Method for manufacturing tungsten/ cobalt carbide composite powder with nanostructure

A composite powder and nanostructure technology, which is applied in the field of preparation of nanostructured WC/Co composite powder, can solve the problem that it is difficult to control the grain size and particle size distribution of WC, reduce, increase the amount of carbonized gas, and it is difficult to evenly distribute the two phases. Compound powder and other problems, to achieve the effect of uniform product particle size distribution, narrow particle size distribution range, and safe and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

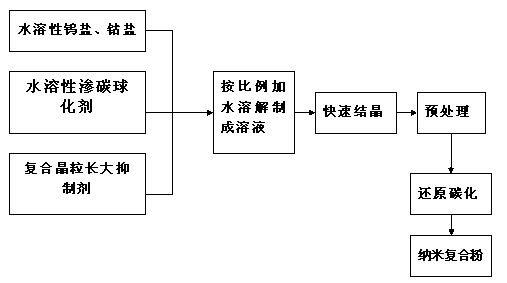

Image

Examples

example 1

[0030] Step 1: Mix 55kg ammonium metatungstate (AMT), 40kg Co(NO 3 ) 2 , 3kg of starch and 2kg of water-soluble compound grain growth inhibitor are dissolved in 300kg of water to prepare a mixed aqueous solution;

[0031] Step 2: performing rapid crystallization of the mixed aqueous solution obtained in step 1;

[0032] Step 3: pretreating the crystals obtained in step 2, the pretreatment temperature is 500°C, to obtain spherical powder;

[0033]Step 4: The powder material obtained after step 3 needs to undergo reduction synthesis and carbon adjustment at a temperature of 900°C to prepare a tungsten carbide / cobalt composite powder material with a nanostructure.

[0034] The ultrafine nanostructure tungsten carbide / cobalt composite powder material produced by the process of Example 1 has a narrow particle size distribution range, good uniformity, and an average grain size ≤ 80nm.

example 2

[0036] Step 1: Dissolve 92kg of ammonium paratungstate (APT), 3kg of cobalt oxalate, 4kg of sugar and 1kg of water-soluble chromium salt in 400kg of water to prepare a mixed aqueous solution;

[0037] Step 2: performing rapid crystallization on the mixed aqueous solution obtained in step 1; using the solution high-pressure spray rapid crystallization method to realize the nanometerization of powder crystal grains;

[0038] Step 3: pretreat the crystals obtained in step 2 at a pretreatment temperature of 700°C to obtain spherical powder; the water-soluble carburizing nodulizing agent will produce obvious foaming after pyrolysis between 250-300°C. According to the process characteristics, the process of passing through the foaming temperature point at a slow speed is adopted, so in step 3, when the heating temperature is below 300°C, the heating rate is 1-5°C / min, and when the heating temperature is above 300°C, the heating rate is 5°C / min. ~10°C / min. In order to realize the ab...

example 3

[0042] Step 1: Mix 56kg ammonium paratungstate (APT), 40kgCoCl 2 , 3.9kg of polyethylene glycol (PEG) and 0.1kg of water-soluble vanadium salt are dissolved in 500kg of water to prepare a mixed aqueous solution;

[0043] Step 2: performing rapid crystallization of the mixed aqueous solution obtained in step 1;

[0044] Step 3: pretreating the crystals obtained in step 2, the pretreatment temperature is 500°C, to obtain spherical powder;

[0045] Step 4: The powder material obtained after step 3 needs to undergo reduction synthesis and carbon adjustment at a temperature of 950°C to prepare a tungsten carbide / cobalt composite powder material with a nanostructure.

[0046] In order to obtain a better process effect, after the pretreatment stage, complete tungsten carbide crystals are not formed, and there are still a large amount of free carbon, which requires reduction synthesis and carbon adjustment at a higher temperature to prepare nanostructured tungsten carbide. Tungsten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com