Patents

Literature

77 results about "Surface tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

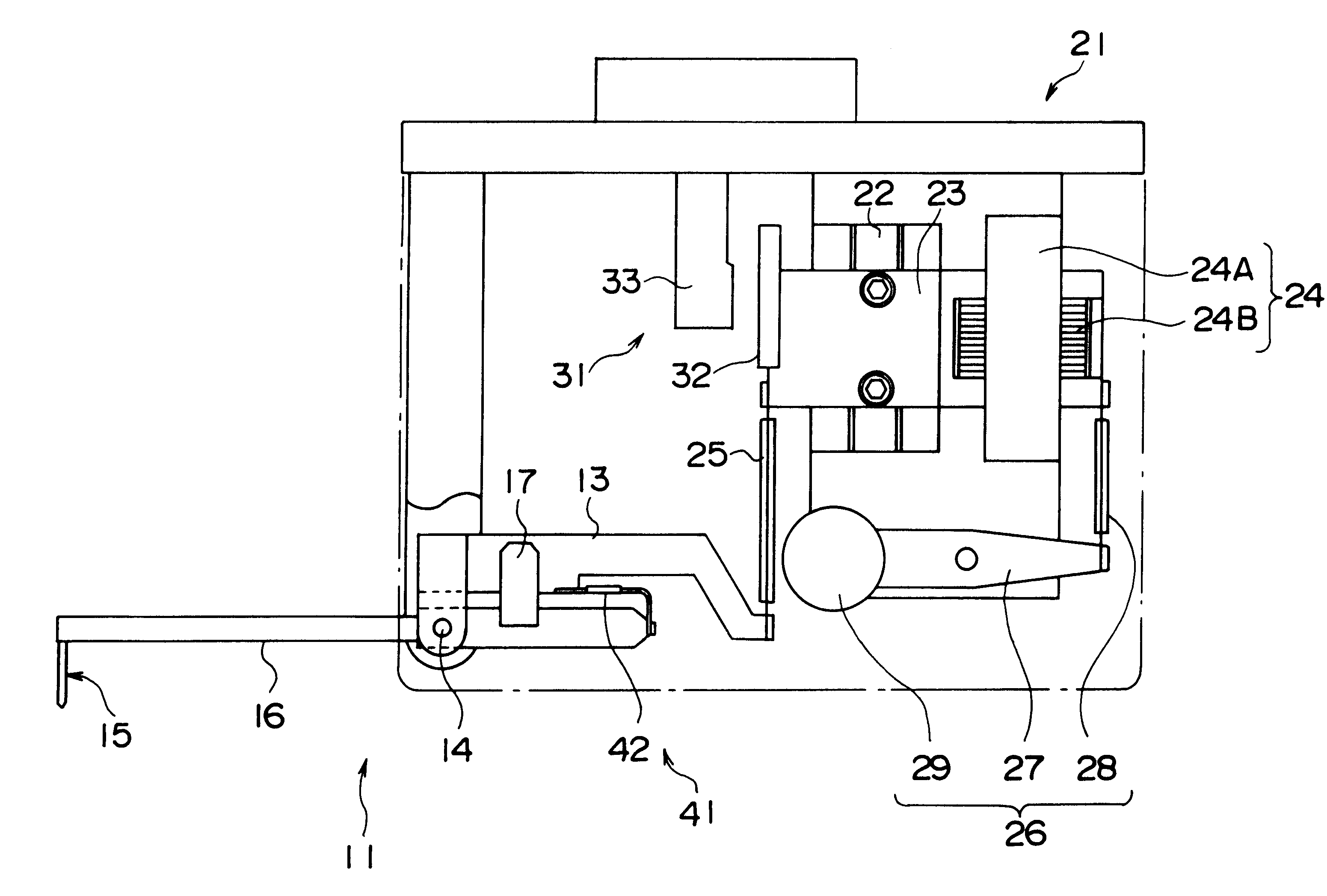

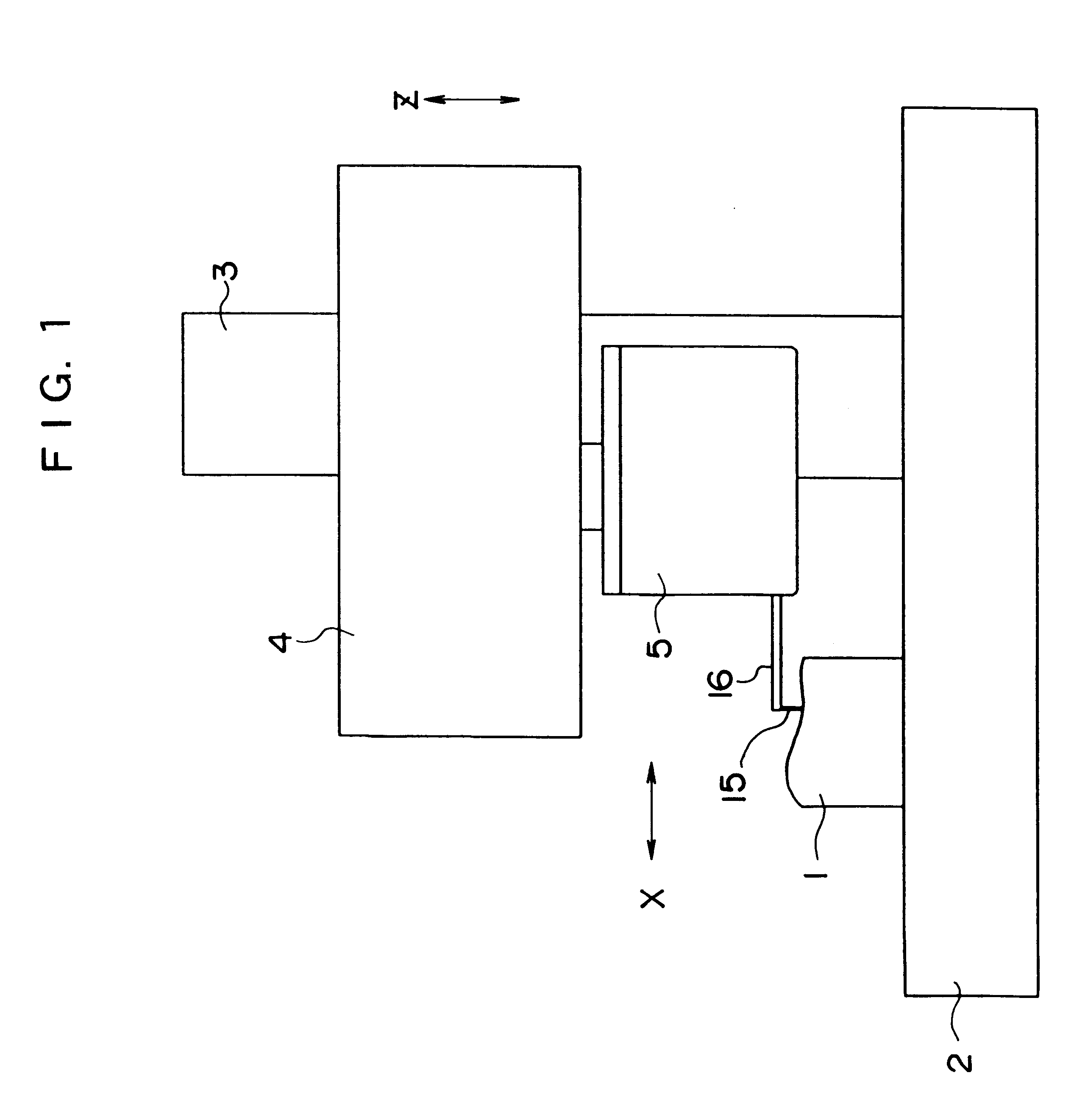

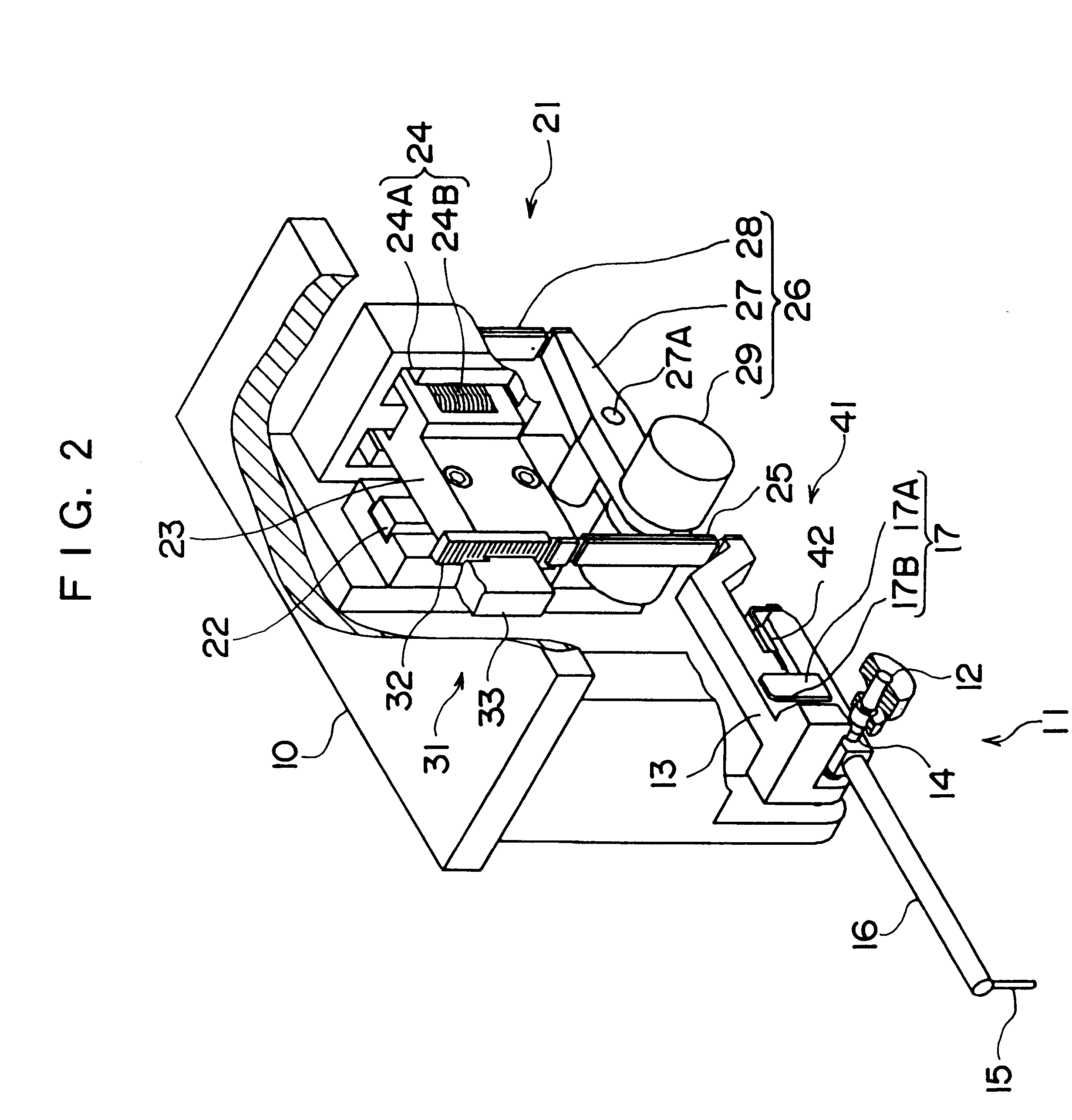

Surface-tracking measuring machine

InactiveUS6295866B1Accurate detectionReduce sensitivityCompasses with pivoted armsMechanical counters/curvatures measurementsResponsivityClassical mechanics

A surface-tracking measuring machine is provided, in which measurement range is enlarged while keeping a measuring force, responsivity, resolution thereof. For the object, the surface-tracking measuring machine has a frame (10), a probe (11) swingably supported by the frame (10) and having a tracer (15) at an end thereof, a measuring force controller (21) for controlling the measuring force applied to the probe, a displacement detector (31) for detecting a displacement of the probe, a measuring force detector (41) for detecting the measuring force applied to the probe, and a controller (51) for comparing a measuring force detected value detected by the measuring force detector and a previously commanded measuring force command value and to control the measuring force controller so that the measuring force detected value is equal to the measuring force command value.

Owner:MITUTOYO CORP

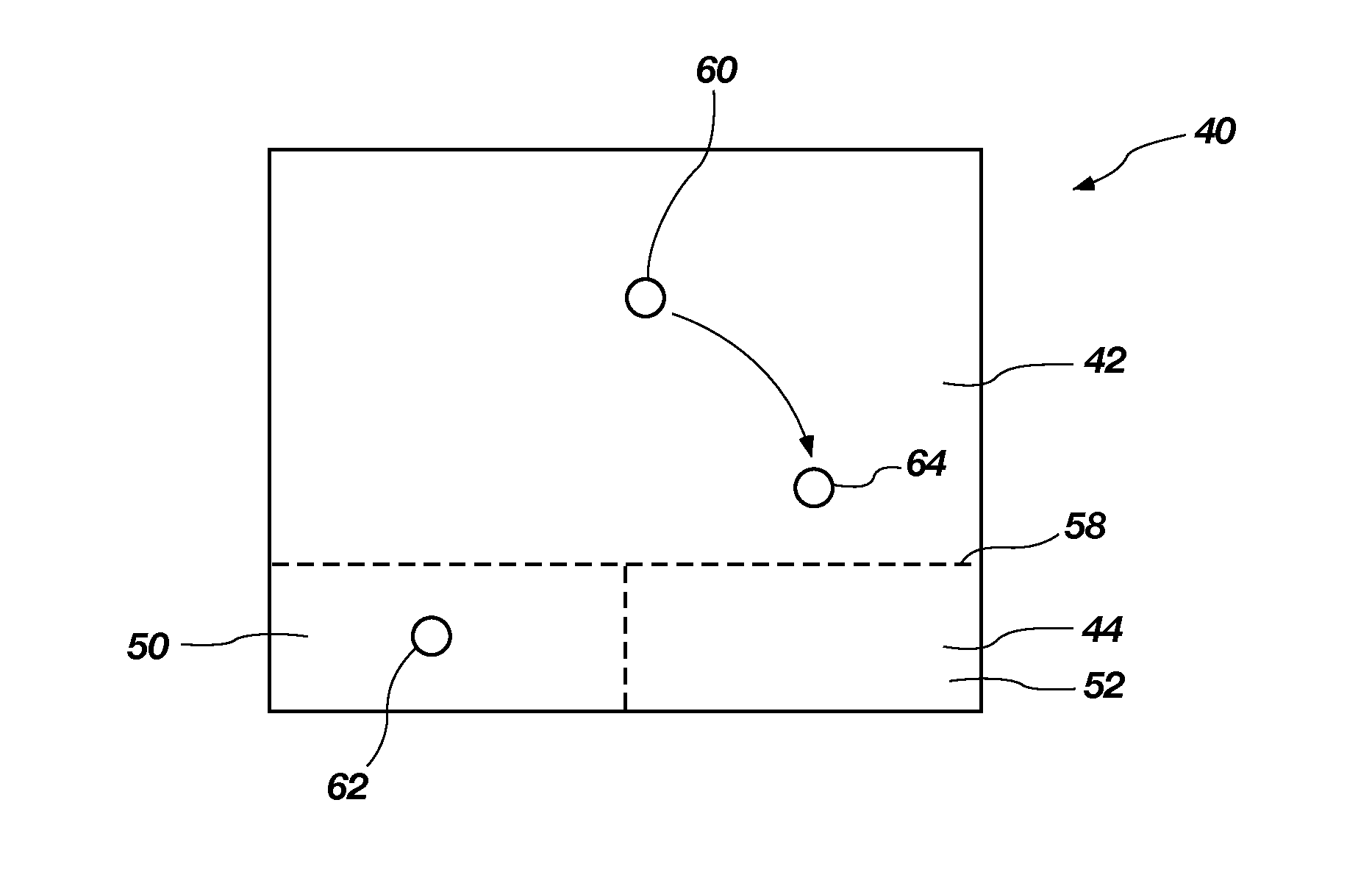

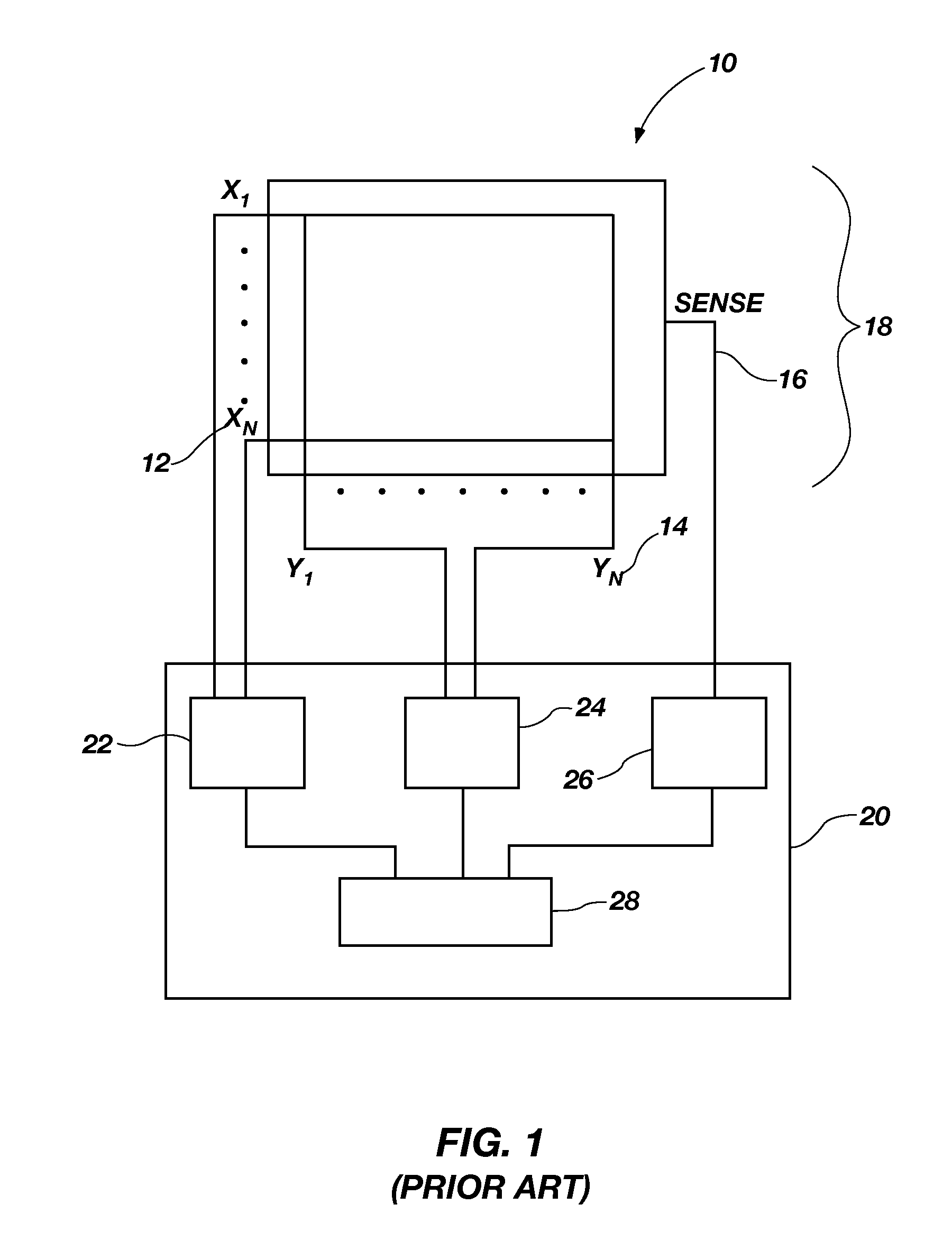

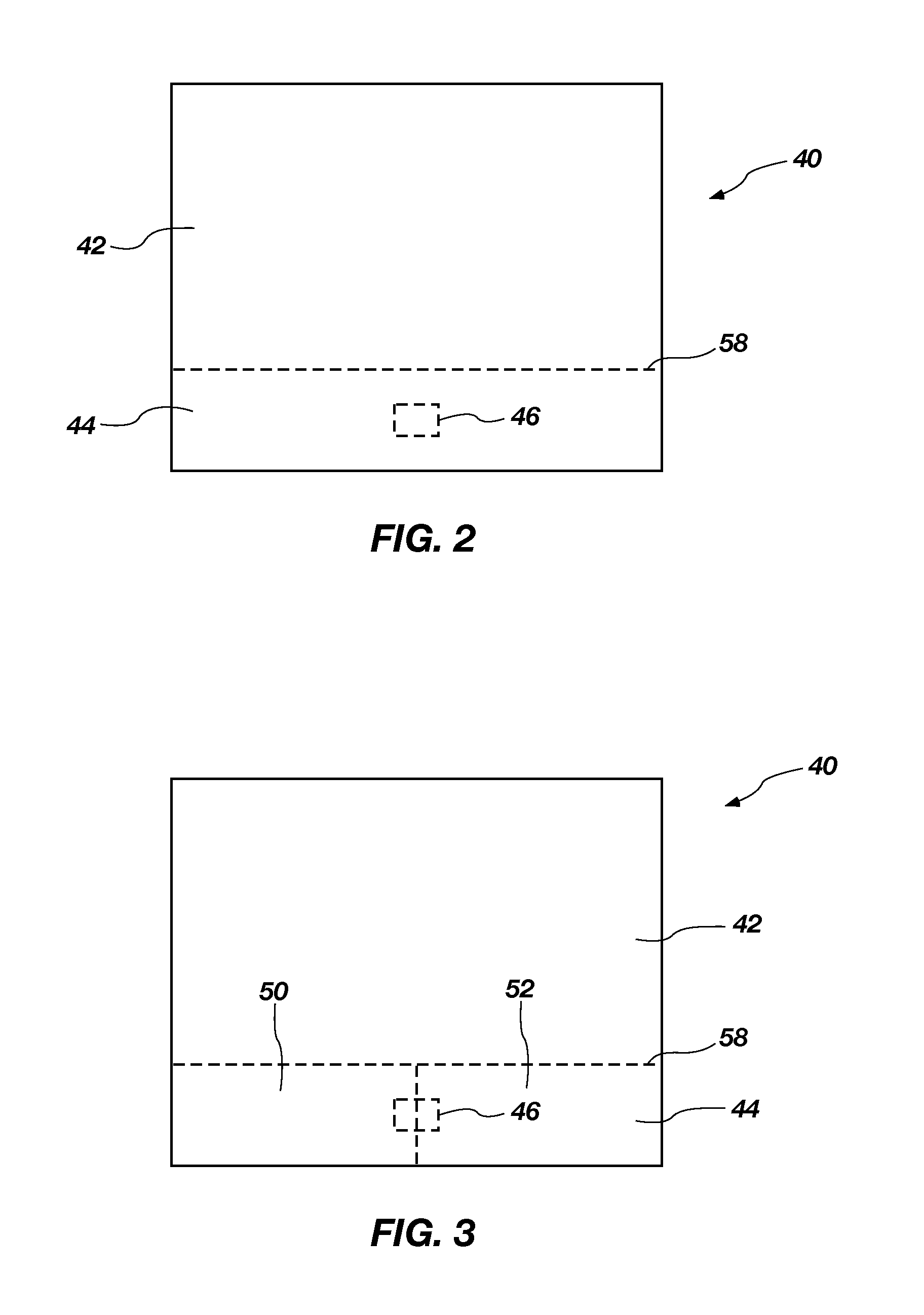

Capacitive touchpad capable of operating in a single surface tracking mode and a button mode with reduced surface tracking capability

A touchpad that operates in two modes, wherein a first mode enables the entire surface of the touchpad to operate in a typical detection single object detection and tracking mode to track the movement of a conductive object such as a finger anywhere on the surface of the touchpad and perform typical touchpad operations such as cursor control, and a second mode of operation wherein a button region of the touchpad is no longer used for the tracking of movement of a finger on the surface of the touchpad, but is instead dedicated to a button function if a finger on the touchpad pushes with sufficient force to activate a switch underneath the touchpad.

