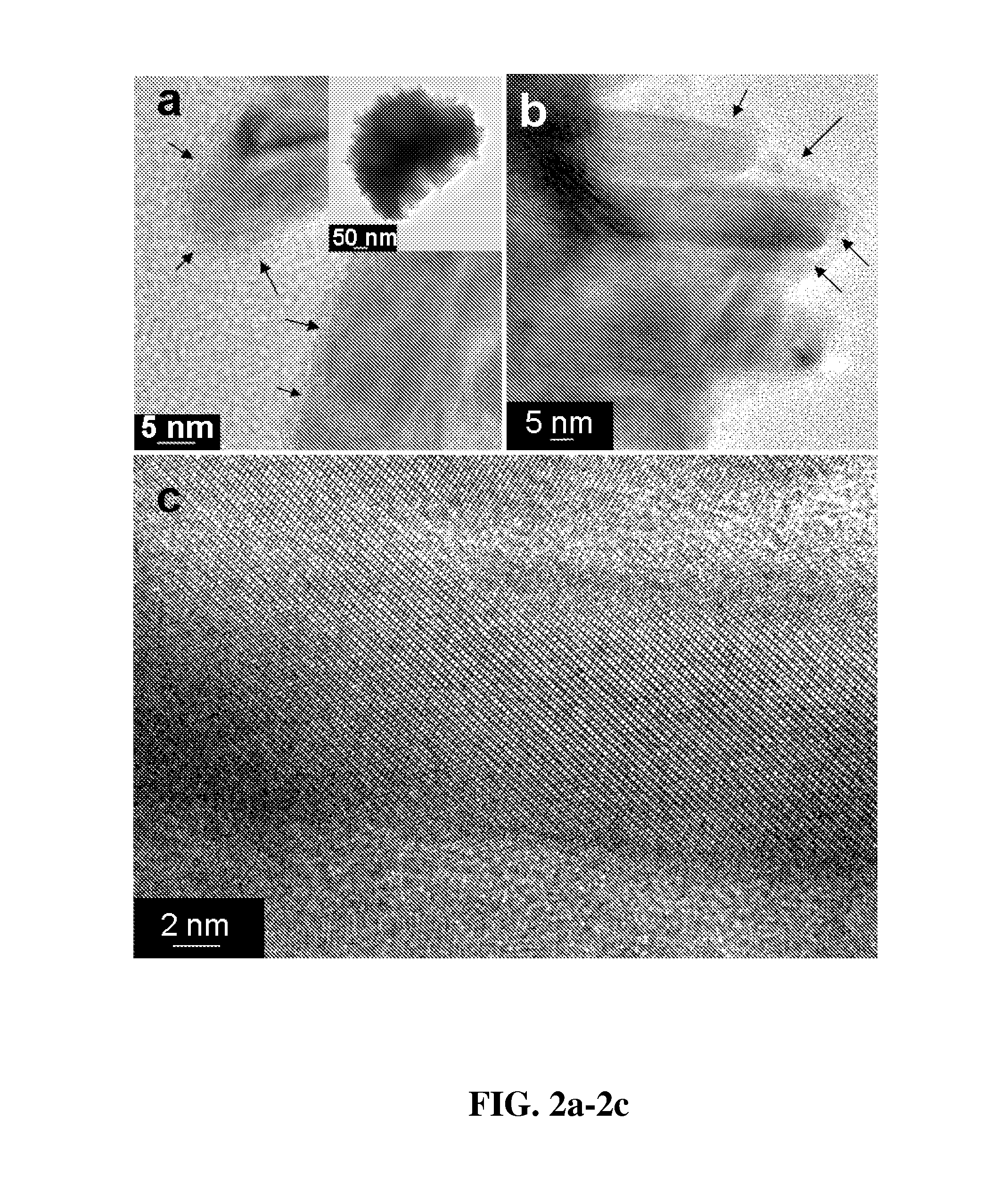

Cobalt carbide-based nanoparticle permanent magnet materials

InactiveUS20120168670A1High energyLow coercivityNanomagnetismCarbon compoundsFerromagnetismMaterials science

