Gantry type multiheaded automatic welding machine

An automatic welding machine and gantry-type technology, which is applied in the field of manufacturing and welding of steel box girder plate elements of bridge steel structures, can solve the problems of difficult welding deformation of plate elements, low work efficiency, and large correction workload, so as to reduce the labor of workers. Strength, ensuring welding quality and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

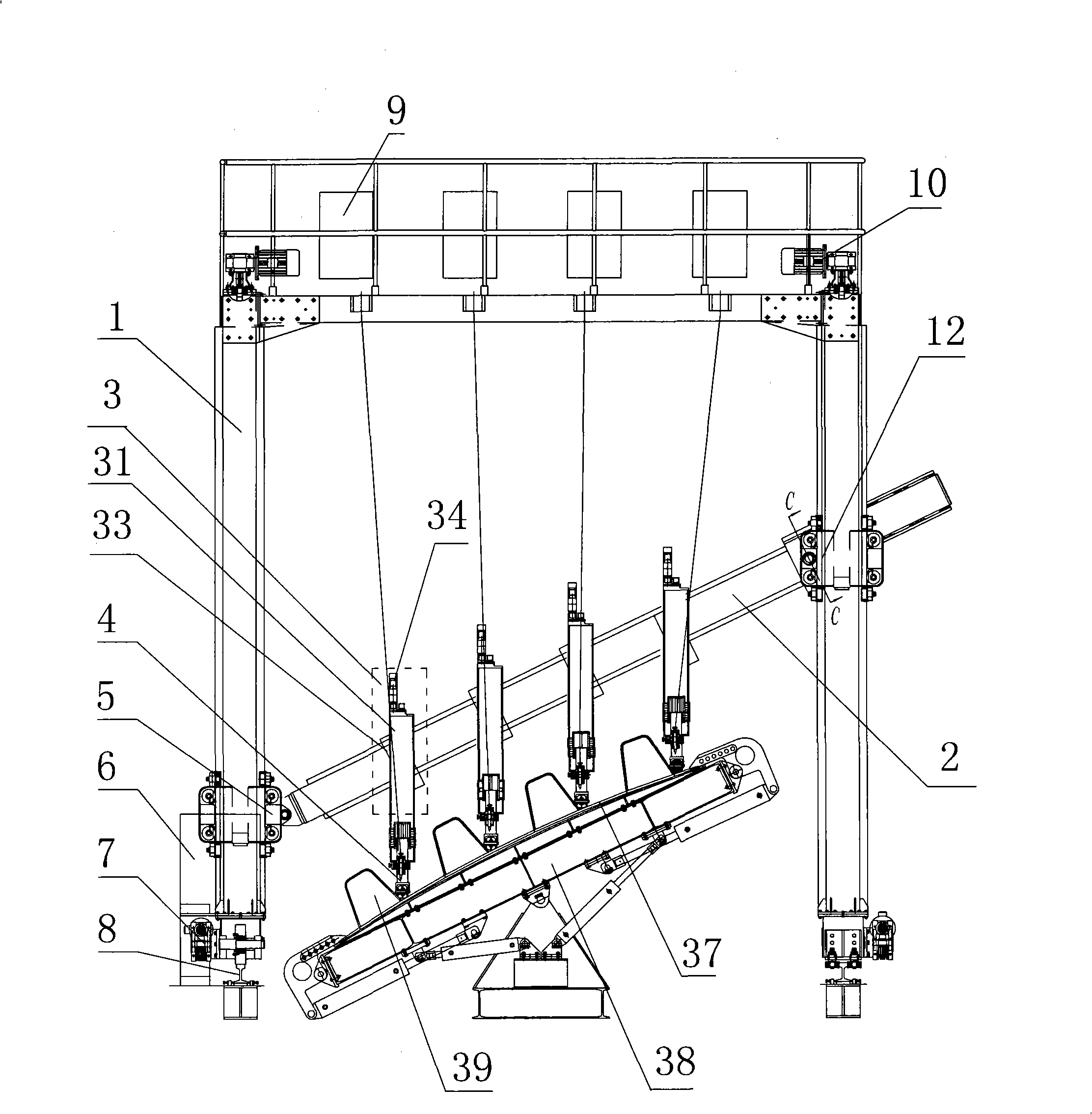

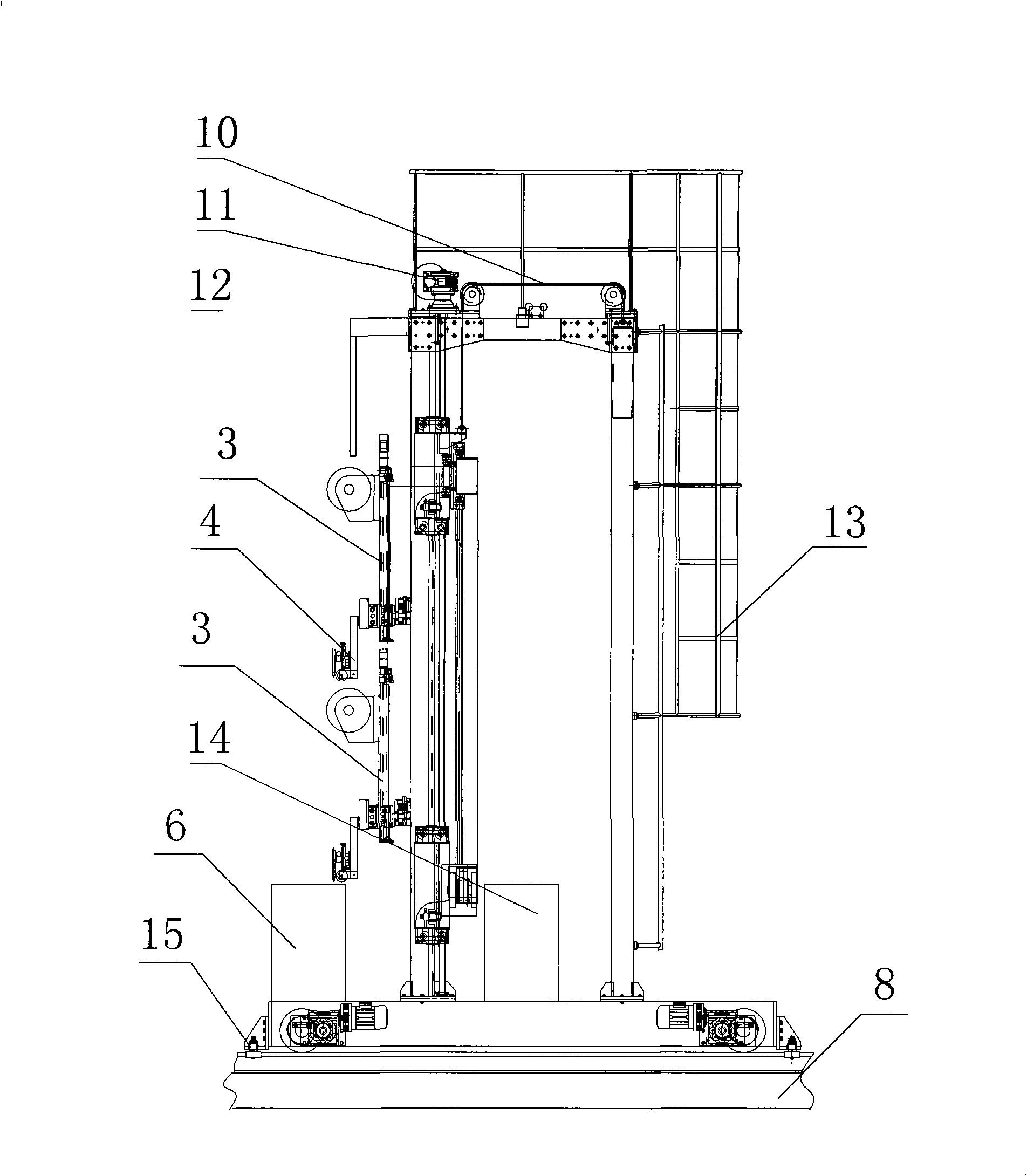