Owner:WOOLLEY RICHARD D +1

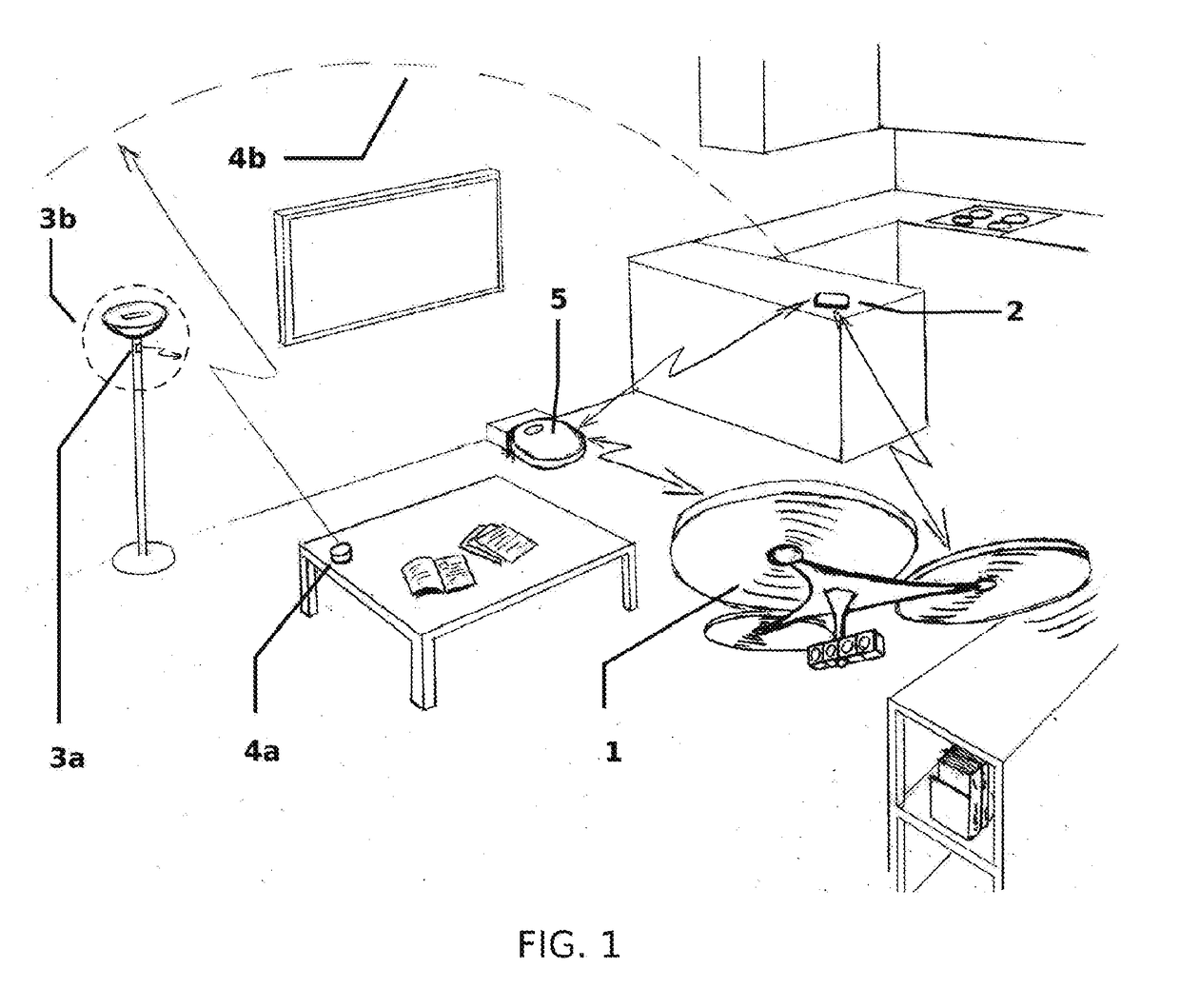

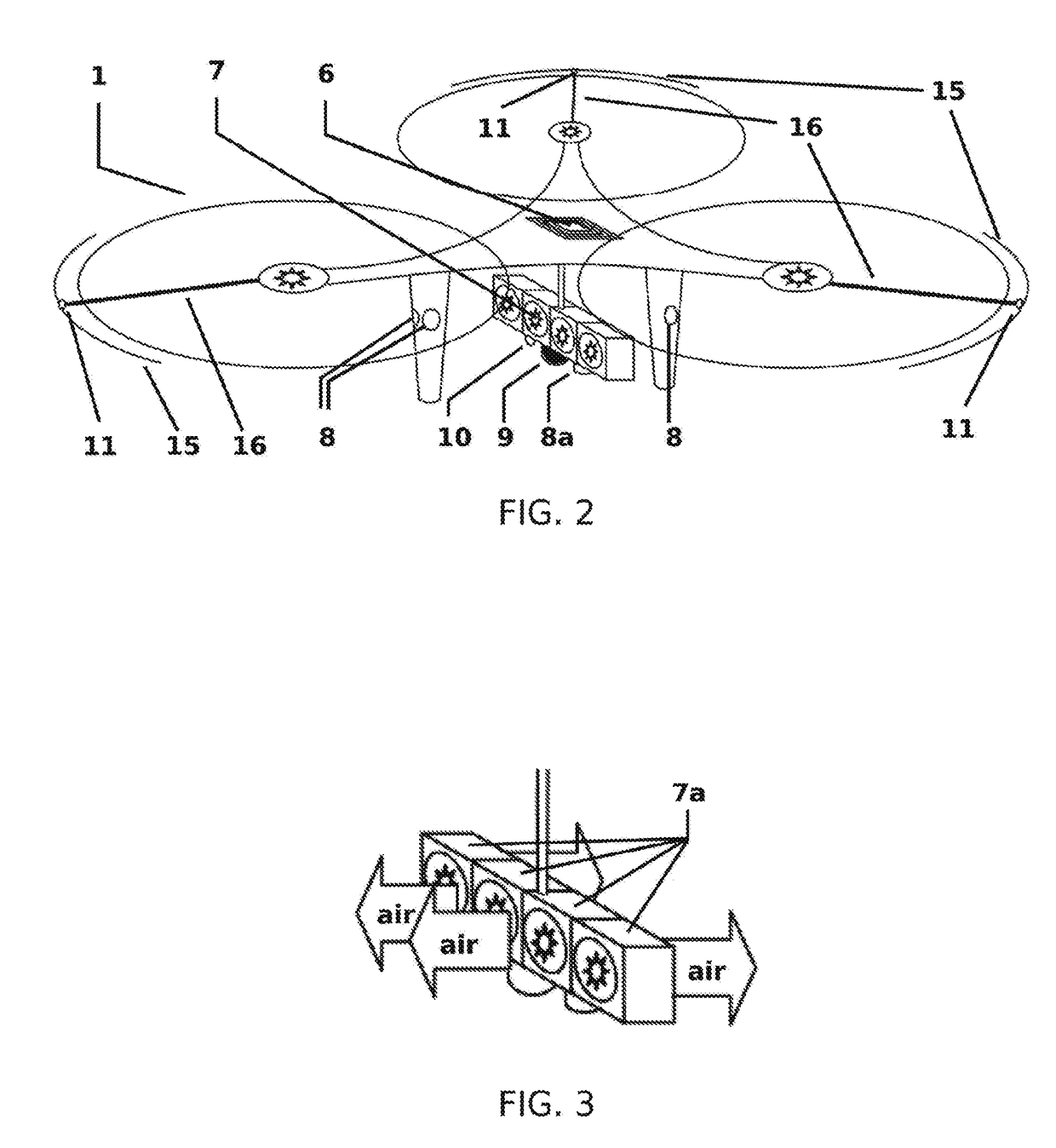

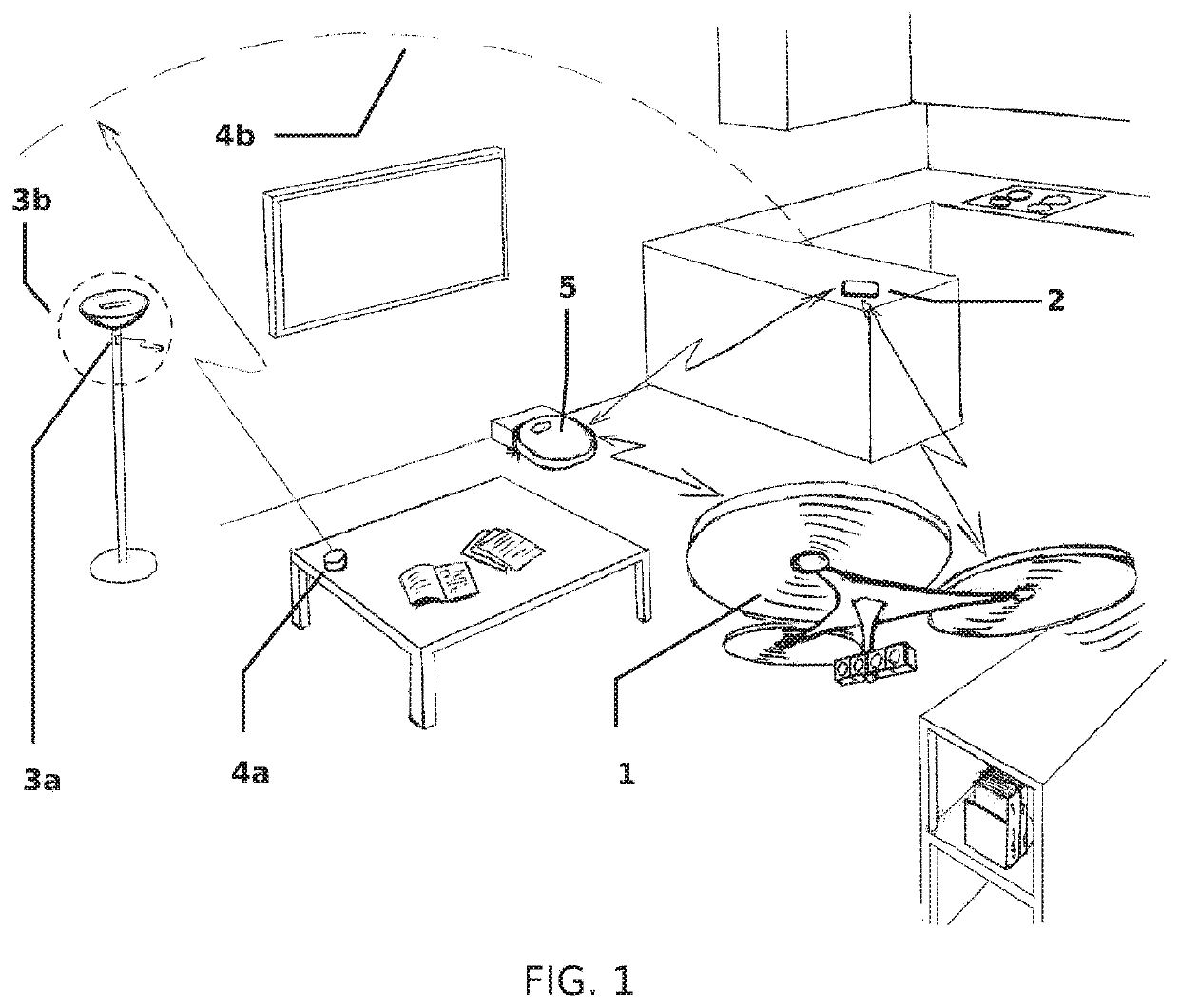

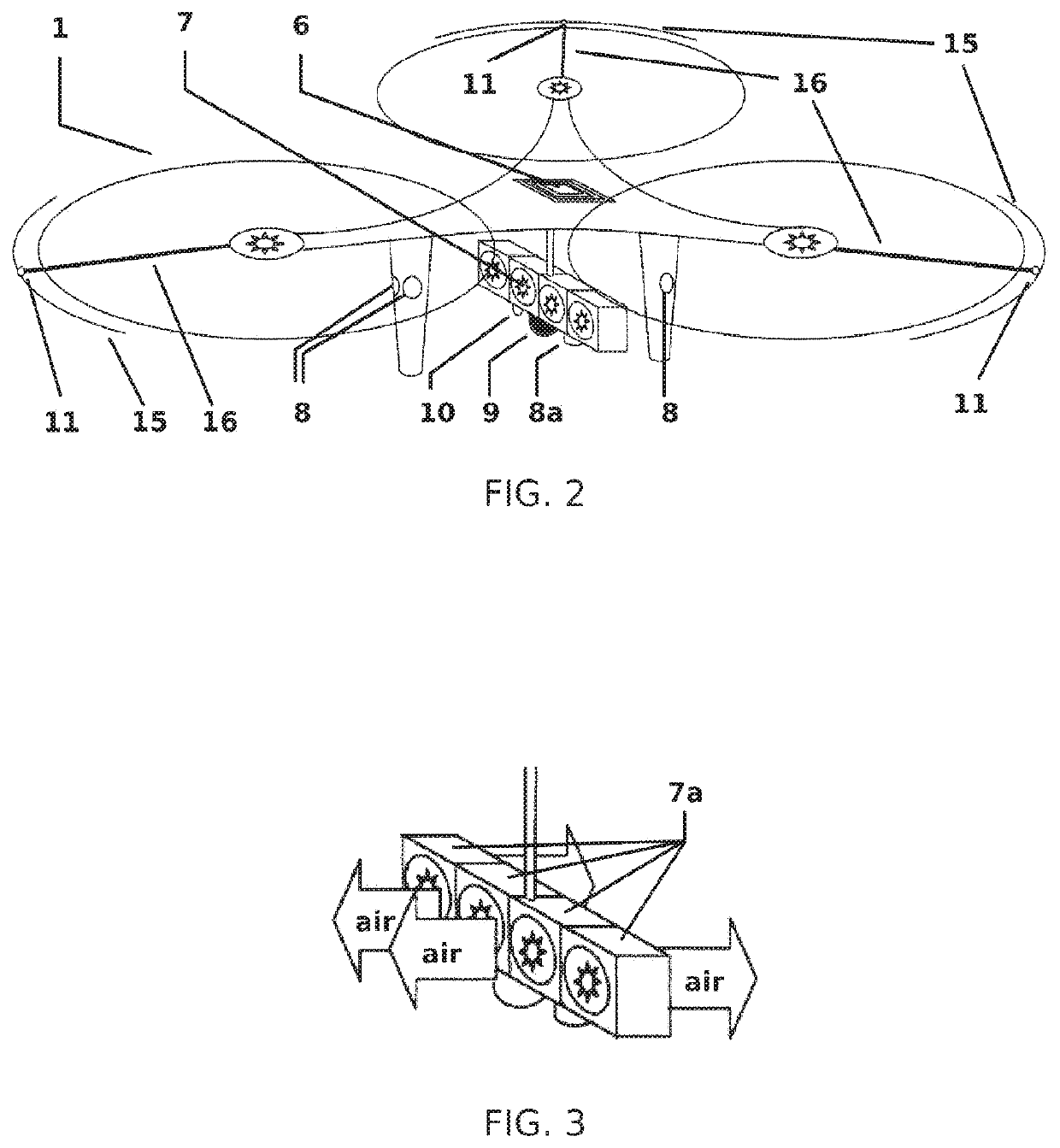

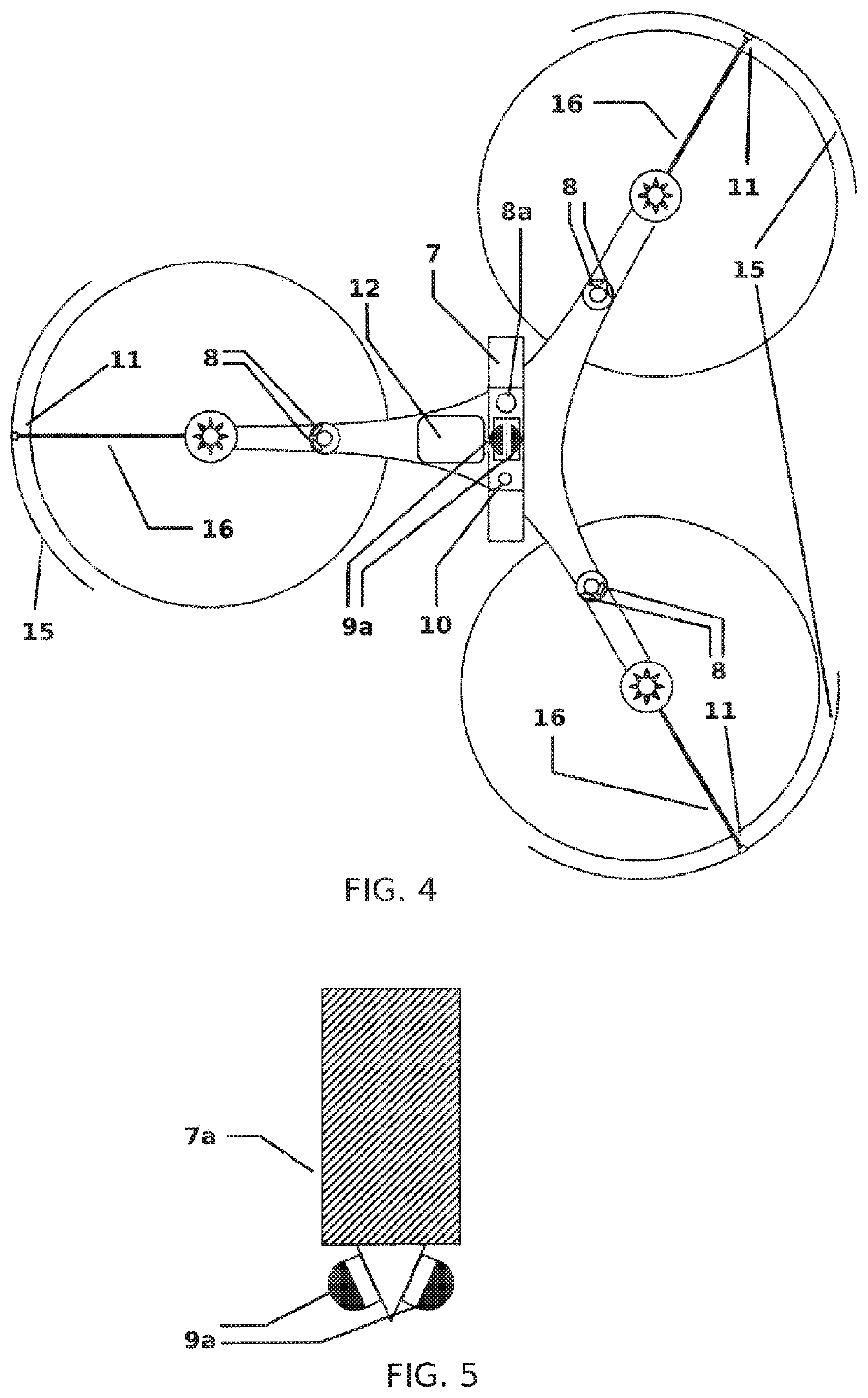

Cleaning drone

ActiveUS20180118337A1Relieve of taskAutonomous decision making processUnmanned aerial vehiclesMotion detectorOn board

A computer-implemented method for managing the flight of a drone comprising a physical treatment device, the method comprises the steps repeated over time of measuring the distance between the drone and an object present in the environment of the drone; adjusting the distance from the drone to the object according to predefined internal parameters; and performing a physical treatment on the object from the drone. Developments describe the management of distances to objects, surface tracking, object recognition, the installation of beacons in the environment, the use of on-board or remotely accessed sensors (e.g. position and contact sensors, cameras, motion detectors) and various types of treatment (e.g. cleaning, dusting, sterilization). Both software aspects (e.g. learning, central or distributed logic, autonomy, cooperation with floor robots) and system aspects (addition of a fan, brush, duster or germicidal lamp) are described.

Owner:VIEL PIERRE EMMANUEL

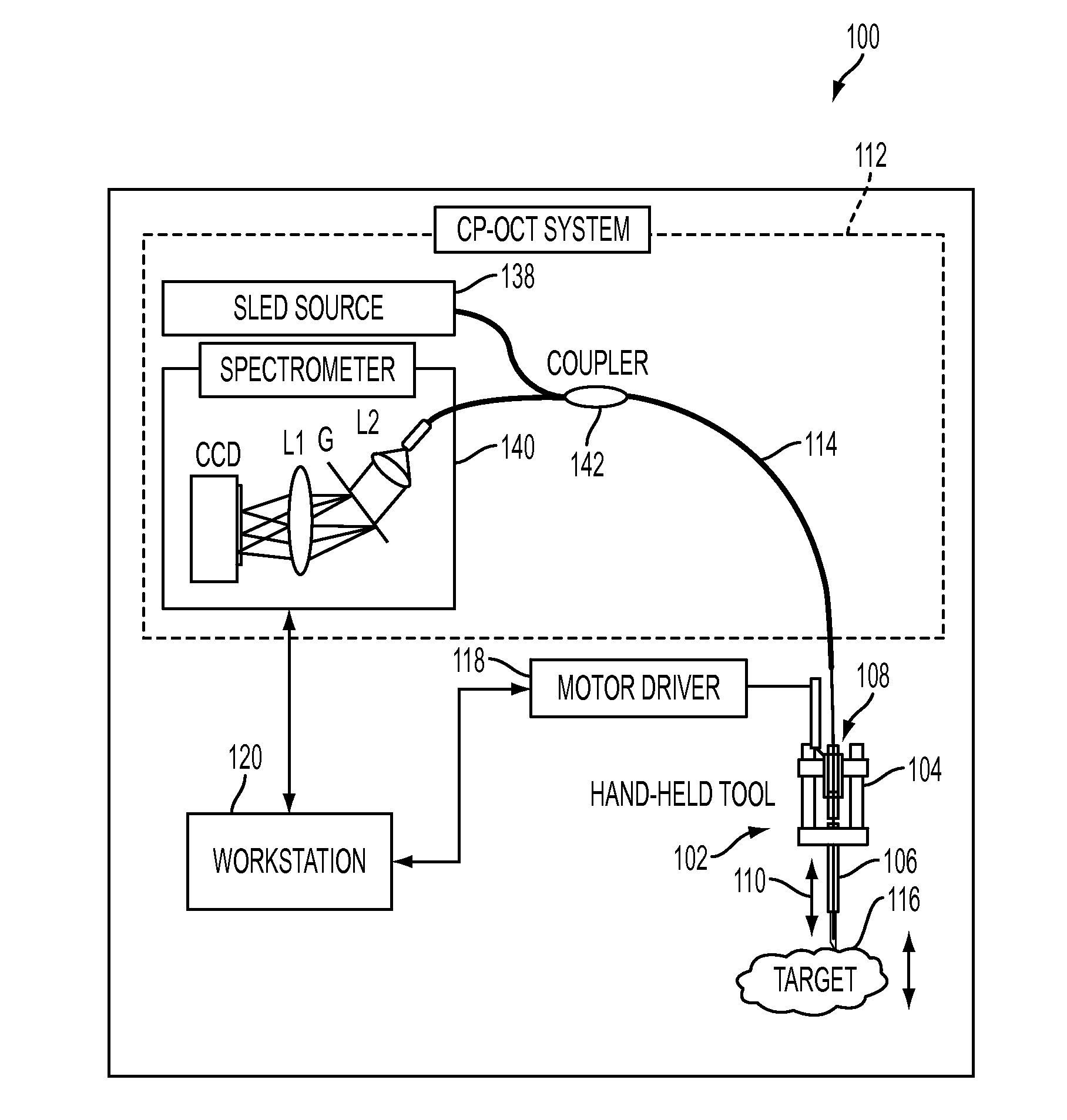

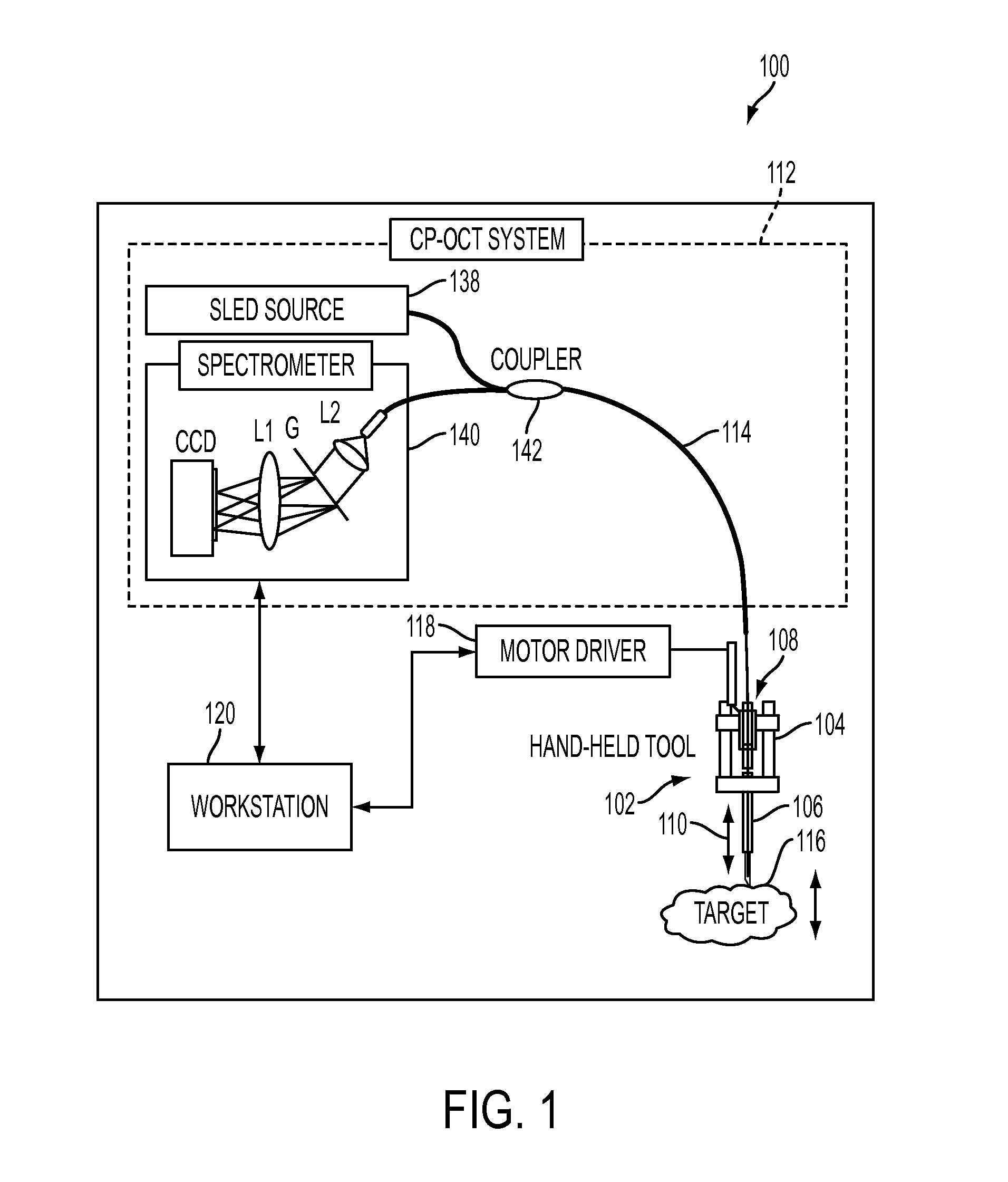

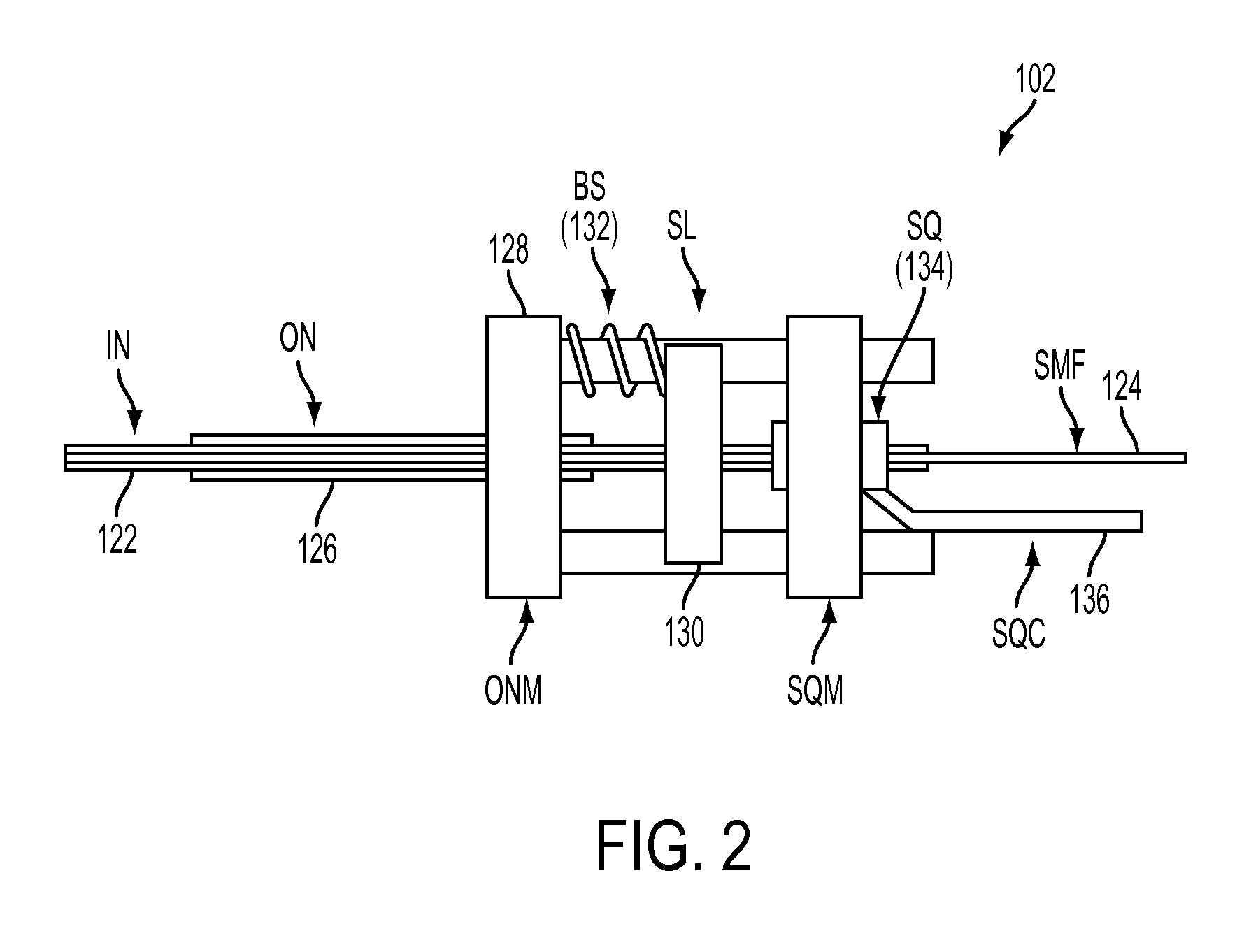

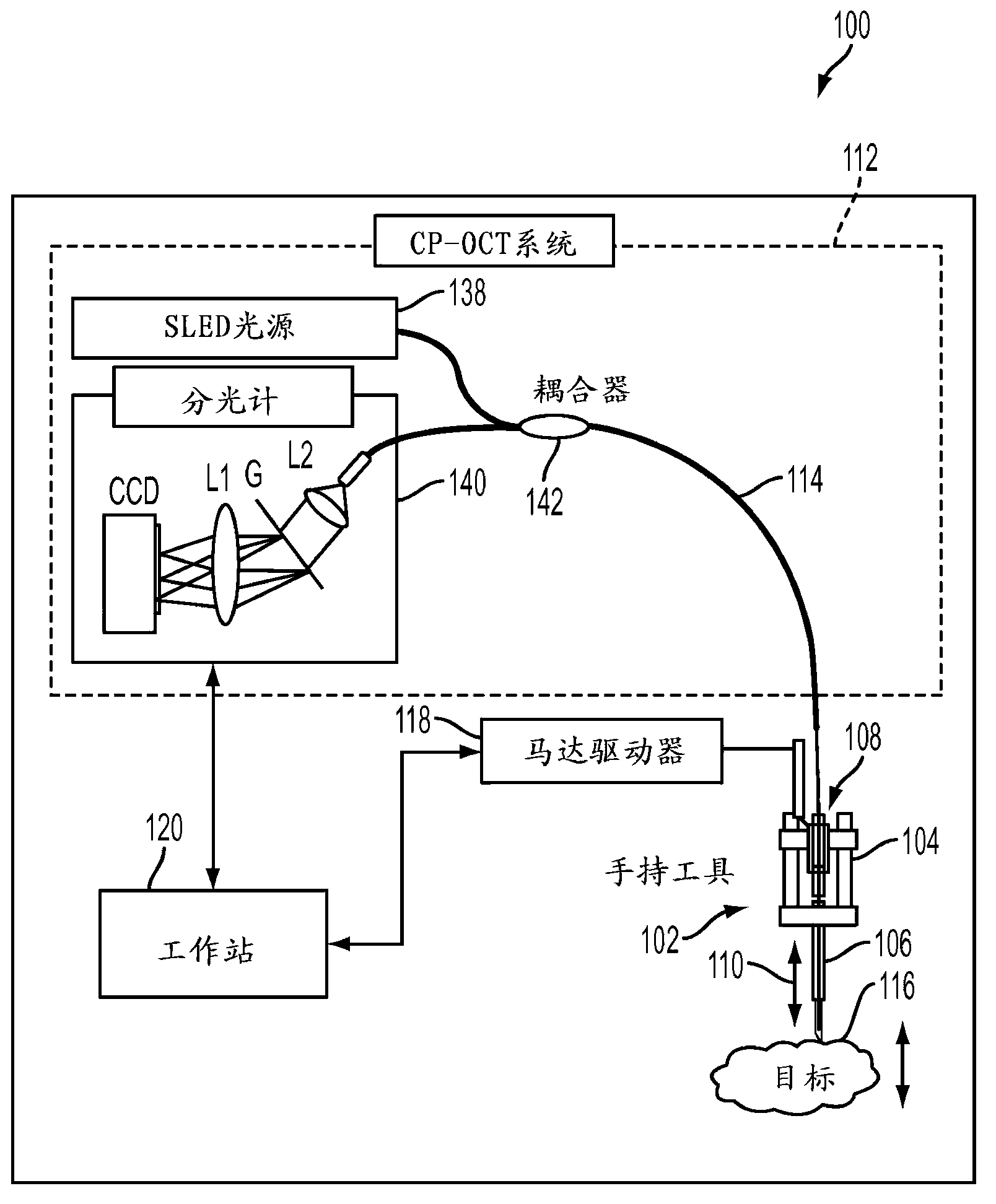

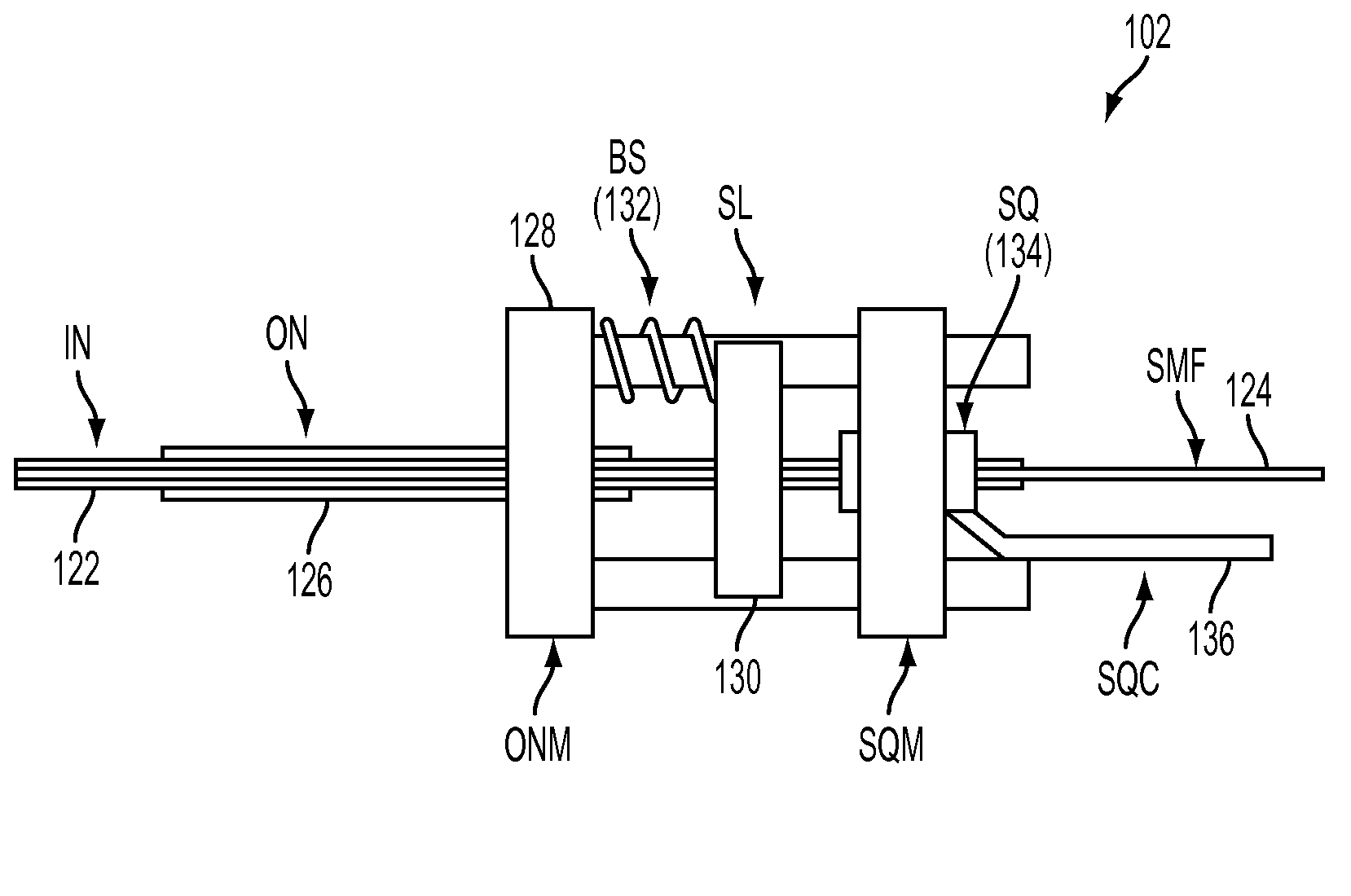

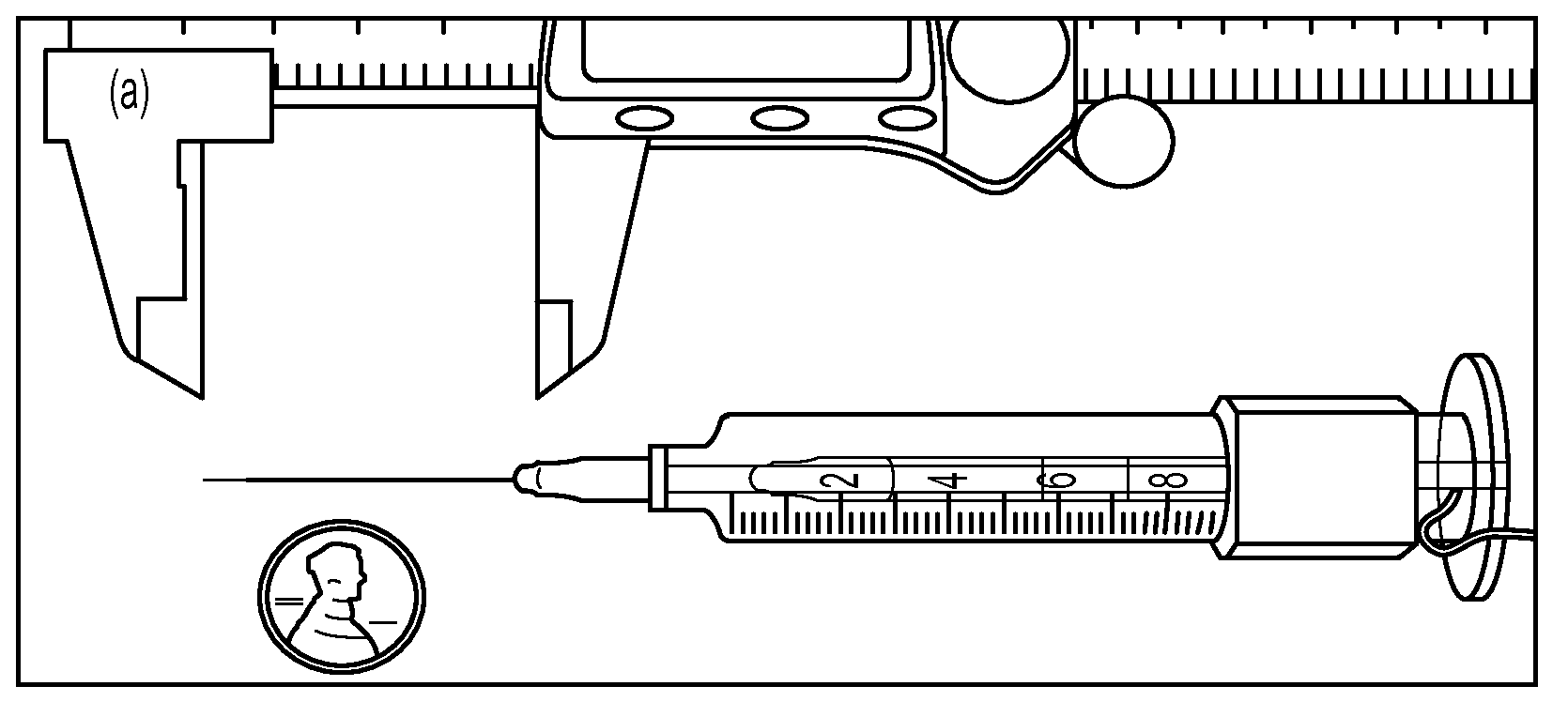

Surface tracking and motion compensating surgical tool system

A motion-compensating surgical tool system includes a surgical tool that includes a hand piece and a moveable component, a drive assembly connecting the moveable component to the hand piece such that the moveable component is movable in an axial direction relative to the hand piece by the drive assembly. The motion-compensating surgical tool system also includes an optical detection system that includes an optical fiber attached to the moveable component with an end at a fixed distance to a distal-most portion of the moveable component. The optical detection system is configured to output a signal for the determination of a distance of the distal-most portion of the moveable component to a target during surgery.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

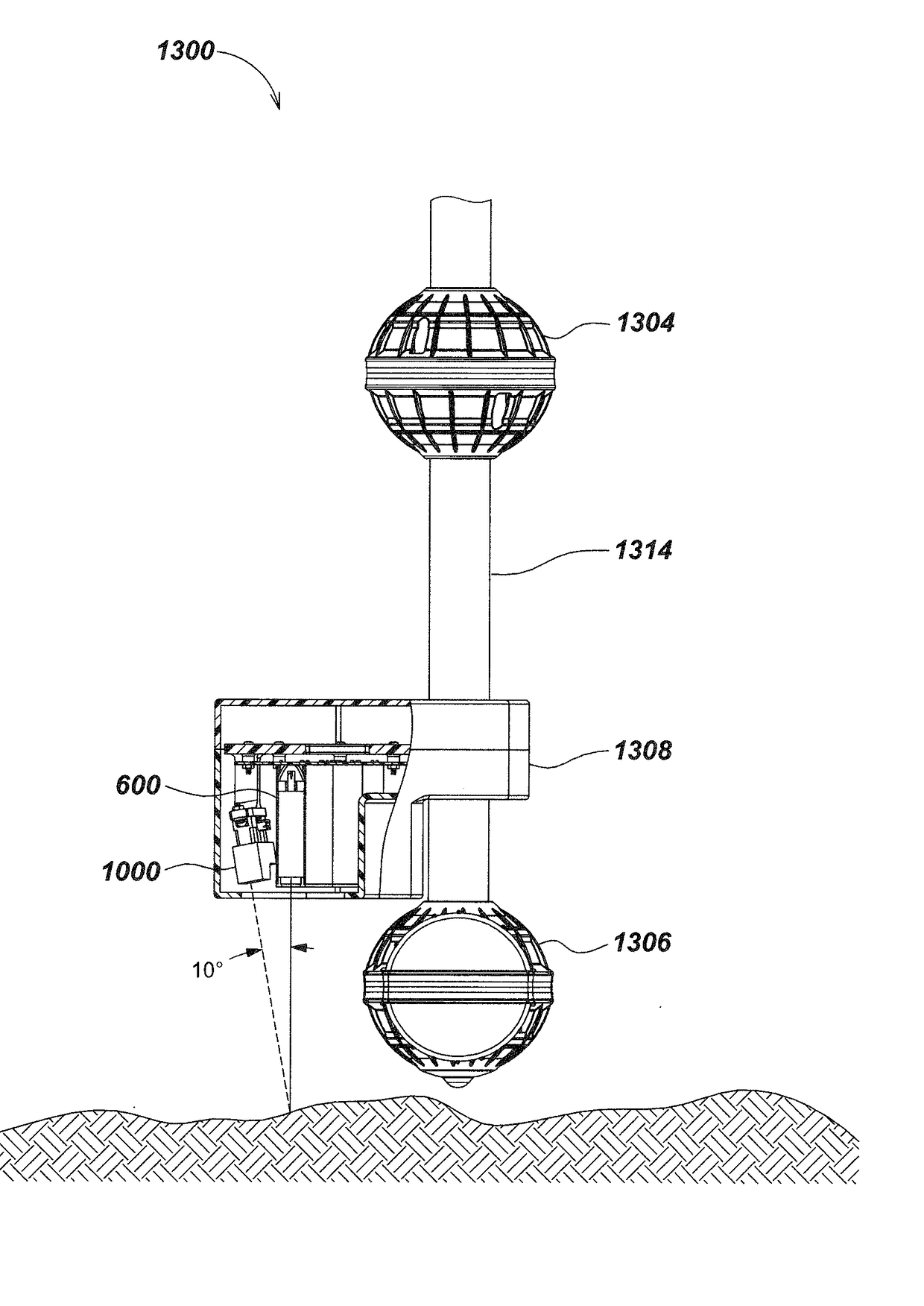

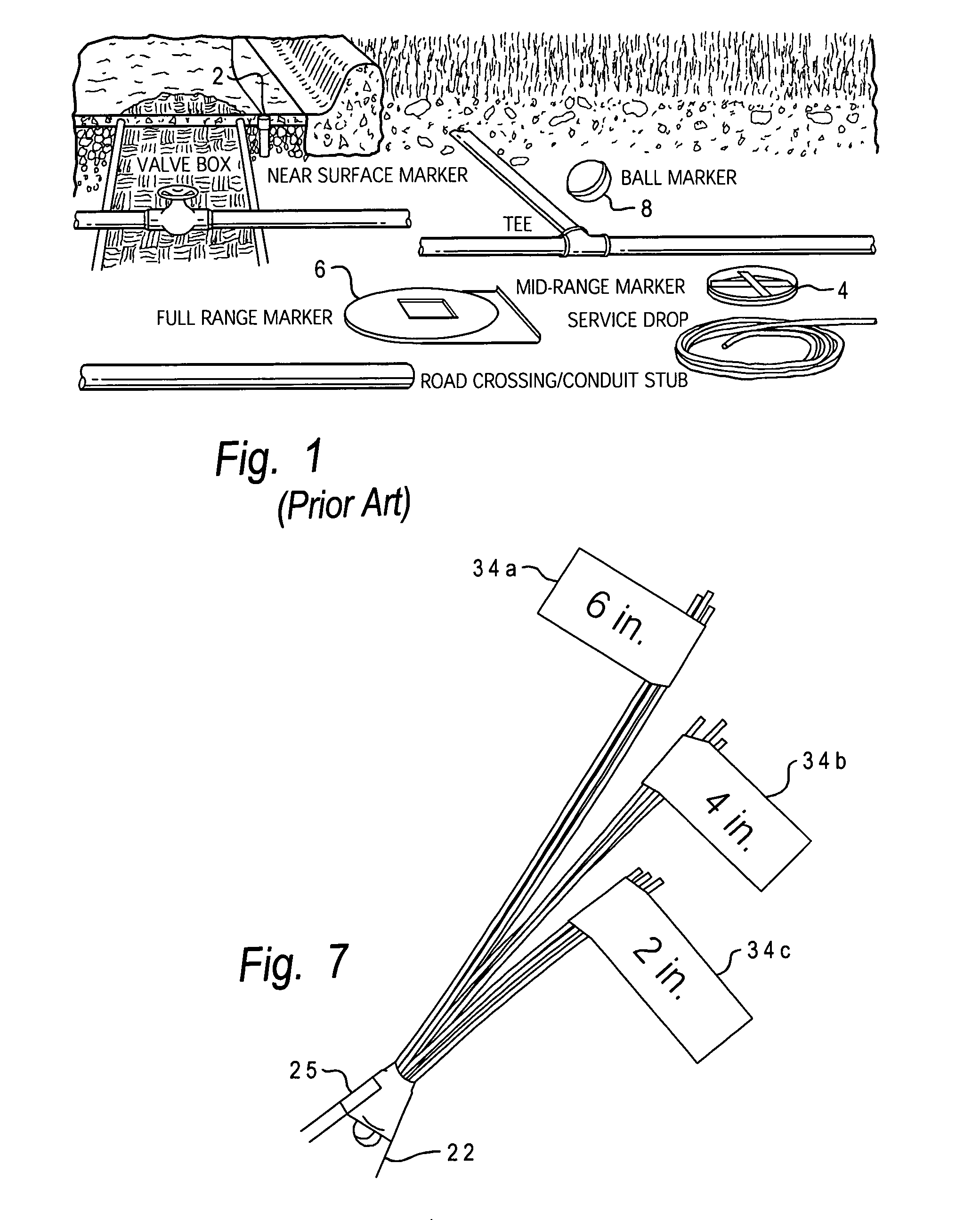

Optical ground tracking apparatus, systems, and methods

Optical ground tracking apparatus for use with buried object locators or other instruments or devices are disclosed. In one embodiment, a buried object locator includes a locator module disposed in our coupled to the housing to sense a buried object based on emitted magnetic fields, and a surface tracking module for determining motion information of the buried object locator based on light reflected from a tracking surface.