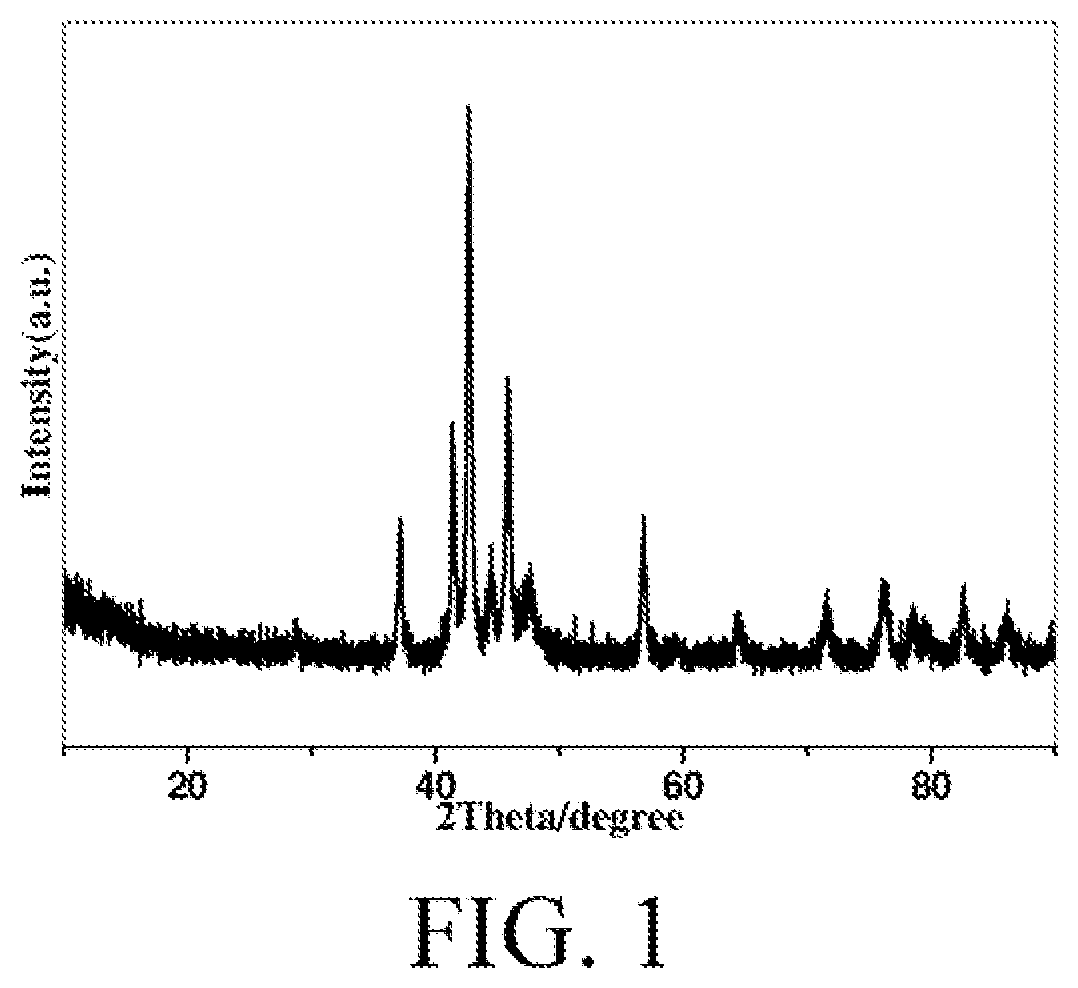

A composition of a crystalline ferromagnetic material based upon nanoscale cobalt carbide particles and to a method of manufacturing the ferromagnetic material of the invention via a polyol reaction are disclosed. The crystalline ferromagnetic cobalt carbide nanoparticles of the invention are useful for high performance permanent magnet applications. The processes according to the invention are extendable to other carbide phases, for example to Fe-, FeCo-carbides. Fe- and FeCo-carbides are realizable by using as precursor salts Fe-, Co-, and mixtures of Fe- and Co-salts, such as acetates, nitrates, chlorides, bromides, citrates, and sulfates, among others. The materials according to the invention include mixtures and / or admixtures of cobalt carbides, as both Co2C and Co3C phases. Mixtures may take the form of a collection of independent particles of Co2C and Co3C or as a collection of particles which consist of an intimate combination of Co2C and Co3C phases within individual particles. The relative proportions of these two phases as well as the morphology of each phase contribute to their attractive permanent magnet properties, particularly at low temperatures through room temperature and up to over 400 K.

Owner:NORTHEASTERN UNIV

Diamond compact and preparation method thereof

The invention relates to the technical field of super-hard composite materials and provides a diamond compact and a preparation method thereof. The diamond compact comprises a diamond layer and a tungsten / cobalt carbide hard alloy layer, a grain inhibitor is added into the diamond layer and serves as a hard phase to be doped into polycrystal, and abnormal growth of diamond grains is alleviated. Inaddition, by doping of diamond micropowder into the tungsten / cobalt carbide hard alloy layer, a grain growth promoting effect of the Co element at an interface can be inhibited. Furthermore, due to containing of diamond in the diamond layer and the tungsten / cobalt carbide hard alloy layer, binding force of the diamond compact at the interface is increased, and the diamond compact is tighter in combination. Therefore, the diamond compact has advantages of fine grains and compact microstructure.

Owner:FUNIK ULTRAHARD MATERIAL

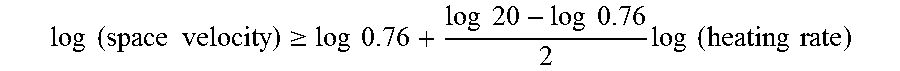

Metal carbide catalyst for catalyzing a CFC-113a hydrogenation coupling reaction and preparation method and application thereof

ActiveCN109772396AIncrease alkalinityImprove conversion ratePhysical/chemical process catalystsHalogenated hydrocarbon preparationGas phaseReaction temperature

The invention discloses a metal carbide catalyst for catalyzing a CFC-113a hydrogenation coupling reaction and a preparation method and application thereof. The metal carbide catalyst is mainly composed of at least one of iron carbide, nickel carbide, ruthenium carbide, palladium carbide and cobalt carbide. When the metal carbide catalyst is used for catalyzing the CFC-113a hydrogenation couplingreaction, the reaction is performed on a fixed bed reaction device, the feeding volume ratio of CFC-113a to H2 is 1:3-5, the reaction temperature is 200-400 DEG C, the gas air speed is 100-1,000 h<-1>, the reaction pressure is normal pressure, the CFC-113a reaction raw materials are easy to obtain, the conversion rate is high (the conversion rate can reach 90% or above), the target product CFC-1316 is high in selectivity (the selectivity can reach 90% or above), and the metal carbide catalyst has the high catalytic stability in a gas phase catalysis hydrogenation coupling dechlorination reaction.

