A new bionic composite roll manufacturing method with high wear resistance and long service life suitable for repair

A composite roll and manufacturing method technology, applied in the field of roll manufacturing, can solve problems such as alloy segregation in the working layer, large thickness difference between upper and lower layers, coarse grain structure, and poor interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Substrate material: 100% ductile iron;

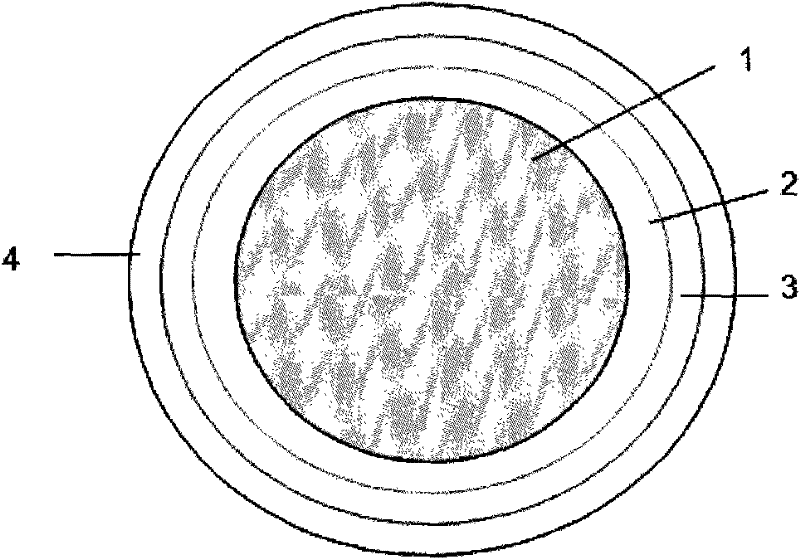

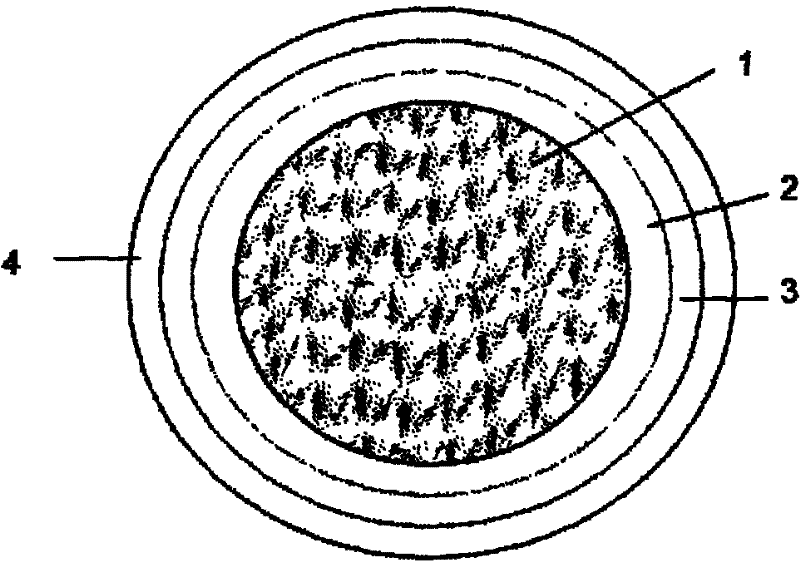

[0020] Transition layer material: The transition layer is divided into three layers, the first layer, the second layer and the third layer from the inside to the outside. 20% WC, 2% Cr, 3% TiC are added to the first layer, and the remaining material is iron; 35% WC, 4% Co, 6% TiC are added to the second layer; the balance is iron. Add 50% WC, 6% Co, 9% TiC to the third layer, and the balance is iron;

[0021] Working layer material: 79% WC, 15% TiC and 6% Co.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com