Owner:SEESCAN

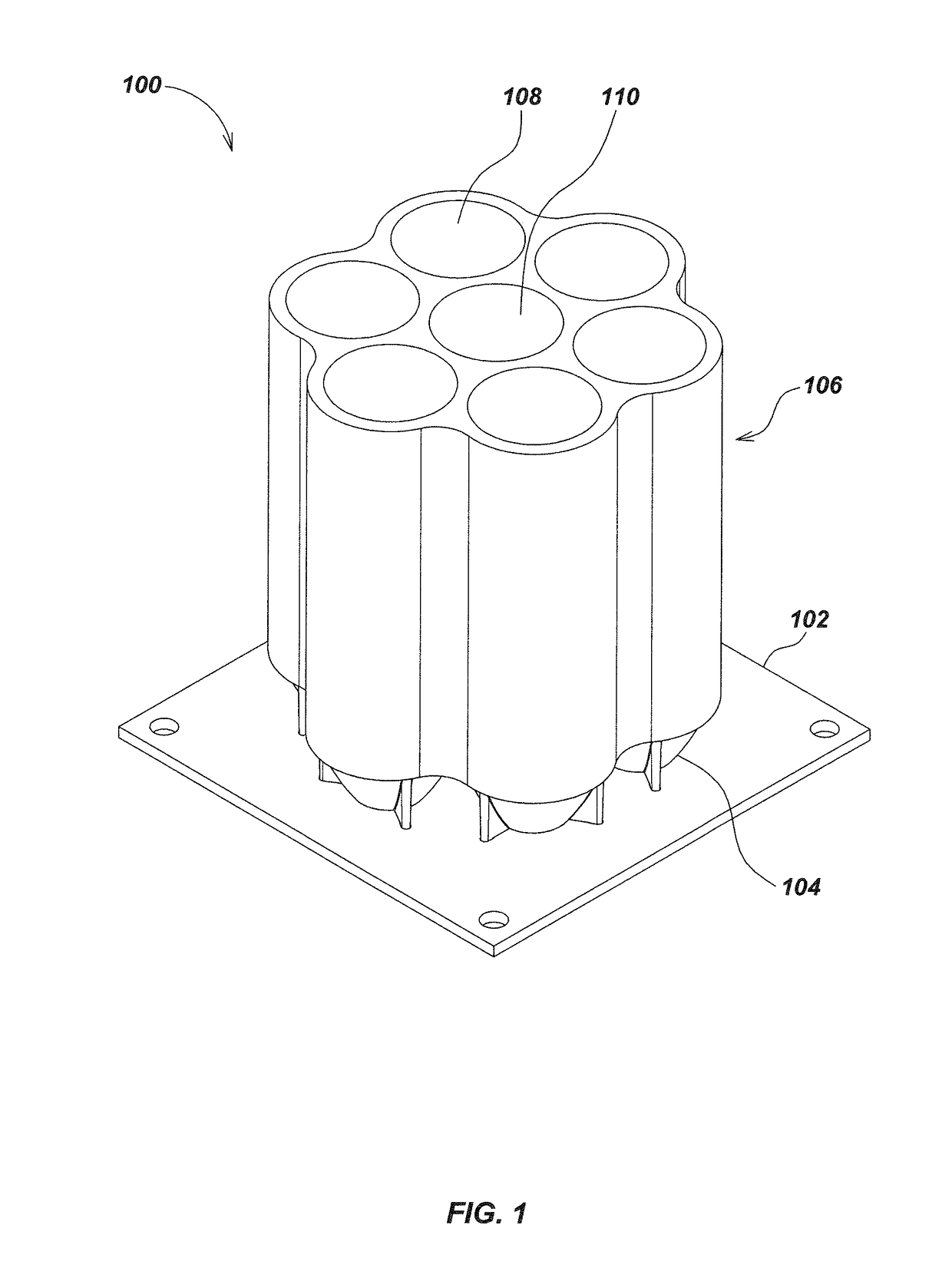

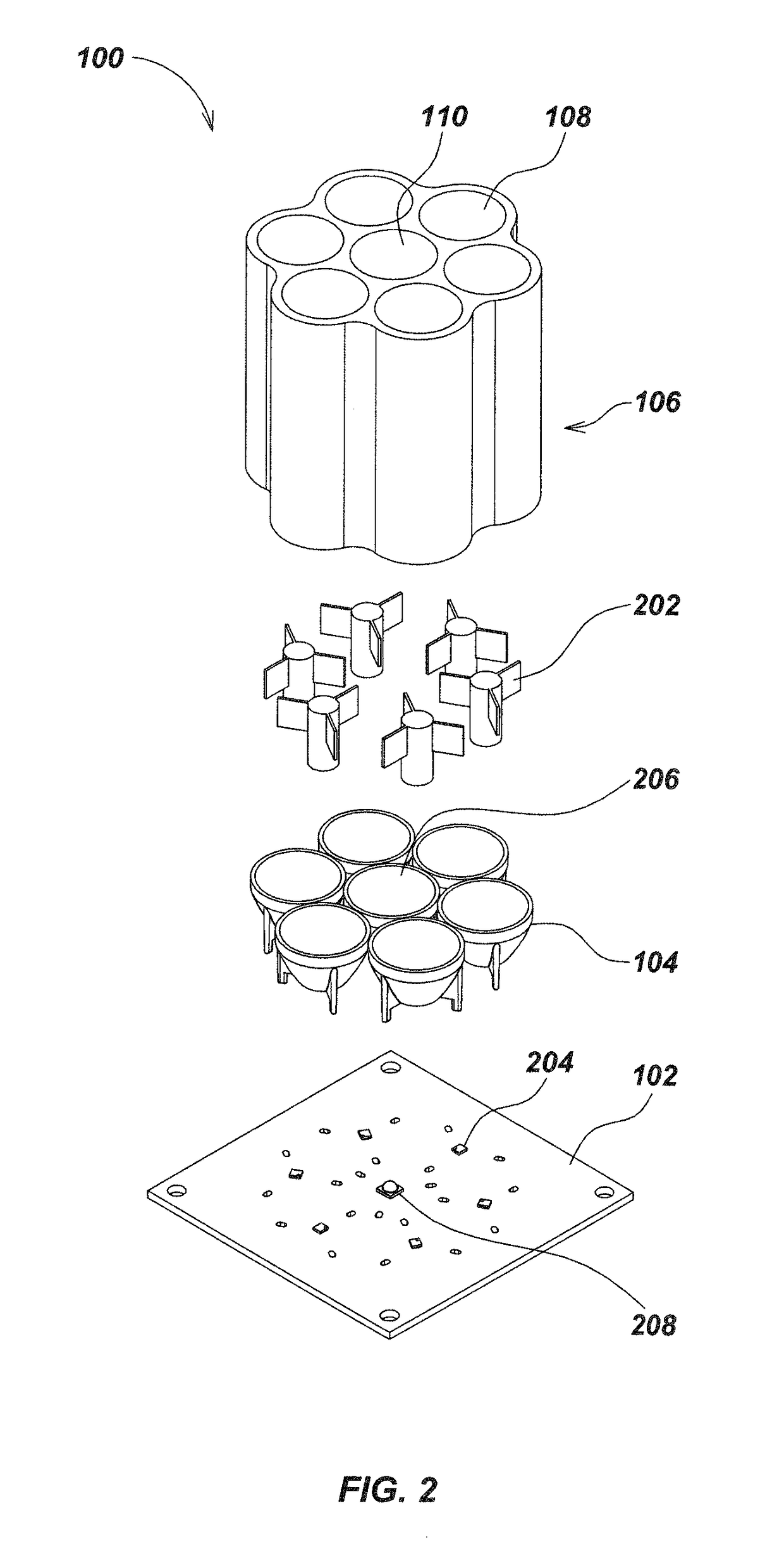

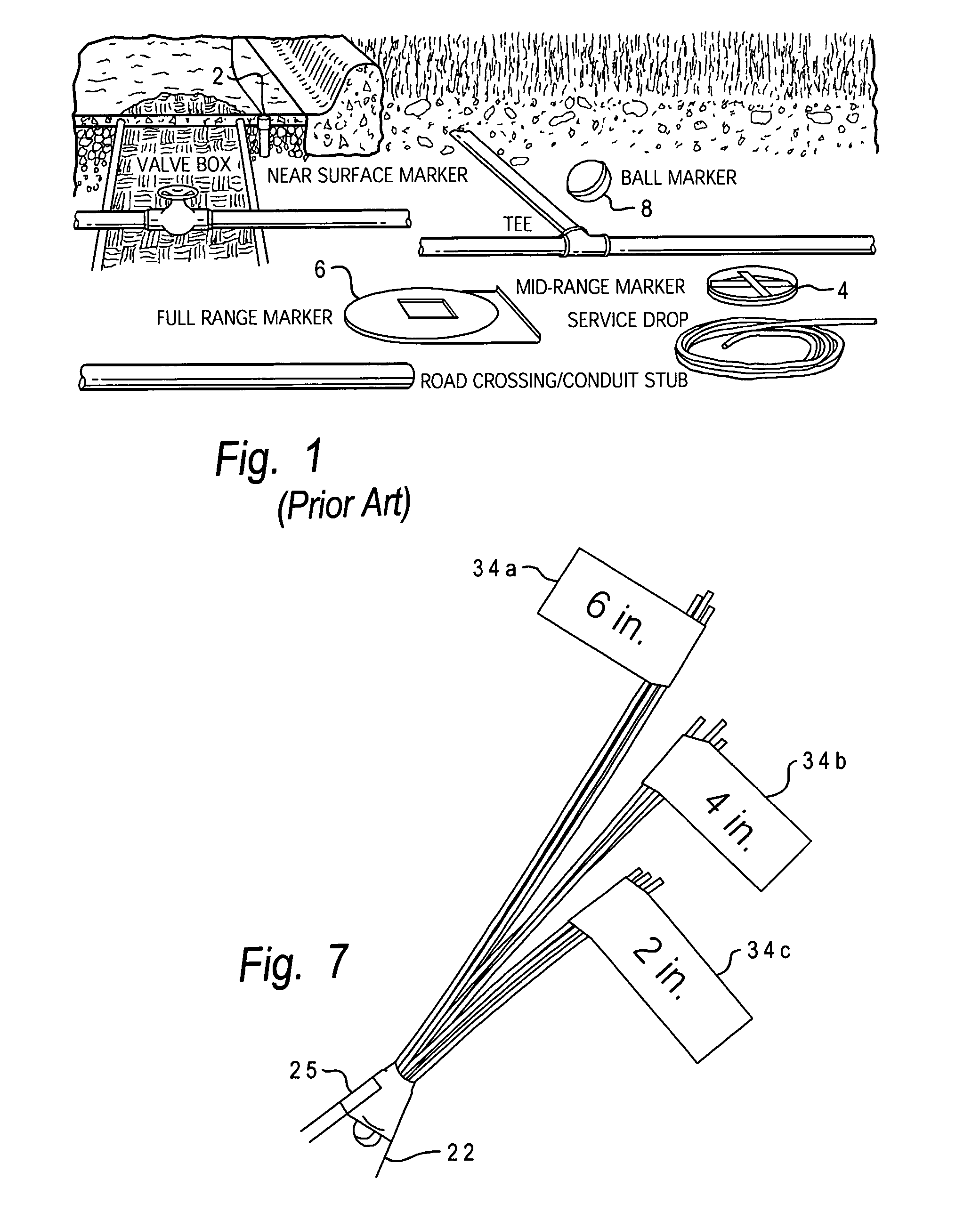

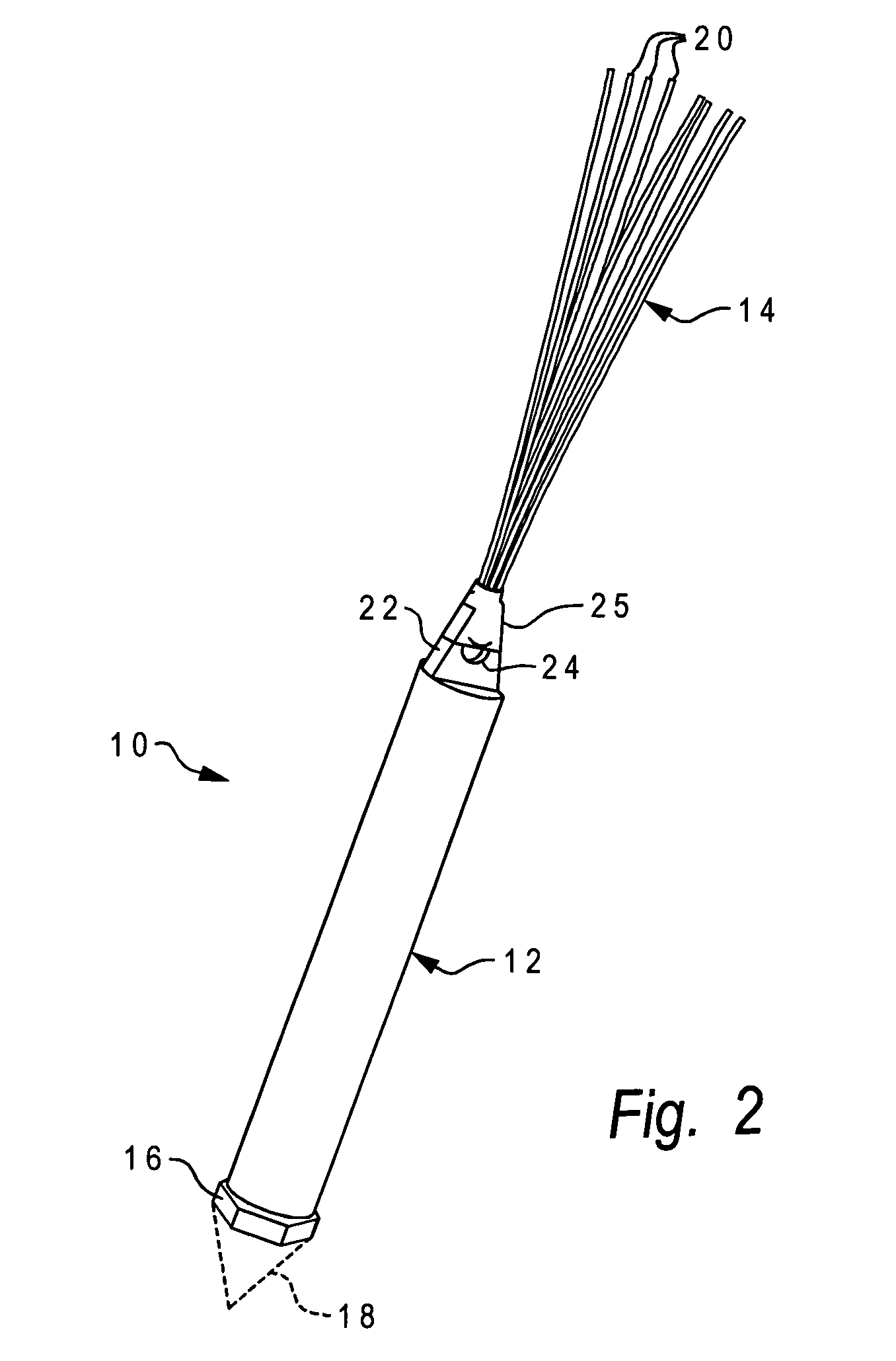

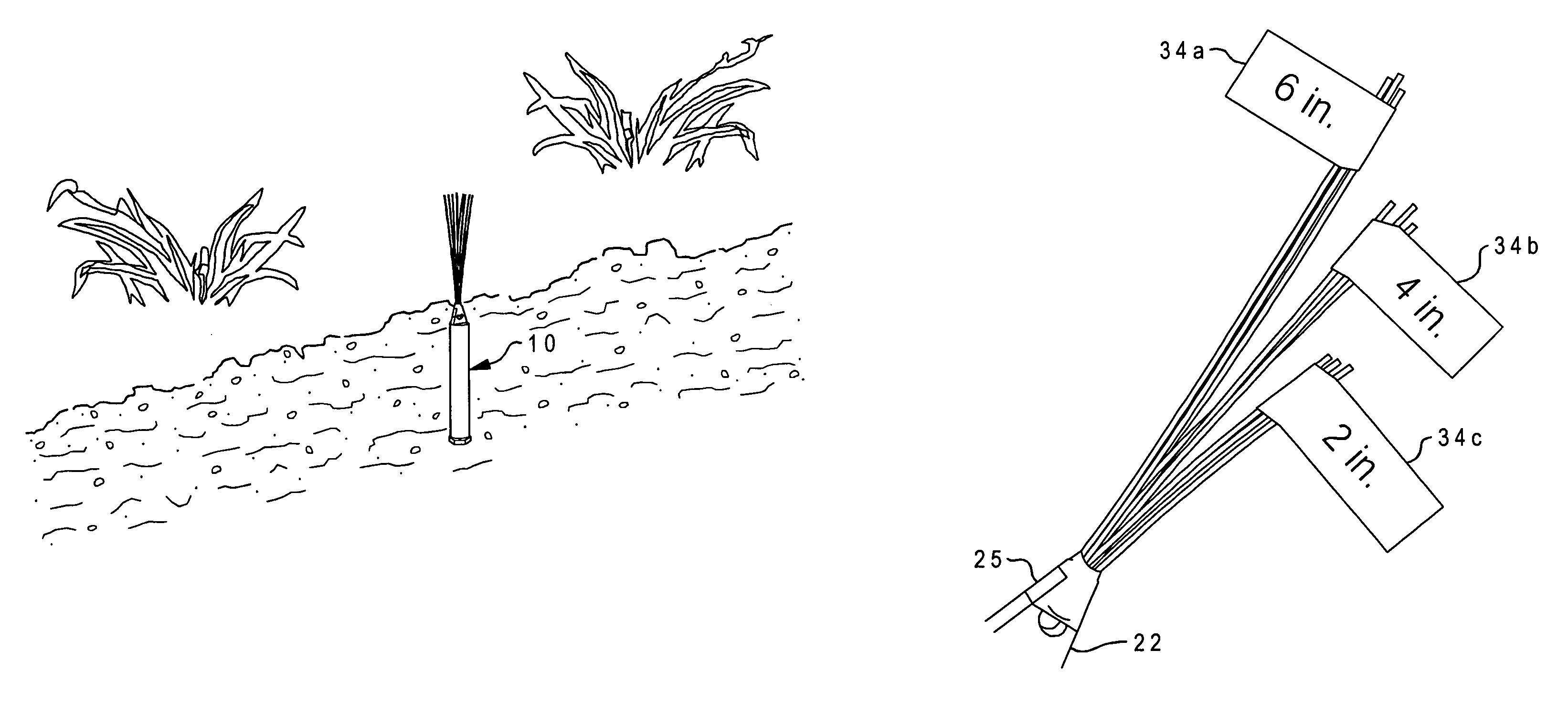

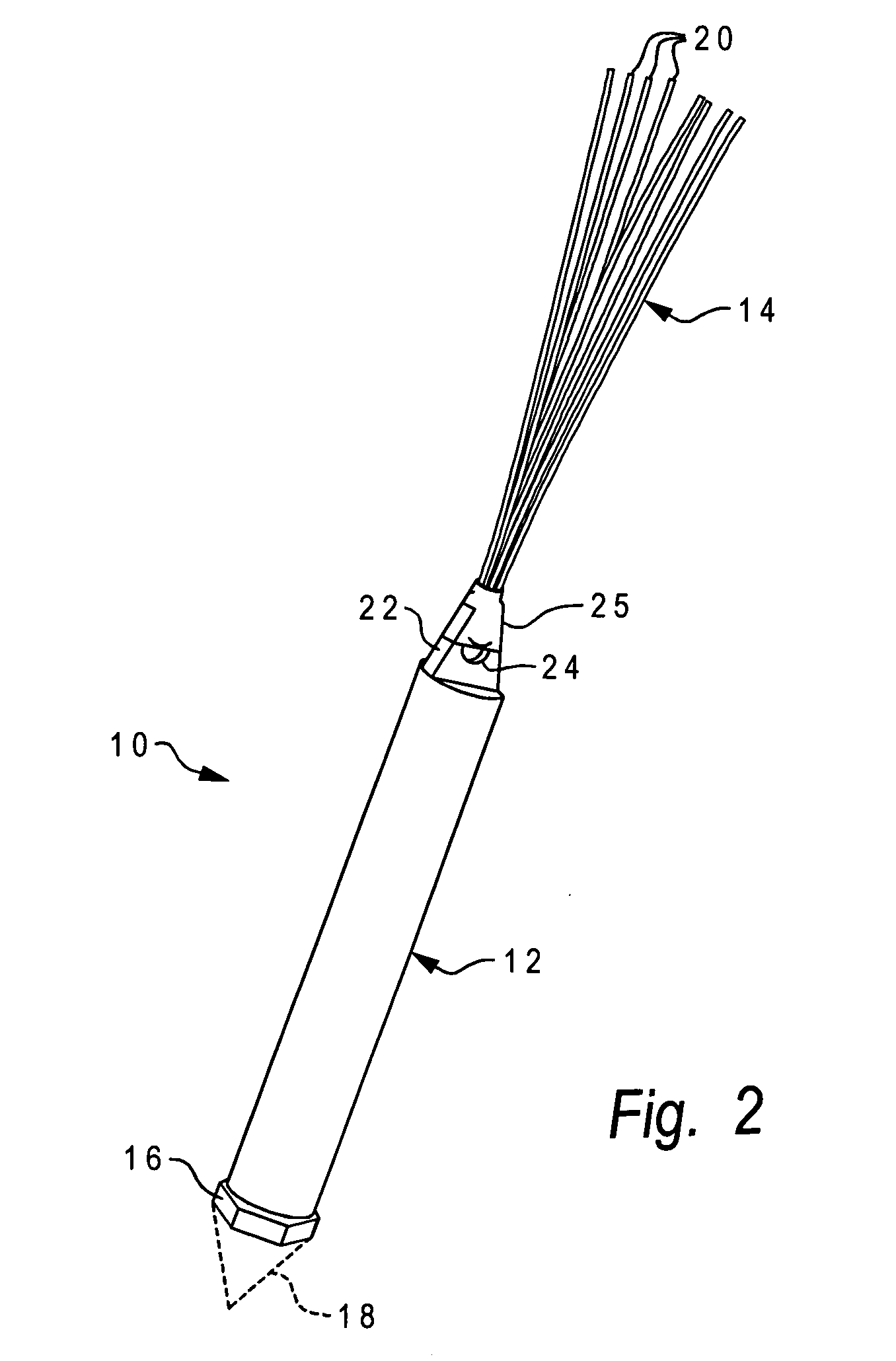

Surface tracker

InactiveUS7081820B2Improve abilitiesAnalysis using chemical indicatorsAntenna arraysAbove groundEngineering

A surface tracker includes a tubular marker body having an interior electronic marker and a visual indicator attached to an upper end of the marker body which extends away from the marker body. When deployed, the marker body is mostly underground and the visual indictor extends upwardly from the ground level to provide above-ground visual recognition. The visual indicator may be a plurality of resilient filaments which pass through a hole in a tab portion of the marker body at the upper end thereof, the filaments being folded about the tab portion and secured to the tab portion using a heat-shrink tube. The visual indication, along with the ability to electronically detect the marker, provides a tracker with superior locating capability.

Owner:MINAROVIC JOE T

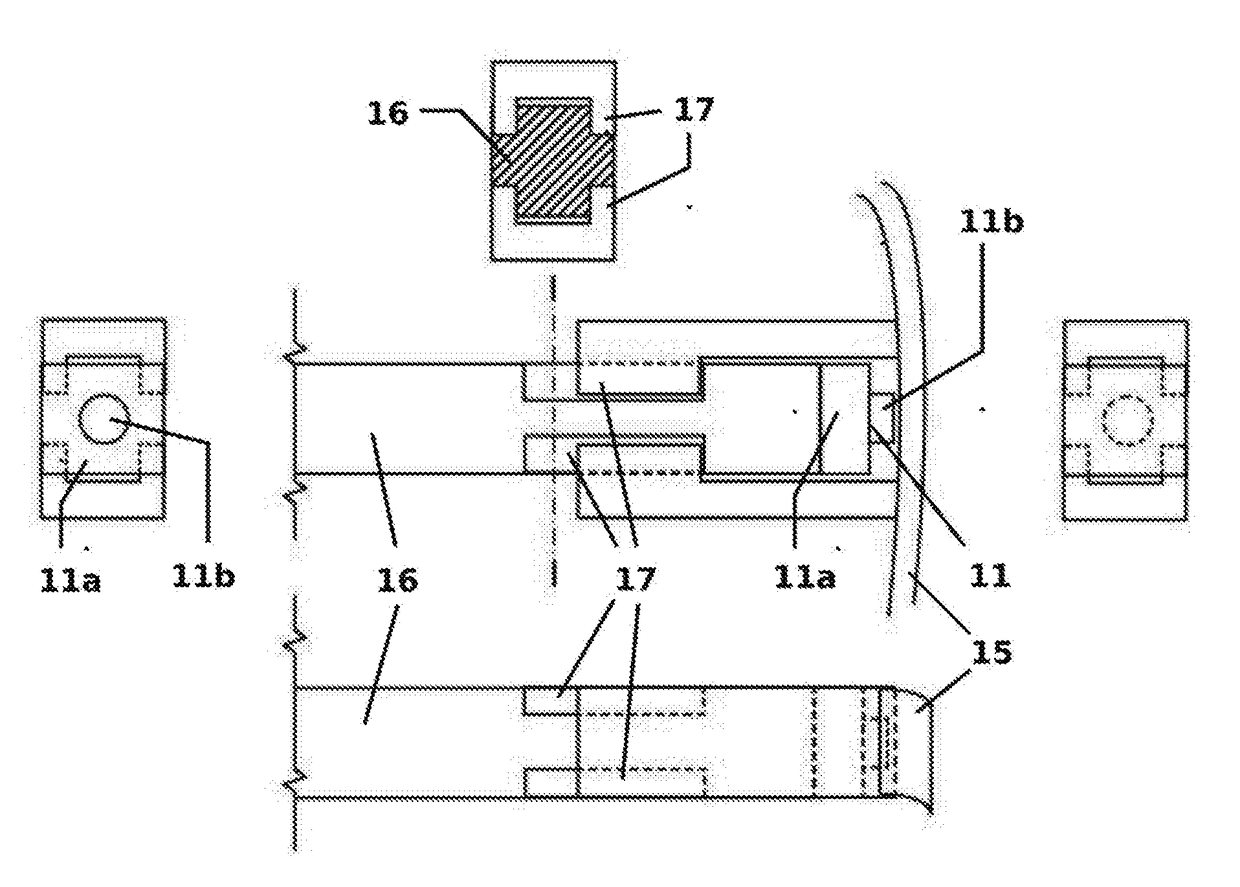

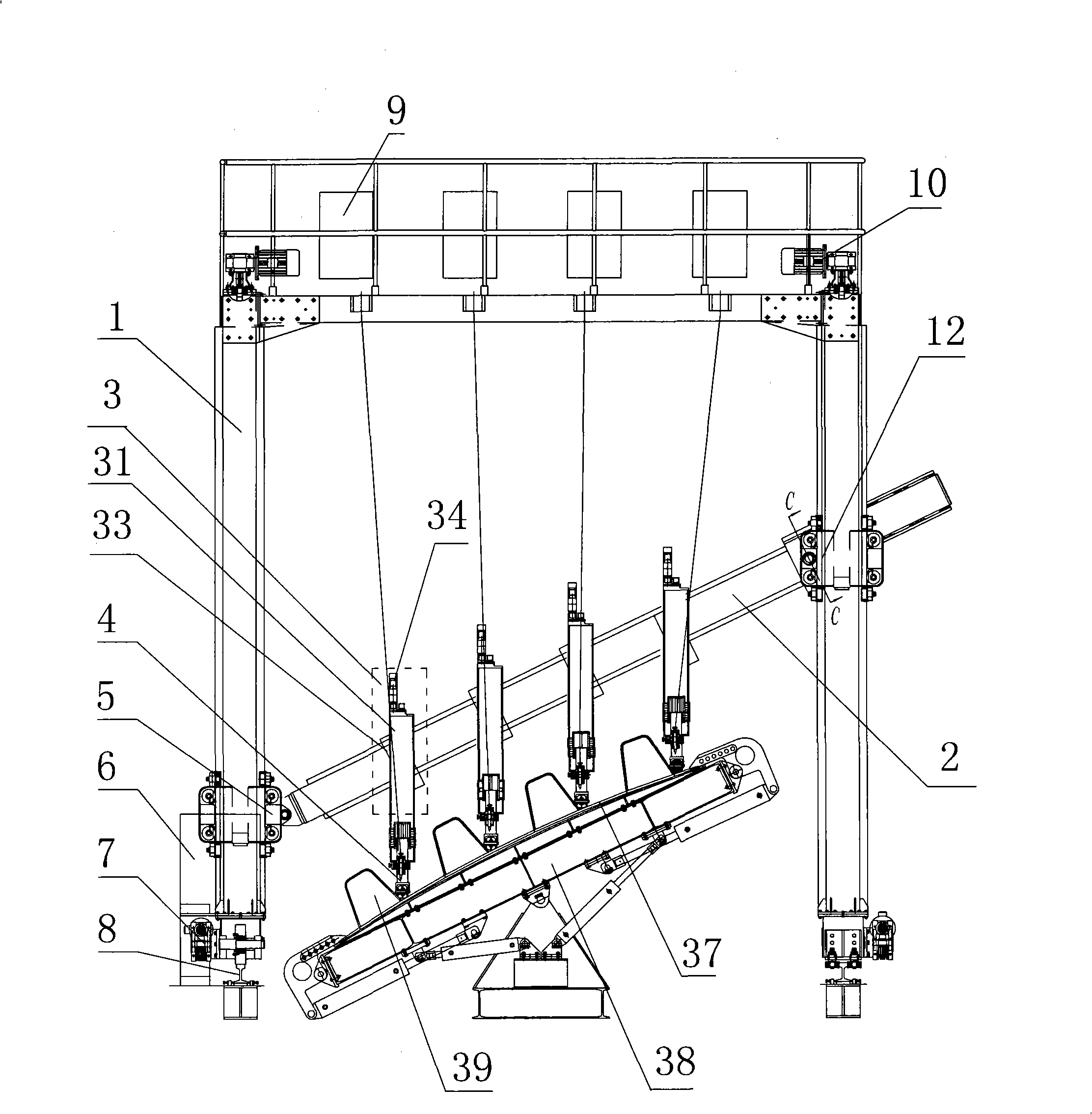

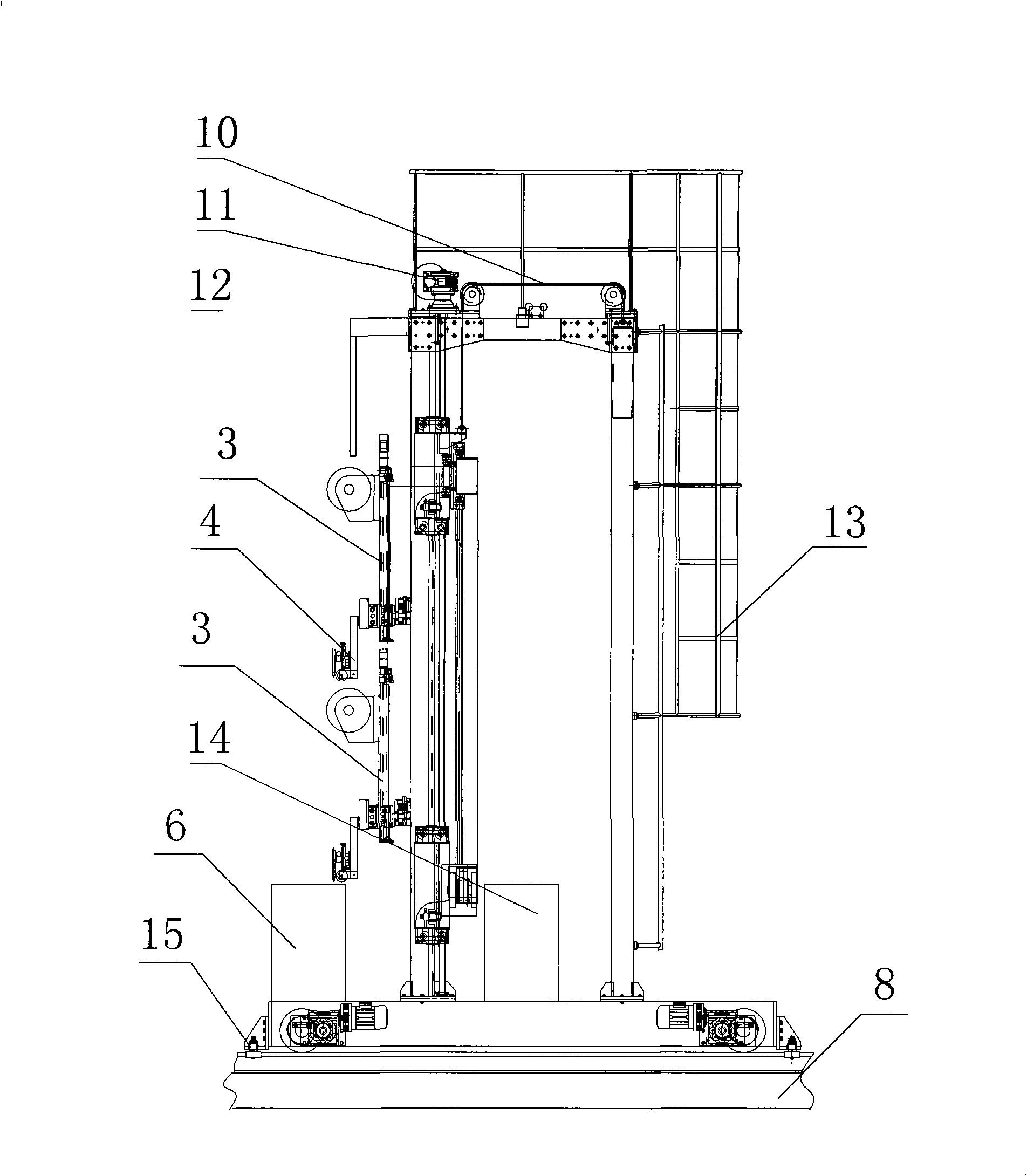

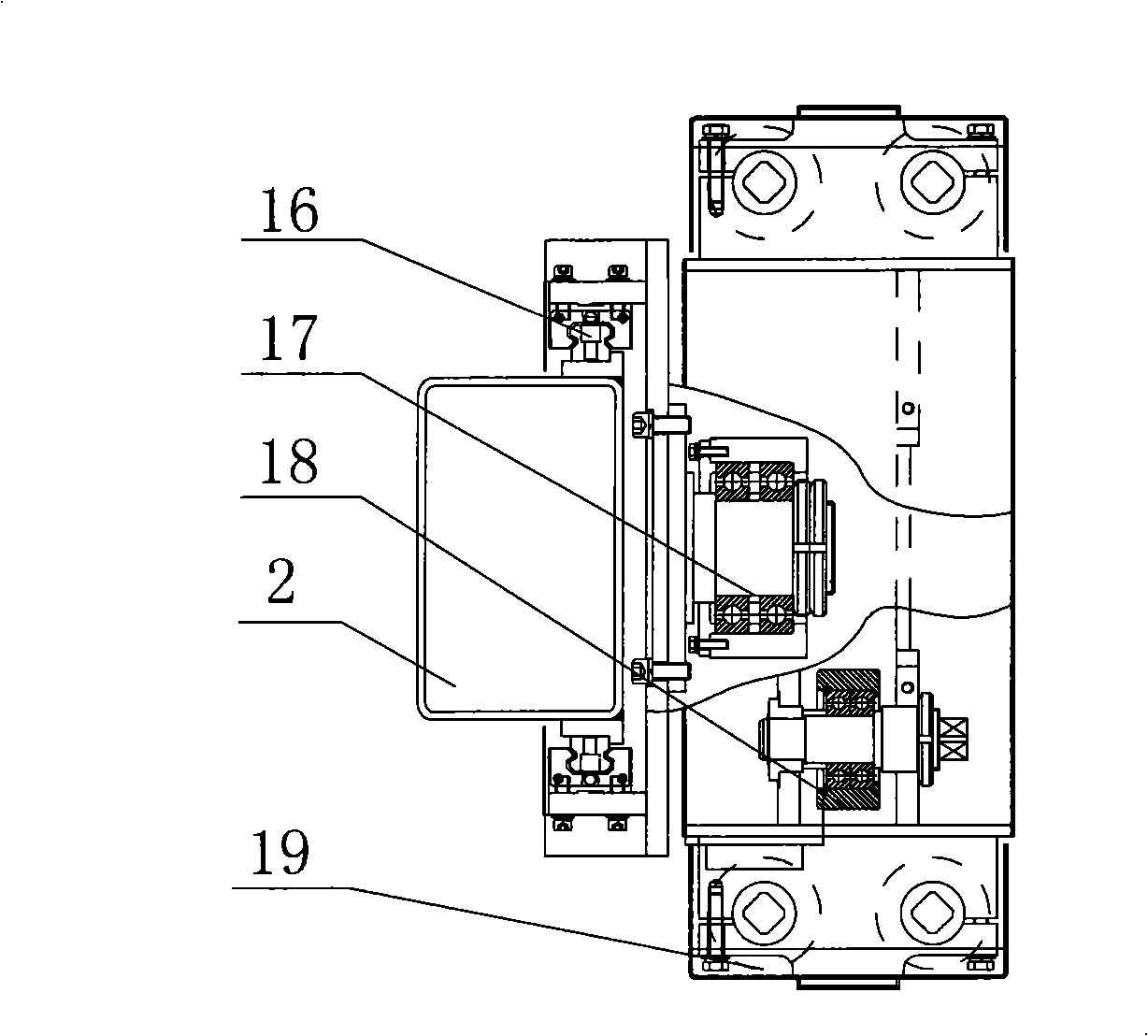

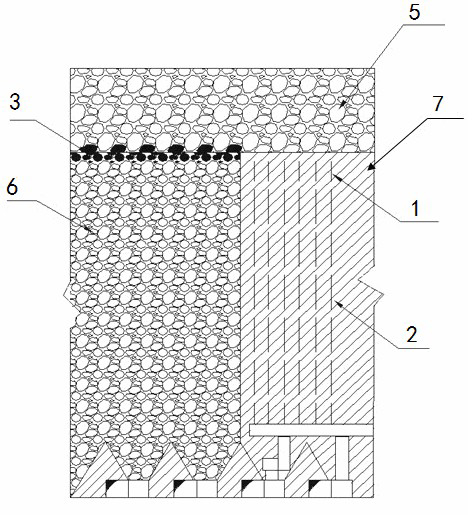

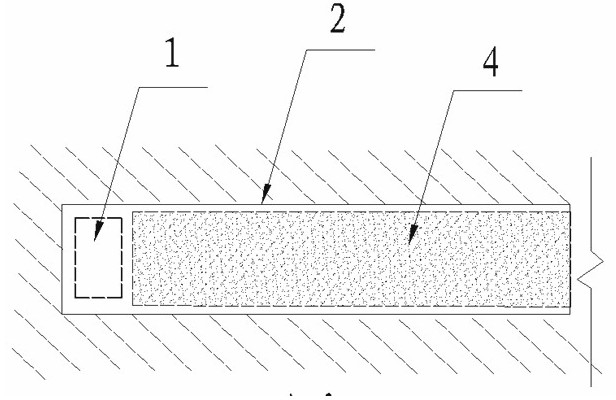

Gantry type multiheaded automatic welding machine

ActiveCN101347860AImprove tracking accuracyReduce labor intensityArc welding apparatusSlide plateEngineering