Owner:ZHEJIANG UNIV OF TECH

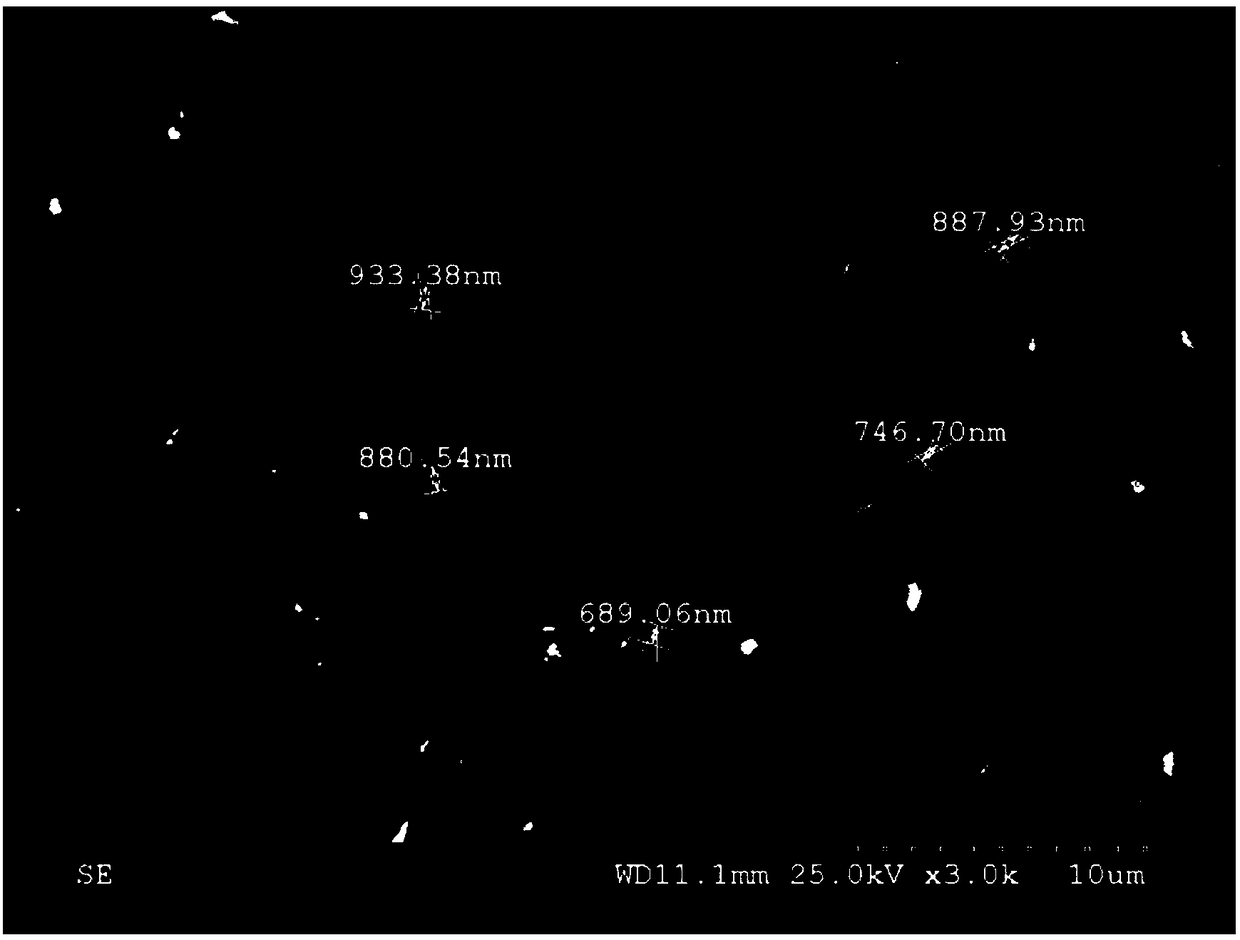

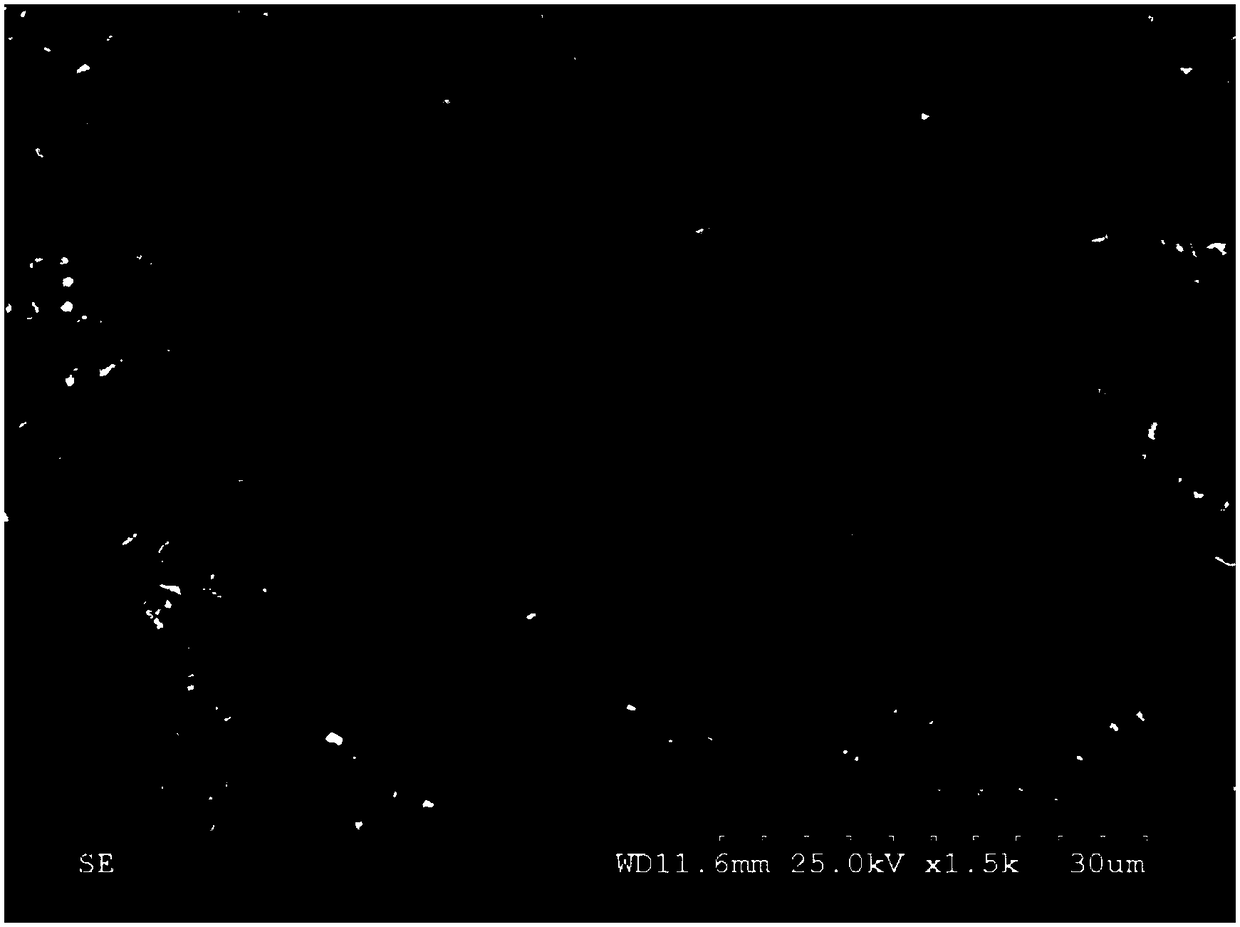

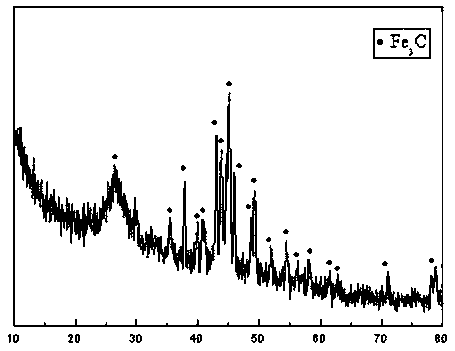

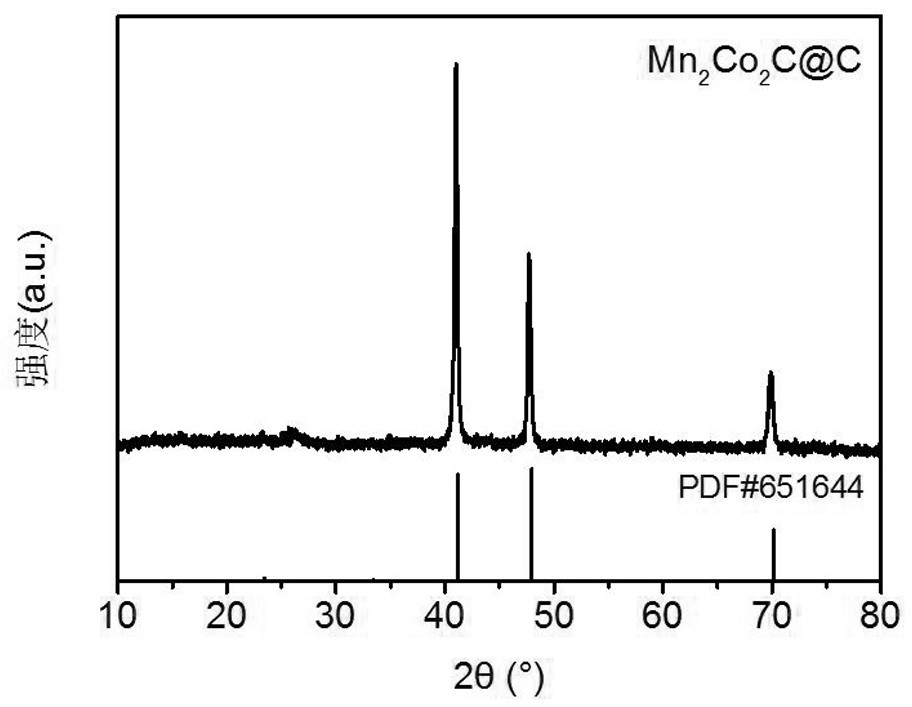

Nitrogen-doped carbon layer coated cobalt manganese carbide composite material and application thereof

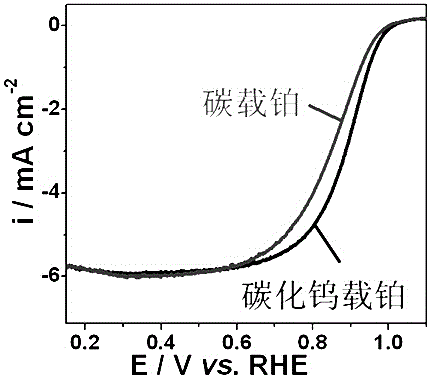

ActiveCN111617790AEasy to synthesizeRapid industrializationEnergy inputCatalyst activation/preparationCarbon layerPtru catalyst

The invention belongs to the technical field of nano materials and photocatalysis, and particularly relates to a nitrogen-doped carbon-coated Mn2Co2C composite material which is prepared by the methodcomprising the following steps: reacting soluble positive bivalent cobalt salt, positive bivalent manganese salt and cobalt potassium cyanide to obtain precipitate, and reacting the precipitate at high temperature under the protection of N2 atmosphere to obtain the nitrogen-doped carbon-coated Mn2Co2C composite material. The nitrogen-doped carbon-coated Mn2Co2C composite material disclosed by theinvention can be used as a hydrogen production cocatalyst to accept electrons and promote a hydrogen evolution reaction, Mn2Co2C@C nanoparticles as a cocatalyst are loaded on the surface of g-C3N4 toobtain a g-C3N4 / Mn2Co2C@C composite photocatalyst material, and the g-C3N4 / Mn2Co2C@C composite photocatalyst material shows efficient activity of photocatalytic decomposition of water to produce hydrogen.

