Complicated curved surface tracking method for welding nuclear power J-type joint

A complex curved surface and nuclear power technology, applied in welding equipment, arc welding equipment, electric controllers, etc., can solve the problems of high cost and complex equipment system, and achieve the effect of simple operation, wide adaptability, and good experimental reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

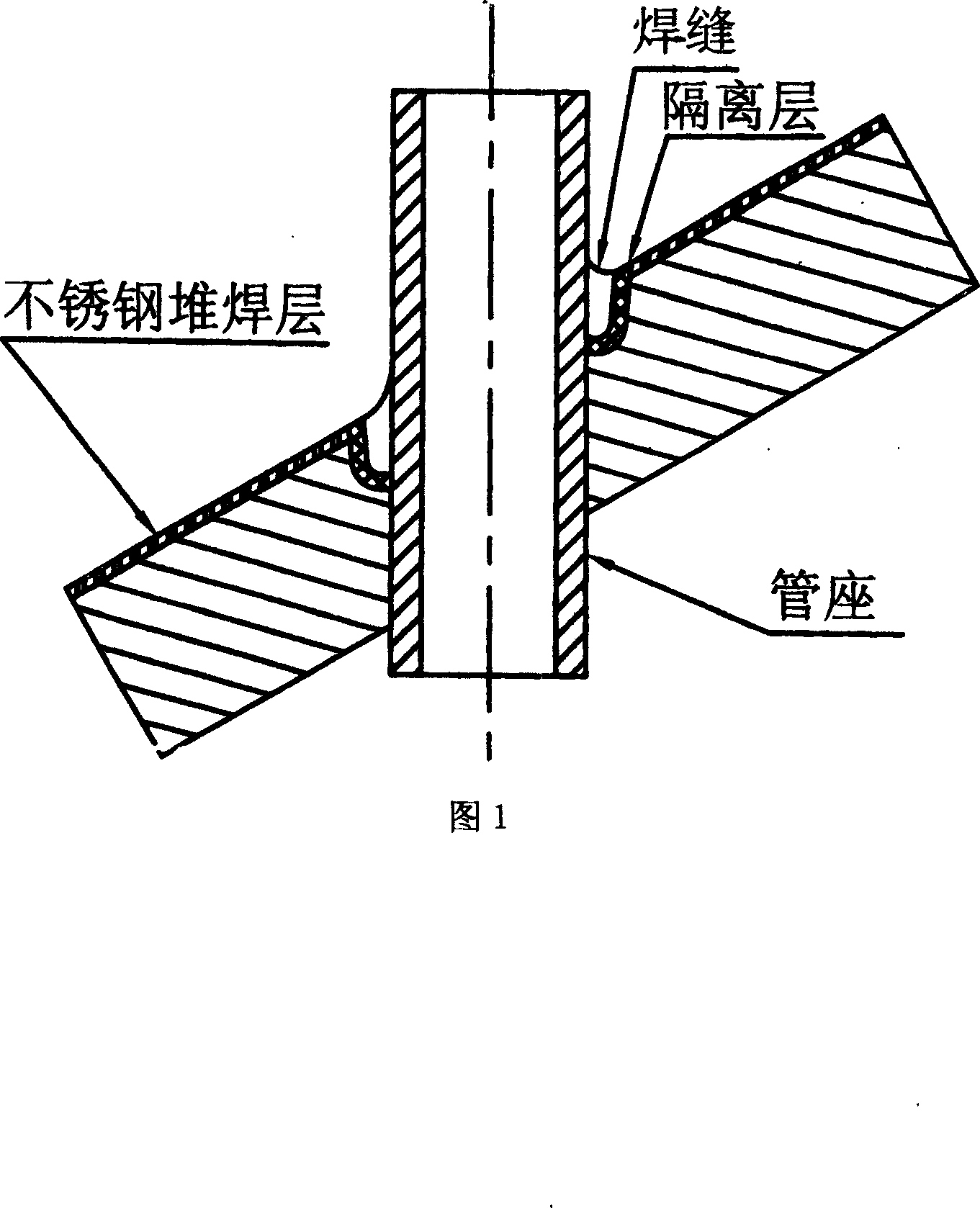

[0017] The complex curved surface is formed by intersecting the outer diameter of the pipe Φ=100mm and the inner radius R=1938mm of the spherical head. The angle between the pipe axis and the tangential direction of the spherical surface is 40-90°, and the shape and trajectory of the intersecting surface are different. Considering that the radius of the spherical surface is much larger than the outer diameter of the pipe, the local area can be approximated as the intersection pipe between the pipe and the inclined plate. As shown in Figure 1, the driving pipe seat is made of nickel-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com