The invention relates to stiffener welding equipment of a beam and slab unit of a steel box of a bridge steel structure, which provides a gantry-typed multiple operator automatic welder and comprises a gantry, a travel driving system, a gas protective welder, an electric control system, a power supply and a gas supplying system; the invention is characterized in that a moveable cross beam is arranged between frame beams at the left side and right side of the gantry; a plurality of vertical steering sliding plates are arranged on the moveable cross beam and are provided with welding seam tracking devices; a welding gun of the gas protective welder is arranged in the welding seam tracking device; the welding is carried out along with the tracking movement of the welding seam by the welding seam tracking device; therefore, the welding seam tracking device adopts a spherical surface tracking wheel mechanism. By adopting the gantry-typed multiple operator automatic welder, the quality problem of forming difference of the welding seam caused by different vibration when in welding due to different lengths of cantilevers in the existing multiple operator welder; simultaneously, the tracking precision of the welding seam is improved greatly, the welding quality of products is guaranteed and the welding efficiency is improved by 3 times to 4 times.

Owner:WUCHUAN HEAVY ENG

Surface tracking and motion compensating surgical tool system

A motion-compensating surgical tool system includes a surgical tool that includes a hand piece and a moveable component, a drive assembly connecting the moveable component to the hand piece such that the moveable component is movable in an axial direction relative to the hand piece by the drive assembly. The motion-compensating surgical tool system also includes an optical detection system that includes an optical fiber attached to the moveable component with an end at a fixed distance to a distal-most portion of the moveable component. The optical detection system is configured to output a signal for the determination of a distance of the distal-most portion of the moveable component to a target during surgery.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

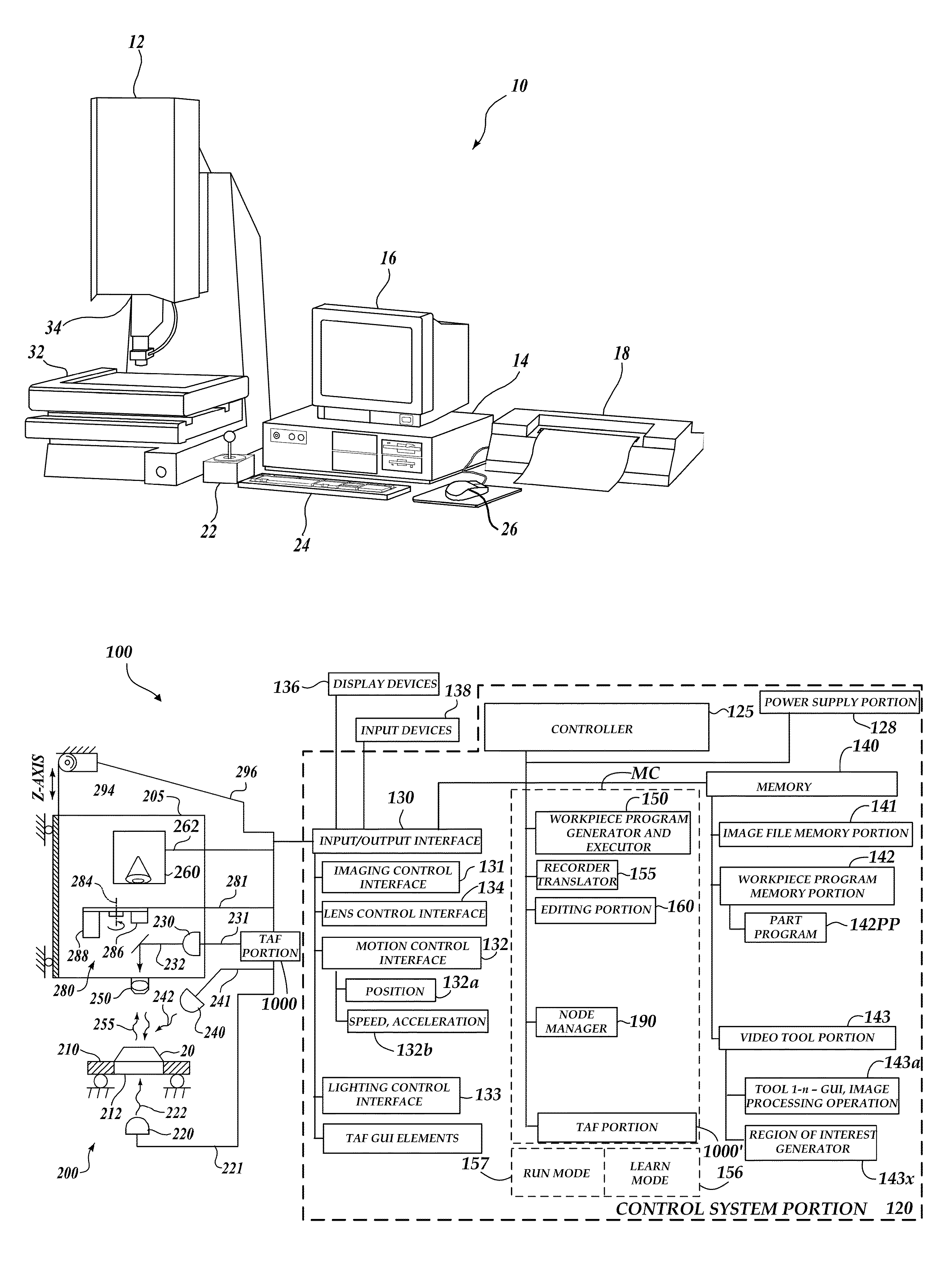

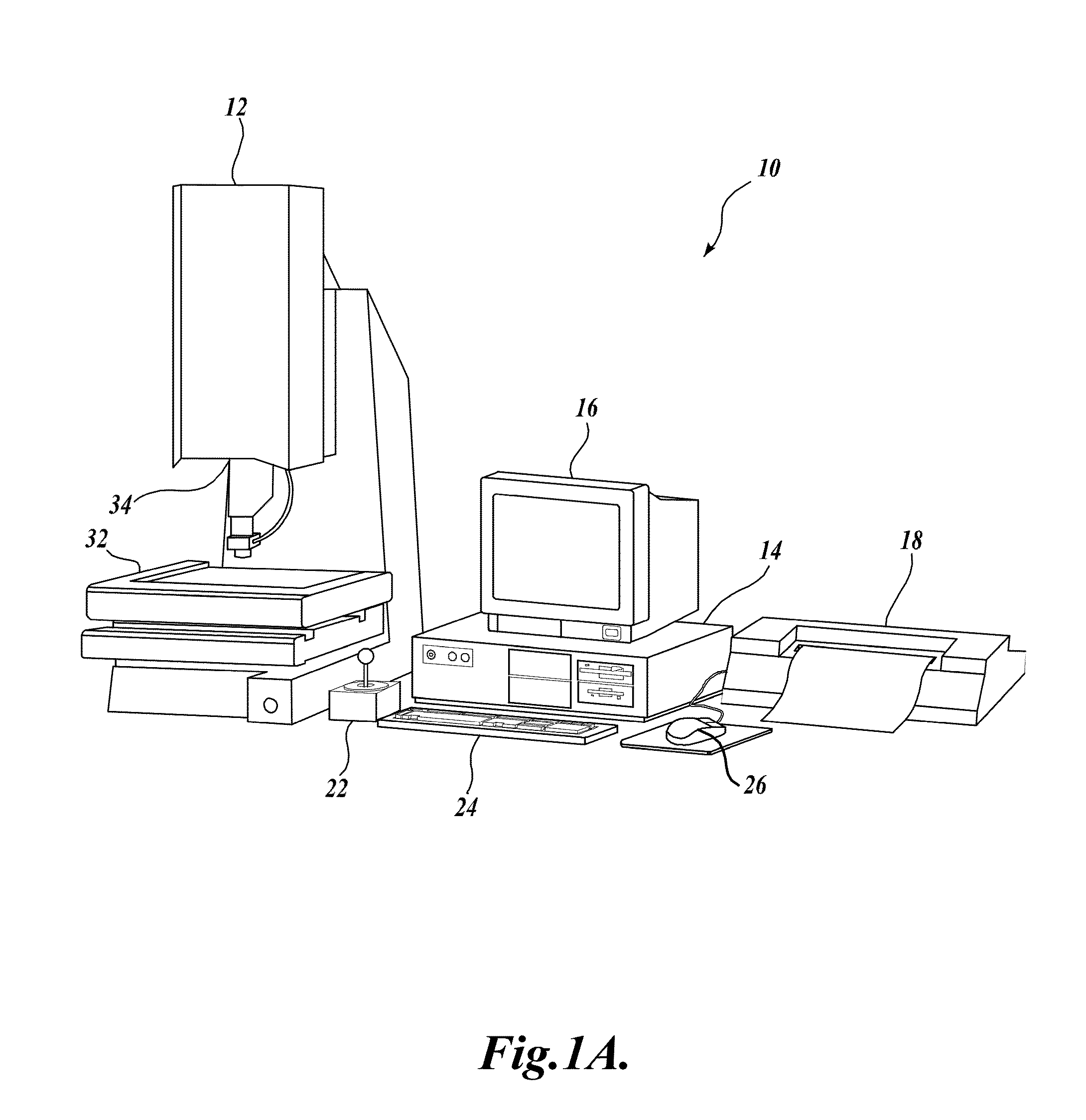

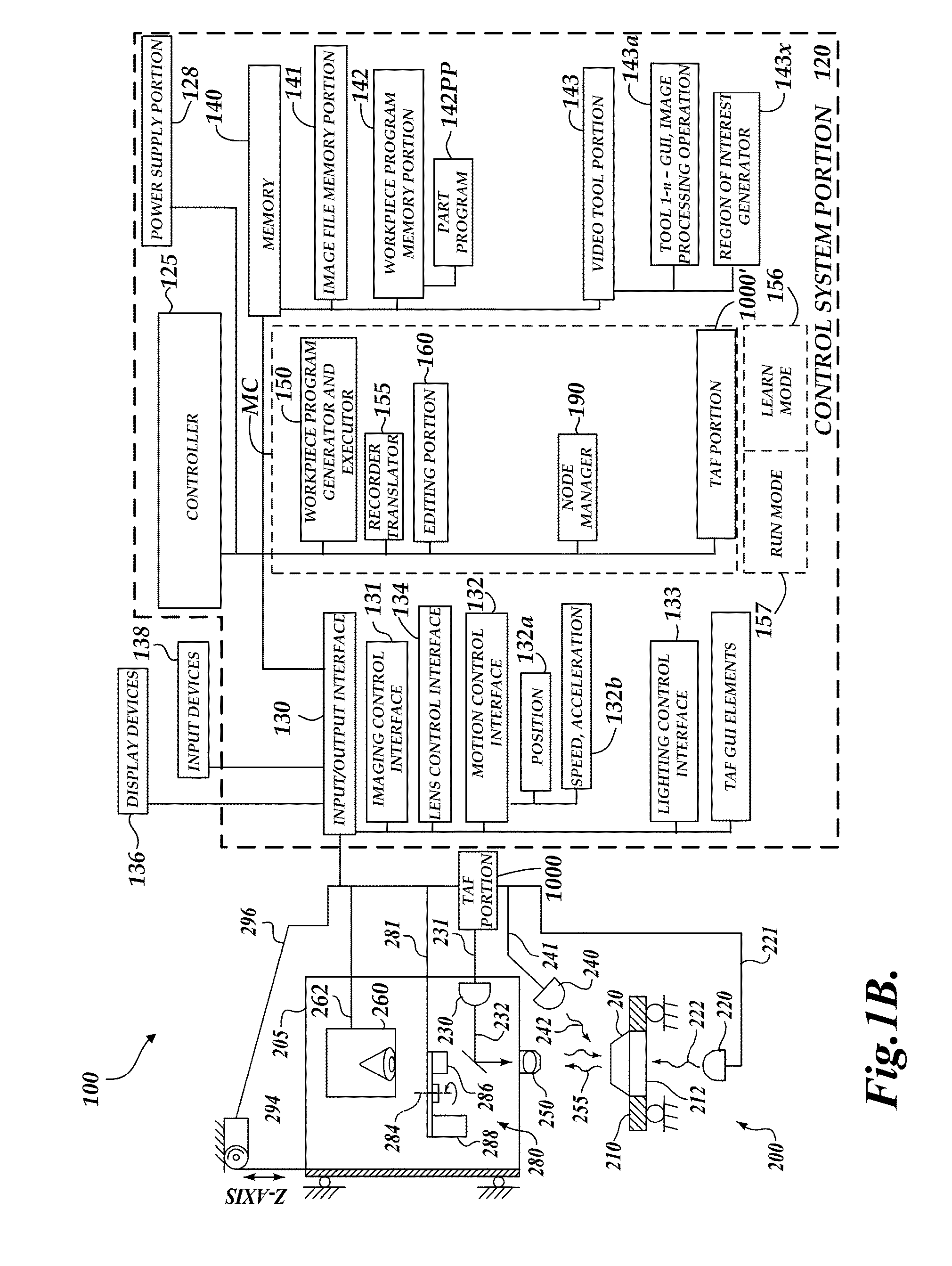

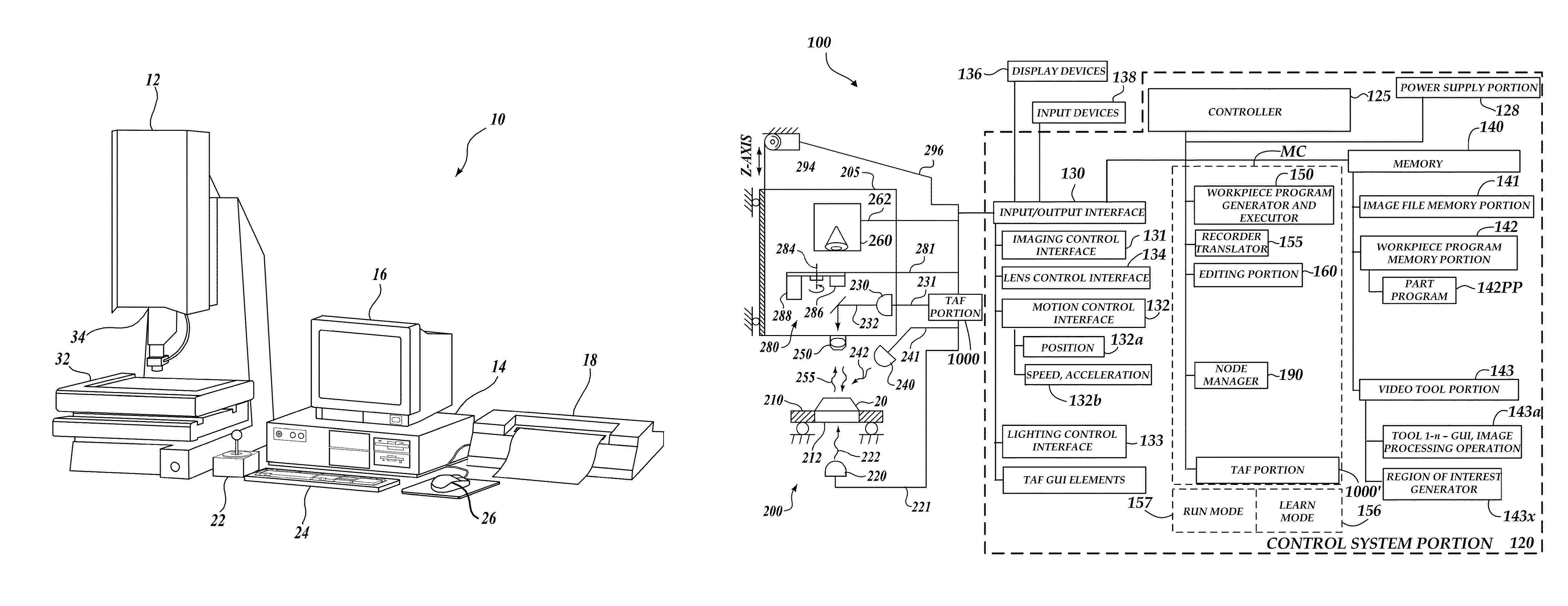

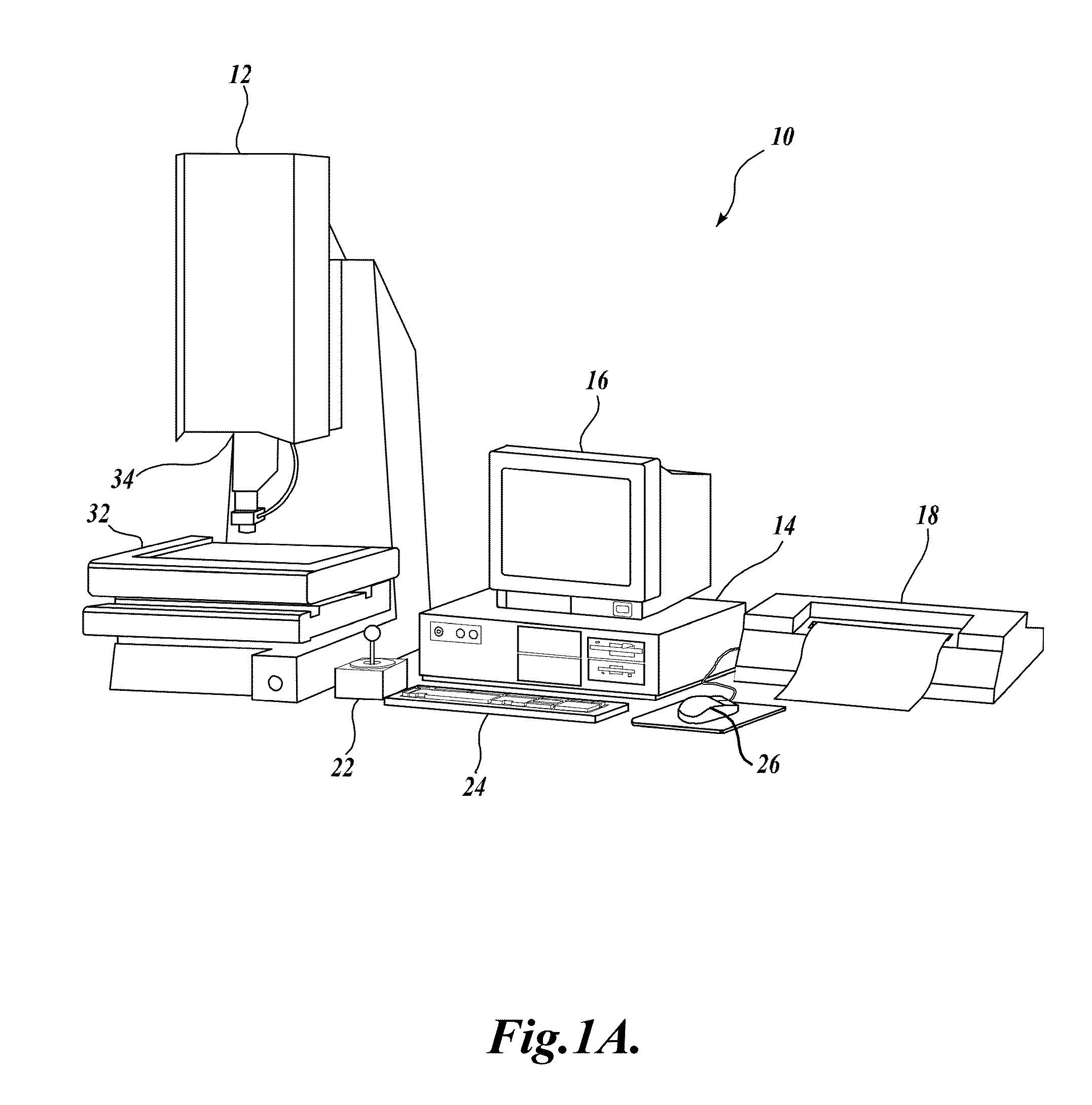

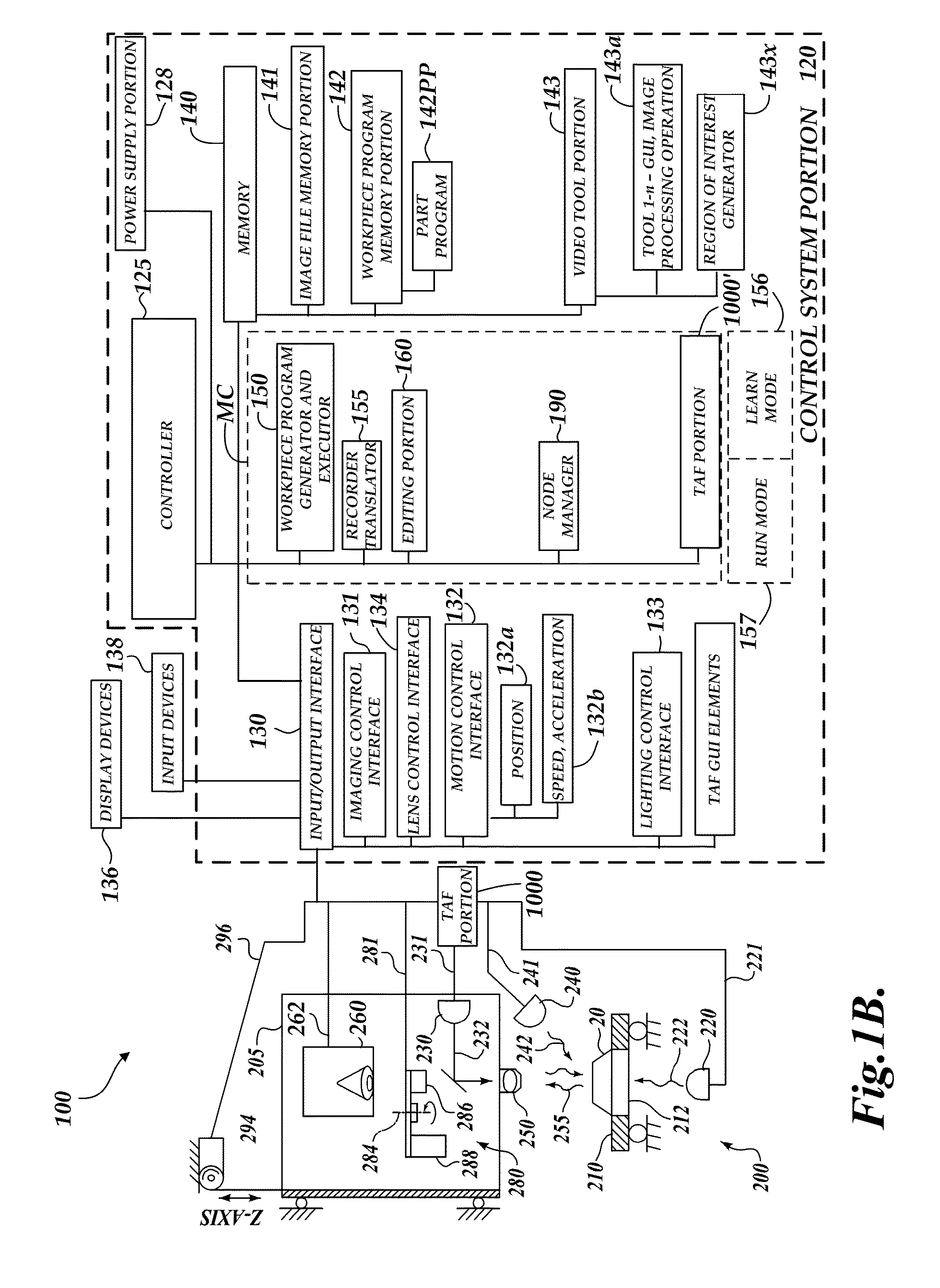

System and method for controlling a tracking autofocus (TAF) sensor in a machine vision inspection system

A method is provided for controlling a Tracking AutoFocus (TAF) portion of a machine vision inspection system including an imaging portion, a movable workpiece stage, a control portion, and graphical user interface (GUI). The TAF portion automatically adjusts a focus position of the imaging portion to focus at a Z height corresponding to a current surface height of the workpiece. The method includes providing the TAF portion, and providing TAF enable and disable operations, wherein: the TAF disable operations comprise a first set of TAF automatic interrupt operations that are automatically triggered by user-initiated operations that include changing the Z height, and the TAF disable operations may further comprise automatic interrupt operations that are automatically triggered based on at least one respective TAF Z height surface tracking characteristic exceeding a previously set TAF disable limit for that respective TAF Z height surface tracking characteristic.

Owner:MITUTOYO CORP

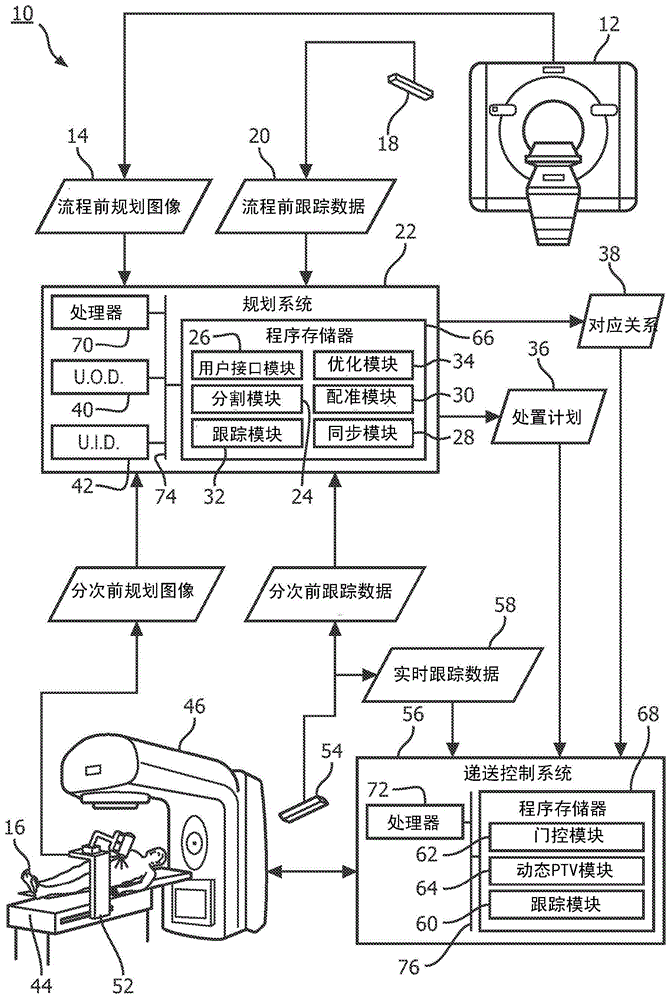

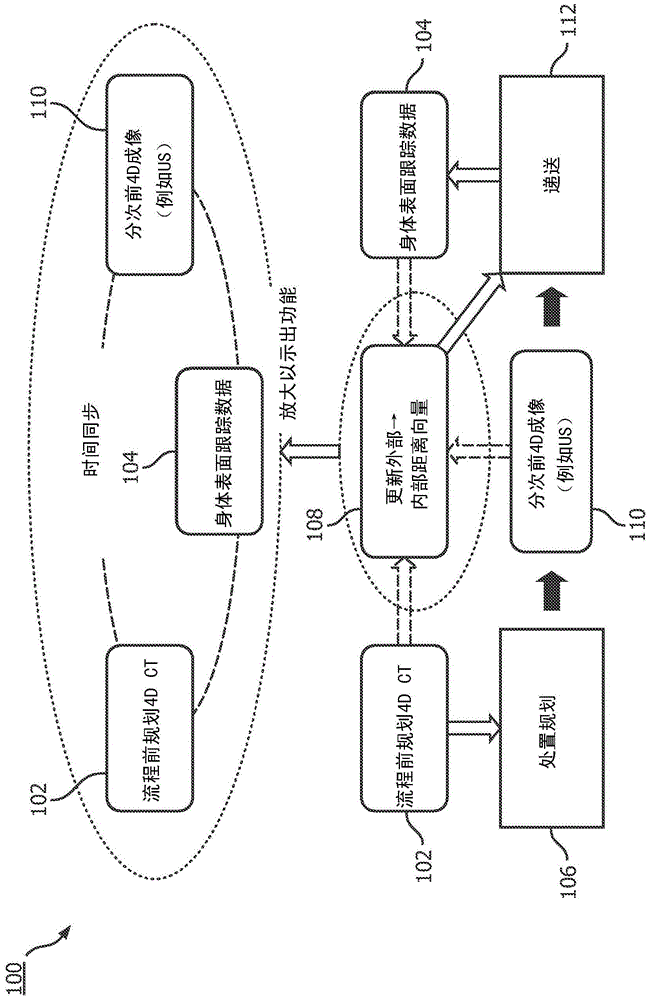

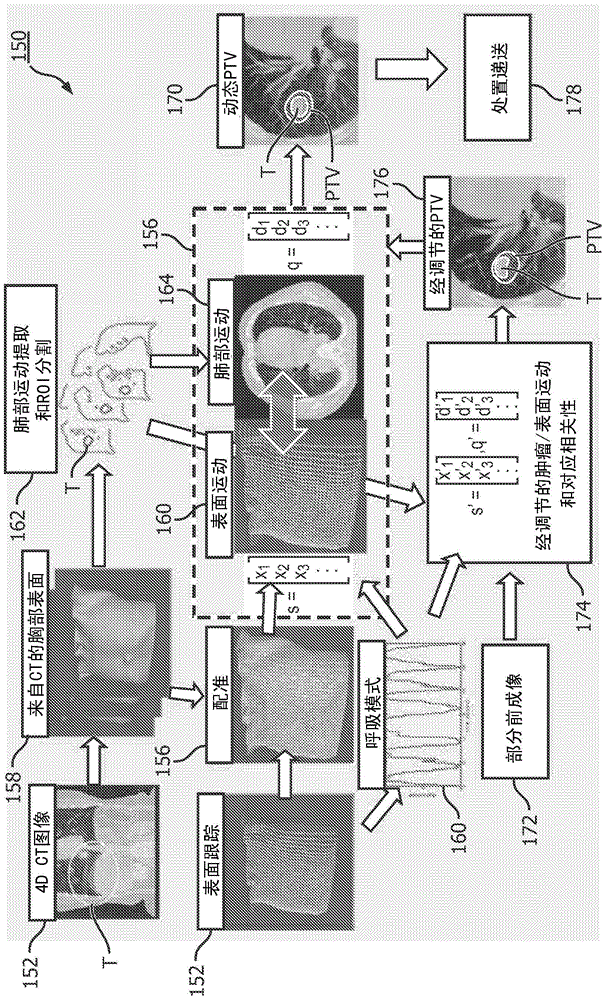

Method for improved surface tracking-based motion management and dynamic planning in adaptive external beam radiation therapy

ActiveCN105102062ASmall doseFull doseRadiation diagnosticsX-ray/gamma-ray/particle-irradiation therapyDynamic planningSelf adaptive

A therapy system and method treats an internal target of a patient (16). A treatment plan (36) is received to treat the internal target. The treatment plan (36) includes a plurality of treatment fractions including correspondences (38) between the internal target and an external body surface based on a pre-procedural planning image (14) and pre- procedural tracking data (20). Before selected treatment fractions of the plurality of treatment fractions, a pre-fraction planning image (50) of the target is received, tracking data (20, 52) of the external body surface of the patient (16) is received, and the correspondences (38) between the internal target and the external body surface are updated based on the received pre-fraction planning image (50) and the received tracking data (20, 52). Therapy is delivered to the patient (16) in accordance with the treatment plan (36) and using the updated correspondences (38).