Owner:GUANGXI NORMAL UNIV

Tungsten-cobalt carbide/molybdenum disulfide composite powder and its preparing method

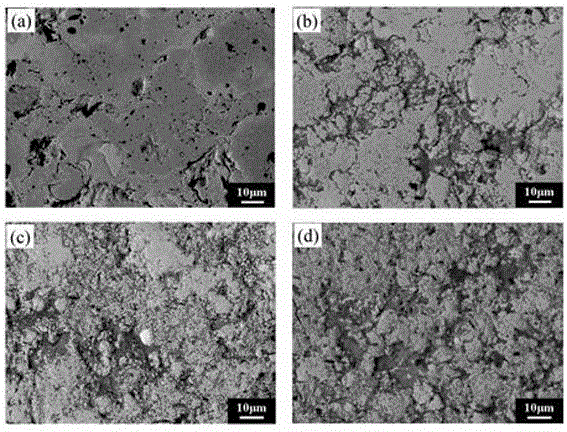

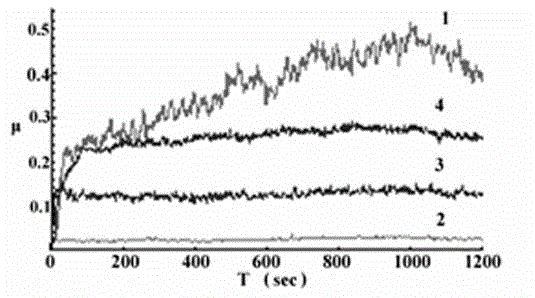

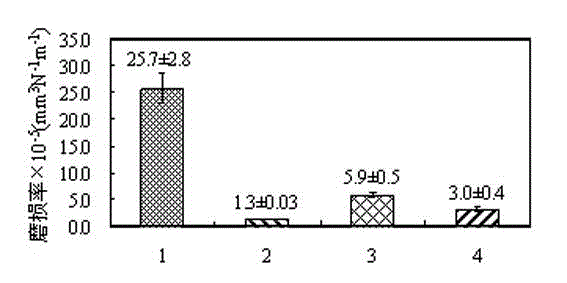

The present invention is WC-Co / MoS2 composite powder and features that the WC-Co / MoS2 composite powder consists of WC-Co in 94-99 wt% and MoS2 in 1-6 wt%. The WC-Co / MoS2 composite powder of the present invention may be used in preparing coating with high hardness, high compactness and high combining strength as well as low friction coefficient and greatly lowered wear rate. That is, the WC-Co / MoS2 composite powder of the present invention may be used in preparing composite self-lubricating hard wear-resistant coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

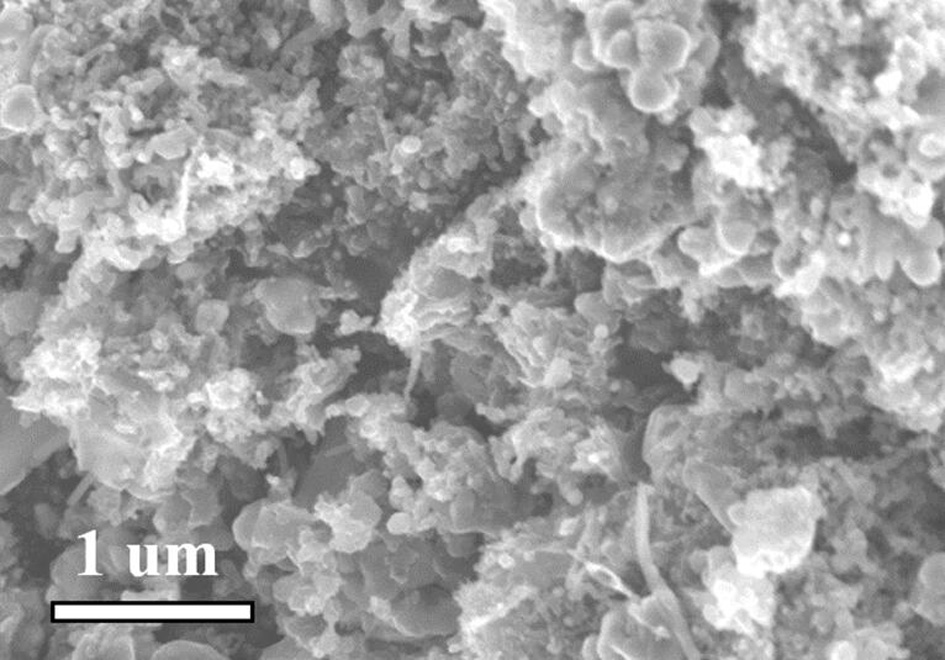

Preparation method of directly-formed metal element-modified cobalt carbide material

ActiveCN109317173AThe method flow is simpleLow costPhysical/chemical process catalystsTO-18Cobalt salt

The invention discloses a preparation method of a directly-formed metal element-modified cobalt carbide material. Sodium alginate powder is used for preparing a homogeneous-phase aqueous solution A with a concentration of 14-60wt%; soluble modified metal salt and soluble cobalt salt are used for preparing an aqueous solution B with a concentration of 10-80wt%; according to a ratio of sodium alginate to the cobalt salt of 0.2 to 18, the aqueous solution A is added into the solution B, which is stirred, dropwise to obtain spherical colloid; the obtained spherical colloid is filtered and dried toobtain dry spheres; in an anaerobic atmosphere, calcination is conducted to obtain the formed metal element-modified cobalt carbide material. The preparation method of the directly-formed metal element-modified cobalt carbide material has the advantages that the method is simple, and the cost is low.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Shaft sleeve material and preparation method

