Angstrom-scale carbide and preparation method thereof

A technology of carbide and metal carbide, applied in the field of materials, can solve the problems of underutilization and inability to fully exert the synergistic effect of precious metals, and achieve the effect of reducing preparation costs and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

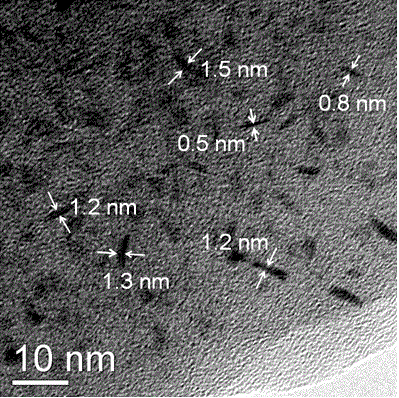

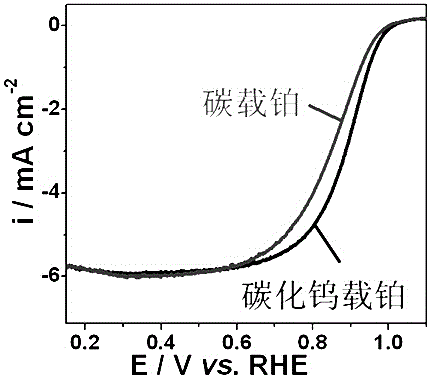

[0023] Take 0.00003 moles of ammonium metatungstate, dissolve it in 100 ml of water, add 10 g of D201 macroporous strongly basic anion exchange resin, stir evenly for 6 hours, pour out the liquid phase, and keep the solid phase. The solid phase was dried in a drying oven at 80 °C for 5 hours, then placed in a tube furnace, and calcined at 800 °C for 1 hour under the protection of nitrogen to obtain Angstrom scale tungsten carbide (rod), such as figure 1 As shown, its average width is 0.9 nm. Such as figure 2 As shown, the mass activity of the obtained tungsten carbide-supported platinum catalyst for oxygen reduction is 237 mA / mg platinum, which is 2.0 times that of the commercial carbon-supported platinum catalyst (TKK, Japan, 120 mA / mg platinum) ( figure 2 ).

Embodiment 2

[0025] Change the amount of ammonium metatungstate substance to 0.000006 moles, and other steps are the same as in Example 1. Angstrom-scale tungsten carbide (dot-like) was obtained with an average diameter of 0.5 nm.

Embodiment 3

[0027] Take 0.00000014 moles of ammonium metatungstate, dissolve it in 10 ml of water, add 10 g of D314 macroporous weakly basic anion exchange resin, stir evenly for 0.3 hours, pour out the liquid phase, and keep the solid phase. Dry the solid phase in a drying oven at 50 °C for 48 hours, then place it in a tube furnace, and bake it at 600 °C for 24 hours under the protection of nitrogen to obtain Angstrom scale tungsten carbide (dot shape), with an average diameter of 0.3 Nano.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com