Owner:KONINKLJIJKE PHILIPS NV

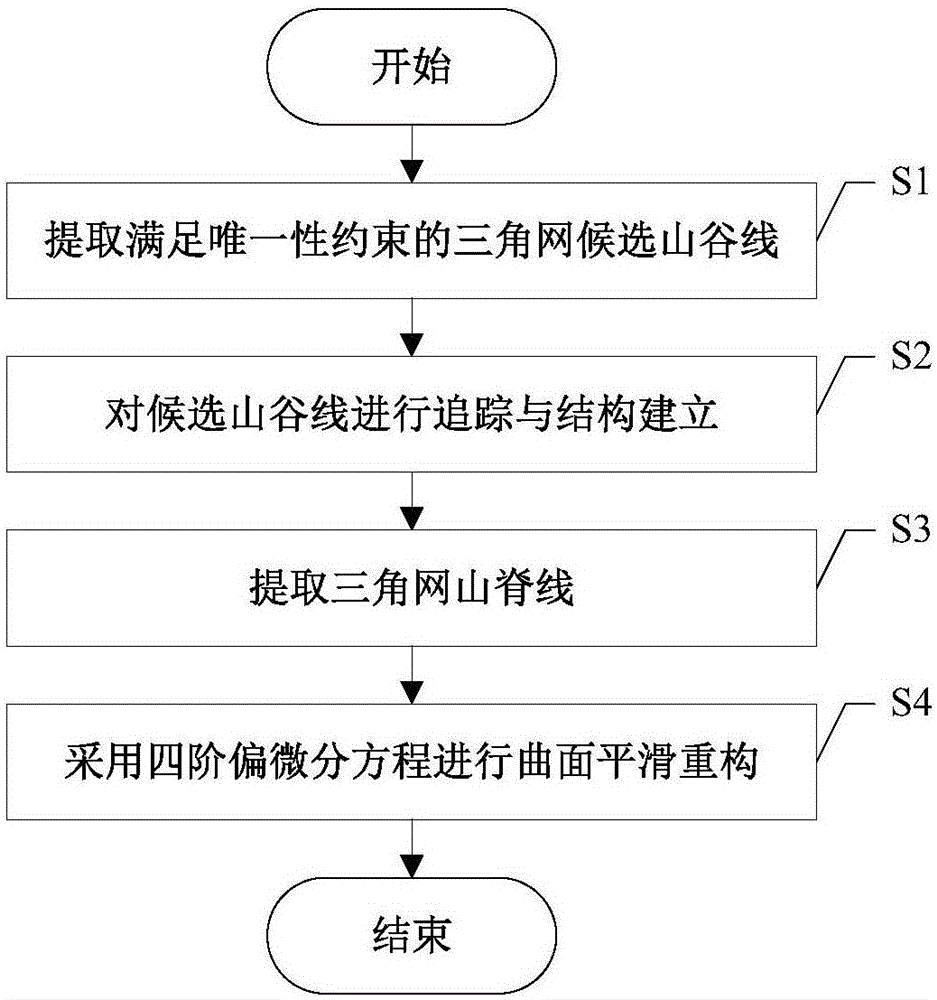

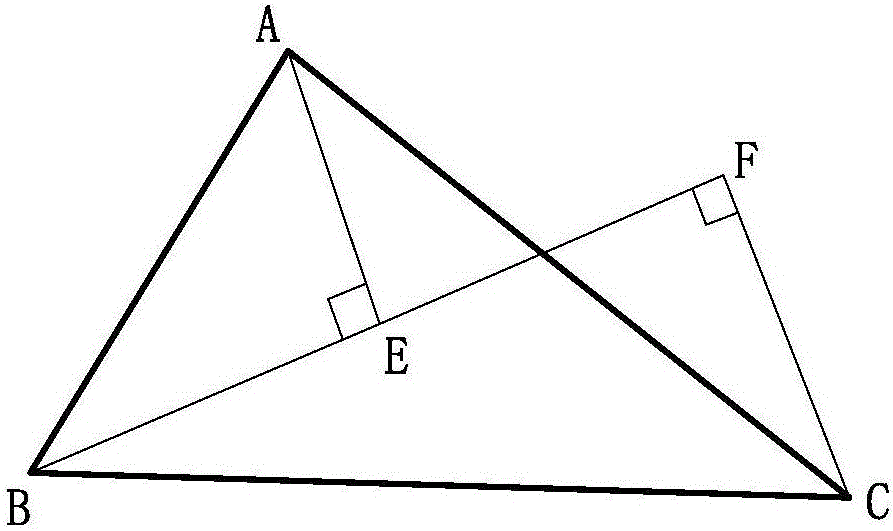

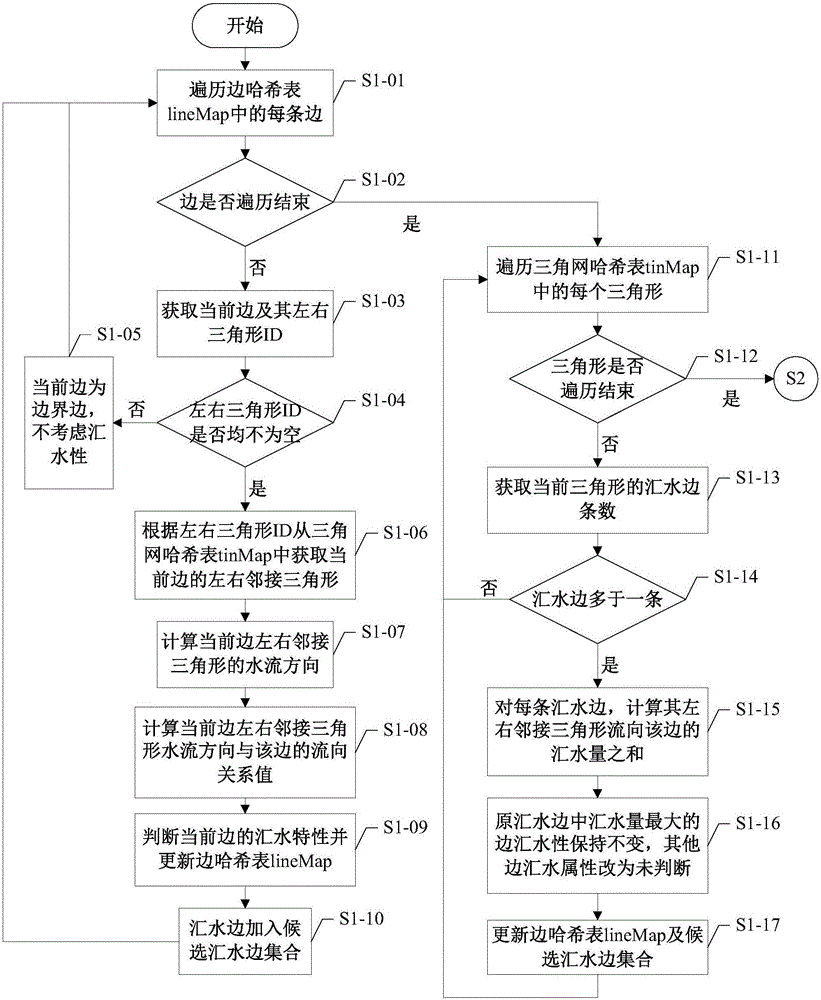

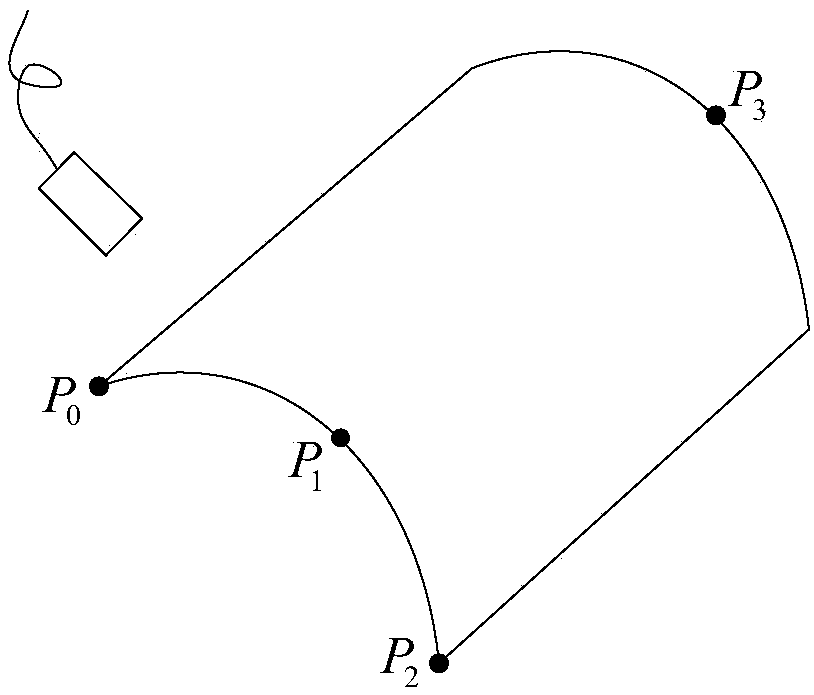

Complex geological curved surface feature extraction and reconstruction method

ActiveCN106446910ASolve FragmentationSmall amount of calculationCharacter and pattern recognitionImage renderingTerrainFeature extraction

The invention discloses a complex geological curved surface feature extraction and reconstruction method. By reference to related knowledge in the aspect of river network tracking in hydrological analysis and introduction of surface tracking, the problem in fragmentization during feature line extraction is solved; and by applying a hash table, the calculation amount of a geological feature extraction part is greatly reduced and the extraction efficiency is greatly improved. In addition, for the deficiencies that the calculation amount is large, terrain skeleton points cannot be determined and are reserved, and the like in an existing terrain reconstruction method, a fourth-order partial differential equation-based geological curved surface smooth reconstruction thought is adopted, and feature point constraints are introduced for reserving terrain features of an original curved surface in a smoothing process, so that relatively good balance is achieved between curved surface smoothing and curved surface feature reservation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

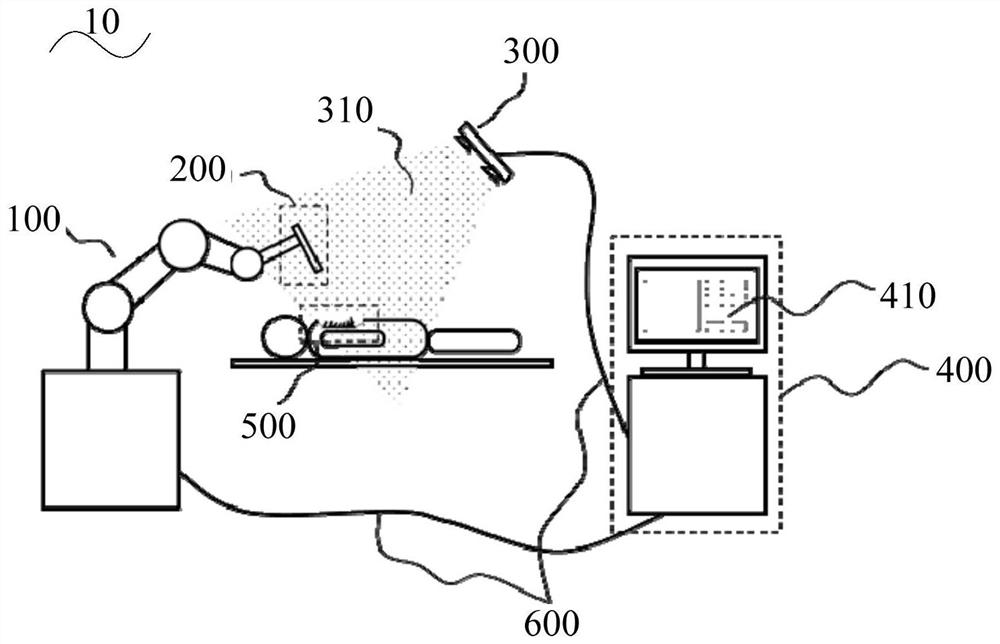

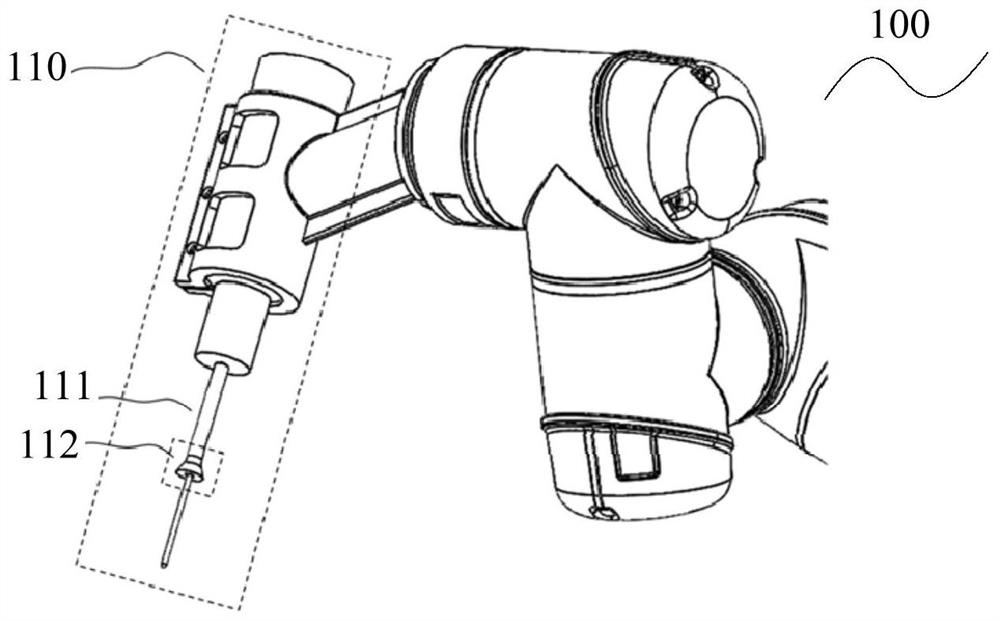

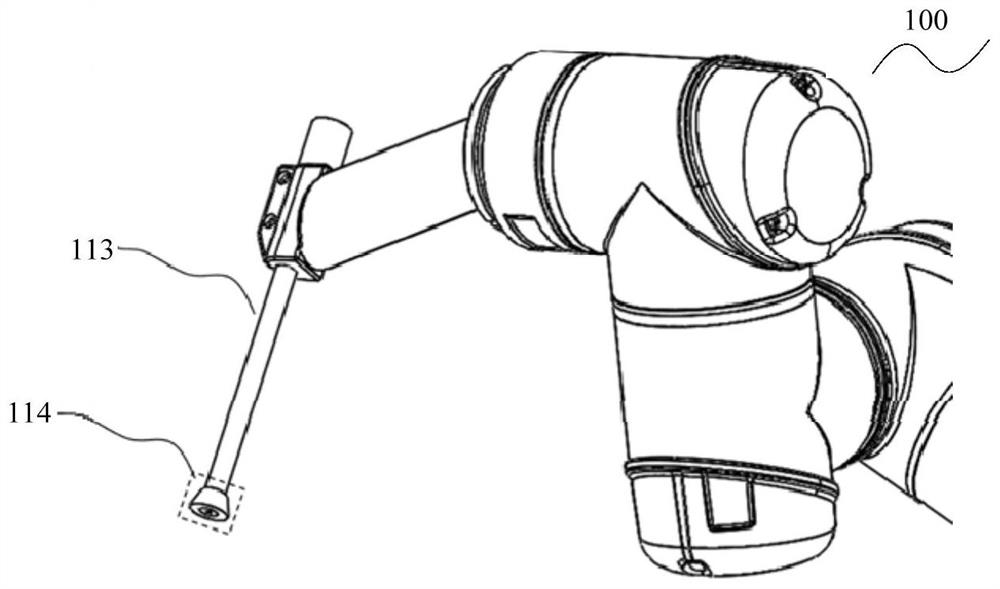

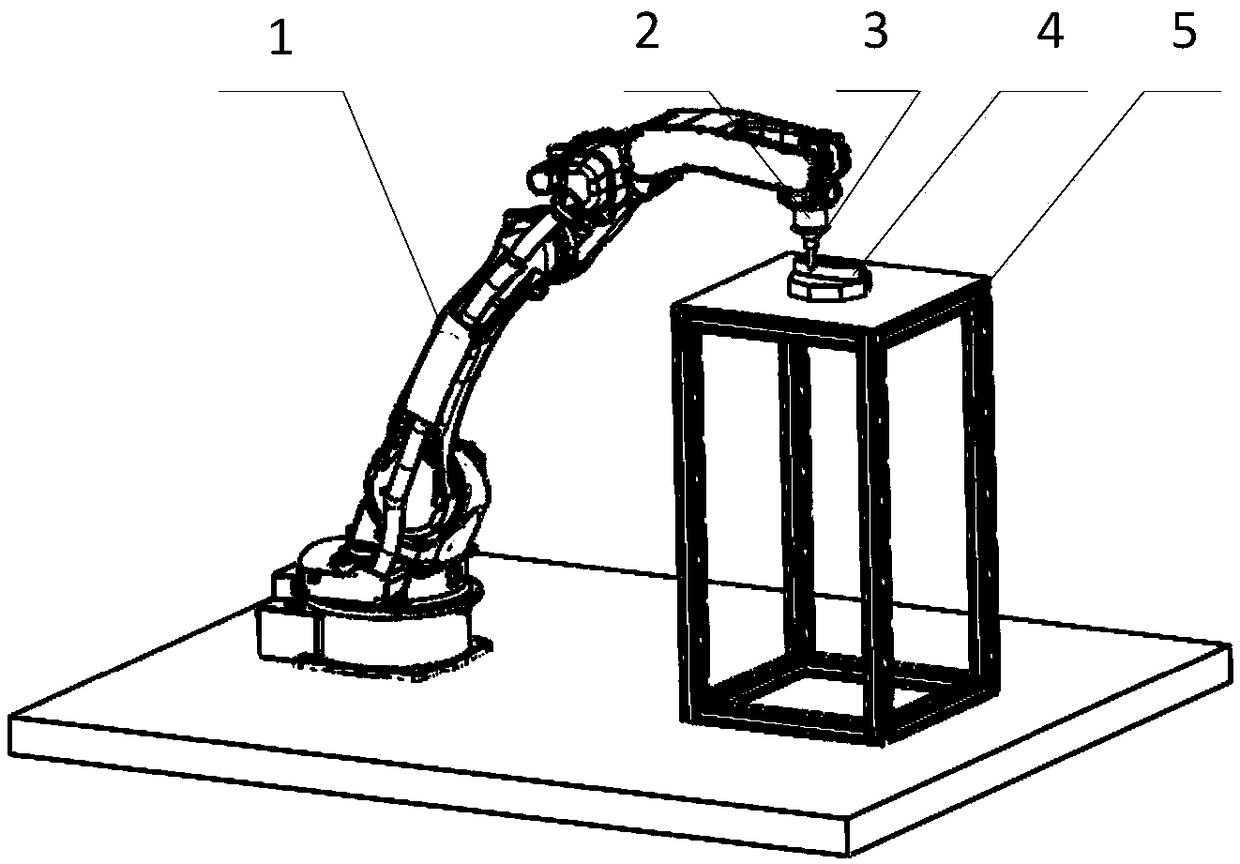

Nailing surgical robot system based on surface tracking and control method

ActiveCN112006777ASurgical navigation systemsSurgical systems user interfaceEngineeringSurgical robotics

The invention discloses a nailing surgical robot system based on surface tracking and a control method, the nailing surgical robot system comprises a mechanical arm, a surgical instrument, a surface scanning device and a workstation, the mechanical arm has a translational degree of freedom and a rotational degree of freedom and is used for moving the surgical instrument; the surgical instrument ismounted at the front end of the mechanical arm and used for drilling and nailing a surgical target; the surface scanning device is used for acquiring surface three-dimensional geometrical informationand color information of the object in the operation area; the workstation is connected with the mechanical arm and the surface scanning device through data lines and used for processing the surfacethree-dimensional geometrical information and color information, obtaining the relative poses of the surgical target and the surgical instrument, planning the drilling and nailing path and controllingthe mechanical arm to move. The system directly performs control according to the surface image without an additional optical mark, is simple in equipment and concise in operation process, can perform feedback adjustment according to image information fed back in real time in an operation, and has higher nailing precision.

Owner:TSINGHUA UNIV

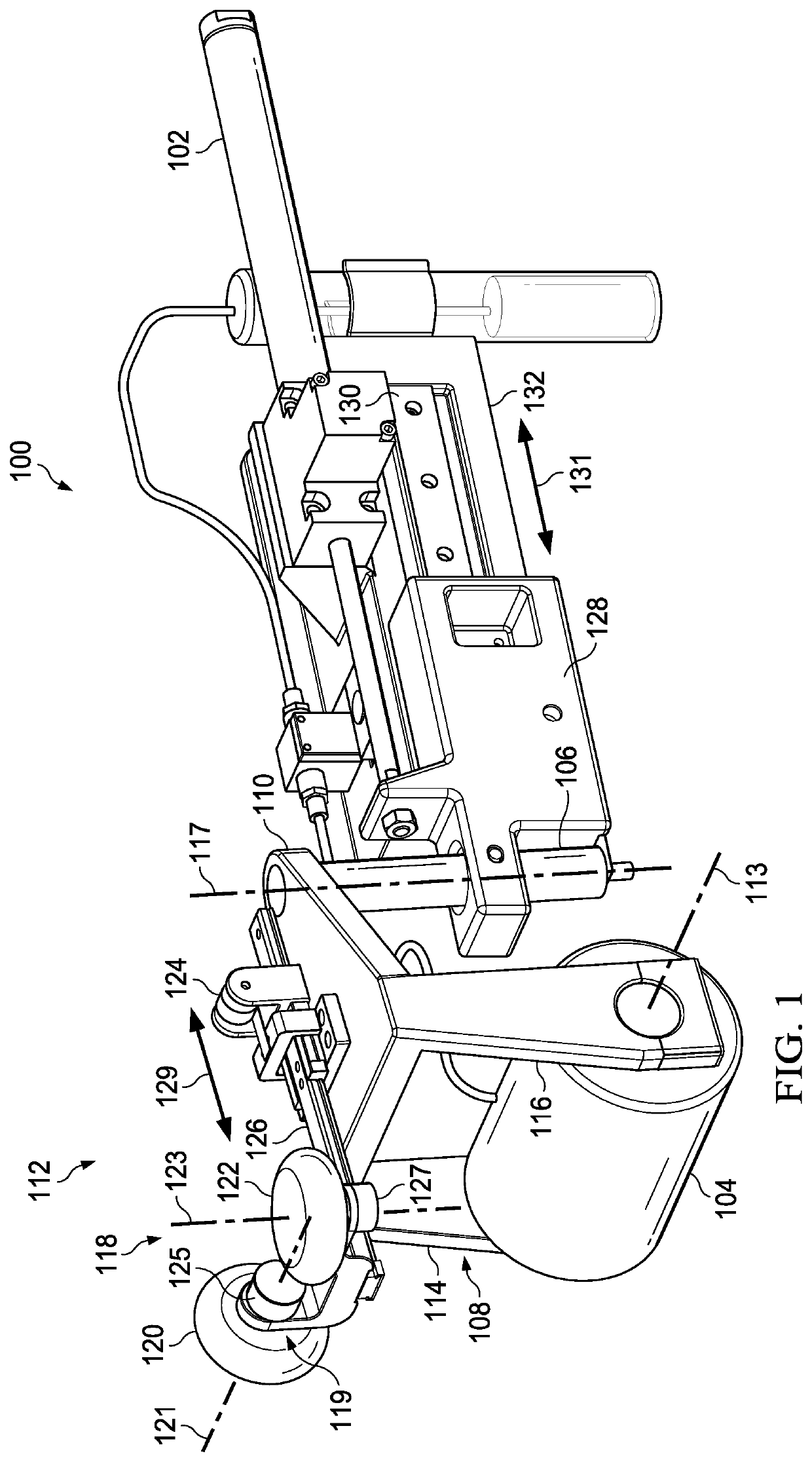

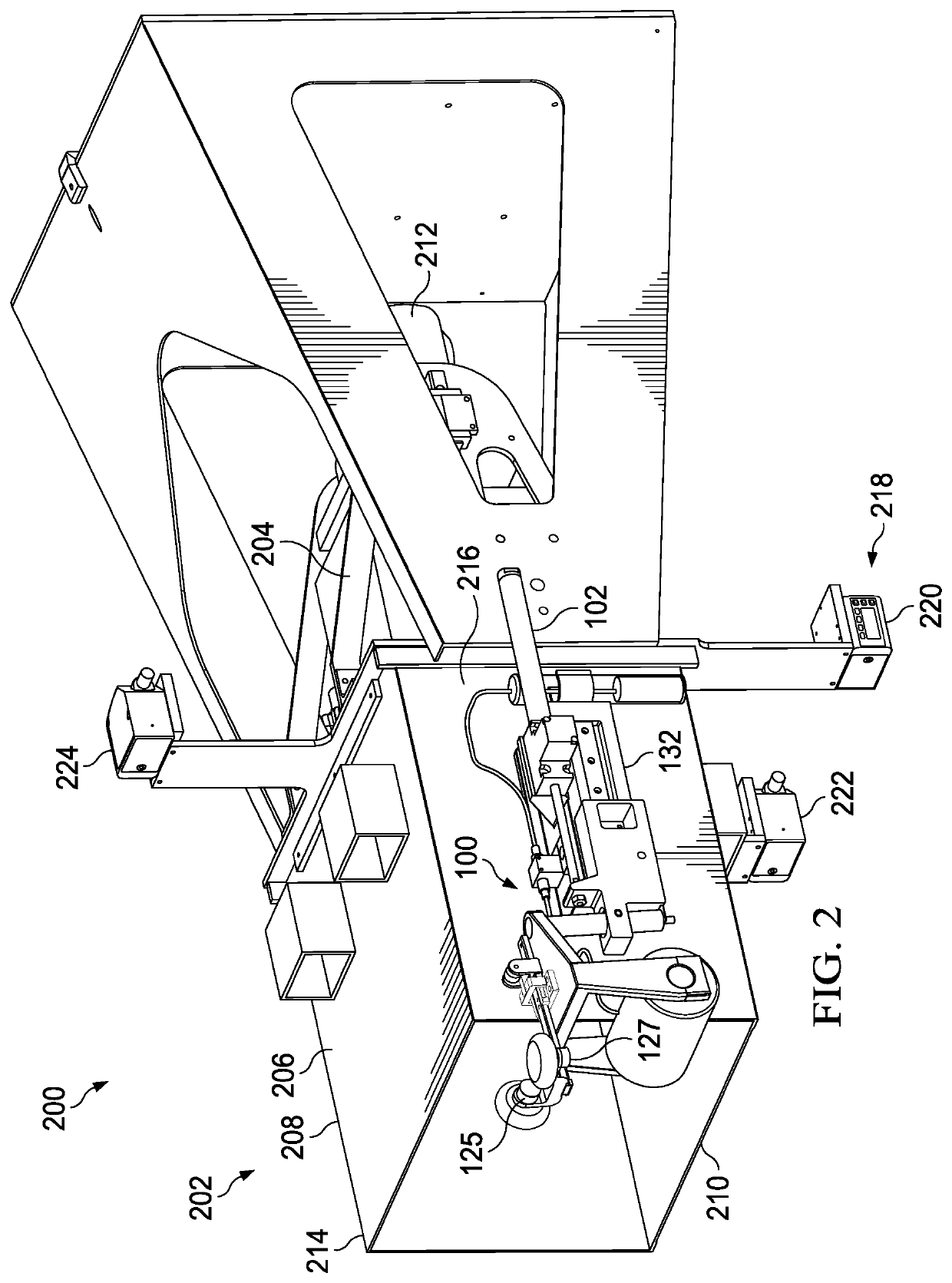

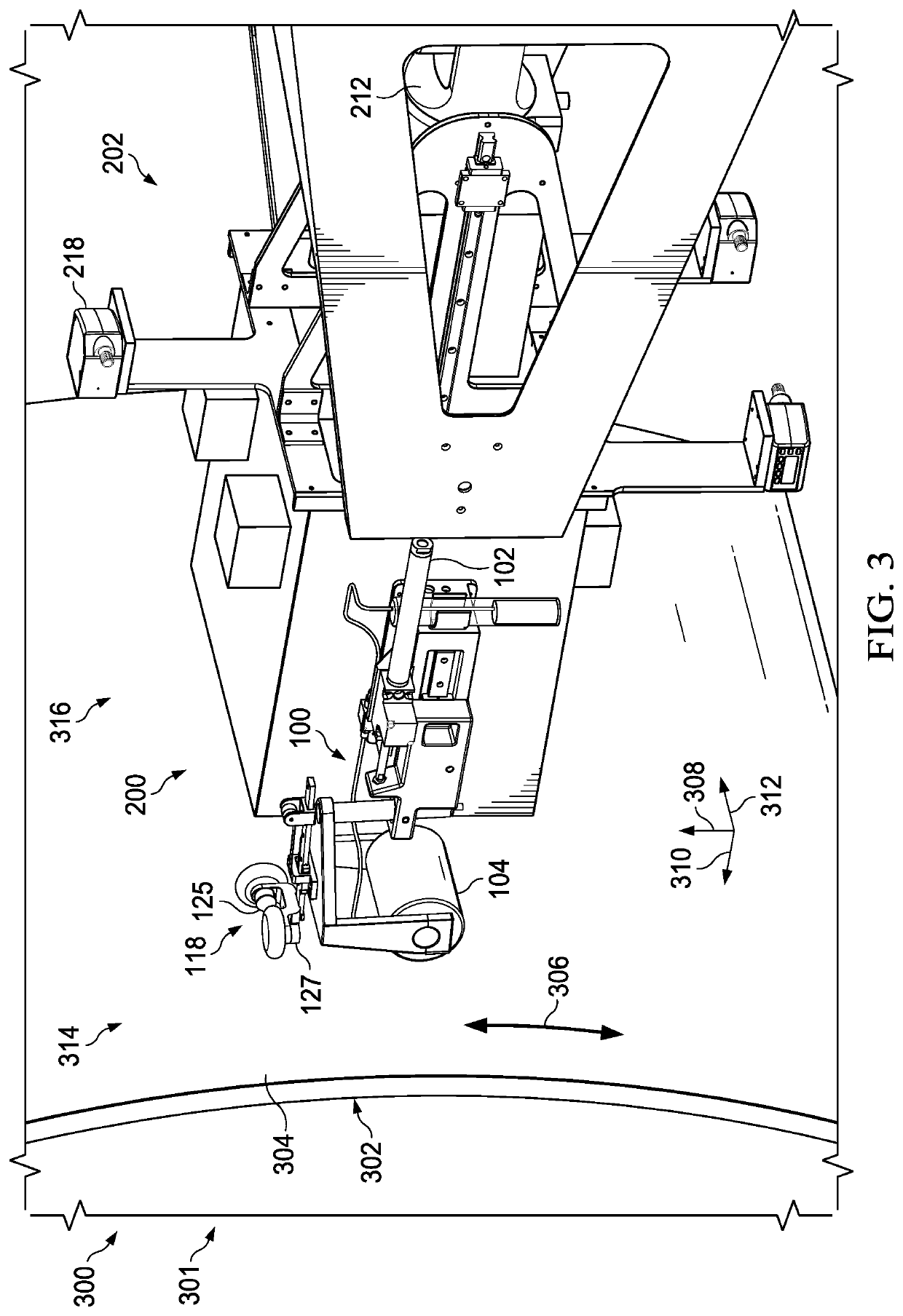

Robotic end effector system with surface tracking and methods for use

ActiveUS20210078177A1Programme-controlled manipulatorMaterial analysis using sonic/ultrasonic/infrasonic wavesControl engineeringRobot end effector

A non-destructive inspection system is presented. The non-destructive inspection system comprises a robotic end effector having an extendable actuator and a flange-mounted roller containing an ultrasonic sensor, the flange-mounted roller connected to the extendable actuator by a pivot connection, the extendable actuator configured to extend the flange-mounted roller until the flange-mounted roller contacts an inspection surface.

