Method for catalytic decomposition of hydrogen sulfide by composite type catalyst

A catalytic decomposition and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problems of high temperature required, low light utilization rate, energy consumption, etc., to achieve mild reaction conditions, The effect of high decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

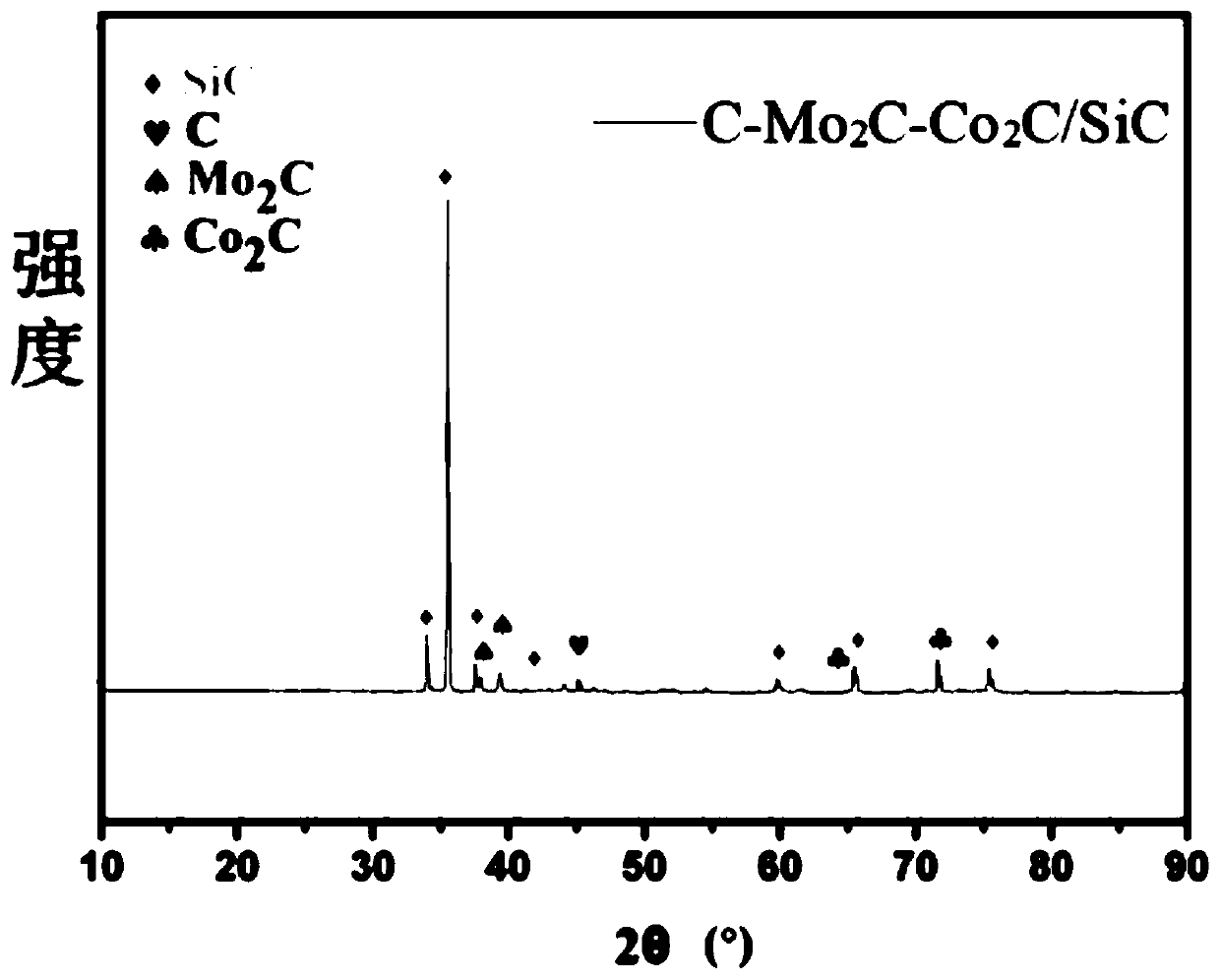

Image

Examples

Embodiment 1

[0021] The specific steps of alkali treatment of silicon carbide: put silicon carbide into an alkali solution of a certain concentration, the treatment temperature is 50-90°C, and the treatment time is 1-6 hours; the alkali solution is sodium hydroxide or potassium hydroxide solution At least one of them, the molar concentration of the alkali solution is 0.2-4 mol / L.

[0022] A kind of preparation method of composite catalyst:

[0023] Step 1: Weigh 0.276g of ammonium molybdate and 0.800g of cobalt nitrate hexahydrate into a beaker, add 40ml of pure water, and stir to dissolve.

[0024] In the second step, 2 g of alkali-treated silicon carbide is weighed and added to the solution in the first step, and stirred on a magnetic stirrer to form a mixed solution.

[0025] The third step is to put the mixed liquid into a constant temperature water bath, firstly age it at 40°C for 30 minutes, then evaporate it at 70°C for 4 hours, and then put it into an oven and dry it at a constant...

Embodiment 2

[0033]The composite microwave catalyst prepared according to Example 1 is applied to the decomposition of catalytic hydrogen sulfide, specifically: first, asbestos is filled in the reaction quartz tube of the microwave reactor to facilitate fixing the catalyst bed, and then the prepared in Example 1 The composite catalyst is placed in a quartz tube to form a microwave catalyst bed, a thermocouple is inserted into the center of the catalyst bed, and then a mixed gas of hydrogen sulfide is introduced to cause a gas-solid phase catalytic reaction to achieve the purpose of decomposing hydrogen sulfide.