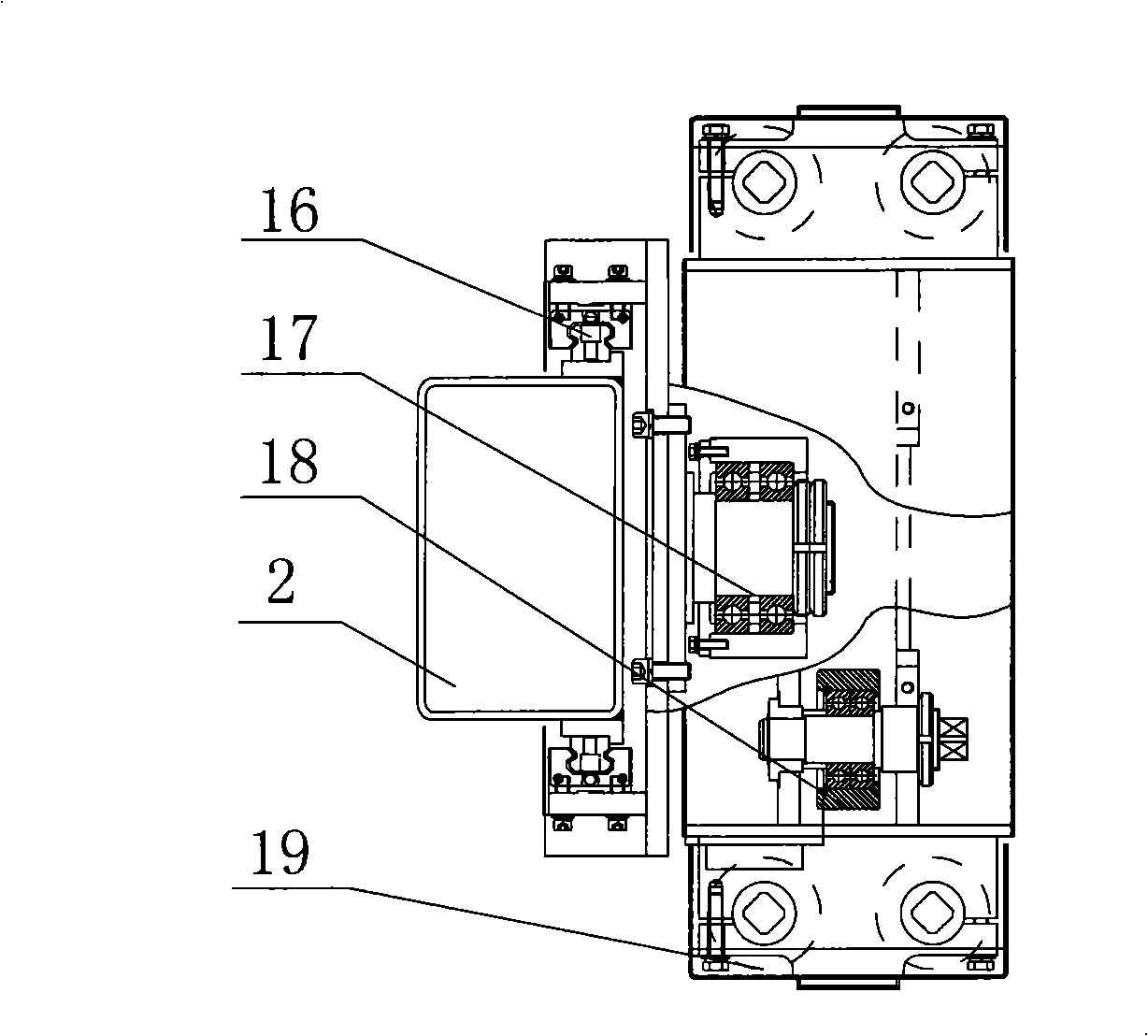

[0019] Such as figure 1 The front view of the structure when the gantry-type multi-head welding machine is used in conjunction with the hydraulic anti-deformation swing tire frame, combined with figure 2 The structure side view of the gantry-type multi-head welding machine shown, the gantry 1 is installed on the walking track 8 through the traveling drive system and the traveling clamping device 15, and the traveling track is composed of track beams, adjustable backing plates and precision rails. Walking drive system 7 is made up of walking beam, wheel system, clamping guide wheel, driving speed reducer and variable frequency motor. The gantry can run along the precision-machined track. It adopts variable frequency AC motor for stepless speed regulation. The speed range covers the welding speed of gas shielded welding and submerged arc welding. The speed regulation range is wide, and the operation is stable and even. It is convenient for the welding machine to return when em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com