Owner:THE BOEING CO

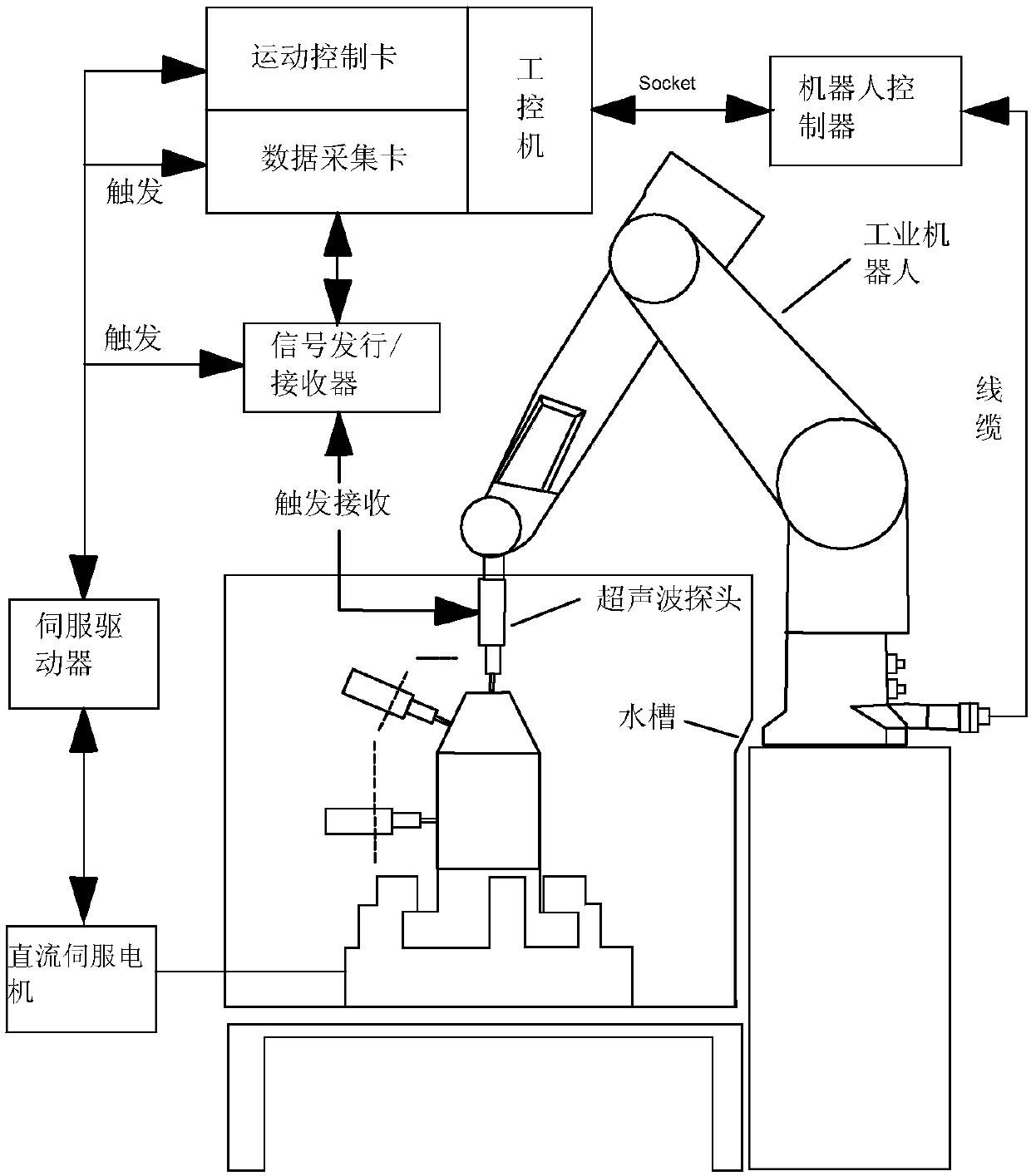

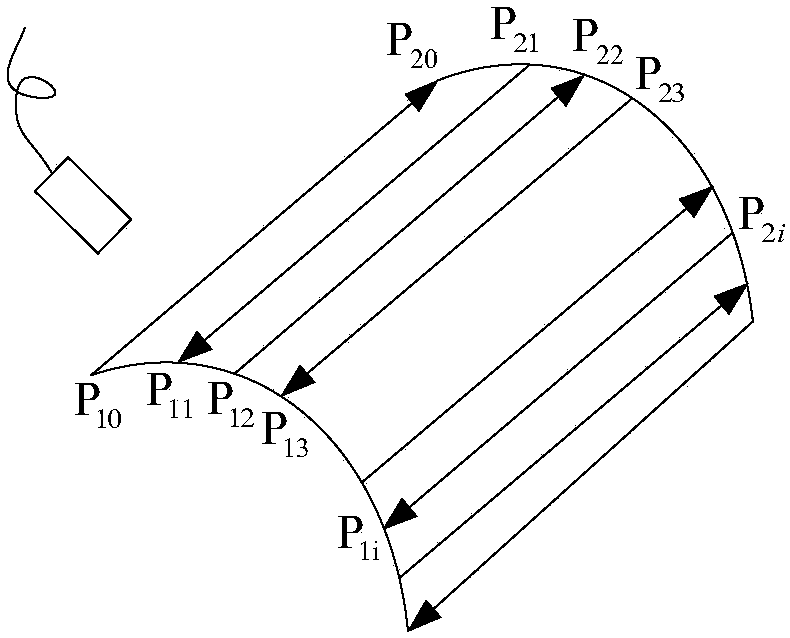

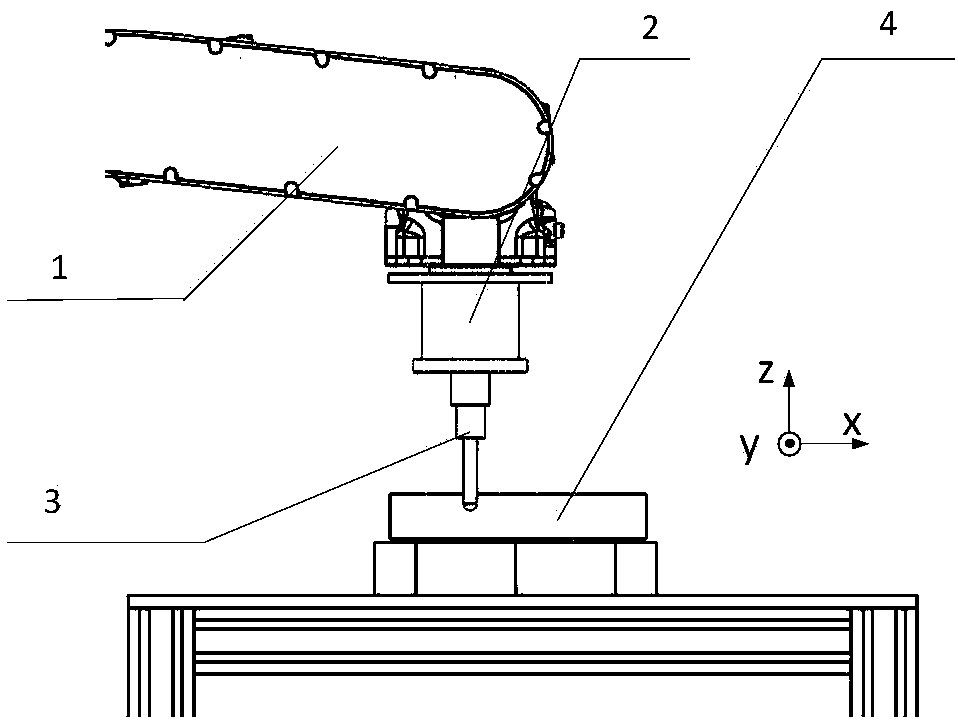

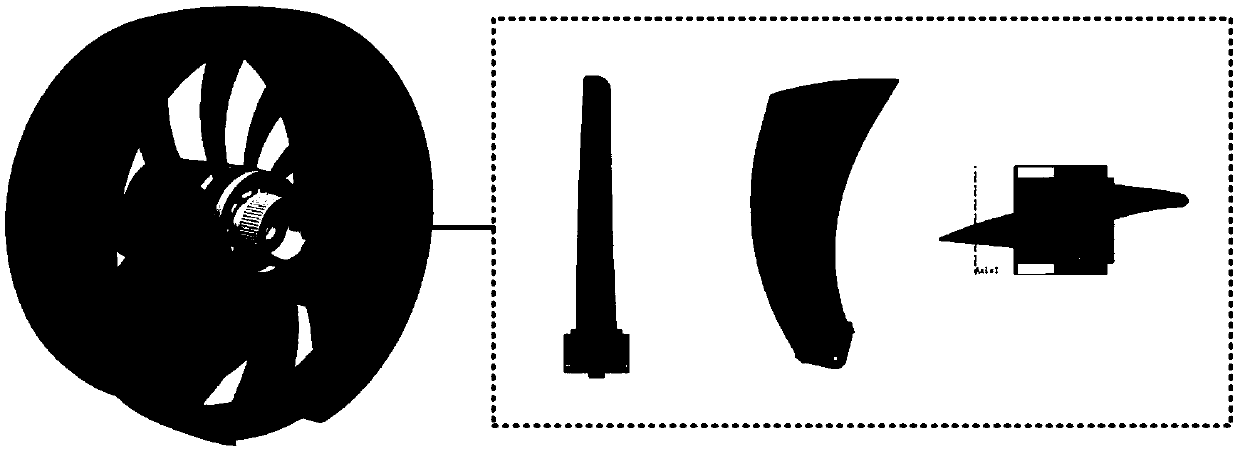

Ultrasonic C scanning automatic detection method for arc surface work pieces, without clamping and positioning

ActiveCN108318581AImprove detection efficiencyRealize ultrasonic automatic detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesCrucial pointManipulator

The invention discloses an ultrasonic C scanning automatic detection method for arc surface work pieces. According to the method, an ultrasonic probe is clamped through a six-degree-of-freedom industrial robot, the fact that a probe beam is always vertically emitted to an arc surface work piece during a detection process can be guaranteed, and real-time collection and plane imaging of original A wave of all scanning points are realized. The specific process comprises the followings steps: arbitrarily laying an arc surface work piece to a detection platform inside a water tank, obtaining Cartesian coordinates of 4 key points of the arc surface work piece by adjusting the position and pose of a mechanical arm and the level of ultrasonic echo signals on the surface of the work piece, and automatically planning a complete probe motion path and accomplishing corresponding ultrasonic acquisition and C scanned images. The method has the advantages that clamping and positioning are not required, arc surface work pieces are rapid and accurate to detect, high-precision and full coverage ultrasonic detection of the arc surface work pieces can be realized, detection efficiency of curved surface tracking is greatly improved, and occurrence of missing detection and false detection is effectively avoided.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

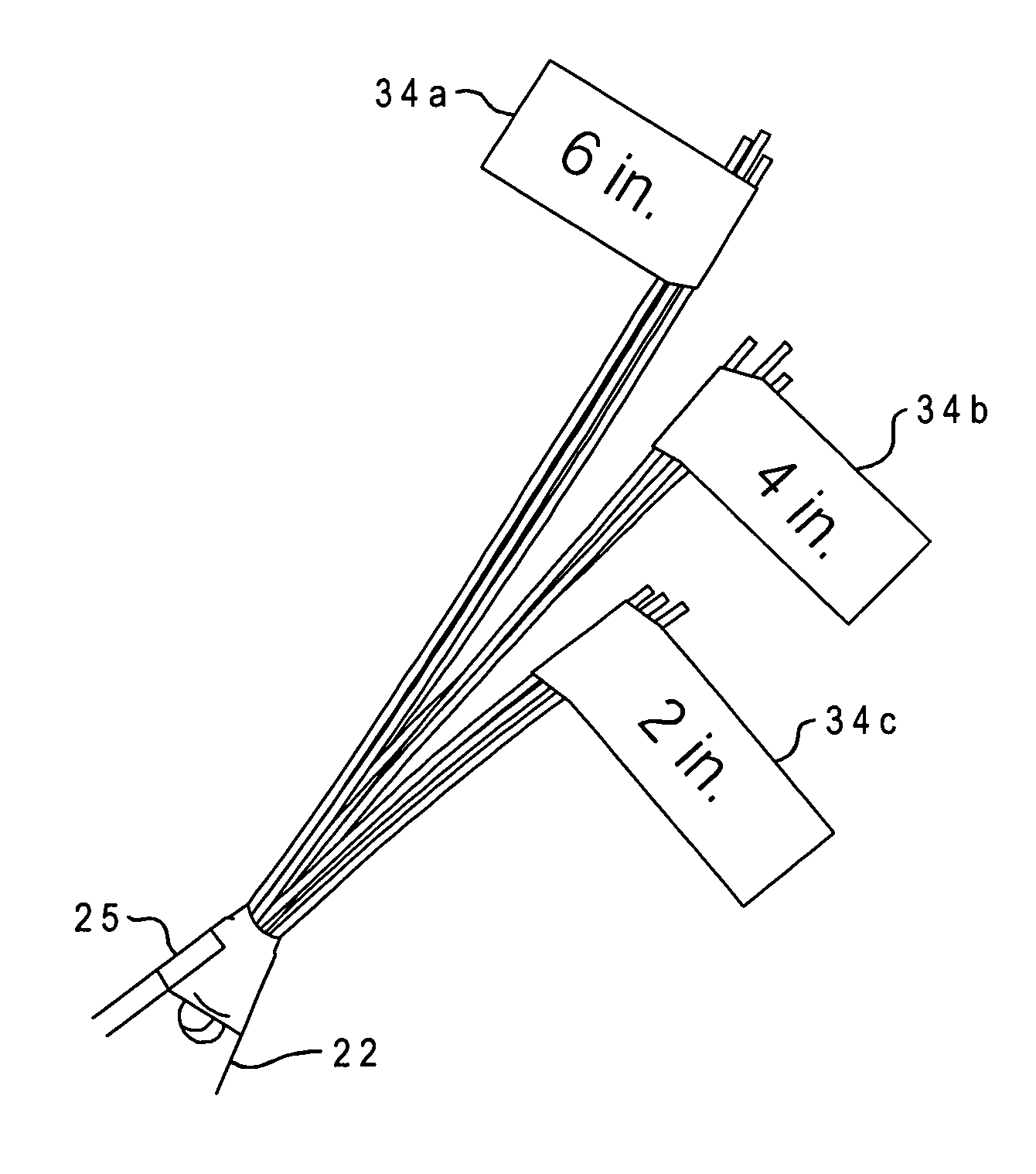

Surface tracker

InactiveUS20050200484A1Long-term locatabilityResistant to wearAnalysis using chemical indicatorsAntenna arraysAbove groundEndurability

A surface tracker includes a tubular marker body having an interior electronic marker and a visual indicator attached to an upper end of the marker body which extends away from the marker body. When deployed, the marker body is mostly underground and the visual indictor extends upwardly from the ground level to provide above-ground visual recognition. The electronic marker may be a passive electronic marker that includes a ferrite core assembly having a longitudinal axis which is generally parallel to a longitudinal axis of the marker body. The visual indicator may be a plurality of resilient filaments which pass through a hole in a tab portion of the marker body at the upper end thereof, the filaments being folded about the tab portion and secured to the tab portion using a heat-shrink tube. In an exemplary embodiment, the filaments extend about six inches from the marker body and are brightly colored. Multiple trackers can be used to mark the path of a buried utility. Due to the resilient and durable nature of the filaments, they are resistant to wear and tear and the elements. The visual indication, along with the ability to electronically detect the marker, provides a tracker with superior locating capability.

Owner:MINAROVIC JOE T

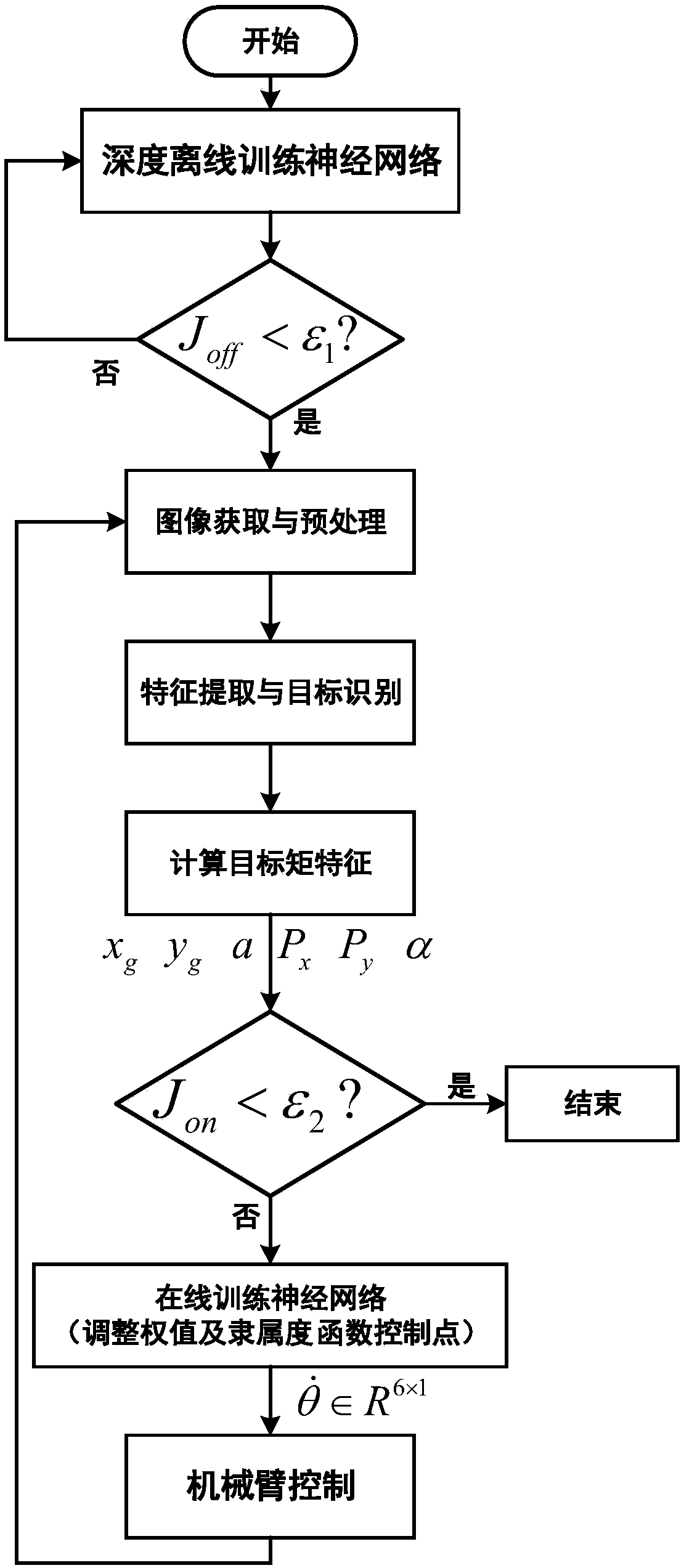

Method for tracking constant force surface of robot based on reinforcement learning

ActiveCN108972546ASolve the problem that it is difficult to obtain a constant tracking forceImprove data utilizationProgramme-controlled manipulatorConstant forceEngineering

The invention discloses a method for tracking a constant force surface of a robot based on reinforcement learning. The method comprises the steps that (1) for a feature of an industrial robot end effector contacting a surface profile, a mapping relation of surface normal force and a known sensor coordinate system is established; (2) an explicit force controller is designed for the contact processbetween the robot and a surface; (3) parameters of the controller are optimized by using a reinforcement learning method based on Gaussian model speculation; (4) iterative experiment is carried out until the error between the obtained force and the expected force is within a set range. The method for tracking the constant force surface of the robot based on reinforcement learning has the advantages that the problem is solved that constant tracking force is obtained difficultly in existing surface tracking of the robot, prior experience is not needed, the data utilization rate is high, the convergence speed is fast, and the obtained surface profile track provides an initial reference trajectory for subsequent grinding, polishing and other processing.

Owner:SOUTH CHINA UNIV OF TECH

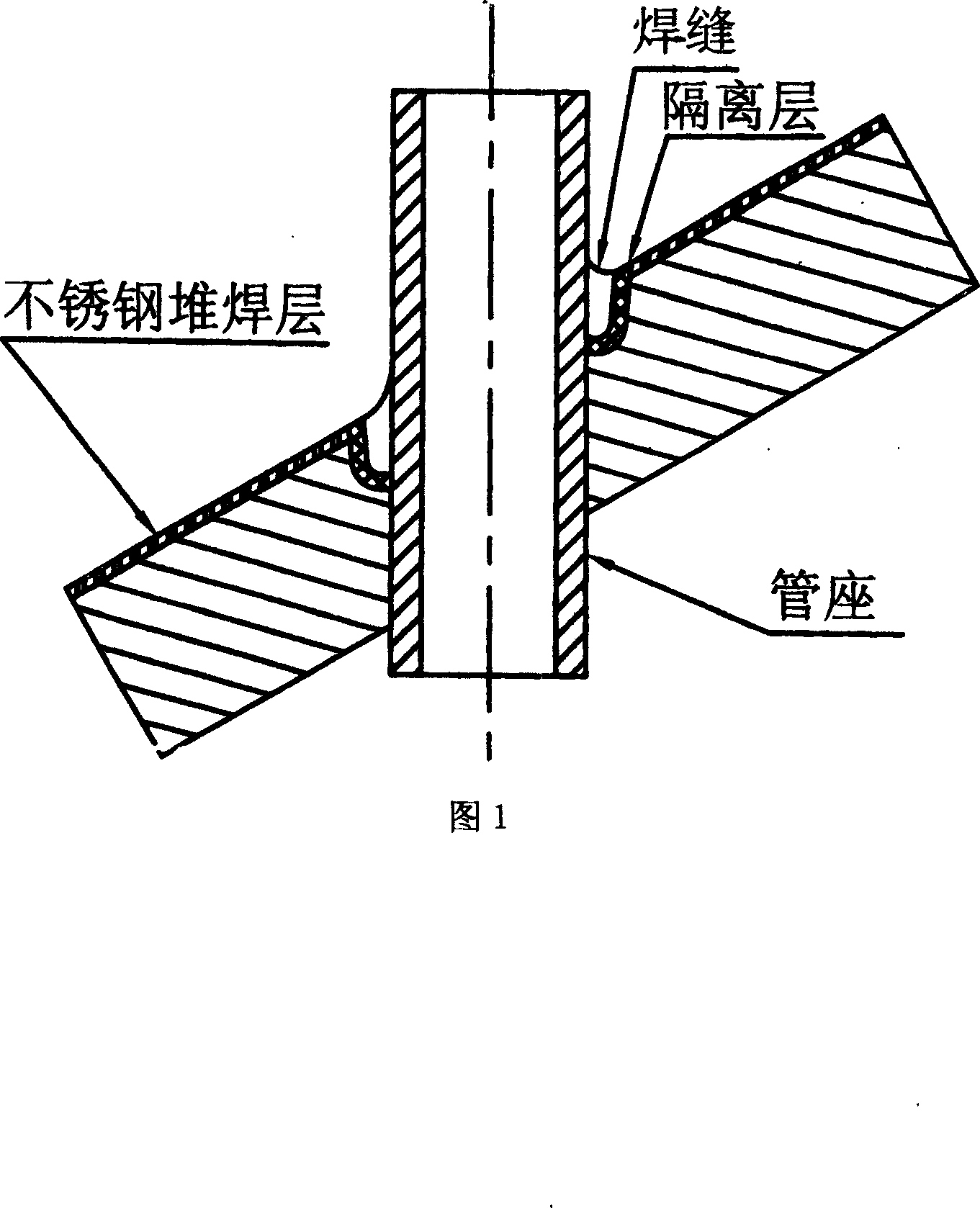

Complicated curved surface tracking method for welding nuclear power J-type joint

InactiveCN1974100AWeld firmlyAchieving Linear AmplificationArc welding apparatusControllers with particular characteristicsNuclear powerServomechanism

The complicated curved surface tracking method for welding nuclear power J-type joint belongs to the field of metal welding technology. The method includes the following steps: detecting the welding power source voltage and current output signal and workpiece position zero point signal to set the double servo mechanism motion; comparing the tested arc voltage value and the set parameter to obtain the difference and obtaining the position difference to start the PID controller; setting the PID parameters by means of the double servo mechanism and the programmable controller to realize the fast response and complete the tracking to complicated curved surface for stable welding. The present invention has wide adaptability, and is simple, repeatable and suitable for different arc striking modes.

Owner:SHANGHAI JIAO TONG UNIV

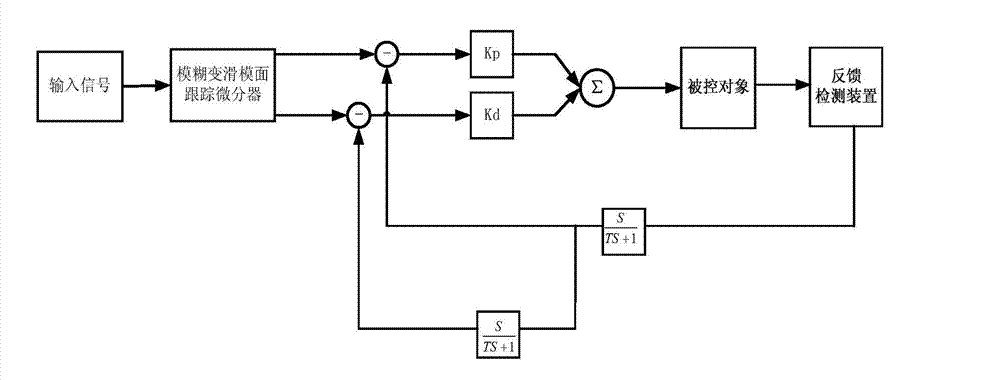

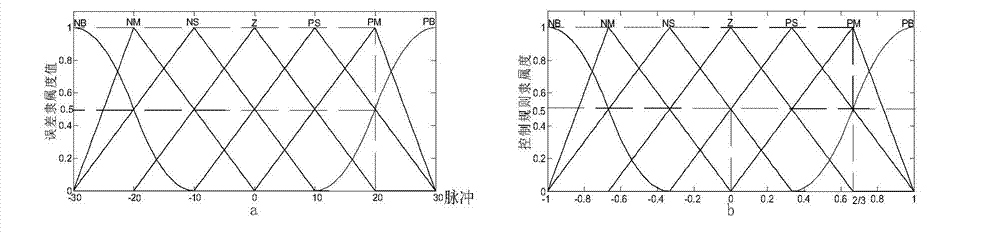

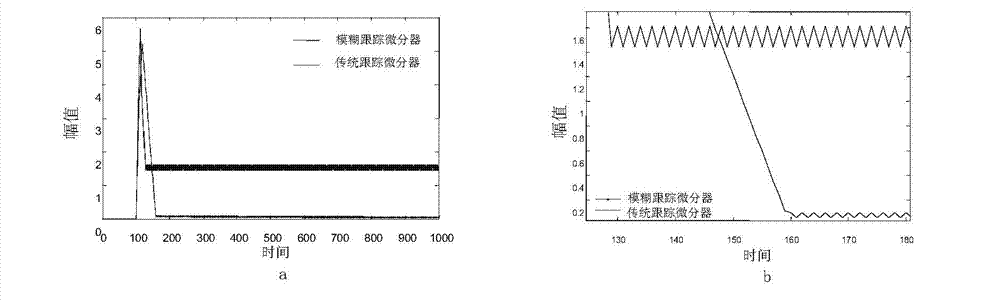

Control method based on fuzzy variable sliding model surface tracking differentiator

ActiveCN103699006ASuppress jitterImprove anti-interference abilityControllers with particular characteristicsDifferentiatorProportional control

The invention relates to a control method based on a fuzzy variable sliding model surface tracking differentiator. The input of the fuzzy variable sliding model surface tracking differentiator is a speed signal of a controlled object; the output of the fuzzy variable sliding model surface tracking differentiator is a tracking reproduction input control signal and the derivative of the tracking reproduction input control signal; the error is equal to the difference between the tracking reproduction input control signal and an input control signal, and comprises seven fuzzy sets. The control method comprises the following steps: calculating the membership of the error corresponding to the seven fuzzy sets; calculating a control rule on each control fuzzy set corresponding to the error according to the obtained error membership vi on each error fuzzy set; calculating the output of the fuzzy variable sliding model surface tracking differentiator; performing proportional control on the difference between the speed output by the differentiator and the feedback speed of the controlled object; performing derivative control on the difference between the acceleration output by the differentiator and the feedback acceleration of the controlled object; controlling the controlled object after the speed difference which is subjected to the proportional control is added to the acceleration difference which is subjected to the derivative control.

Owner:BEIJING UNIV OF TECH

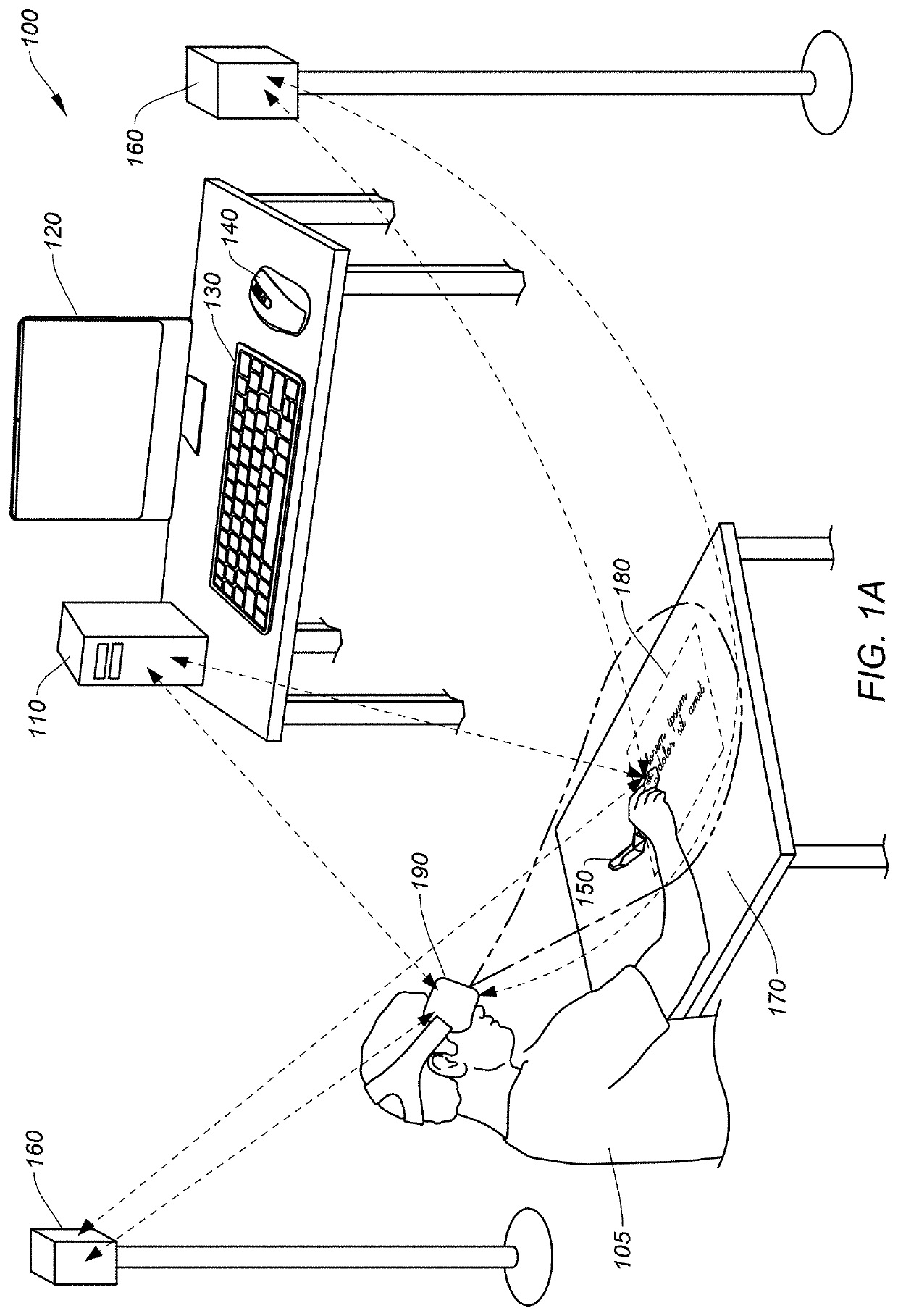

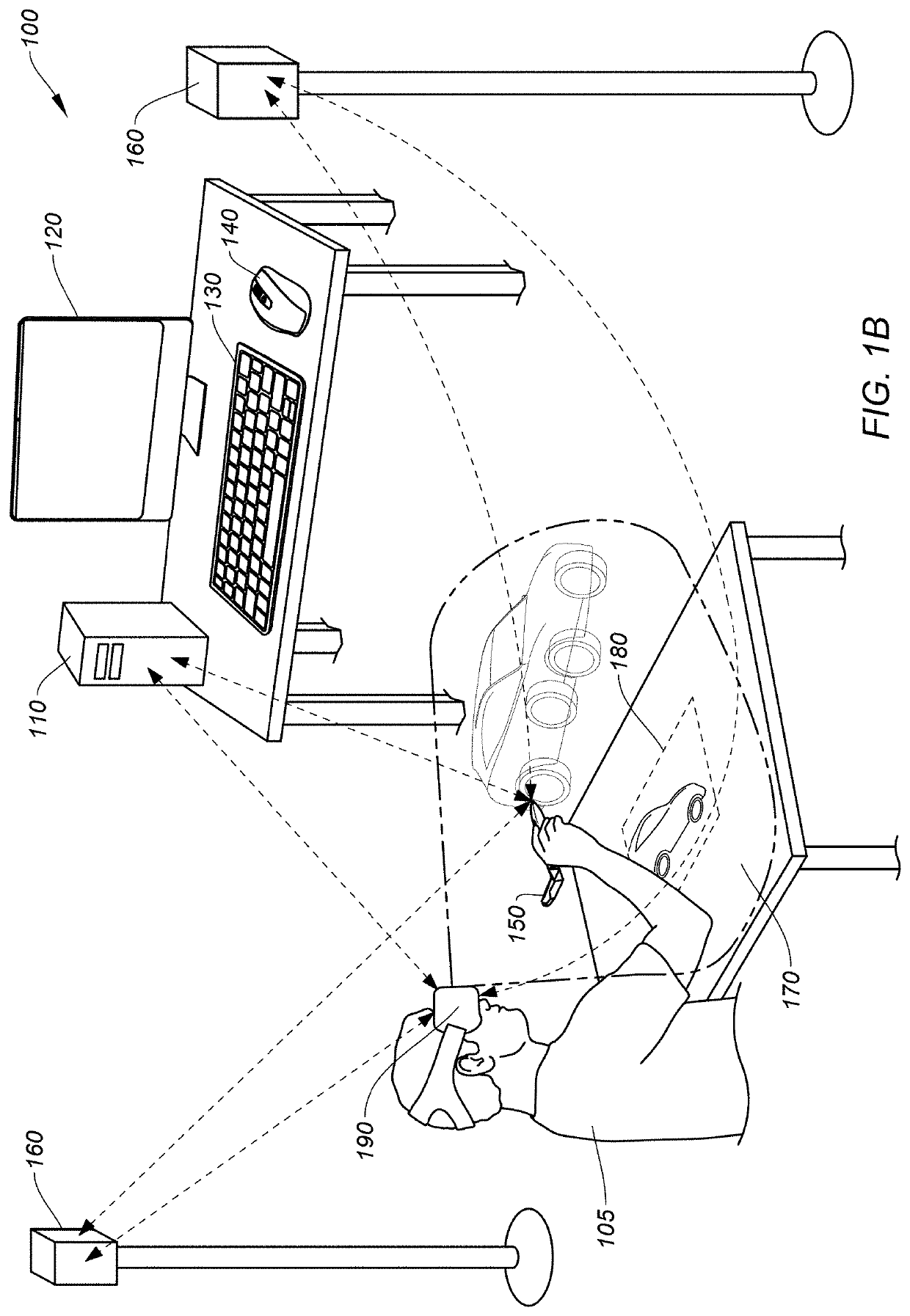

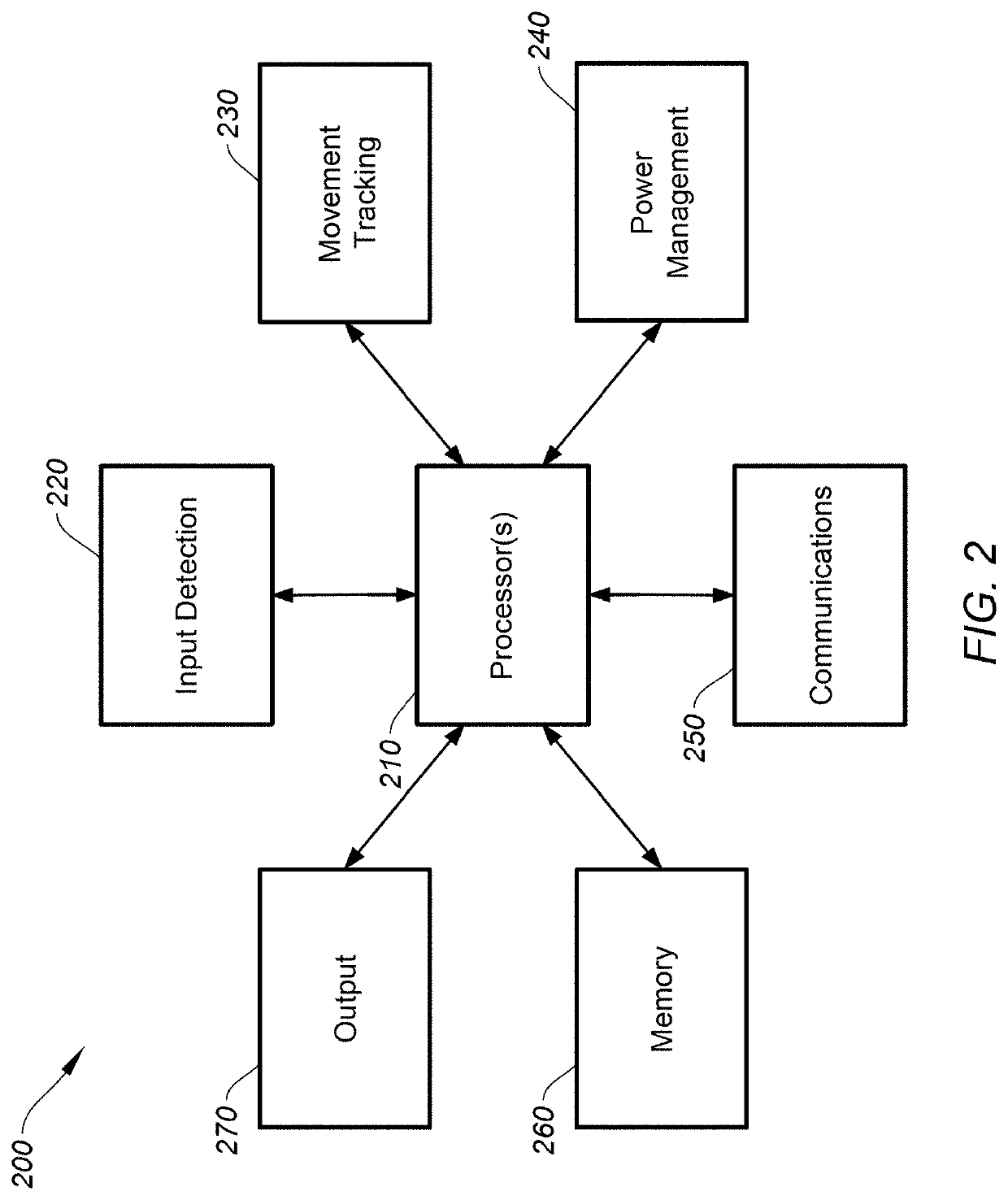

Systems, devices, and methods for physical surface tracking with a stylus device in an AR/VR environment

ActiveUS11397478B1Reduce tracking errorEasy to drawInput/output for user-computer interactionComputer graphics (images)Engineering

A method includes receiving sensor data from one or more sensors that corresponds to a location of a stylus device and determining that a tip of the stylus device is in contact with a physical surface based on the sensor data. While in contact, the method includes determining a new location of the tip of the stylus device based on the location data, mitigating a tracking error of the determined new location of the tip of the stylus device by translating the new location from a 3D space domain to a 2D space domain that corresponds to the physical surface and adjusting the new location based on a comparison of the new location and historical locations.

