Co-nitrogen co-doped carbon aerogel catalyst for fuel cell and preparation method thereof

A carbon aerogel, fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of increased mass transfer resistance, difficulty in breaking through stability and taking into account the activity, etc., to reduce the preparation cost and achieve excellent electrocatalytic activity. and stability, the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

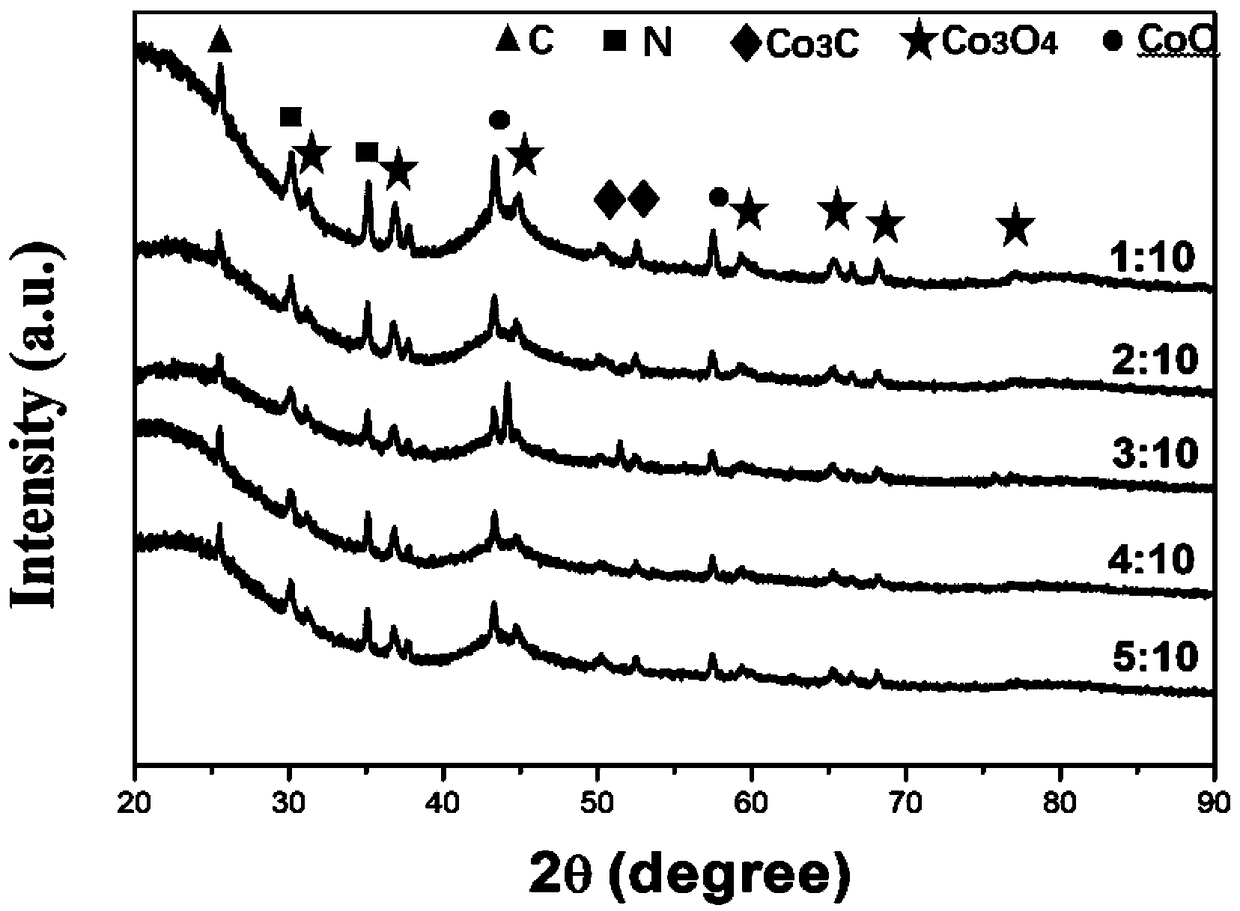

[0032] The preparation method of the non-precious metal catalyst for the fuel cell of the present invention comprises two major steps. First, the hydrothermal reaction method is used to synthesize Co-phen by controlling the pH, reaction temperature and time of the reaction, and then the carbon airgel is synthesized by the sol-gel method; Then Co-phen was coated with carbon aerogel, and the composite material obtained in the previous step was 2 Preparation of cobalt-nitrogen co-doped carbon airgel catalyst by calcination at high temperature. Specific steps are as follows:

[0033] (1) Preparation of metal-organic framework complexes (Co-phen).

[0034] Such as Image 6 shown. A: Pyridine 2,6-dicarboxylic acid dissolved in 20ml of methanol, B: Co(NO 3 ).6H 2 O and o-phenanthroline were dissolved in a mixed solution of 15ml of methanol and 20ml of deionized water, and the completely dissolved A was added to the completely dissolved B solution, stirred at room temperature for...

Embodiment 1

[0044] (1) Weigh Co-phen and carbon airgel with a ratio of 1:10 into a 100ml beaker, add 20-40ml of ethylene glycol, and stir it ultrasonically to dissolve it completely;

[0045] (2) Add 0.5-5mol / L NaOH solution to adjust the pH to 7-10, stir at room temperature for 12-24h, and dry by suction;

[0046] (3) Put the composite material obtained in (2) in a porcelain boat, and put it in N 2 Under the atmosphere, use a tube furnace to treat it at a high temperature of 600-800° C. for 2-5 hours to obtain a non-precious metal catalyst.

Embodiment 2

[0048] (1) Weigh Co-phen and carbon airgel with a ratio of 2:10 into a 100ml beaker, add 20-40ml of ethylene glycol, and stir ultrasonically to completely dissolve it;

[0049] (2) Add 0.5-5mol / L NaOH solution to adjust the pH to 7-10, stir at room temperature for 12-24h, and dry by suction;

[0050] (3) Put the composite material obtained in (2) in a porcelain boat, and put it in N 2 Under the atmosphere, use a tube furnace to treat it at a high temperature of 600-800° C. for 2-5 hours to obtain a non-precious metal catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com