[0034] The mixed gas is provided by Dalian Date Gas Co., Ltd., and consists of nitrogen and hydrogen sulfide, wherein the hydrogen sulfide content is 15vol%.

[0035] The gas chromatograph was GC-7890A manufactured by Agilent Corporation, USA.

[0036] The range of microwave power is 0-1350W, preferably 300-800W, and the frequency is 2450MHz.

[0037] Details are as follows:

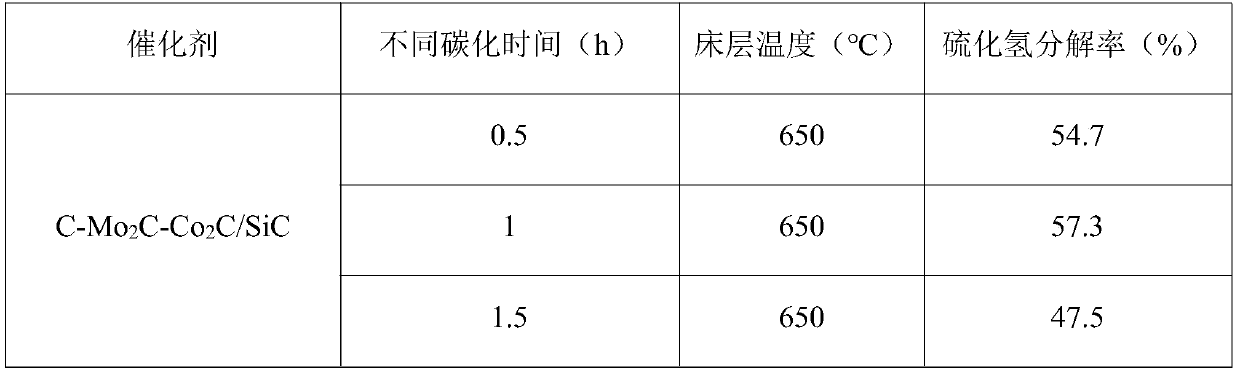

[...

Embodiment 3

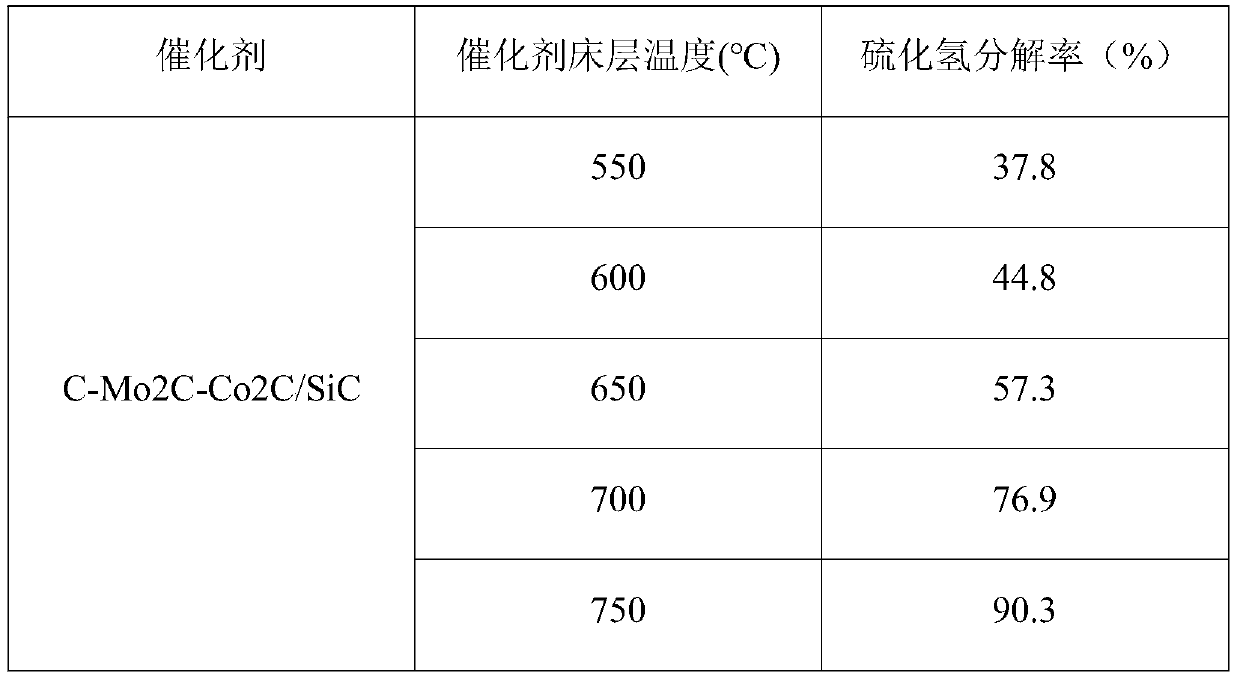

[0043] In this example, different kinds of composite catalysts were selected to carry out the hydrogen sulfide decomposition reaction experiment. The dosage of the composite catalyst was 2 g, the mesh size was 40-60 mesh, and the bed temperature of the catalyst was 650°C. The carbonization time was all 1 hour. Hydrogen sulfide mixed gas (use 15vol% H in the present invention 2 S and 85vol% N 2 The mixed gas was tested) the inlet flow rate was 60ml / min, the reaction pressure was normal pressure, and the temperature of the reaction bed was regulated by adjusting the microwave power. The experimental results are shown in Table 2. Table 2 shows the decomposition rate of different catalysts for microwave catalytic decomposition of hydrogen sulfide.

[0044] Table 2

[0045] catalyst

[0046] C-Mo 2 C / SiC, C-Co 2 The decomposition rates of C / SiC and C-WC / SiC catalysts were 50.1%, 49.5%, and 47.3% when the bed temperature was 650°C. This shows that different types of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com