Catalyst for preparing low-carbon mixed alcohol through carbon oxide hydrogenation and preparation method of catalyst

A technology of low-carbon mixed alcohols and catalysts, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reduction and catalyst preparation Problems such as lengthy steps and difficulty in alcohol separation, to achieve the effect of dense particles, good space-time yield and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 0.8g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.46g terephthalic acid (H 2 BDC) was placed in a 150mL Shrek tube, and a mixed solution formed by adding 20mL N,N-dimethylformamide and 5mL absolute ethanol was added, sealed and heated to 110°C for 15h, then filtered while hot, and 100mL N,N- DMF was washed three times, and finally dried in air at 100° C. for 6 h to obtain Co-MOF-71 metal-organic framework material.

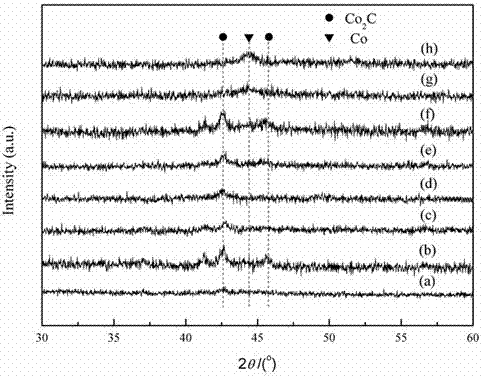

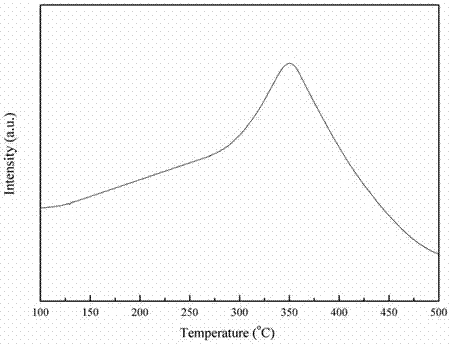

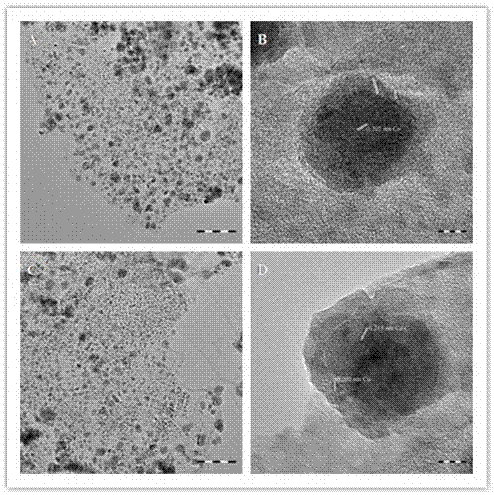

[0035] 1.48g Co-MOF-71 was placed in a fixed-bed stainless steel reactor, and heated to 500°C for 8 hours in an Ar atmosphere at a heating rate of 5°C / min to obtain a carbon-supported Co intermediate material. The mass percentage of Co element in this material was determined to be 27.0% by atomic absorption spectroscopy (AAS). After the pyrolysis is completed, cool down to room temperature, cut into pure CO gas with a space velocity of 24L / h / g-sample, increase the pressure to 2MPa, raise the temperature to 250°C at a heating rate of 1°C / min, k...

Embodiment 2

[0039] 0.8g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.46g terephthalic acid (H 2 BDC) was placed in a 150mL Shrek tube, a mixed solution formed by adding 40mL N,N-dimethylformamide and 10mL absolute ethanol was added, sealed and heated to 120°C for 12h, then filtered while hot, and 100mL N,N- DMF was washed three times, and finally dried in air at 80° C. for 12 hours to obtain Co-MOF-71 metal-organic framework material.

[0040] 1.48g Co-MOF-71 was placed in a fixed-bed stainless steel reactor, and heated to 600°C for 4 hours in an Ar atmosphere at a heating rate of 1°C / min to obtain a carbon-supported Co intermediate material. The mass percentage content of Co element was determined to be 33.1% by AAS characterization. After the pyrolysis was completed, the temperature was lowered to room temperature, and the pure CO gas with a space velocity of 30L / h / g-sample was cut in, and the pressure was increased to 3MPa. The heating rate was raised to 280 °C, kept for ...

Embodiment 3

[0044] 0.8g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.46g terephthalic acid (H 2 BDC) was placed in a 150mL Shrek tube, and a mixed solution formed by adding 30mL N,N-dimethylformamide and 10mL absolute ethanol was added, sealed and heated to 110°C for 15h, then filtered while hot, and 100mL N,N- DMF was washed three times, and finally dried in air at 80° C. for 12 hours to obtain Co-MOF-71 metal-organic framework material.

[0045] According to the following steps to prepare carbon-supported Co&Co with a mass content of 14.1% silica additives 2 Catalyst C: Weigh 0.070g of tetraethyl orthosilicate and place it in 1.58g of absolute ethanol to form a mixed solution, add 0.37g of Co-MOF-71, stir at room temperature for 10min, then add 0.1g of ammonia water, and then in air at 80°C After drying for 12 hours, the obtained material was then placed in a fixed-bed reactor, and the temperature was raised to 500°C under Ar at 5°C / min and kept for 8h. The mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com