Owner:LOGITECH EURO SA

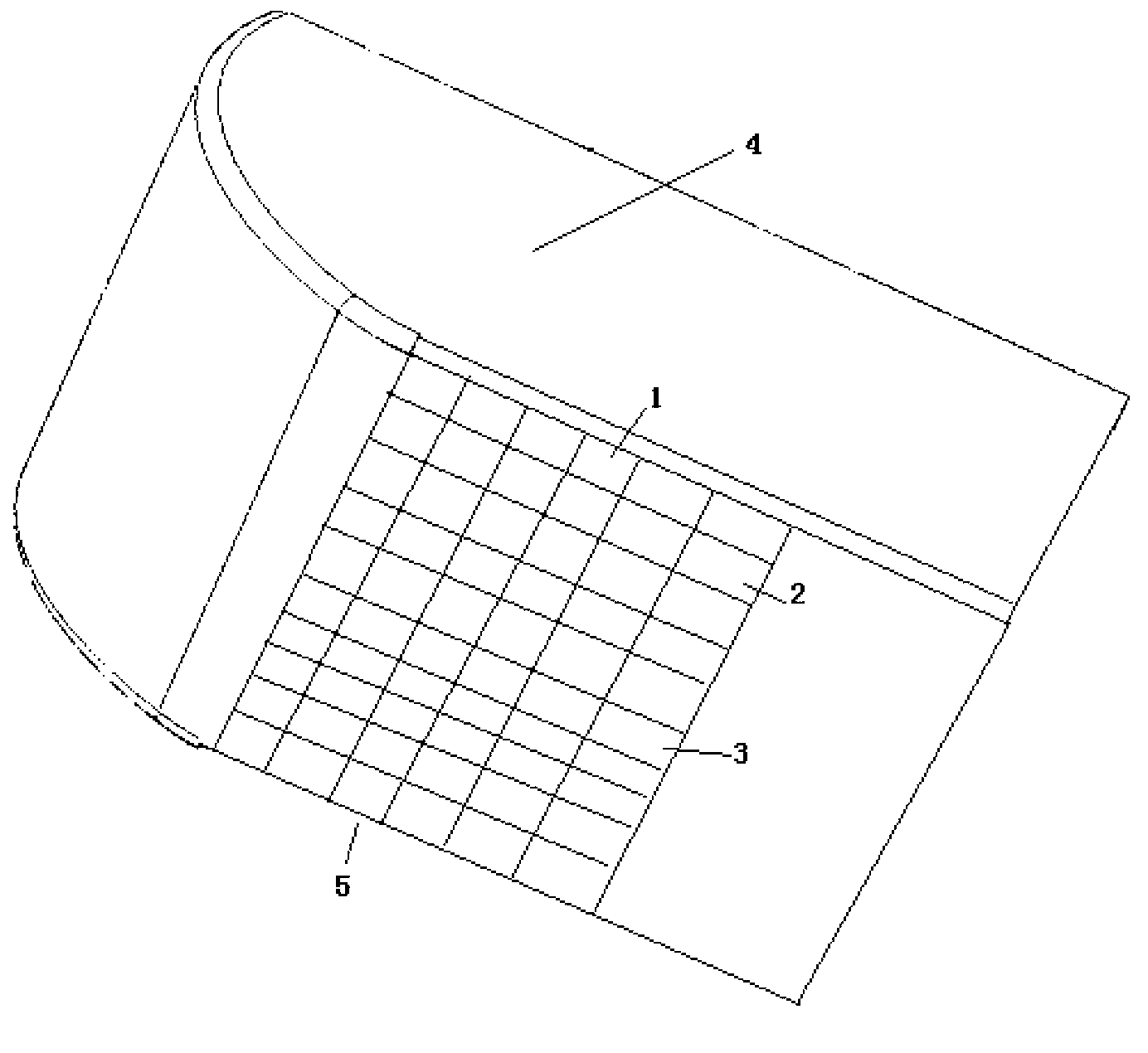

Robot dexterous hand curved-surface tracking method based on pressure sensor array

ActiveCN103223675AImplement grab controlImplement plane detectionManipulatorSensor arrayConstant force

The invention discloses a robot dexterous hand curved-surface tracking method based on a pressure sensor array, and belongs to the technical field of robot dexterous hand control. The method comprises the following steps of: firstly, arranging the pressure sensor array on a robot dexterous hand; secondly, scanning and detecting the positive pressure stressed on each sensor in the pressure sensor array; thirdly, selecting three pressure sensors which are not located on the same straight line and are stressed with non-zero positive pressure; fourthly, adjusting an included angle between a plane on which the sensor array is located and a curved surface with which the robot dexterous hand is in contact according to the difference of the positive pressure stressed on the three pressure sensors from the third step, until the positive pressure stressed on the three pressure sensors are equal; and fifthly, adjusting the equal positive pressure stressed on the pressure sensors to a preset value. According to the method, the robot dexterous hand can sweep through one curve surface with constant force, plane detection can be realized, and simultaneously the curve surface of an unknown object can be predicated, so that the control on grabbing the unknown object can be realized by the robot dexterous hand.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

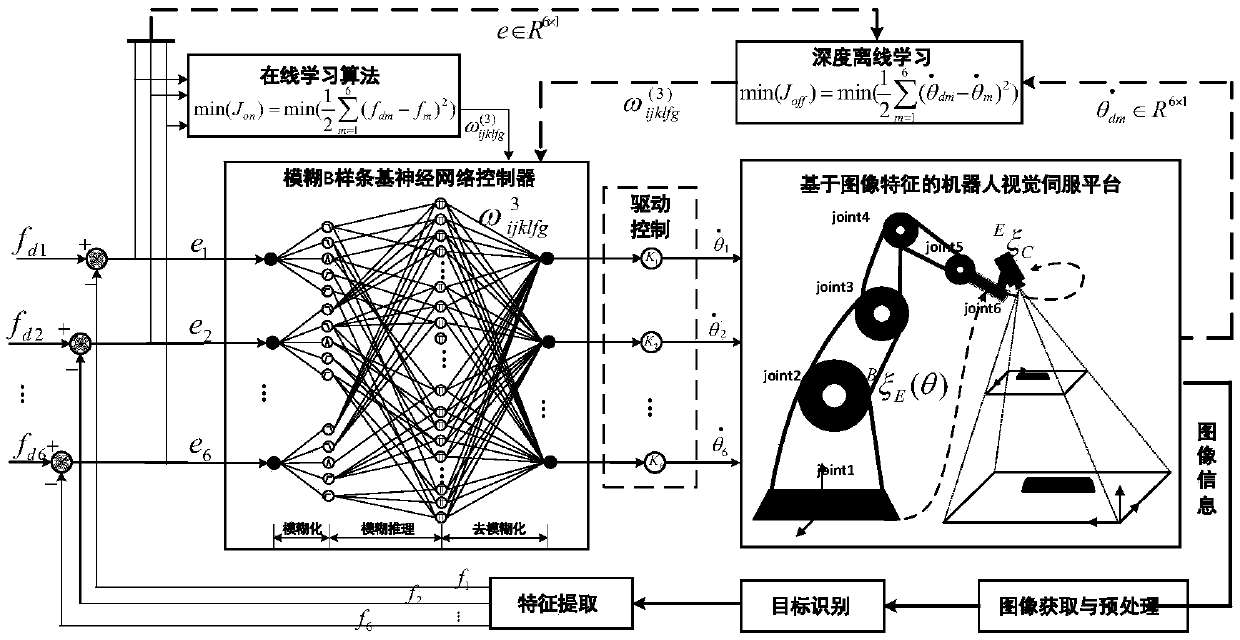

Irregular curved surface tracking method and system based on matrix feature learning neural network

ActiveCN108717262AEasy to controlRealize tracking and positioningAdaptive controlFeature vectorNeural network controller

The invention discloses an irregular curved surface tracking method and system based on a matrix feature learning neural network. The method comprises the steps that an expectation feature vector is obtained; an initial matrix feature vector, the Jacobian matrix of the initial matrix feature vector and the target joint angular velocity vector of a mechanical arm are obtained; deep off-line training is conducted on a b-spline-based neural network controller by using the initial matrix feature vector, the Jacobian matrix of the initial matrix feature vector and the target joint angular velocityvector of the mechanical arm; feature errors of the current matrix feature vector and the expectation matrix feature vector are input to the trained b-spline-based neural network controller by the mechanical arm joint angular velocity vector to obtain the mechanical arm joint angular velocity vector under the current pose; the mechanical arm is controlled to move according to the mechanical arm joint angular velocity vector under the current pose to make a camera at the end of the mechanical arm to move along with the mechanical arm. By means of the method, the accurate positioning tracking ofan irregular curved surface can be achieved.

Owner:HUNAN UNIV

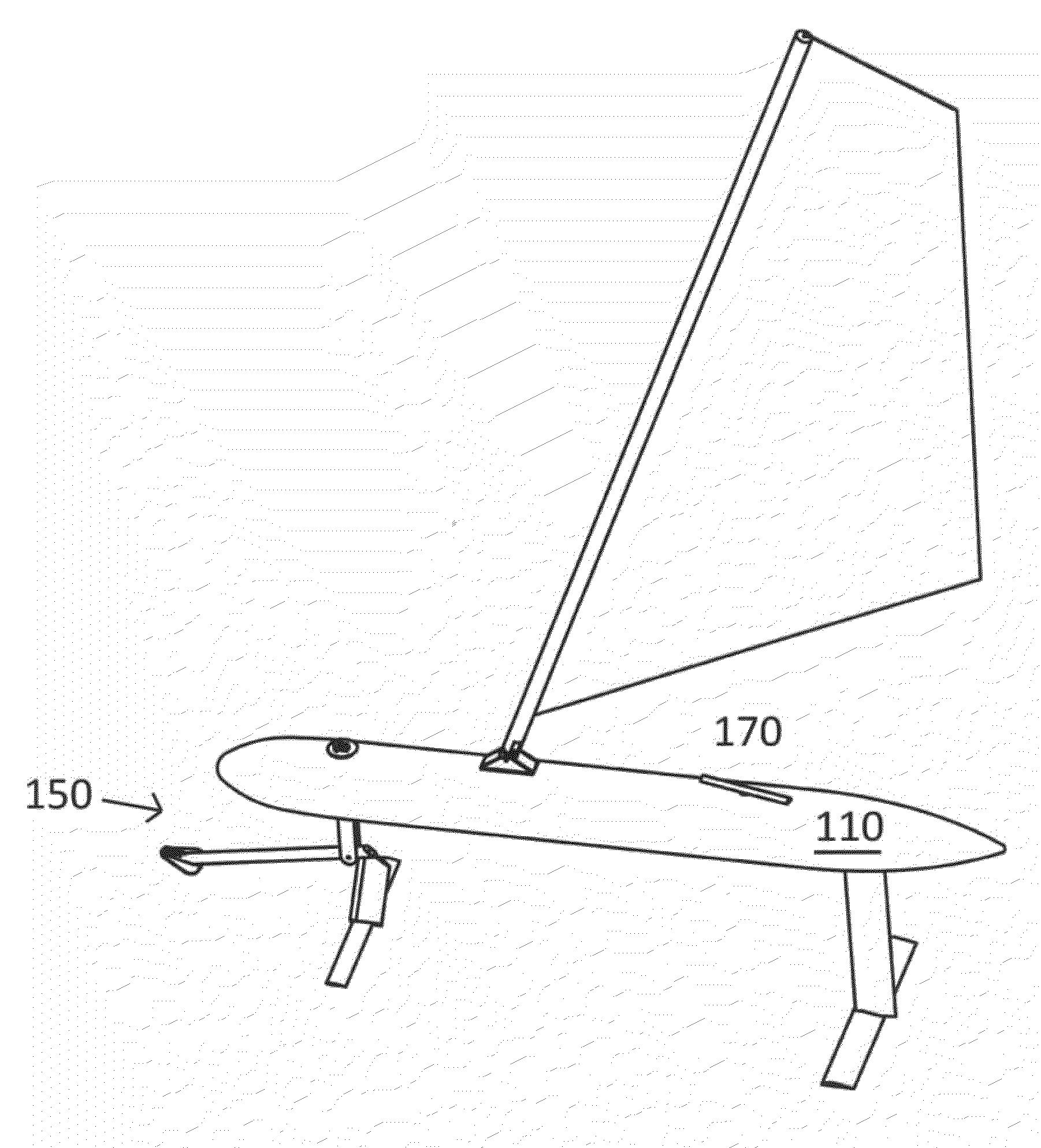

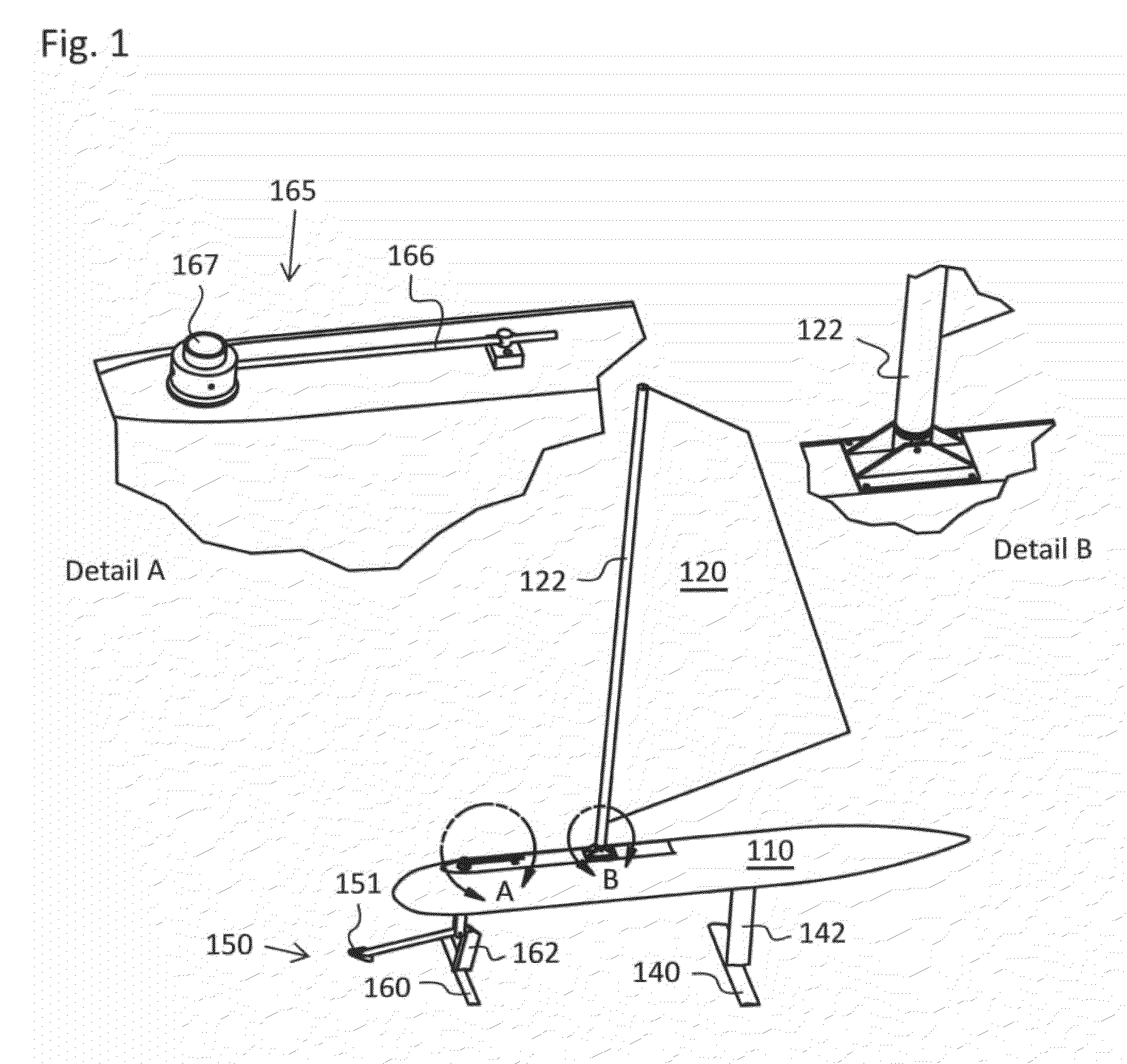

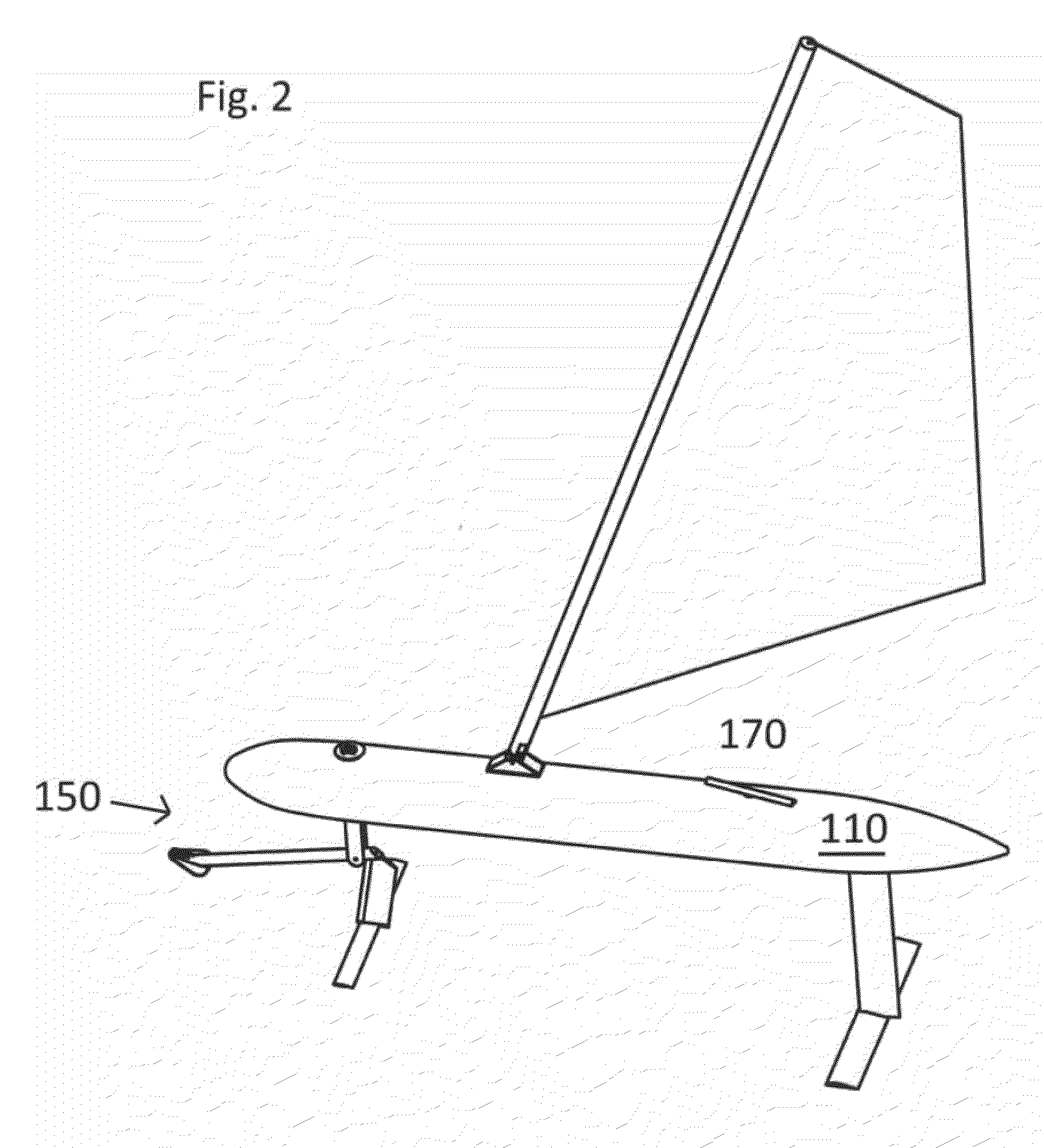

Wind-Powered Personal Hydrofoil Watercraft

A personal wind-powered hydrofoil watercraft having a sail supported by a mast coupled to a buoyant body, where the mast is tiltable forward and backward but not side to side, in order to prevent excessive rolling of the buoyant body when it is lifted clear of the water on the hydrofoils. Additionally, the buoyant body may be in the shape of a pontoon, the watercraft may be steerable by a steering mechanism actuated by a human operator's foot or feet, and the front hydrofoil may be associated with a surface tracking means in order to stabilize the altitude of the watercraft.