The invention discloses a shaft sleeve material and a preparation method. A shaft sleeve is manufactured through the following process steps of raw material preparation, pretreatment, powder mixing, preliminary molding, high-temperature sinter molding, heat treatment and the like. The shaft sleeve material is prepared from, by mass, 1-2% of silicon dioxide, 0.5-1.2% of manganese dioxide, 0.5-1.6% of molybdenum disulfide, 0.5-2% of lanthanum oxide, 0.2-0.9% of nickel oxide, 0.5-1.2% of cobalt carbide, 1-2% of silicon carbide, 0.3-1% of graphite, 0.2-0.8% of wax micro-powder, 0.2-0.8% of chromium, 1.5-3% of tin, 2-10% of copper, 0.1-0.5% of phosphorus, 0.1-0.5% of zirconium and the balance iron and inevitable impurities. The produced shaft sleeve material has high wear resistance and hardness as well as high strength and impact resistance.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

Preparation method of porous cobalt carbide

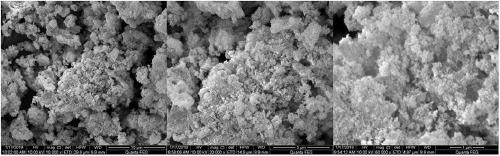

ActiveCN109675597AInhibit growthAddress controllabilityPhysical/chemical process catalystsCarbon compoundsActivated carbonInorganic Chemical

The invention discloses a preparation method of porous cobalt carbide, and belongs to the technical field of inorganic chemical engineering. A nitric acid modified activated carbon carrier is evenly impregnated with cobalt salt and a precipitator, and is roasted in a muffle furnace at the temperature of 300-900 DEG C, and then a reducing gas is introduced to obtain the porous cobalt carbide. The rich-pore activated carbon is used as a hard template carrier, the cobalt salt and the precipitator are impregnated in pores of the activated carbon to precipitate and react to form an ultrafine precipitation particle, and the particle is prevented from growing so as to control the particle size and the morphology. Moreover, the activated carbon left after the roasting reacts with the oxygen produced in the carbonizing of cobaltosic oxide, so that the balance of the carbonation reaction is broken, the efficiency of the carbonation reaction is improved, and a large quantity of time required forthe carbonation reaction is shortened.

Owner:FUZHOU UNIV

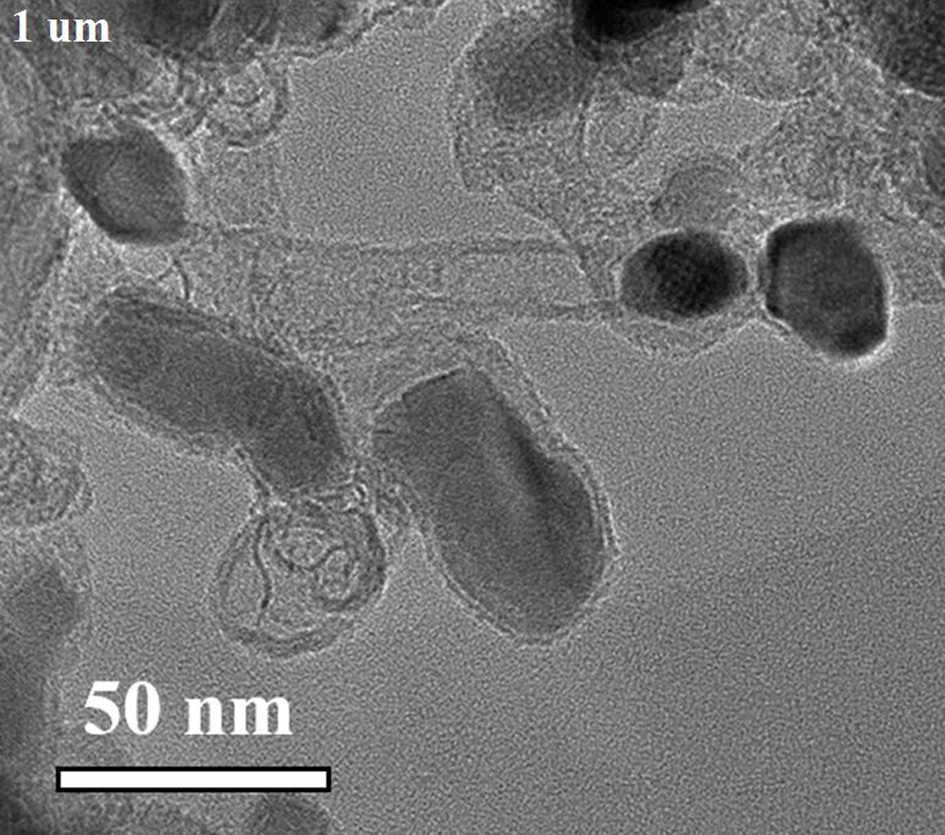

Cobalt carbide-based catalyst for direct preparation of olefin from synthesis gas, preparation method therefor and application thereof

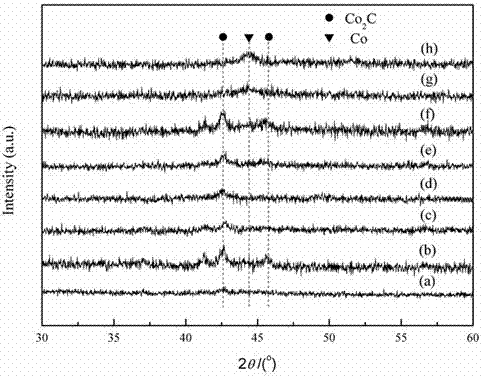

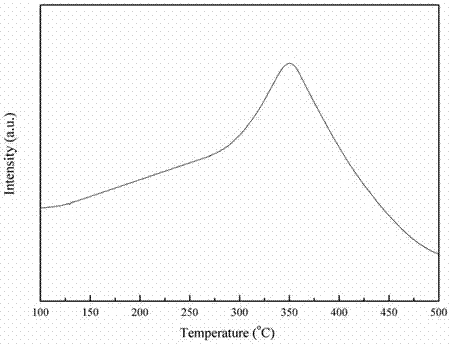

ActiveUS20200406239A1High selectivityLow selectivityHydrocarbon from carbon oxidesCarbon compoundsSyngasPtru catalyst

