Ultrasonic C scanning automatic detection method for arc surface work pieces, without clamping and positioning

An automatic detection and arc surface technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, instruments, analysis materials, etc., can solve the problems of high cost and unsatisfactory detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

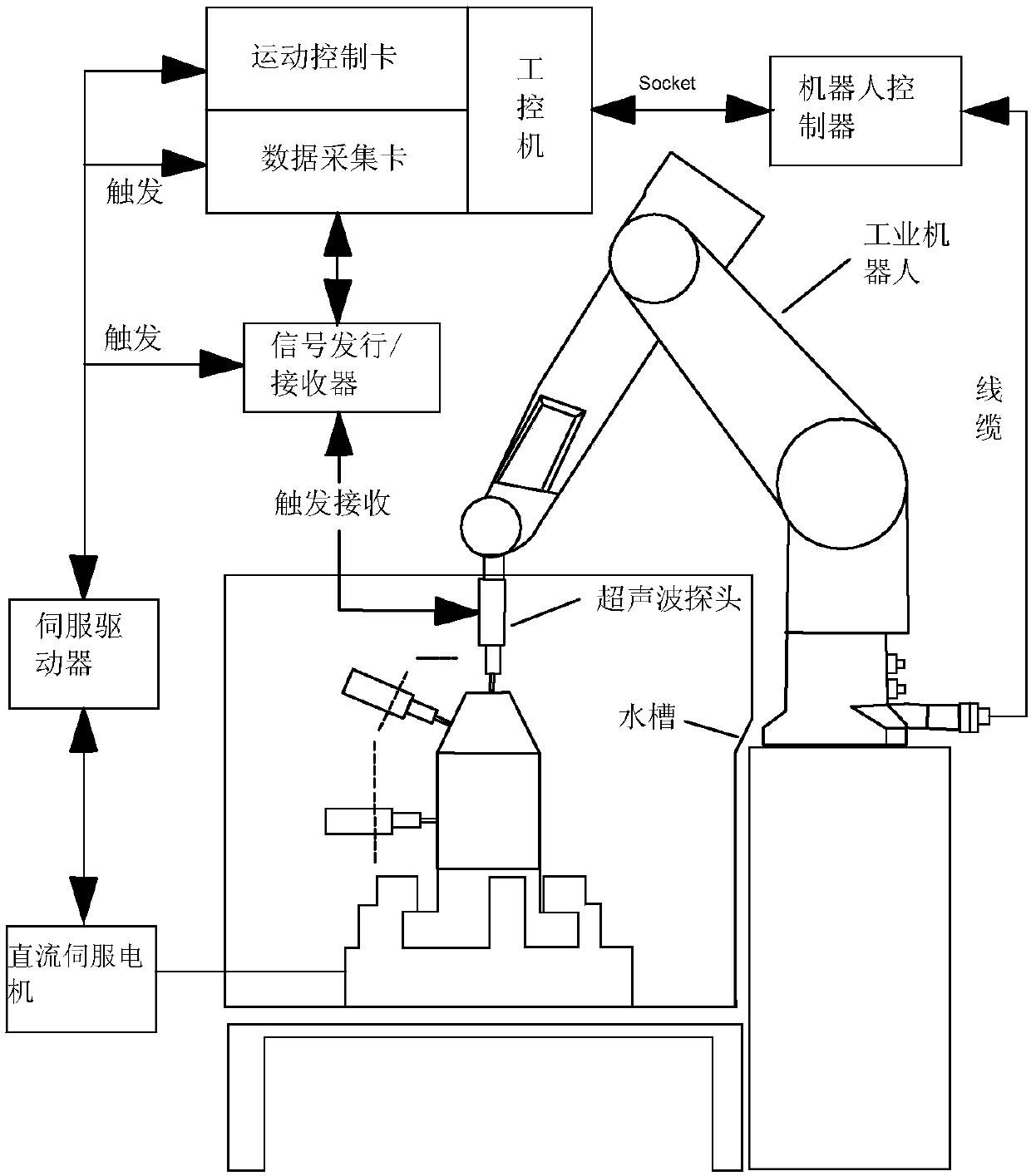

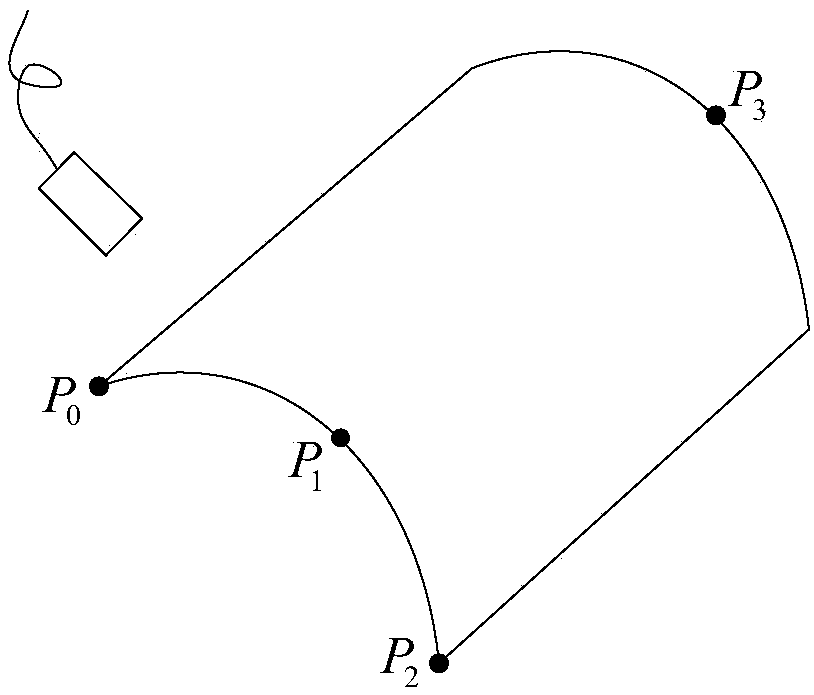

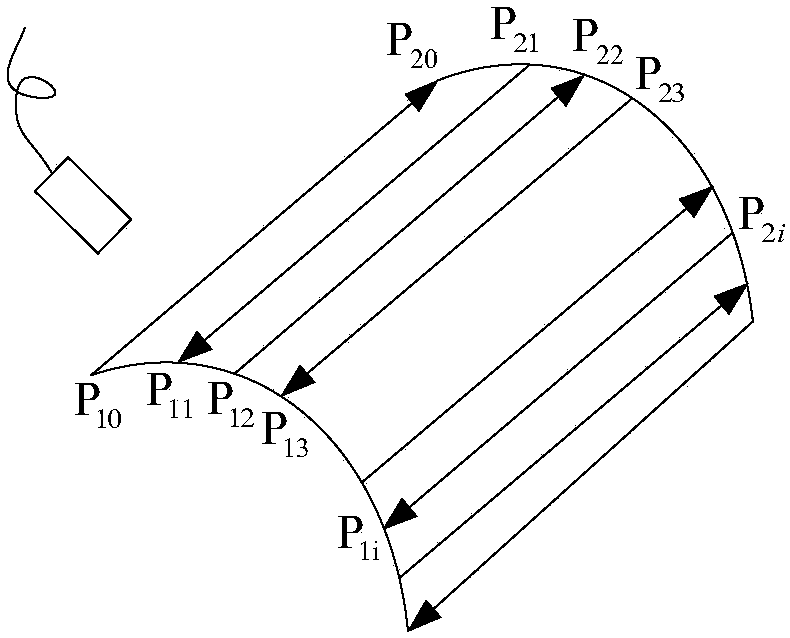

[0051] Such as figure 1 As shown in ~5, an ultrasonic C-scan automatic detection method for circular arc surface workpieces without clamping and positioning uses a 7-degree-of-freedom ultrasonic automatic detection system for detection. The structure of the detection system is as follows figure 1 As shown, including 6 degrees of freedom industrial robot, robot controller, water tank, independent turntable, DC servo motor, servo driver, ultrasonic probe, signal generator / receiver, industrial computer and supporting cables, etc., the ultrasonic probe is always guaranteed to The axis of the axis is perpendicular to the surface of the workpiece; the specific structure is that the 6-DOF industrial robot is connected to the robot controller through a cable, and the robot controller is connected to the industrial computer. The industrial computer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com