Manufacturing technology of heat resisting laminating document material

A manufacturing process and high temperature resistant technology, which is applied in the field of anti-counterfeiting materials in the field of public security, and can solve problems such as the inability to meet 135°C

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

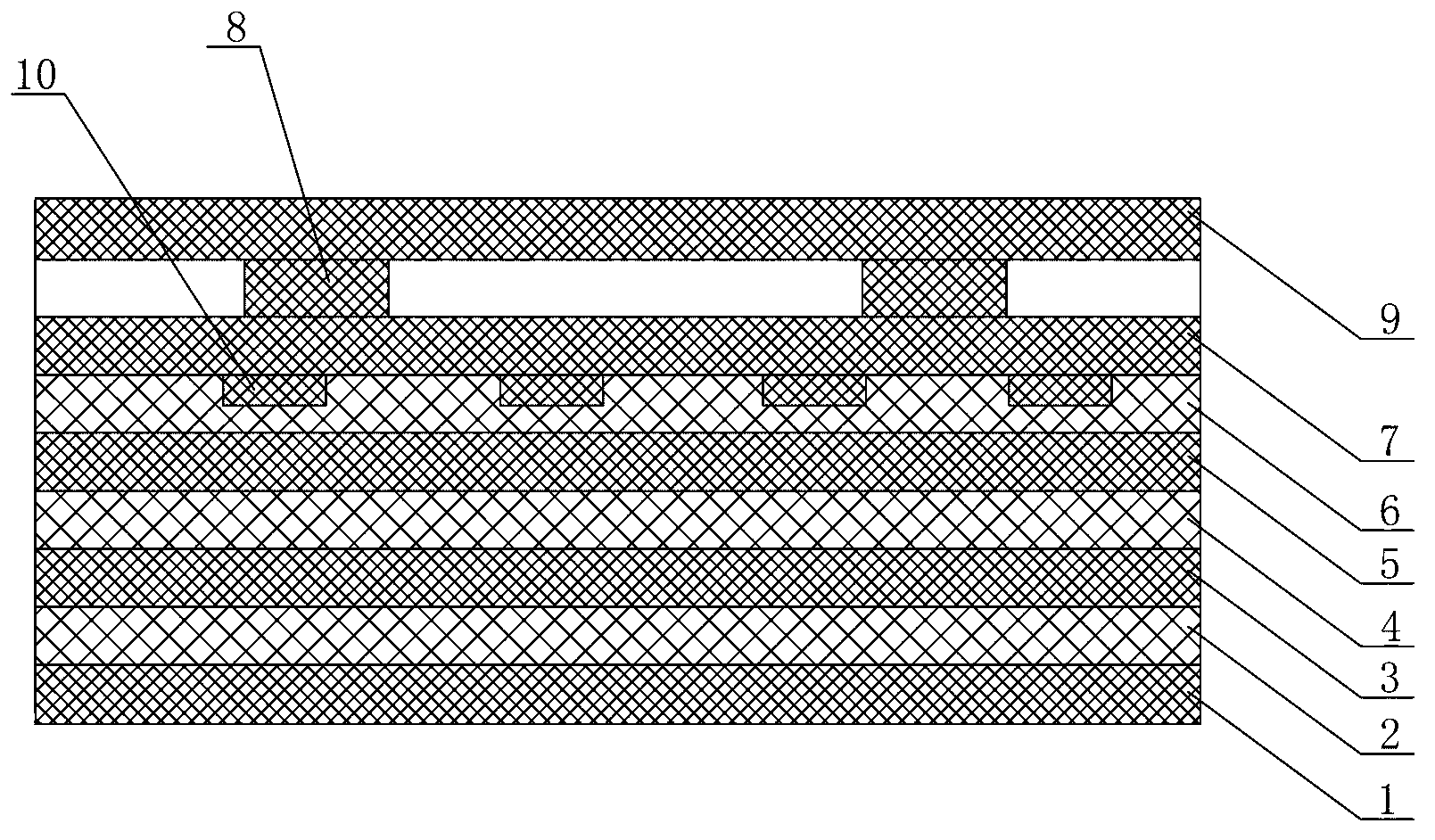

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

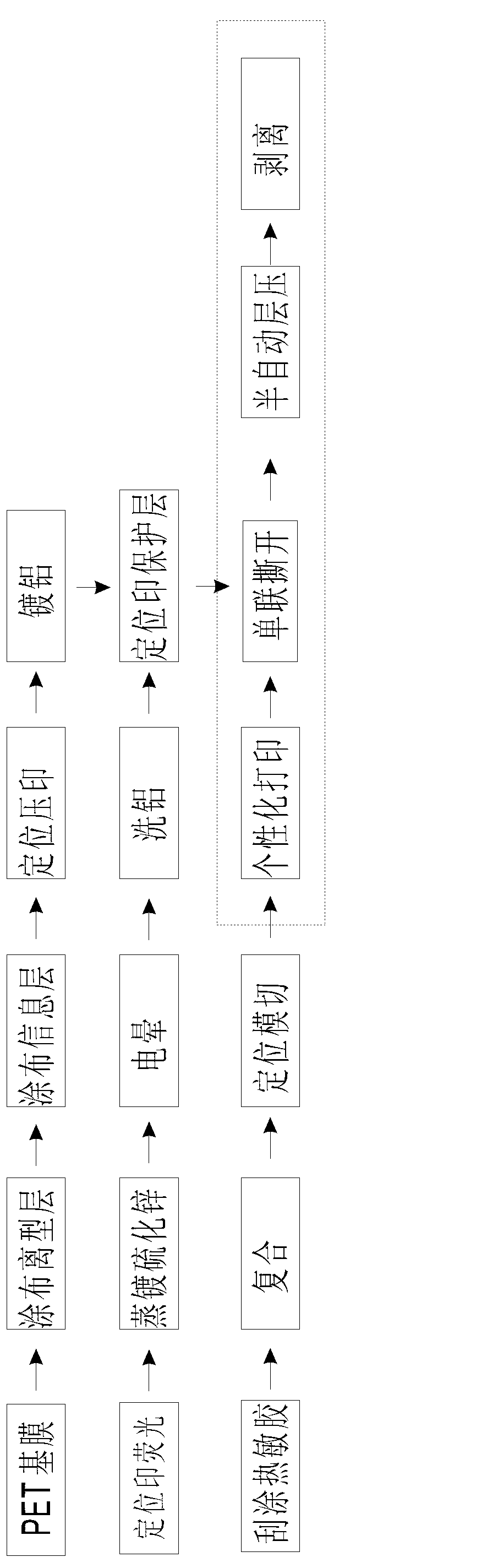

[0032] like figure 1 The manufacturing process of a high-temperature-resistant laminated certificate material shown, the steps are as follows:

[0033] 1) Coat the release layer on the 20μm PET base film, the thickness of the release layer is 1.2~1.5μm; the drying temperature is 100℃~155℃, the speed is 90m / min, drying and winding:

[0034] 2) Coat the information layer on the release layer, the thickness of the information layer is 1.0~1.2 microns; the drying temperature is 100°C~135°C, and the speed is 100m / min;

[0035] 3) After drying and rewinding, use a positioning embossing machine to perform positioning embossing of laser holographic patterns. The embossing temperature is 183°C~188°C, the embossing speed is 32~38m / min, and the molding pressure is 4~4.2 MPa; at the same time, the longitudinal direction is embossed Plain surface tracking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com