A cobalt carbide-based catalyst for direct production of olefin from synthesis gas, a preparation method therefor and application thereof are disclosed. The method for preparing the catalyst comprises the following steps: 1) mixing a cobalt source with water, or mixing a cobalt source, an electron promoter and water to obtain a first solution; and mixing a precipitant with water to obtain a second solution; 2) adding the first solution and the second solution to water, or water and a structure promoter for precipitation, crystallizing, separating, drying and calcination; and 3) reducing a solid obtained in Step 2) in a reducing atmosphere, and then carbonizing in a carbonizing atmosphere. The prepared catalyst has high activity and high selectivity to olefins for direct production of olefins via syngas conversion.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Angstrom-scale carbide and preparation method thereof

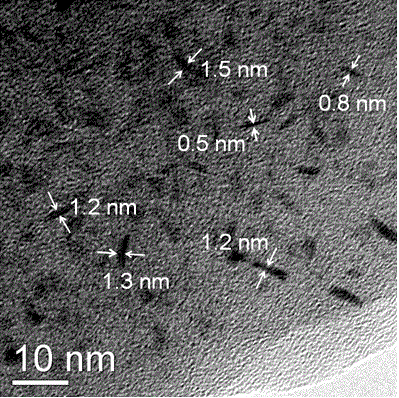

InactiveCN104874413AReduce contentReduce manufacturing costPhysical/chemical process catalystsTungsten/molybdenum carbideMolybdenum carbideTitanium carbide

The invention belongs to the field of materials, and particularly discloses an angstrom-level transition metal carbide and a preparation method thereof. The angstrom-level transition metal carbide is prepared according to the following technical scheme: preparing a transition metal precursor into a solution, then adding with ion exchange resin as a carbon source, mixing and stirring, then separating the solid and liquid phases, collecting the solid phase, and finally drying and roasting the solid phase so as to obtain the angstrom-level transition metal carbide. The transition metal carbide takes carbon as a base body, and comprises one or more of tungsten carbide, molybdenum carbide, zinc carbide, chromium carbide, nickel carbide, ferrum carbide, cobalt carbide and titanium carbide.

Owner:JIANGSU UNIV

Fischer-tropsch catalysts containing iron or cobalt selective towards higher hydrocarbons

ActiveUS8987160B2Molecular sieve catalystsOrganic compound preparationCarboxylic acidAlpha hydroxy acid

Cryptomelane-type manganese oxide octahedral molecular sieves (OMS-2) supported Fe and Co catalysts are utilized in a method for producing hydrocarbons by a Fischer-Tropsch mechanism. The hydrocarbon producing method includes providing a catalyst of a manganese oxide-based octahedral molecular sieve nanofibers with an active catalyst component of at least one of iron, cobalt, nickel, copper, manganese, vanadium, zinc, and mixtures thereof, and further containing an alkali metal. The formation of iron carbides and cobalt carbides by exposing the catalyst to conditions sufficient to form those carbides is also taught. After the catalyst has been appropriately treated, a carbon source and a hydrogen source are provided and contacted with the catalyst to thereby form a hydrocarbon containing product. The catalyst have high catalytic activity and selectivity (75%) for C2+ hydrocarbons in both CO hydrogenation and CO2 hydrogenation. Highly selective syntheses of high value jet fuel, C2-C6 alkenes, C2-C6 carboxylic acids; α-hydroxylic acids and their derivatives have been realized by tuning the oxidation ability of OMS-2 supports and by doping with Cu2+ ions.