Owner:CHEN SHANE

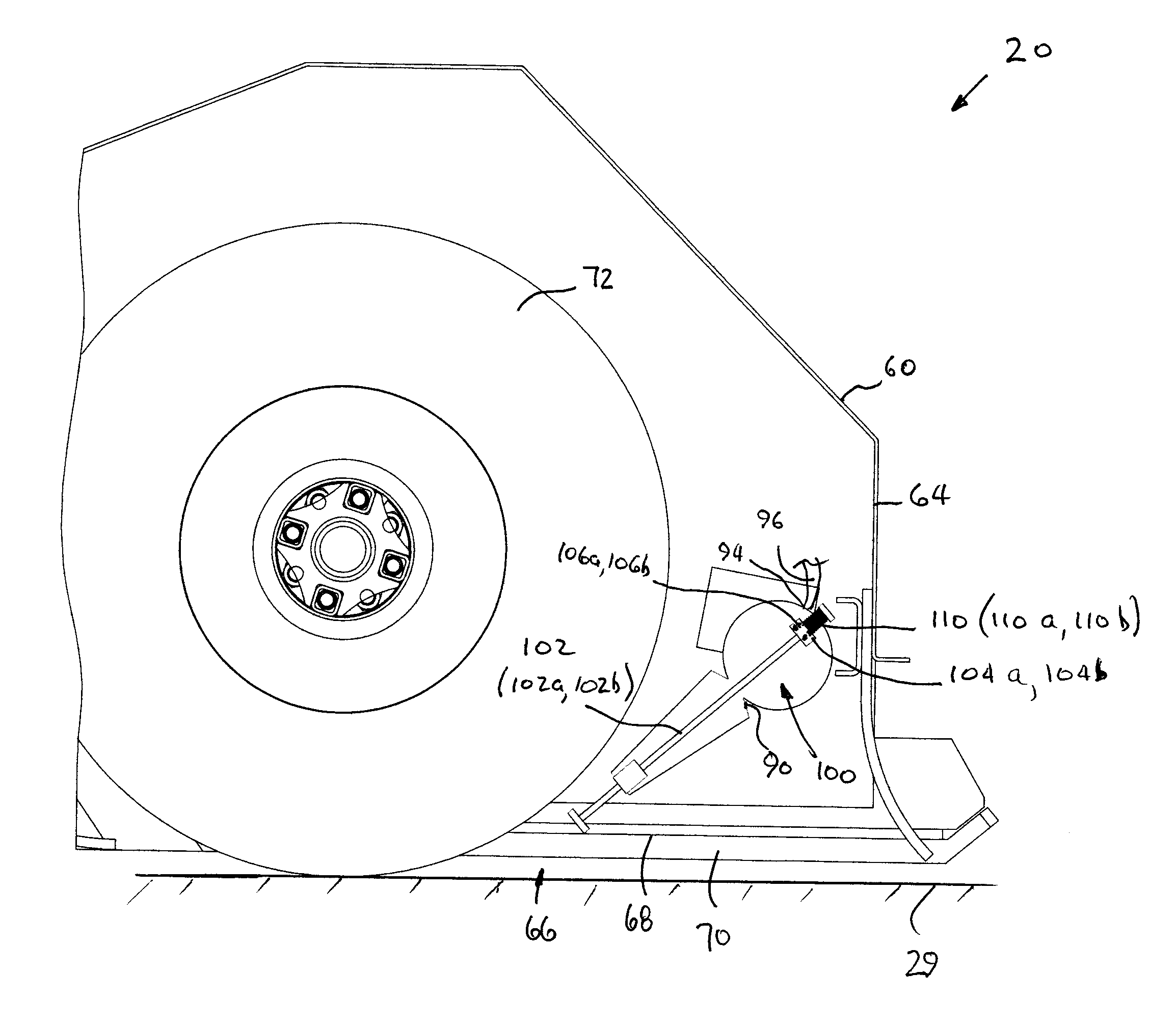

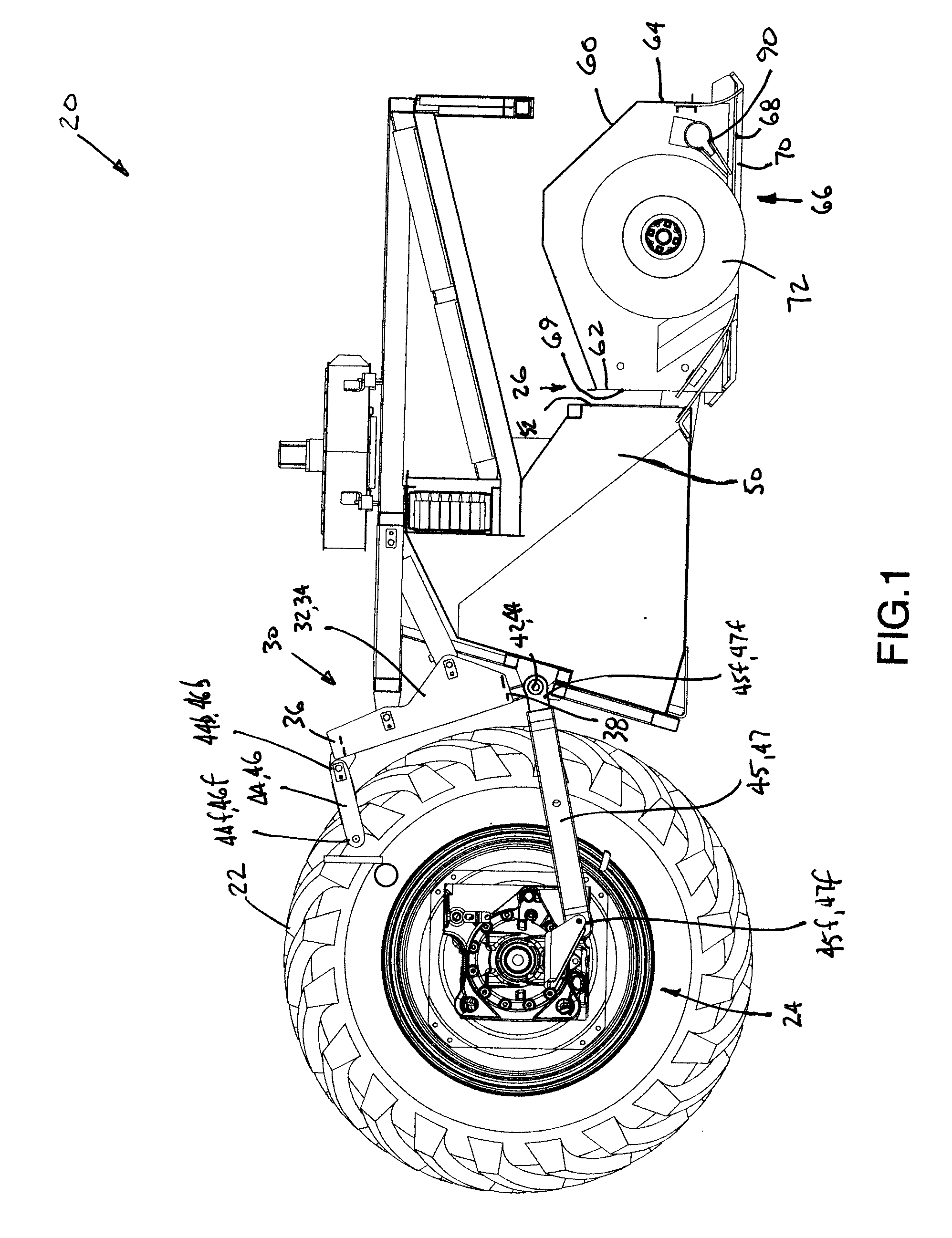

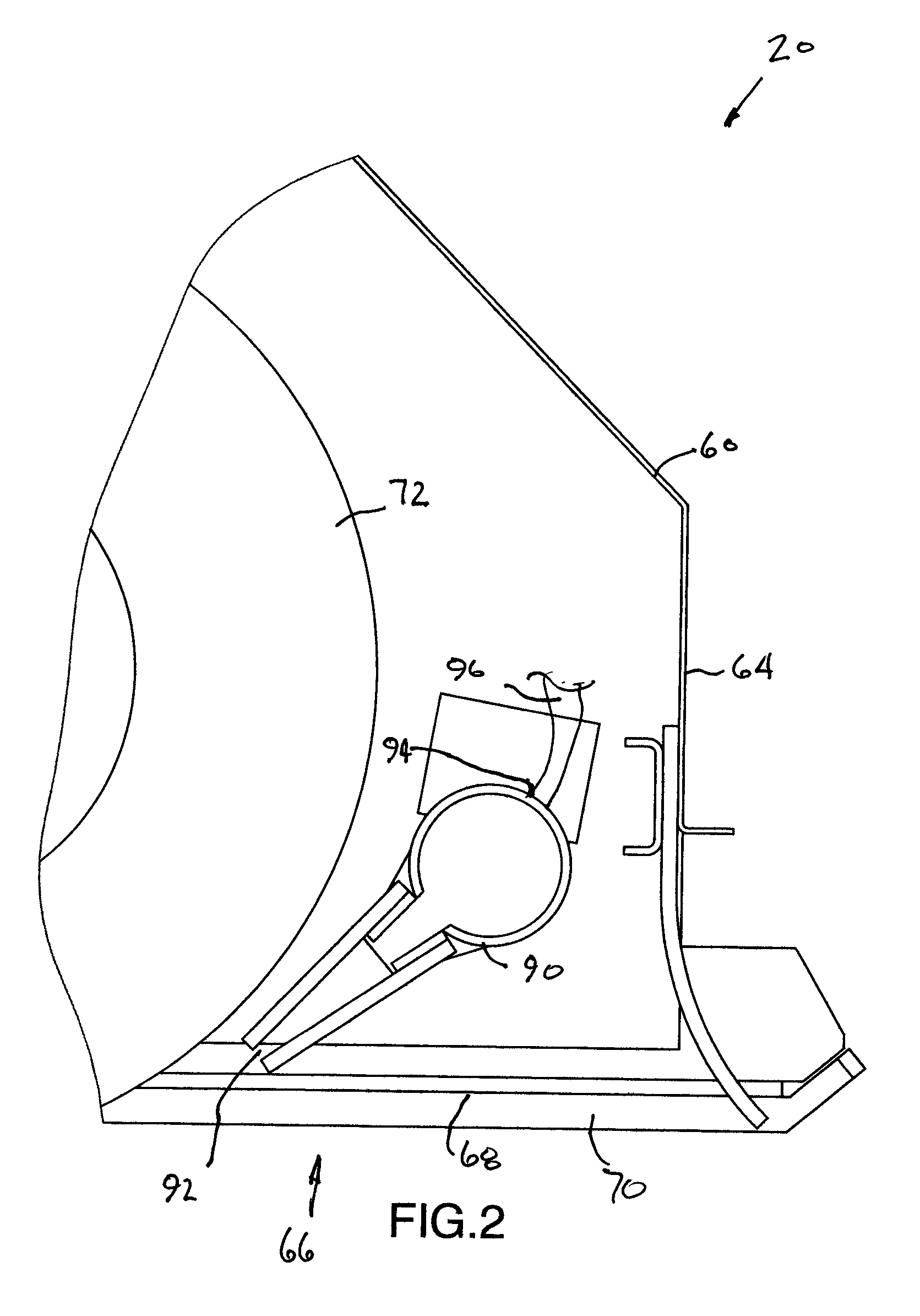

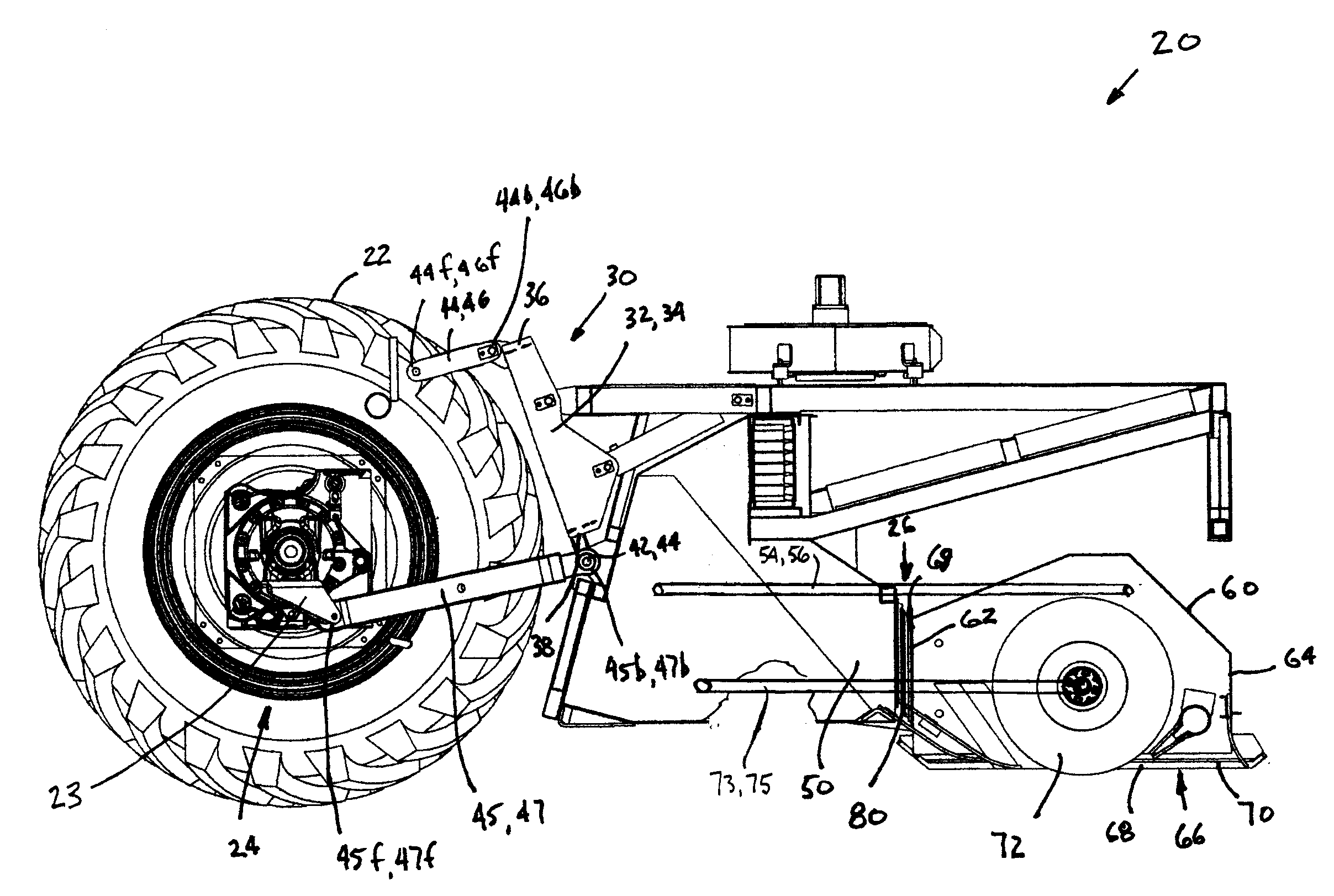

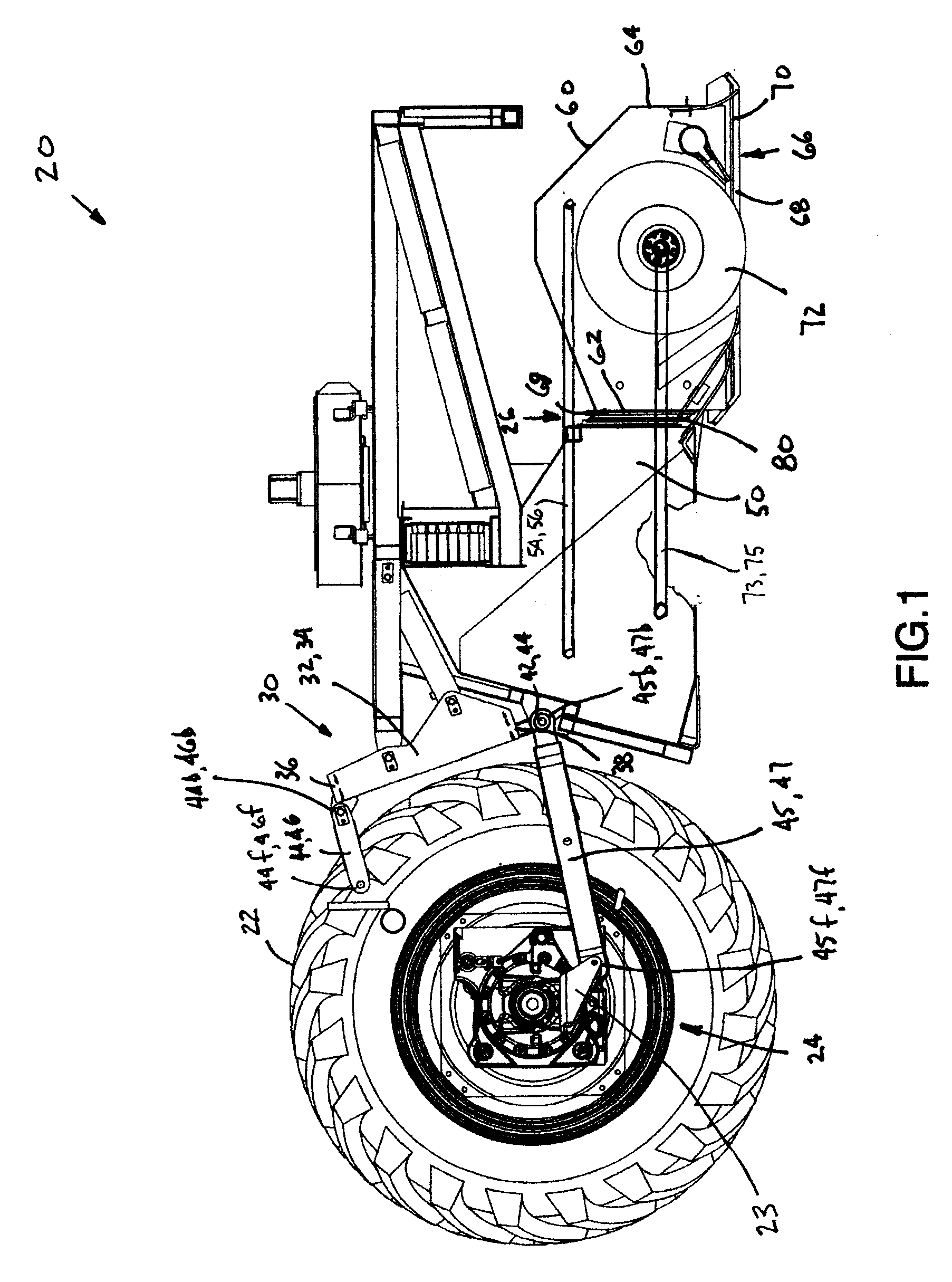

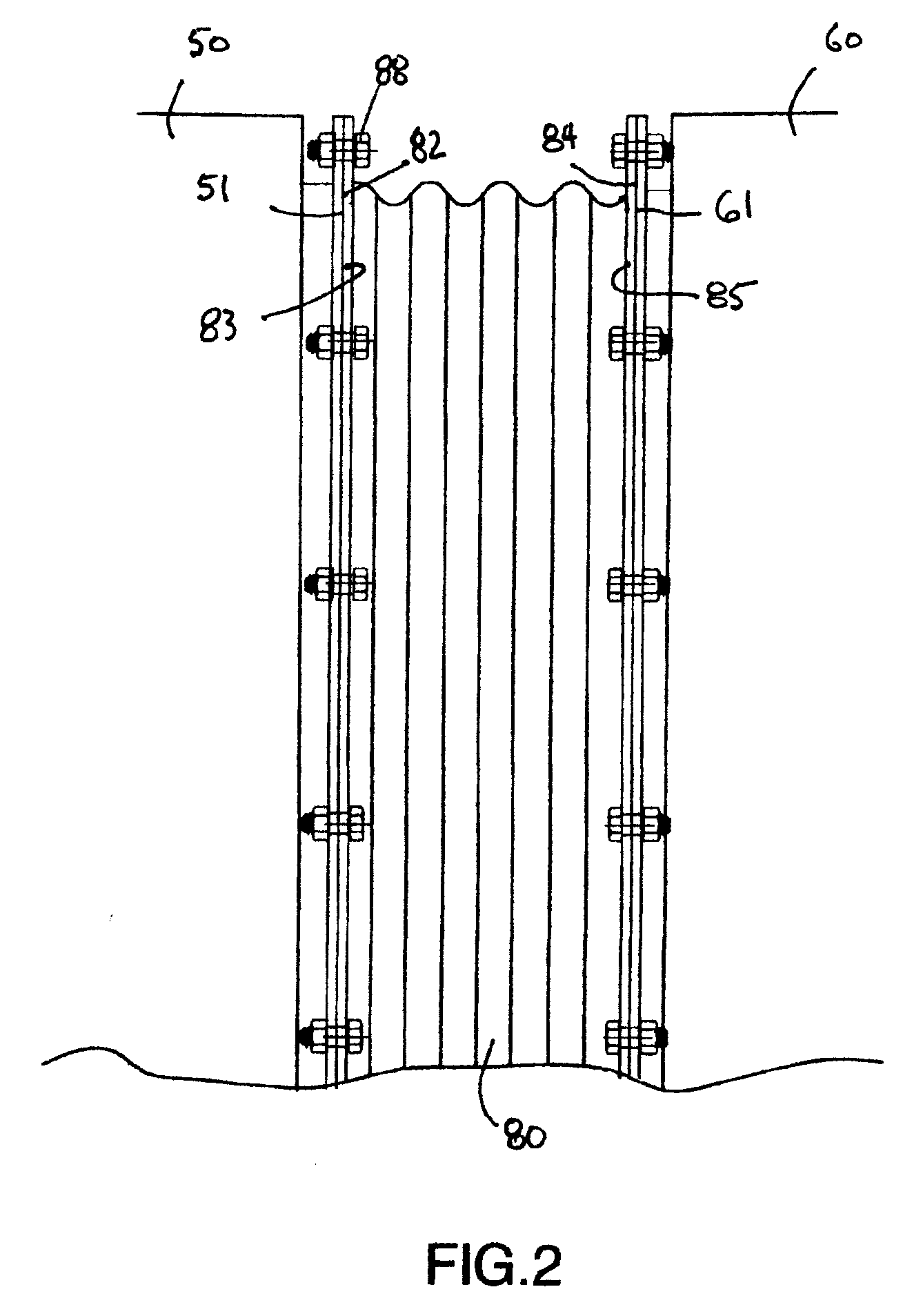

Sweeping broom apparatus having a surface tracking air blast nozzle

A sweeping broom apparatus for use with a vehicle comprises a main body with a debris receiving inlet, and a broom shroud with an open bottom. Airflow obstructing flaps are disposed around the bottom edge of the broom shroud. A forwardly facing debris outlet in the broom shroud permits the directed egress of debris therefrom as a forwardly propelled stream of debris. A main sweeping broom is mounted within the broom shroud for propelling debris forwardly, thereby creating a stream of debris propelled forwardly through the forwardly facing debris outlet. An air blast nozzle is connected in fluid communication to a source of compressed air for receiving compressed air therefrom. There is a nozzle mount for mounting the air blast nozzle for movement between a lower position whereat the air blast nozzle is disposed adjacent the surface being cleaned and to emit air in a forward and downward direction to impact on the surface being cleaned, and a raised impact-absorbing position. There is also a biasing spring for biasing the air blast nozzle to the lower position.

Owner:VANDERLINDEN ROGER P

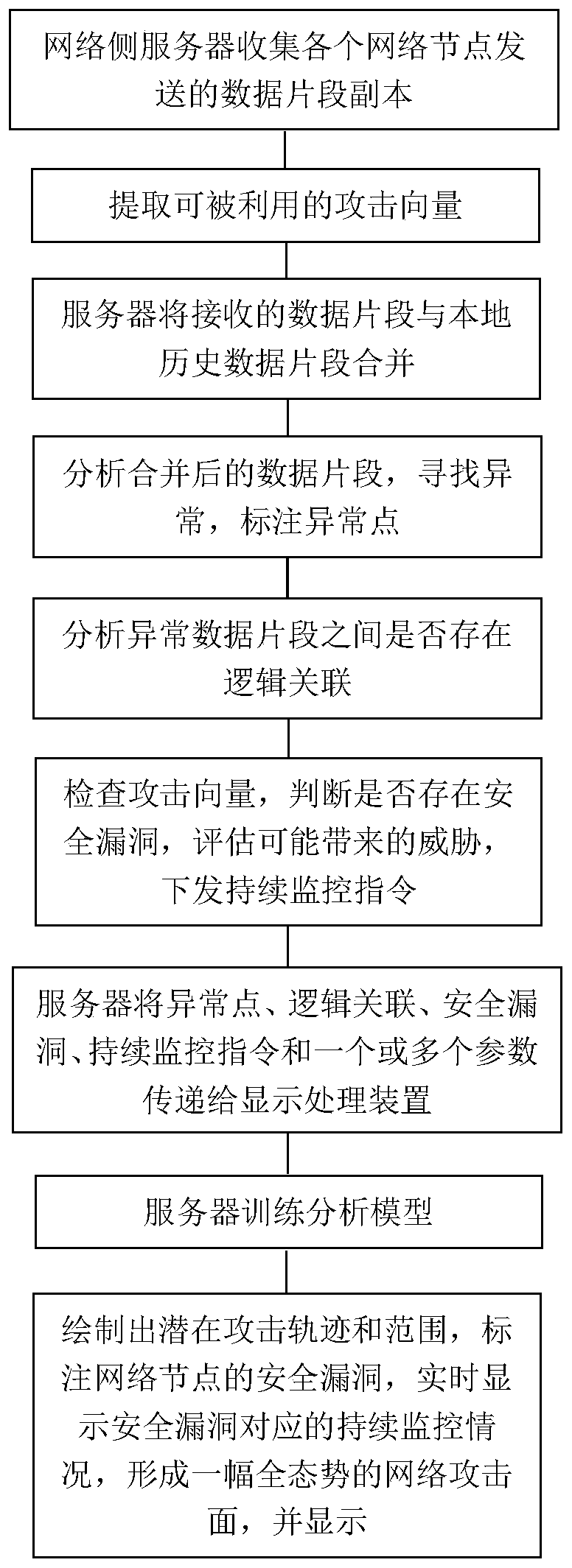

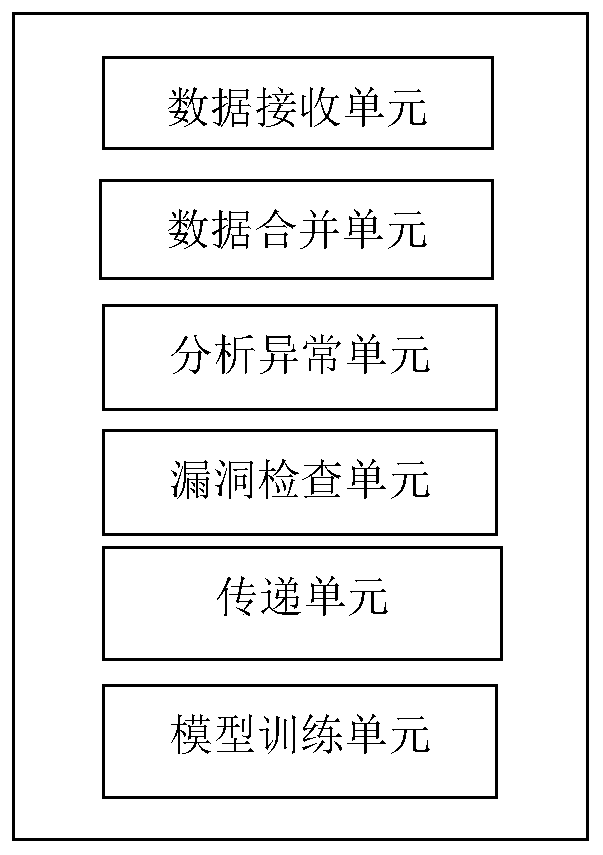

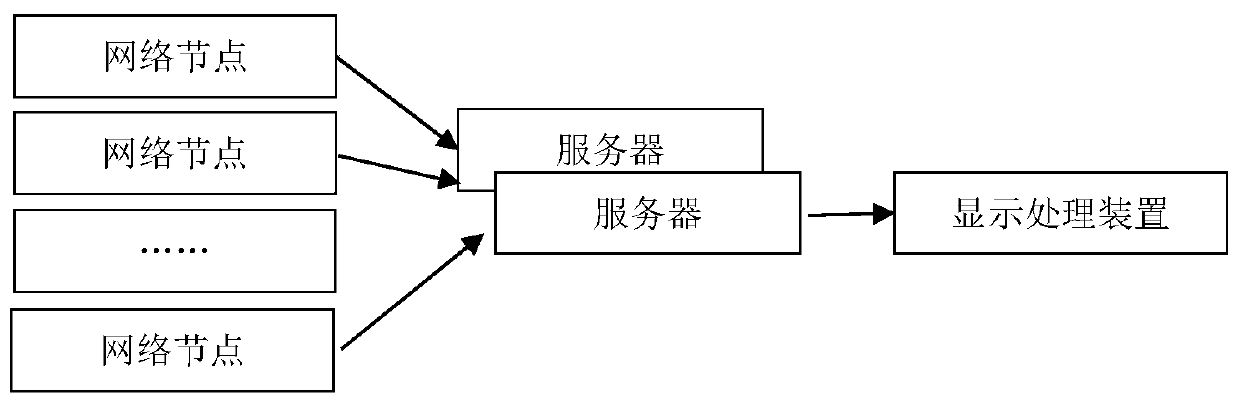

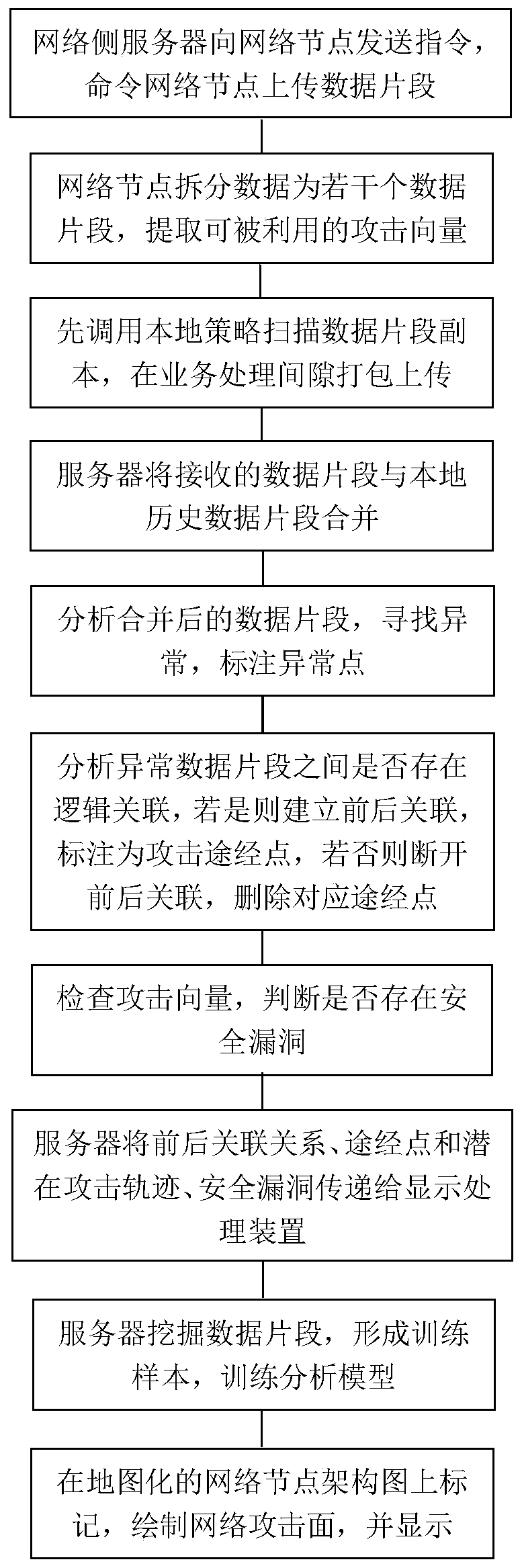

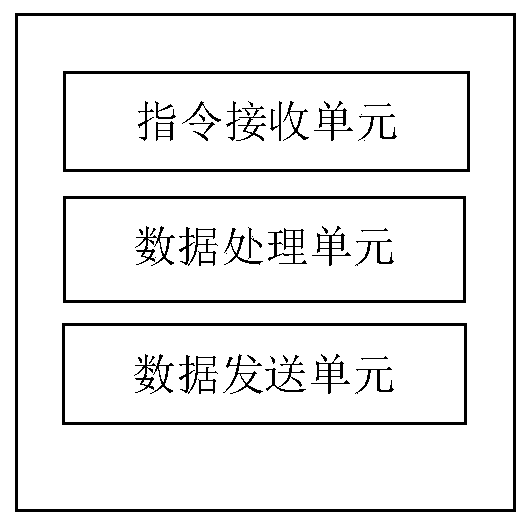

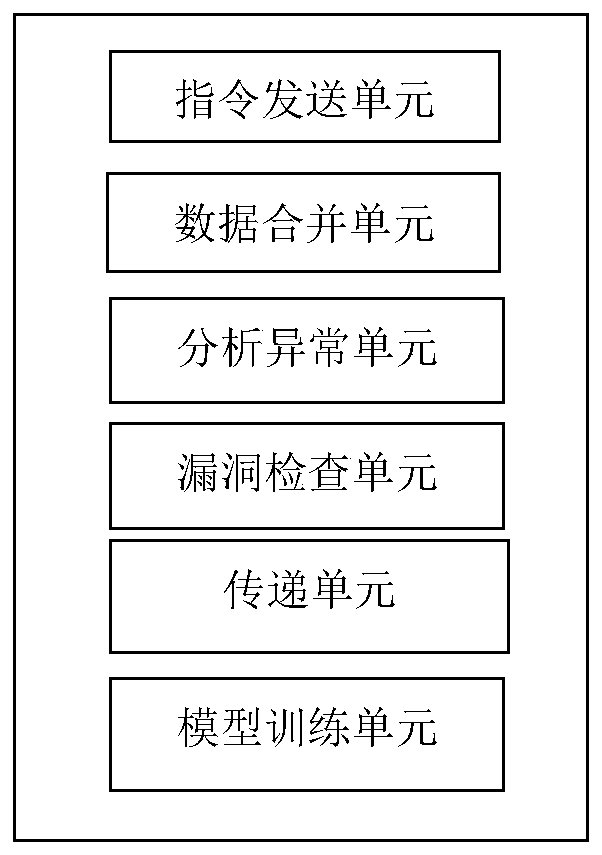

Network attack surface tracking method, server and system

ActiveCN110381047ARealize the purpose of tracking the attack surfaceRemove threatTransmissionAnalysis dataNetwork attack

The invention discloses a network attack surface tracking method, a server and a system. The method comprises: collecting data fragment copies on each network node; extracting available attack vectors; and combining the data fragment copies with historical big data, analyzing whether the data fragments are abnormal or not, and whether logic association exists among the abnormal data fragments or not, thereby determining and labeling abnormal points, obtaining potential attack trajectories and security vulnerabilities of network nodes, and achieving the purpose of tracking attack surfaces in alarge number of network nodes. For different vulnerabilities of a single network node, whether the vulnerabilities are threatened or not can be continuously monitored according to evaluation of each network node, and possible threats are eliminated.

Owner:武汉思普崚技术有限公司

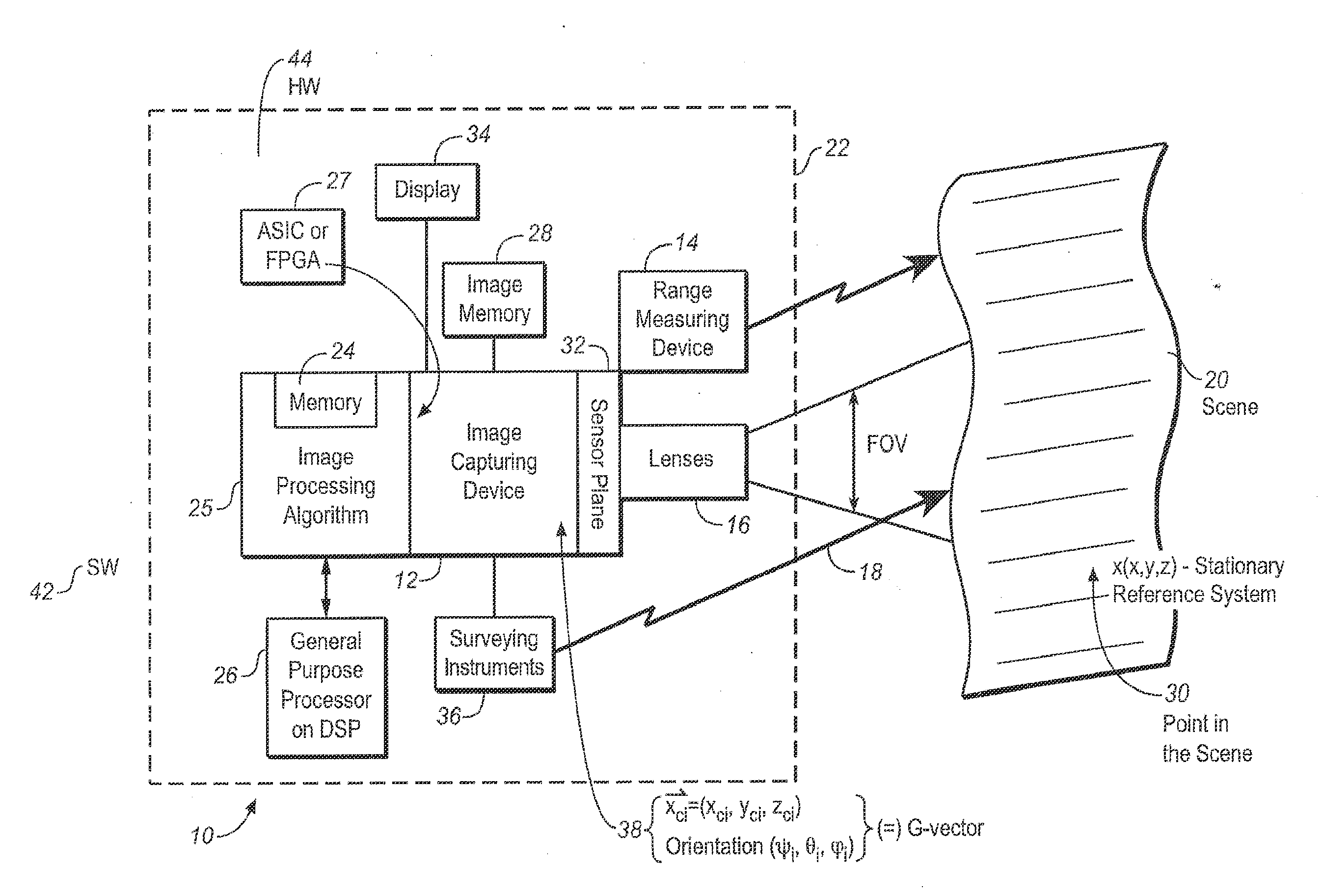

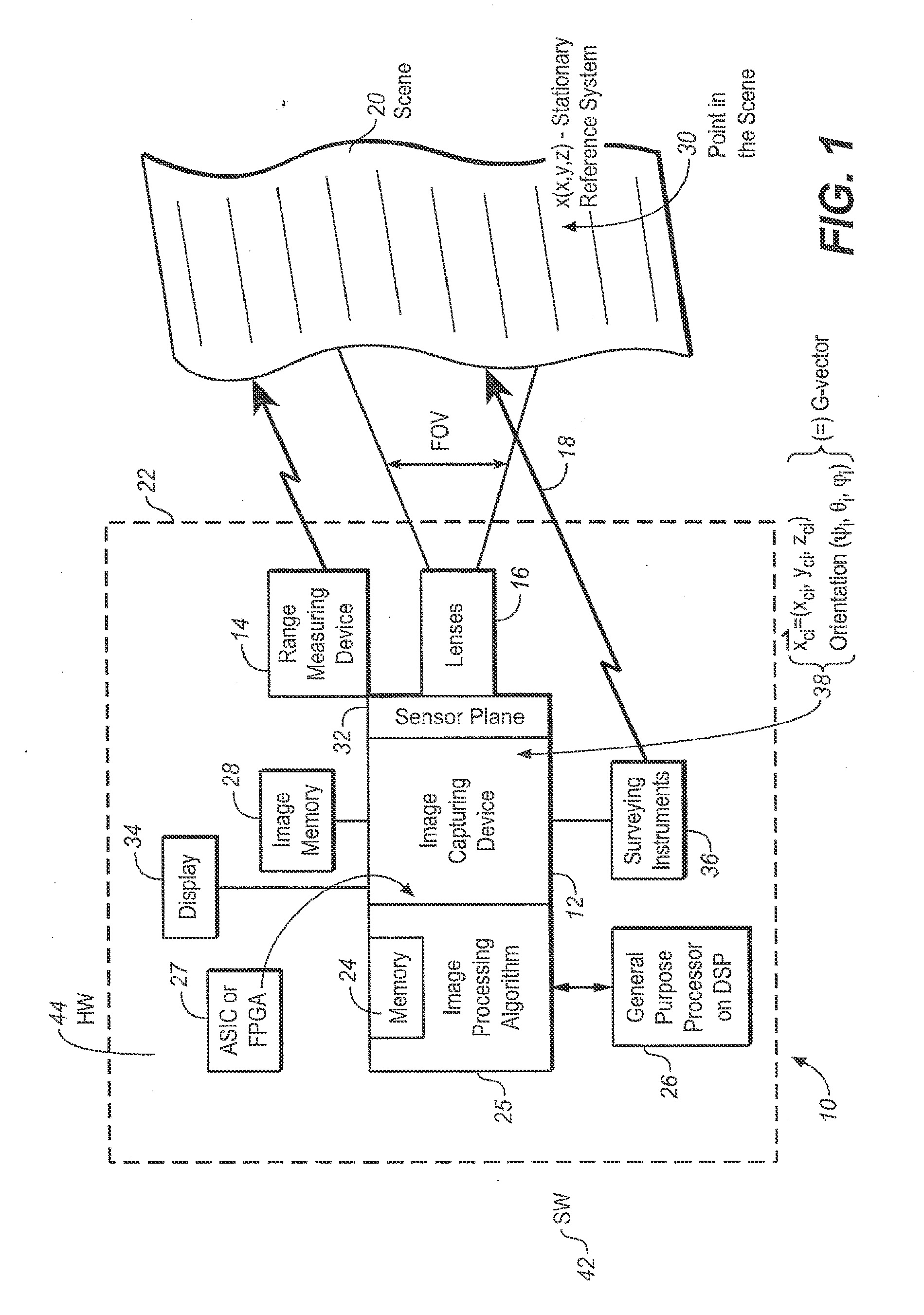

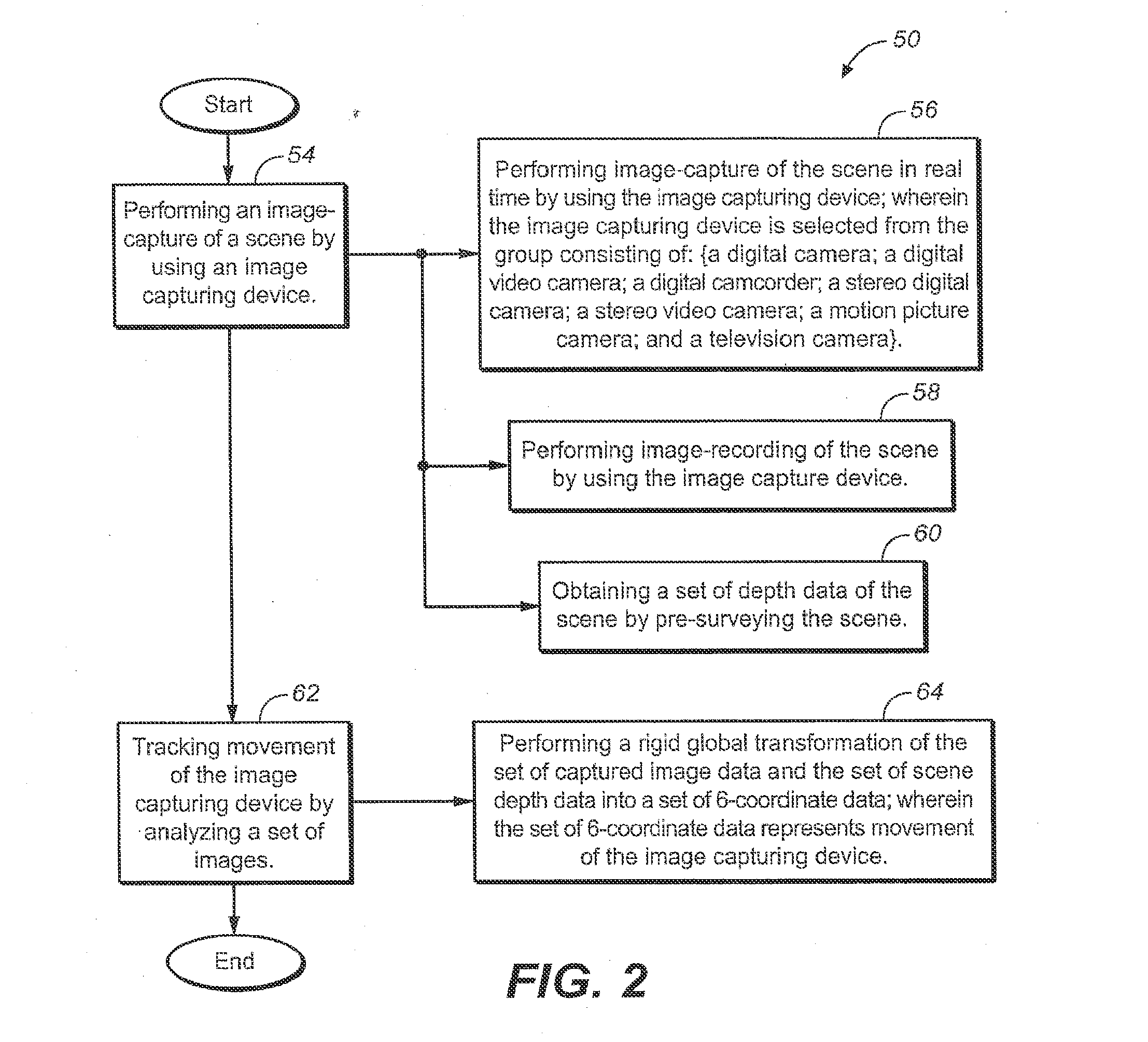

Image-based surface tracking

A method of image-tracking by using an image capturing device (12). The method comprises: performing an image-capture of a scene (54) by using an image capturing device; and tracking movement (62) of the image capturing device (12) by analyzing a set of images by using an image processing algorithm (64).

Owner:TRIMBLE INC

Ore rock contact surface tracking method

InactiveCN102495429AConducive to controlling poverty indicatorsImprove accuracyElectric/magnetic detectionAcoustic wave reradiationMining engineeringFerromagnetism

The invention relates to an ore rock contact surface tracking method, which belongs to the technical field of ore extraction. By attaching ferromagnetism powder on explosion broken ores and / or surrounding rocks of ore rock contact surfaces, arranging a monitoring device on an ore tapping hole or an ore removal working surface of a scrapper and dynamically monitoring ferromagnetism abnormal signals of ore rock contact surface ores or dead rocks discharged by a mine mouth through detecting instruments on site, the ore rock contact surface tracking method can improve the accuracy and timeliness of judgment of the ore rock contact surfaces, provides reliable foundation for draw control and is favorable for controlling loss index of ores.

Owner:KUNMING UNIV OF SCI & TECH

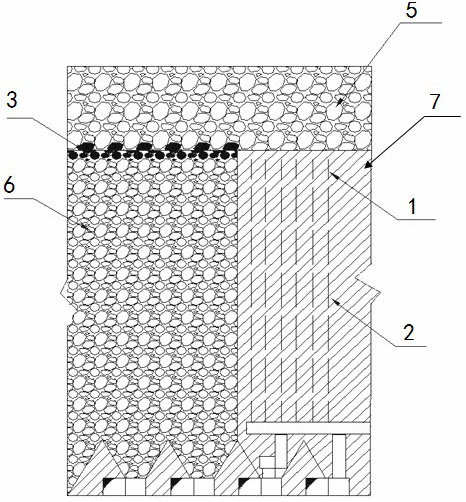

Surface tracking sweeping broom apparatus for use with a vehicle

A sweeping broom apparatus comprises a main body having a debris receiving inlet, and connecting arms for operatively connecting the main body to a vehicle. A broom shroud has a forwardly facing debris outlet for permitting the directed egress of debris therefrom as a forwardly propelled stream of debris. There are arms for mounting the broom shroud on the main body, for free vertical movement of the broom shroud with respect to the main body. A main sweeping broom is operatively mounted free vertical movement within the broom shroud for propelling debris forwardly from a surface being cleaned, thereby creating a stream of debris propelled forwardly through the forwardly facing debris outlet to a the debris receiving inlet of the vehicle. A dust-containing pliable cover is connected in substantially sealed relation to the broom shroud at the forwardly facing debris outlet and connected in substantially sealed relation to the vehicle at the debris receiving inlet for containing dust from the stream of debris propelled forwardly through the forwardly facing debris outlet.

Owner:VANDERLINDEN ROGER P

Cleaning drone

ActiveUS10597156B2Autonomous decision making processUnmanned aerial vehiclesMotion detectorDust control

Owner:VIEL PIERRE EMMANUEL

Network attack surface tracking method, server and system

ActiveCN110351274ARealize the purpose of tracking the attack surfaceTransmissionData segmentAnalysis data

The invention discloses a method, a server and a system for tracking a network attack surface. Firstly, enabling each network node to check a data segment by itself; extracting available attack vectors; collecting data segment copies on each network node; combining a plurality of abnormal data segments with historical big data, analyzing whether the data segments are abnormal or not and whether logic association exists among the abnormal data segments or not, so that abnormal points and path points are determined and marked, potential attack trajectories and security vulnerabilities of networknodes are obtained, and the purpose of tracking attack surfaces in a large number of network nodes is achieved.

Owner:武汉思普崚技术有限公司

System and method for controlling a tracking autofocus (TAF) sensor in a machine vision inspection system

A method is provided for controlling a Tracking AutoFocus (TAF) portion of a machine vision inspection system including an imaging portion, a movable workpiece stage, a control portion, and graphical user interface (GUI). The TAF portion automatically adjusts a focus position of the imaging portion to focus at a Z height corresponding to a current surface height of the workpiece. The method includes providing the TAF portion, and providing TAF enable and disable operations, wherein: the TAF disable operations comprise a first set of TAF automatic interrupt operations that are automatically triggered by user-initiated operations that include changing the Z height, and the TAF disable operations may further comprise automatic interrupt operations that are automatically triggered based on at least one respective TAF Z height surface tracking characteristic exceeding a previously set TAF disable limit for that respective TAF Z height surface tracking characteristic.

Owner:MITUTOYO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com