Owner:UNIV OF CONNECTICUT +1

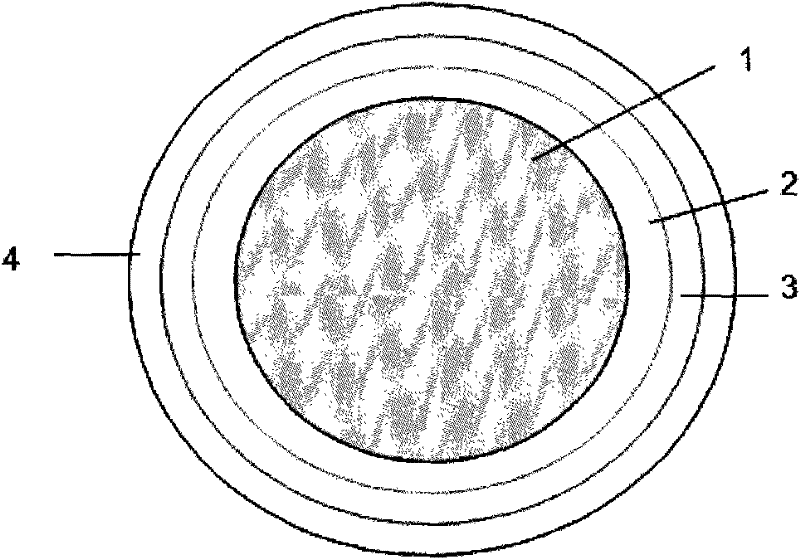

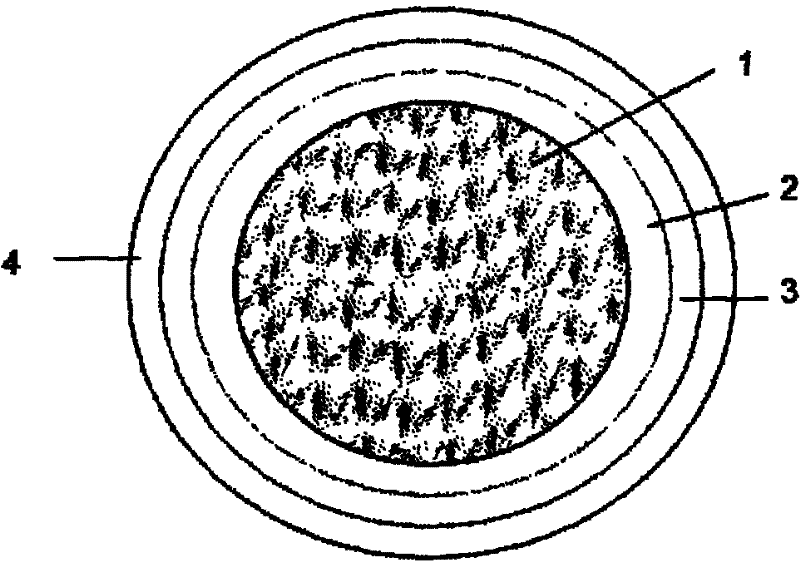

Mining hard alloy

InactiveCN102453822AImprove wear resistanceGive full play to the role of key partsPosition effectAlloy

The invention relates to a mining hard alloy, in particular to a hard alloy specially applied to a rock drilling tool. The hard alloy is mainly prepared from tungsten carbide and cobalt carbide by sintering, and the hard alloy is characterized in that the whole hard alloy is divided into more than two layers from inside to outside, cobalt contents and particle sizes of the layers are different. Thus the hard alloy has the optimal abrasion resistance and toughness, rock drilling efficiency and service life are effectively improved. Meanwhile, key position effect of cobalt is fully exerted, and useful effect of the hard alloy is played, thus the effect of cobalt saving is achieved.

Owner:山东凿岩钎具有限公司

High-polymerization-degree polyvinyl chloride wear-resistant sole material

InactiveCN106432982AImprove wear resistanceConducive to lightweightSolesWear resistantPolyvinyl chloride

The invention discloses a high-polymerization-degree polyvinyl chloride wear-resistant sole material. The sole material is prepared from, by weight, 100 parts of HPVC (high-polymerization-degree polyvinyl chloride), 10-20 parts of nitrile butadiene rubber, 40-60 parts of dioctyl phthalate, 10-20 parts of white carbon black, 5-15 parts of calcium carbonate filler, 5-10 parts of graphene and 2-5 parts of tungsten-cobalt carbide hard alloy particles. The high-polymerization-degree polyvinyl chloride wear-resistant sole material can improve wear resistance and can realize light weight, tensile strength is greater than 20MPa, elongation at break is greater than 370%, abrasion loss is smaller than 0.15cm<2> / 2km, stripping strength is greater than 4.8kN / m, and breaking strength is greater than 47kN / m.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Low-density microcellular polyurethane wear-resisting sole material

The invention discloses a low-density microcellular polyurethane wear-resisting sole material. The low-density microcellular polyurethane wear-resisting sole material is prepared from the following components in parts by weight: 100 parts of polyester polyol, 5 to 20 parts of diol chain extender, 0.5 to 1.2 parts of silicone surfactant, 0.3 to 1.0 part of tertiary amine catalyst, 0 to 0.5 part of metal catalyst, 5 to 10 parts of graphene fiber and 2 to 5 parts of tungsten-cobalt carbide hard alloy particles. According to the material, the defect of plastic feeling caused by reduction of the density of a backing material of an ordinary sole is improved, and light weight is improved while the wear resistance can be improved.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Process for preparing a fischer-tropsch catalyst

ActiveUS20150273443A1Organic compound preparationOxygen compounds preparation by reductionCobalt metalHydrogen

A process for preparing a cobalt-containing hydrocarbon synthesis catalyst includes, in a carbide formation step, treating an initial catalyst precursor comprising a catalyst support supporting cobalt and / or a cobalt compound, with a CO containing gas at a temperature T. T is from 200° C. to 280° C. The cobalt or cobalt compound is converted to cobalt carbide thereby obtaining a cobalt carbide containing catalyst precursor. The CO containing gas (when it contains H2) does not have a CO to H2 molar ratio equal to or less than 33:1. The carbide formation step is carried out under non-oxidative conditions. In a subsequent activation step, the cobalt carbide containing catalyst precursor is subjected to treatment with a hydrogen containing gas at a temperature T2. T2 is at least 300° C. The cobalt carbide is converted to cobalt metal thereby activating the cobalt carbide containing catalyst precursor and obtaining a cobalt-containing hydrocarbon synthesis catalyst.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Self-lubricating abrasion-resistant coating and preparation method thereof

The invention discloses a self-lubricating abrasion-resistant coating. The coating comprises the following components in percentage by weight: 60-80% of tungsten cobalt carbide, 10-30% of copper and the balance of fluoride; the thickness of the coating is 100-500mu m. The preparation method of the self-lubricating abrasion-resistant coating comprises the following steps: a, ball milling and mixing tungsten cobalt carbide powder, copper powder and fluoride powder in an anhydrous ethanol medium, wherein the ball milling rotating speed is controlled at 100-150r / min and the mixing time is 24-48 hours; b, drying the mixed powder at 40-80 DEG C, carrying out vacuum sintering on the dried powder at a sintering temperature of 1000-1200 DEG C and carrying out heat preservation for 1-3 hours; c, crushing a block formed after sintering into powder of which the particle size is not more than 75mu m; and d, preparing the coating by using the powder obtained in the step c as a raw material by virtue of an atmospheric plasma spraying method.

Owner:郴州市泰益表面涂层技术有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com